Professional Documents

Culture Documents

Proposed Multipurpose Building - S1

Proposed Multipurpose Building - S1

Uploaded by

Eric Estremera EstilleroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proposed Multipurpose Building - S1

Proposed Multipurpose Building - S1

Uploaded by

Eric Estremera EstilleroCopyright:

Available Formats

GENERAL NOTES: n.

Diameters, welding or the use of approved mechanical devices maybe permitted provided 500

Excavation, Filling and Grading not more than alternative bars are welded or spliced at any level and the minimum vertical (Baseplate)

1. If the required safe bearing power of the soil is not obtained at the excavation depth distance between two adjacent bar splices shall be 24"

indicated on the drawings, the excavation shall be continued until such safe bearing power is o. CMU walls: Vertical bars shall be spliced at the top of the wall

reached.

2. Fills to be used to support the foundations shall be placed in accordance with accepted 20. Unless indicate otherwise, all beams terminating at the column shall have top and bottom

engineering practices. A soil investigation report of satisfactory placement of fill shall be bars extending to the far face of the column. Terminating in a standard 90 degree hook length

(Baseplate)

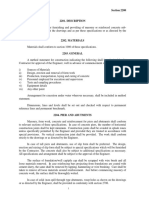

8-25mmf A307

acceptable to the Engineer. of anchorage shall not be less than 24” Anchor Bolts

500

3. The Contractor shall at all times protect the excavations and trenches from damages of 21. Shop drawing for reinforcement shall be submitted for approval to the contracting officer

rainwater, spring water, backing of drains, and all other water. prior to fabrication.

4. The Contractor shall do no pouring of concrete unless the bearing surfaces has been 22. Development length, LD of reinforcing bars shall be as follows;

inspected and approved by the Engineer.

5. After the forms have been removed from the footings, walls, and piers, the materials taken Size of rebar Development length (inches) Baseplate & Anchor Bolts Layout

from excavations (free from waste and objectionable matter) may be used for back filling #3 6

around them and properly compacted. #4 8

6. Filling materials shall be made in layers not to exceed 15 centimeters and thoroughly #5 10

tamped before the next fill is placed. #6 14

7. In spaces where slabs rest on earth-fill, shall be labeled and accurately graded with 10 #8 22 1600 1200

centimeter thick of gravel and sand, and tamped thoroughly before concrete pouring is done.

23. When the reinforcing bars conform to the Philippine Standard, SAO 33, the following shall 525 550 525 400 400 400

8. All exterior grades shall be formed in accordance with the drawings and specifications,

taking into account the requirements for landscaping work, if any, and giving due allowances apply

for the top soil depth.

English Metric Equivalent

Plain and Reinforced Concrete #3 10mm

1. Portland cement materials shall conform to the requirements of ASTM C-150 Type for #4 12mm

normal Portland cement. #5 16mm

2. Sand shall be clean, hard, coarse river sand or crushed sand free from injurious amount of #6 20mm

clay loam and vegetable matter and shall conform to ASTM C-33 or C-330. #8 25mm

3. Gravel shall be river run gravel or broken stones. The maximum size shall be 20mm.

4. Water used in mixing concrete shall be clean and free from injurious amount of oils, acids, 24. Form Works:

525

alkali, organic materials or other deleterious substances.

325

5. Minimum compressive cylinder strength of concrete fc' at 28 days shall be 3000 psi a) Forms shall conform to the shape, lines and dimensions shown on the drawings. They shall

6. The Contractor shall employ an approved testing, laboratory which shall design the mix for be strong to resist the pressure and weight of the concrete.

each type of concrete required by the Specifications and drawings to obtain strength as b) Forms shall be properly tied and braced so as to maintain their position and shape. Forms

shall be sufficiently tight and strong to prevent leakage of the mortar.

1600

1200

determined by test cylinder at least 15% higher than required.

550

550

7. The adequacy of the mix design shall be verified by a test on a minimum of 6 cylinders, 3 c) Side forms of footings may be omitted and concrete be placed against the next excavation 12-20mmf Main Vertical 8-20mmf Main Vertical

tested at 7 days; 3 at 28 days, in accordance with ASTM C-192 and G-39 and by Slump Test in only when approved by the Engineer. Bars with 10mmf Bars with 10mmf

d) Forms shall be coated with non-staining form oil before setting reinforcement. The form oil Ties Placed & Spaced Ties Placed & Spaced

accordance with ASTM C-143. As Shown As Shown

8. The water content shall not exceed 28 liters per 40 kilograms per bag cement, and the shall not contain chemicals that will impair the strength of the concrete.

325

slump test shall not exceed 10 cm. in all cases unless otherwise changed by the Engineer. e) Removal of forms or shoring is subject to the approval by the Engineer, and under no

525

9. Unless otherwise authorized by the Engineer, concrete shall be machine mixed at the site or circumstances shall bottom form and shoring is removed until after the members have

by ready-mixed concrete. Only ready-mixed concrete shall be used for column and footing. acquired sufficient strength to support their weight and the load thereon. Forms shall remain

10. Pouring of concrete should not be started until after the forms and reinforcement for the in place for a minimum time as follows:

whole unit are properly laid and installed, cleaned, inspected and approved.

11. Concrete during and immediately after depositing shall be thoroughly compacted by Columns, shear and bearing walls ------------------------- 3 days

mechanical vibration. The vibration shall be internal unless special authorization of the other Beams, Slabs and Stairs (bottom forms) ------------------ 21 days 200

methods is given by the Engineer. Plan

12. The vibration shall be of sufficient duration and intensity to compact the concrete Notes on Structural Steel:

thoroughly but shall not be continued so as to cause segregation.

13. Construction joints shall be roughened and cleaned thoroughly before any pouring starts. 1. All structural steel sections shall be ASTM A-36.

Wet and slush surface with cement mortar. 2. Light-Gauge Cold-formed Structural Steel shall conform to specifications of the American

14. Immediately after the concrete is mixed, it shall be conveyed by approved push cart or Iron and Steel Institute.

buggies to designated locations, carefully deposited in such manner as to prevent the 3. Machine Bolts shall conform to ASTM A-325. Each bolt shall be provided with standard nuts

separation of ingredient or displacement of the reinforcements. The concrete for columns and and washers.

(Baseplate)

(Nonshrink

footing shall not be transported this way. 4. Anchor Bolts shall conform to ASTM A-141

Grout)

25

25

5. Cross Bracing with Turnbuckles shall conform to ASTM A-307

50

50

15. After the initial sets of the concrete, the forms shall not be jarred, and no strains shall be

6. Welding Electrodes shall conform to AWS A-5.1 or A-5.5; E 70 Electrodes.

4@50

4@50

=200

=200

placed on the ends of the projecting reinforcing bars. Foundation shall be free from water

during concrete pouring. Construction joints shall be determined by the Engineer. 7. Field fabrication shall be kept to a minimum. And shop fabrication shall be employed to the

16. Concrete mixture which has developed initial setting shall not be re-tampered and use. greatest extent possible with the members shop fabricated as practicable with a minimum

1362 (Verify Architect)

1362 (Verify Architect)

17. All concrete work shall be protected from drying out after removal of forms by covering requirement for field connections.

with waterproofed paper, polyethylene sheeting, burlap, with a coating of approved 8. Welding, shearing, and all other works involved in the fabrication of structural steel shall be

membrane curing compound having a retention equal to 90% based on ASTM C-309 and done with accuracy and the highest quality of workmanship, within the allowable tolerance

C-156, applied in accordance with the manufacturer's instructions for use. prescribed in the AISC specifications. Floor Floor

Maximum Spacing @ 150

Maximum Spacing @ 150

18. Concrete Cover: 9. Welding of structural members in shop and on field, shall be done only by certified and Line Line

Minimum concrete cover for reinforcing bars shall not be less than: experienced welder.

a. 75mm concrete deposited against ground. 10. Surfaces to be welded shall be free from loose side, rust, grease, paint and other foreign

b. 50mm Formed concrete against ground or exposed to weather for bar lager than 16mm materials that will impair the soundness of the weld.

in diameter. 11. The steel structures shall be erected plumb and true to line and grade.

c. 40mm Formed concrete against ground or exposed to weather for bars of 16mm 12. Bracing and supports shall be introduced whenever necessary to take care of all loads to

which the structure may be subjected. Such bracing shall be left in place as long as may be

Verify

Verify

diameter and smaller. Natural Natural

d. 40mm Beams and column not exposed to ground or weather. required for safety. Grade Line Grade Line

e. 20mm Slab and walls not exposed to ground or to weather. 13. Base plates and bearing plates shall be supported on steel wedges until the supported

f. 75mm Concrete exposed to sewage. members shall have been aligned and plumb, following which the entire bearing area shall be

19. Reinforcement: grouted solid with non-shrink cement grout.

a. Welded wire fabric for concrete reinforcement shall conform to ASTM A-185. 14. Grouting mortar shall be of the commercial type approved by the Engineer.

b. The Contractor shall furnish 2 copies of the manufacturer's certificate of mill test of all 15. Steel works to be encased in concrete shall not be painted. All other steel works shall be

reinforcing steel. given one coat of shop paint of red lead primer, applied thoroughly and evenly to dry surfaces, 16mmf Bottom Bars 16mmf Bottom Bars

1500 (Minimum)

1500 (Minimum)

which have been cleaned, by brush. Spaced @ 200 O.C. Spaced @ 250 O.C.

8@100=800

8@100=800

c. The Contractor shall employ an approved testing laboratory, which shall conduct testing Bothways Bothways

of all reinforcement sizes of each bulk under the supervision of the Engineer. 16. Steel work prior to painting and after inspection and approval shall be cleaned of loose mill

d. All reinforcement shall be placed according to the approved drawings. The Contractor scale, loose rust, weld slag or flux deposit, dirt and other foreign materials.

shall provide sufficient bar supports ties, anchors and other accessories to hold all bars 17. Oil and grease shall be removed by solvent.

securely in place. 18. All steel work after complete erection shall be field painted with the type andcolor specified

e. Reinforcing steel shall be cleaned of oil, grease, scale, rust or other coatings, which will in the section of painting of this Specification.

50

impair bond.

300

300

f. All bars shall be bent cold STRUCTURAL DESIGN CRITERIA

g. Reinforcing bars shall have a minimum yield strength fy=40,000.00 psi

All reinforcing bars shall be accurately and securely placed before pouring concrete or applying 1. National Structural Code of the Philippines (NSCP) 2015

2. Soil Bearing Pressure Capacity (Refer to Geotechnical Report)

mortar or grout.

3. Concrete Compressive Strength(fc') = 20670 kN/m2

Elevation

h. Lapped splices shall be staggered where possible

i. Unless indicated otherwise, splicing of reinforcement shall be in accordance w/ ACI 318, 4. Reinforcing Bar Yield Strength

except that the minimum lap splice shall be 40 bars diameters, but not less than 2'-0" For Bar Diameter 16mm and Smaller, fy = 276000 kN/m2

j. Unless shown otherwise on plan, splices shall be as follows:

k. Suspended slabs, joists (Resting on beams) and RC bond beams; top bars shall be

For Bar Diameters Greater than 16mm, fy = 414000 kN/m2

5. Hot Rolled Steel Sections fy = 248000 kN/m2

1 C1/F1 DETAIL 2 C2/F2 Detail

SCALE : 1:25 SCALE : 1:25

splices @ midspan and bottom bars @ the support. 6. Light Gage Steel fy = 275600 kN/m2 S1 S1

l. Beams and footing tie beams: top and bottom bars shall not be spliced w/in the column 7. Specified Live Loads

or w/in the distance of twice the member depth from the face of the column. At lease two Corridors and Stairs Live Load = 100 Psf = 4.8 kN/m2

stirrups ties shall be provided @ all splices. The splice length shall not be less than 1.3x the Floor Live Loads = 65 Psf = 3.11 kN/m2

development length (LD) in 4.29 below but not less than 12" 8. Seicmic Zone = Zone 4

m. Columns: Lap splices shall be made w/in the center haft of column. Height and the 9. Wind Speed = 155 mph = 250 kph

splice shall not be less than 30 bars. 10. Importance Factor = 1

Civil/Structural Design By PRC REG. NO. : 22328 PROJECT TITLE PROJECT OWNER DESIGN BY: REVISIONS SHEET NO.

PTR NO. : 0782007 DATE:

Date Issued: January 14, 2021 DRAFTED BY:

Jen Sandoval Pugne, MsCE

STRUCTURAL ENGINEER Place Issued: Quezon City DATE:

S1

OWNER

ADDRESS: 51 Gold Street Filinvest-II Batasan Hills, Quezon City TIN NO. : 109-387-036 LOCATION: ADDRESS: CHECKED BY:

You might also like

- Method Statement For Kitchen Counter Work For Crest-21 (Ggl/Gem/Ssb)Document7 pagesMethod Statement For Kitchen Counter Work For Crest-21 (Ggl/Gem/Ssb)mayank dixit50% (2)

- Sp3-3 - Reinforced Concrete SpecDocument11 pagesSp3-3 - Reinforced Concrete SpecJon WadsworthNo ratings yet

- Three Storey General SpecificationsDocument5 pagesThree Storey General SpecificationsCarlos Gozon50% (2)

- Technical DataDocument202 pagesTechnical DataIsaac JebNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Structural Specifications - OakridgeDocument13 pagesStructural Specifications - OakridgeJuliet Lobrino RozosNo ratings yet

- Excavation, Filling and Grading 1.1 Excavation: Building SpecificationsDocument3 pagesExcavation, Filling and Grading 1.1 Excavation: Building Specificationsjoanna carrenNo ratings yet

- Trigonometry TutorialDocument4 pagesTrigonometry TutorialPd ProxyNo ratings yet

- Project: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle OrinaDocument7 pagesProject: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle Orinatyn de guzmanNo ratings yet

- SECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)Document9 pagesSECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)akvosmNo ratings yet

- Structural For TenderDocument18 pagesStructural For Tenderrimshabatoool72No ratings yet

- Purchaser Name: Andrew Henderson Revision Initial Date: ACN: 610 855 260 TNC Engineering Pty LTDDocument18 pagesPurchaser Name: Andrew Henderson Revision Initial Date: ACN: 610 855 260 TNC Engineering Pty LTDSwaminathan VivekananthamNo ratings yet

- General Construction SpecificationsDocument6 pagesGeneral Construction SpecificationsCOMPASS LanguageAndskillsTrainingNo ratings yet

- ConstructionDocument8 pagesConstructionGaspar Lig-ang TolomiaNo ratings yet

- Annex A - SpecificationsDocument5 pagesAnnex A - SpecificationsDesigners Eng'gConsultancyNo ratings yet

- Archi Specifications SampleDocument19 pagesArchi Specifications SampleChin TuasonNo ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- Specification of Gabion WallsDocument2 pagesSpecification of Gabion WallsAnam JabbarNo ratings yet

- Car TutorialDocument3 pagesCar TutorialFILE 1131No ratings yet

- General SpecificationsDocument7 pagesGeneral SpecificationsWilliam Harvey EvangelistaNo ratings yet

- ManholeDocument11 pagesManholeNia ZainorinNo ratings yet

- Building SPECS 1Document5 pagesBuilding SPECS 1Giselle EspinosaNo ratings yet

- 05 - Part A - Rds & PFsDocument17 pages05 - Part A - Rds & PFsSyed Nizam ElahiNo ratings yet

- Two Storey General SpecificationsDocument5 pagesTwo Storey General SpecificationsNicole Marie PadualNo ratings yet

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- Bricklayer Bricklayer Bricks GenerallyDocument4 pagesBricklayer Bricklayer Bricks GenerallyLee CwNo ratings yet

- t000005030 - Filename2 - Final Tender ScheduleDocument71 pagest000005030 - Filename2 - Final Tender SchedulePratik VermaNo ratings yet

- SpecificationDocument6 pagesSpecificationArnold VercelesNo ratings yet

- Compound Wall Tender (Kadapa)Document90 pagesCompound Wall Tender (Kadapa)div_misNo ratings yet

- Division 3: Concrete SpecificationsDocument12 pagesDivision 3: Concrete SpecificationsKae MoNo ratings yet

- Tech SpecsDocument13 pagesTech SpecsZidd PerezNo ratings yet

- Is 777 For Glazed Tiles PDFDocument15 pagesIs 777 For Glazed Tiles PDFRahul BadgujarNo ratings yet

- New Carparking BOQ - Gate2Document3 pagesNew Carparking BOQ - Gate2Siva SankarNo ratings yet

- General SpecificationDocument3 pagesGeneral SpecificationKakoliNo ratings yet

- General SpecificationsDocument6 pagesGeneral SpecificationsMaire Joy E. AzañaNo ratings yet

- MR. LYDIA GUTIERREZ SpecificationDocument5 pagesMR. LYDIA GUTIERREZ SpecificationMario BayotNo ratings yet

- Two Storey General SpecificationsDocument7 pagesTwo Storey General SpecificationsJoseph MalabananNo ratings yet

- Specifications: PROJECT: "Perimeter Fence" OwnerDocument2 pagesSpecifications: PROJECT: "Perimeter Fence" OwnerThe One50% (2)

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamNo ratings yet

- Building SPECSDocument5 pagesBuilding SPECSGi SelleNo ratings yet

- Sub-Structure Section 2200Document3 pagesSub-Structure Section 2200aalignup arc & const. pvt ltdNo ratings yet

- Until The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcDocument5 pagesUntil The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcJillian Flaire VillarNo ratings yet

- Until The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcDocument5 pagesUntil The Architects or Engineers Judgment, A Goo Level Is Reached For Foundations, EtcJillian Flaire VillarNo ratings yet

- Guideline Notes For RCC WorkDocument10 pagesGuideline Notes For RCC Workvikas WaghmareNo ratings yet

- Bldg. Spec and Volume 3 Completed (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) 1Document120 pagesBldg. Spec and Volume 3 Completed (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) (Autosaved) 1francita bergoniaNo ratings yet

- SPecifications-FOR PERMIT VITASDocument6 pagesSPecifications-FOR PERMIT VITASPHEBY MOOGNo ratings yet

- Hiyao SpecificationDocument5 pagesHiyao SpecificationMario BayotNo ratings yet

- BT5 SpecificationsDocument11 pagesBT5 SpecificationsJoharah CuizonNo ratings yet

- Sec-02 Underground Drainage SystemDocument5 pagesSec-02 Underground Drainage SystemOmer HayatNo ratings yet

- General Specifications Musngi Residence - As Per SiteDocument8 pagesGeneral Specifications Musngi Residence - As Per SiteJanine Palec100% (1)

- Construction SpecificationsDocument7 pagesConstruction SpecificationsVincent FilomenaNo ratings yet

- Wearing CoatDocument5 pagesWearing Coatnandi_scrNo ratings yet

- Specification For PermitDocument3 pagesSpecification For PermitErnie ConcepcionNo ratings yet

- Method Statement - Water RecDocument6 pagesMethod Statement - Water Rechadi putraNo ratings yet

- Diaphragm Wall SpecificationDocument12 pagesDiaphragm Wall SpecificationLee Cw100% (3)

- SEC 1600 (MOST Version)Document7 pagesSEC 1600 (MOST Version)shubhapal883No ratings yet

- P Brickwork1Document3 pagesP Brickwork1daveleyconsNo ratings yet

- General NotesDocument11 pagesGeneral NotesJADEL ALCANTARANo ratings yet

- PCCP Method StatementDocument4 pagesPCCP Method StatementWendell ParasNo ratings yet

- Demolition Plan: Brgy. SAN NicolasDocument1 pageDemolition Plan: Brgy. SAN NicolasEric Estremera EstilleroNo ratings yet

- Demolition Plan: MethodologyDocument1 pageDemolition Plan: MethodologyEric Estremera EstilleroNo ratings yet

- Demolition Plan: Scope of Works: LegendDocument1 pageDemolition Plan: Scope of Works: LegendEric Estremera EstilleroNo ratings yet

- Proposed Multipurpose Building - S3Document1 pageProposed Multipurpose Building - S3Eric Estremera EstilleroNo ratings yet

- Affidavit of Change EngineerDocument1 pageAffidavit of Change EngineerEric Estremera EstilleroNo ratings yet

- Proposed Multipurpose Building - S4Document1 pageProposed Multipurpose Building - S4Eric Estremera EstilleroNo ratings yet

- Common Reasons For Price IncreasesDocument2 pagesCommon Reasons For Price IncreasesEric Estremera EstilleroNo ratings yet

- KURIHARA A1 On A3 072423Document1 pageKURIHARA A1 On A3 072423Eric Estremera EstilleroNo ratings yet

- KURIHARA A2 On A3 072423Document1 pageKURIHARA A2 On A3 072423Eric Estremera EstilleroNo ratings yet

- ALTHEA'S Bakeshop A2Document1 pageALTHEA'S Bakeshop A2Eric Estremera EstilleroNo ratings yet

- Visitor Rules 1 PDFDocument2 pagesVisitor Rules 1 PDFEric Estremera EstilleroNo ratings yet

- Emergency Stairs E000Document1 pageEmergency Stairs E000Eric Estremera EstilleroNo ratings yet