Professional Documents

Culture Documents

MA105 Bridgemaster Datasheet (Issue 9)

MA105 Bridgemaster Datasheet (Issue 9)

Uploaded by

aCopyright:

Available Formats

You might also like

- ScreedMax Pro S30 TDS and MSDS PDFDocument16 pagesScreedMax Pro S30 TDS and MSDS PDFfuaunNo ratings yet

- Tiki Tar Industries - Asphalt, Modified Bitumen Manufacturers, Bitumen Emulsion & MembraneDocument2 pagesTiki Tar Industries - Asphalt, Modified Bitumen Manufacturers, Bitumen Emulsion & MembraneSanjay PatelNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- MasterBrace LAM - Updated.1 2Document2 pagesMasterBrace LAM - Updated.1 2Obrobb 92No ratings yet

- Polyhard: Mineral Based Dry Shake Floor HardenerDocument2 pagesPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNo ratings yet

- Sikalastic 632 R PDFDocument4 pagesSikalastic 632 R PDFDan BermasNo ratings yet

- (Sika) Sikacem 133 Gunite Safety Data SheetDocument5 pages(Sika) Sikacem 133 Gunite Safety Data Sheet_at_to_No ratings yet

- Promat Masterboard: The Versatile BoardDocument6 pagesPromat Masterboard: The Versatile BoardcodefinderNo ratings yet

- Masteremaco S 433 - TdsDocument3 pagesMasteremaco S 433 - TdsMudassir AliNo ratings yet

- DR Fixit Piditop 444 106 1Document3 pagesDR Fixit Piditop 444 106 1Mohammed Abdul BaseerNo ratings yet

- Sika Chapdur® - CorundumDocument2 pagesSika Chapdur® - Corundummuhammednaar32No ratings yet

- Promat Masterboard: The Versatile BoardDocument6 pagesPromat Masterboard: The Versatile BoardDiego Fernandes do NascimentoNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Sika ChapdurDocument2 pagesSika ChapdurRialno TambunanNo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- BitumenDocument7 pagesBitumenArjun KumarNo ratings yet

- 63db379fced6e DF Fastflex Brochure PDFDocument4 pages63db379fced6e DF Fastflex Brochure PDFEr Shashank SharmaNo ratings yet

- Coreflor: (Non-Metallic Monolithic Surface Hardening Compound)Document2 pagesCoreflor: (Non-Metallic Monolithic Surface Hardening Compound)Ye YintNo ratings yet

- RCC PresentationDocument33 pagesRCC PresentationRAGHAV RATTAN DUBEY 19bce043No ratings yet

- Sika Damp ProofingslurryDocument4 pagesSika Damp ProofingslurryAhmadAlsekaweNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Mastic Asphalt Handbook: by PermaniteDocument50 pagesMastic Asphalt Handbook: by PermaniteDilhara WickramaarachchiNo ratings yet

- PDS - Sika FerroGard-903 - 2017.04.06Document4 pagesPDS - Sika FerroGard-903 - 2017.04.06arizqolmahbubNo ratings yet

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 pagesDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404No ratings yet

- FloArm Screed Eco Ver7Document4 pagesFloArm Screed Eco Ver7imsNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Basf Masterprotect 300 TdsDocument3 pagesBasf Masterprotect 300 TdsEngTamerNo ratings yet

- MasterTop 430Document32 pagesMasterTop 430Ahmad ElghazolyNo ratings yet

- Expanse Al 600Document4 pagesExpanse Al 600raza102No ratings yet

- Xypex Crystalline Repair System: Repair of Concrete Spalling and HoneycombingDocument3 pagesXypex Crystalline Repair System: Repair of Concrete Spalling and HoneycombingUcok DedyNo ratings yet

- Sika PDS - E - SikaCem Gunite - 133Document2 pagesSika PDS - E - SikaCem Gunite - 133lwin_oo2435No ratings yet

- Sika PDS - E - Sikagard - 680 SDocument5 pagesSika PDS - E - Sikagard - 680 Slwin_oo2435No ratings yet

- Masteremaco S 488 - TdsDocument3 pagesMasteremaco S 488 - TdsShesh ManiNo ratings yet

- BASF - MasterEmaco S5300CI - TDSDocument3 pagesBASF - MasterEmaco S5300CI - TDSKelvinNo ratings yet

- Sikawrap® Hex-230 C: Product Data SheetDocument4 pagesSikawrap® Hex-230 C: Product Data SheetArindam SarkarNo ratings yet

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelNo ratings yet

- Technical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksDocument3 pagesTechnical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksSpiros LicoudisNo ratings yet

- PDS Sika ChapdurDocument3 pagesPDS Sika ChapdurMuhammad Nurul FajryNo ratings yet

- (Sika) Sika Monotop 612Document5 pages(Sika) Sika Monotop 612_at_to_No ratings yet

- (Sika) Sikatop 122hbDocument5 pages(Sika) Sikatop 122hb_at_to_No ratings yet

- Chem Poxy Grout E999 Tds Am22319Document2 pagesChem Poxy Grout E999 Tds Am22319Navid HashemiNo ratings yet

- DR Fixit Piditop 333 105 1Document3 pagesDR Fixit Piditop 333 105 1hunky11No ratings yet

- Profi FOOD - CTP Bucharest ParkDocument26 pagesProfi FOOD - CTP Bucharest ParkGaftoi TicaNo ratings yet

- Low Modulus 1 Part Polyurethane SealantDocument2 pagesLow Modulus 1 Part Polyurethane SealantVietpapayaNo ratings yet

- CGBM Revised NoteDocument10 pagesCGBM Revised NoteSunil Bose100% (2)

- PDS - Sika Chapdur - 20190416 - 221102 - 110241Document4 pagesPDS - Sika Chapdur - 20190416 - 221102 - 110241Andre SitumeangNo ratings yet

- Sika Chapdur CorondumDocument4 pagesSika Chapdur CorondumTolga YazanNo ratings yet

- Preprufe 300R & 160R PDFDocument6 pagesPreprufe 300R & 160R PDForlandomcortezNo ratings yet

- Terrace Water ProofingDocument3 pagesTerrace Water ProofingKvrd PrasadNo ratings yet

- Launch FRPDocument6 pagesLaunch FRPRana MahatoNo ratings yet

- Pavement Materials: AggregatesDocument41 pagesPavement Materials: AggregatesSri Bindu KajaNo ratings yet

- RAF026-SiKA QUARTZTOPDocument11 pagesRAF026-SiKA QUARTZTOPEmil ElkinNo ratings yet

- Speaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadDocument38 pagesSpeaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadRainakNo ratings yet

- PDS Sika Chapdur 2019.04.16Document3 pagesPDS Sika Chapdur 2019.04.16Ahmad aliNo ratings yet

- Emaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion InhibitorDocument4 pagesEmaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion Inhibitormohamed ayadNo ratings yet

- Plio CureDocument2 pagesPlio Curepravi3434No ratings yet

- Renderoc S: Constructive SolutionsDocument2 pagesRenderoc S: Constructive SolutionsMuhammad.FaisalNo ratings yet

- WorkTip 11 Bituminous Surfacing CharacteristicsDocument3 pagesWorkTip 11 Bituminous Surfacing CharacteristicsLa FoliakNo ratings yet

- MASTERFLEX 700i v4Document2 pagesMASTERFLEX 700i v4RUDRA KARMAKARNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- SSPC Paint ComDocument10 pagesSSPC Paint ComanoopkumarNo ratings yet

- Interthane 990 HS DatasheetDocument4 pagesInterthane 990 HS DatasheetBalasubramanian Ananth100% (1)

- PlastijointDocument2 pagesPlastijointzeroicesnowNo ratings yet

- Samsung Hdc6d90tg Hdc6d90ug Hdc9d90tg Hdc9d90ug Hdc6c55tx Hdc6c55ux Hdc9c55tx Hdc9c55ux Hdc6a90tx Hdc6a90ux Hdc9a90tx Hdc9a90ux Hdc9a90ux Eur Hdc6c55uDocument3 pagesSamsung Hdc6d90tg Hdc6d90ug Hdc9d90tg Hdc9d90ug Hdc6c55tx Hdc6c55ux Hdc9c55tx Hdc9c55ux Hdc6a90tx Hdc6a90ux Hdc9a90tx Hdc9a90ux Hdc9a90ux Eur Hdc6c55usgraureNo ratings yet

- Fosroc Cemtop 200: Constructive SolutionsDocument4 pagesFosroc Cemtop 200: Constructive SolutionsVincent JavateNo ratings yet

- Panavia v5 Ifu PDFDocument2 pagesPanavia v5 Ifu PDFdajfldsaljNo ratings yet

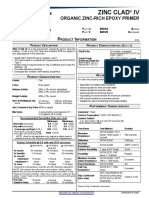

- Protective & Marine Coatings: Zinc Clad IVDocument4 pagesProtective & Marine Coatings: Zinc Clad IVJoseph Cristian Cruz LuqueNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158gstketutNo ratings yet

- Masterseal SP120Document2 pagesMasterseal SP120Shahsoor Shah MajeedNo ratings yet

- CIKOcrete Micro HSDocument3 pagesCIKOcrete Micro HSMuhammathu Anver AbdullahNo ratings yet

- Sikaflex® Precast: Product Data SheetDocument4 pagesSikaflex® Precast: Product Data SheetRoyce MarchaNo ratings yet

- Basf Masterkure 181 TdsDocument2 pagesBasf Masterkure 181 Tdssirui xuNo ratings yet

- Sigmazinc 109hs PDFDocument5 pagesSigmazinc 109hs PDFAneesh Lie A YoungNo ratings yet

- Tds-Uk-699vz (Seajet 023 Teichi) - 09-03-2021Document2 pagesTds-Uk-699vz (Seajet 023 Teichi) - 09-03-2021Ben Abdelkader MehdiNo ratings yet

- HPSR Building2009Document467 pagesHPSR Building2009Mandeep Singh100% (7)

- Hi Pon 20 01 Epoxy Primer Ver 8.0Document4 pagesHi Pon 20 01 Epoxy Primer Ver 8.0PushpendraNo ratings yet

- Mil C 53072Document43 pagesMil C 53072Valerie Schmid BurnsNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Zainal ArifinNo ratings yet

- MIL-DTL-53072D With Amendment 1Document38 pagesMIL-DTL-53072D With Amendment 1pmicjenNo ratings yet

- DOWSIL™ 896 PanelFixDocument7 pagesDOWSIL™ 896 PanelFixChris Hung WeiNo ratings yet

- Epilux 78Document2 pagesEpilux 78MuthuKumar100% (1)

- Fosroc Nitoproof 800HT System: Liquid Applied Waterproofing SystemDocument5 pagesFosroc Nitoproof 800HT System: Liquid Applied Waterproofing SystemVincent JavateNo ratings yet

- Resist 65: Technical Data SheetDocument5 pagesResist 65: Technical Data Sheetchristian210789No ratings yet

- Mastertop P10 TDSDocument2 pagesMastertop P10 TDSطه اللوذعيNo ratings yet

- 701 Construction Manual Intro 18pages PDFDocument18 pages701 Construction Manual Intro 18pages PDFPanosNo ratings yet

- SHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationDocument42 pagesSHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationOliver JimmyNo ratings yet

- Method Statement of Steel Structures (TS TRUSS SDN BHD)Document21 pagesMethod Statement of Steel Structures (TS TRUSS SDN BHD)Calvin OhNo ratings yet

- Question Bank - 1: ApixamsDocument24 pagesQuestion Bank - 1: ApixamsChabdi EssenzNo ratings yet

- Hempel Paints (Qatar) WLLDocument36 pagesHempel Paints (Qatar) WLLmimrusfan100% (1)

MA105 Bridgemaster Datasheet (Issue 9)

MA105 Bridgemaster Datasheet (Issue 9)

Uploaded by

aCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MA105 Bridgemaster Datasheet (Issue 9)

MA105 Bridgemaster Datasheet (Issue 9)

Uploaded by

aCopyright:

Available Formats

Cl/SfB

PRODUCT DATASHEET

PR

Bridgemaster®

COMBINED WATERPROOFING & SURFACING

DESCRIPTION High mechanical strength

Can be tailored to individual project requirements

Trafficable within one hour

Quality assured - applied only by Stirling Lloyd authorised and

trained contractors

SURFACE PREPARATION

All substrates must be clean, dry and structurally sound. They must

be free from laitance, oils and other surface contaminants.

Concrete

New concrete decks should be a minimum of fourteen days old. If

additives, cement replacement or curing agents have been used

please contact us.

All concrete decks must be prepared by suitable mechanical means

such as vacuum blasting to provide a sound surface.

Rapid repairs to damaged concrete can be made using Metaset®

rapid repair products.

Bridgemaster is a fast curing, waterproof, skid resistant wearing Where the use of a non-structural screed or a lightweight concrete

course for the protection of bridge decks, where light weight allied substrate is proposed, please seek advice from us first.

to durability is required. Based on Stirling Lloyd’s advanced resin

technology and extensive experience in the development of Steel

infrastructure waterproofing and trafficked surfaces, Bridgemaster All surfaces must be free from rust, dirt, scale and other

comprises an impermeable, flexible resin screed with an aggregate contaminants. The surface finish shall comply with Swedish

overscatter and durable sealer coat. Standard SIS 05 59 00 (1967) Sa 2.5.

APPLICATION

USES

Primer

Bridgemaster can be used to surface and protect a wide variety of

Concrete substrates must be primed using PAB1 Primer.

structures operating under a range of climatic environments and

Steel substrates must be primed with ZED S94 Primer.

traffic conditions, from light duty pedestrian structures to major

Please refer to the relevant datasheet for further information.

bridges and viaducts subject to heavy vehicular traffic. It is suitable

for application to concrete, steel and aluminium substrates. Bridgemaster

Bridgemaster is available in two standard grades: The standard application temperature range for Bridgemaster is 0°C

(32°F) to 35°C (86°F). For temperatures outside this range please

PD Grade – For pedestrian areas. A 4mm screed plus aggregate

contact Stirling Lloyd.

and sealer.

Bridgemaster is a three-part screed, supplied in pre-weighed

HD Grade – For vehicular trafficked areas. A 6mm screed plus quantities ready for on-site mixing. Application is by pouring and

aggregate and sealer. spreading using a toothed rake or trowel, followed by a spiked

roller.

Bridgemaster is designed for use on gradients up to 1:12. For

gradients greater than this please contact us. Once rollered the screed is blinded with dry aggregate.

Typical applications include: Once the screed has cured the excess aggregate should be

removed.

Road Bridges Loading Bays

Bascule bridges Footbridges A coat of SL Sealer Matt Clear is then applied to enhance

Swing bridges Walkways aggregate retention and help maintain a clean surface. The system

can be trafficked once the SL Sealer Matt Clear has fully cured.

Roll-on/off ramps Steps

Marine structures Stadium Spectator areas

COVERAGE

FEATURES Thickness Binder Aggregate Sealer

Waterproof 6 mm 12.6 kg/m² 4-7 kg/m²

0.3-0.5

High friction surface kg/m²

Durable 4 mm 8.4 kg/m² 4-7 kg/m²

0.3-0.5

Rapid cure even at low temperatures kg/m²

Economical and easily maintained The binder coverage rate will vary with surface texture.

Lightweight Aggregate and sealer consumption will vary depending upon the

Aids composite action size of aggregate used.

High bond strength to substrate

MA105 Bridgemaster Datasheet Issue 9

Page 1 of 2

Cl/SfB

PRODUCT DATASHEET

PR

Bridgemaster®

COMBINED WATERPROOFING & SURFACING

AGGREGATES & COLOUR

The current aggregates acceptable for use are Chinese Bauxite,

Guyanan Bauxite and Green Granite. Use of any other aggregate is

prohibited unless approval has been granted by us. Please see our

Aggregate Price List for further details.

The Bridgemaster resin is available is black and neutral colours.

CLEANING

All tools and equipment should be cleaned with Stirling Lloyd

Solvent No.1 (Acetone) before the material is allowed to cure.

PACKAGING & STORAGE

Primer: 5 & 20kg kits

Screed: 24kg kits

Aggregate: 25kg bags (typically)

SL Sealer Matt Clear (Resin): 5 & 20kg

(BPO): 150g & 600g bags

All components of the Bridgemaster system should be stored in

cool, dry, protected conditions, out of direct sunlight and in

accordance with the relevant Health & Safety regulations. Storage

temperatures must not exceed 25oC. Do not store near naked

flames or foodstuffs.

Stored in unopened containers, under the correct conditions, the

components have a minimum shelf life of six months. If your

product is more than six months old you must contact us before

use.

ANCILLARIES

Stirling Lloyd produces a range of products to compliment the

Bridgemaster system. These include:

Metaset Scratch Coat – a rapid cure, levelling screed.

Metaset – a range of resin based rapid repair mortars.

Safetrack® LM – a flexible, bright, abrasion resistant line

marking available in a range of colours.

Sealants – a range of flexible sealants for all joints and cracks.

Sentinel® - a range of mechanical joints.

HEALTH & SAFETY

Please refer to our Safety Data Sheets for further information.

GENERAL INFORMATION

Bridgemaster is one of a wide range of specialist waterproofing,

surfacing and repair materials manufactured and supplied by

Stirling Lloyd. If you require any further information on this or any

other of our products, please contact us or visit our website:

www.stirlinglloyd.com. ® BRIDGEMASTER, METASET, SAFETRACK & SENTINEL are registered

trademarks of Stirling Lloyd Polychem Ltd

© 2015 Stirling Lloyd Polychem Ltd

The information presented herein is accurate to the best of our knowledge. We pursue a

progressive research and development policy and reserve the right to alter any of the

details herein without notice. The information given must not be taken in any way to form

a specification. All technical properties quoted are from laboratory prepared samples. We

will not accept liability whatsoever arising out of the use of the information contained

herein.

Union Bank, King Street, Knutsford, Cheshire, WA16 6EF, England

Tel: +44 (0) 1565 633111 Fax: +44 (0) 1565 633555

E-Mail: info@stirlinglloyd.com

Website: www.stirlinglloyd.com

MA105 Bridgemaster Datasheet Issue 9

Page 2 of 2

You might also like

- ScreedMax Pro S30 TDS and MSDS PDFDocument16 pagesScreedMax Pro S30 TDS and MSDS PDFfuaunNo ratings yet

- Tiki Tar Industries - Asphalt, Modified Bitumen Manufacturers, Bitumen Emulsion & MembraneDocument2 pagesTiki Tar Industries - Asphalt, Modified Bitumen Manufacturers, Bitumen Emulsion & MembraneSanjay PatelNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- MasterBrace LAM - Updated.1 2Document2 pagesMasterBrace LAM - Updated.1 2Obrobb 92No ratings yet

- Polyhard: Mineral Based Dry Shake Floor HardenerDocument2 pagesPolyhard: Mineral Based Dry Shake Floor HardenerAlexi ALfred H. TagoNo ratings yet

- Sikalastic 632 R PDFDocument4 pagesSikalastic 632 R PDFDan BermasNo ratings yet

- (Sika) Sikacem 133 Gunite Safety Data SheetDocument5 pages(Sika) Sikacem 133 Gunite Safety Data Sheet_at_to_No ratings yet

- Promat Masterboard: The Versatile BoardDocument6 pagesPromat Masterboard: The Versatile BoardcodefinderNo ratings yet

- Masteremaco S 433 - TdsDocument3 pagesMasteremaco S 433 - TdsMudassir AliNo ratings yet

- DR Fixit Piditop 444 106 1Document3 pagesDR Fixit Piditop 444 106 1Mohammed Abdul BaseerNo ratings yet

- Sika Chapdur® - CorundumDocument2 pagesSika Chapdur® - Corundummuhammednaar32No ratings yet

- Promat Masterboard: The Versatile BoardDocument6 pagesPromat Masterboard: The Versatile BoardDiego Fernandes do NascimentoNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Sika ChapdurDocument2 pagesSika ChapdurRialno TambunanNo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- BitumenDocument7 pagesBitumenArjun KumarNo ratings yet

- 63db379fced6e DF Fastflex Brochure PDFDocument4 pages63db379fced6e DF Fastflex Brochure PDFEr Shashank SharmaNo ratings yet

- Coreflor: (Non-Metallic Monolithic Surface Hardening Compound)Document2 pagesCoreflor: (Non-Metallic Monolithic Surface Hardening Compound)Ye YintNo ratings yet

- RCC PresentationDocument33 pagesRCC PresentationRAGHAV RATTAN DUBEY 19bce043No ratings yet

- Sika Damp ProofingslurryDocument4 pagesSika Damp ProofingslurryAhmadAlsekaweNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Mastic Asphalt Handbook: by PermaniteDocument50 pagesMastic Asphalt Handbook: by PermaniteDilhara WickramaarachchiNo ratings yet

- PDS - Sika FerroGard-903 - 2017.04.06Document4 pagesPDS - Sika FerroGard-903 - 2017.04.06arizqolmahbubNo ratings yet

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 pagesDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404No ratings yet

- FloArm Screed Eco Ver7Document4 pagesFloArm Screed Eco Ver7imsNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Basf Masterprotect 300 TdsDocument3 pagesBasf Masterprotect 300 TdsEngTamerNo ratings yet

- MasterTop 430Document32 pagesMasterTop 430Ahmad ElghazolyNo ratings yet

- Expanse Al 600Document4 pagesExpanse Al 600raza102No ratings yet

- Xypex Crystalline Repair System: Repair of Concrete Spalling and HoneycombingDocument3 pagesXypex Crystalline Repair System: Repair of Concrete Spalling and HoneycombingUcok DedyNo ratings yet

- Sika PDS - E - SikaCem Gunite - 133Document2 pagesSika PDS - E - SikaCem Gunite - 133lwin_oo2435No ratings yet

- Sika PDS - E - Sikagard - 680 SDocument5 pagesSika PDS - E - Sikagard - 680 Slwin_oo2435No ratings yet

- Masteremaco S 488 - TdsDocument3 pagesMasteremaco S 488 - TdsShesh ManiNo ratings yet

- BASF - MasterEmaco S5300CI - TDSDocument3 pagesBASF - MasterEmaco S5300CI - TDSKelvinNo ratings yet

- Sikawrap® Hex-230 C: Product Data SheetDocument4 pagesSikawrap® Hex-230 C: Product Data SheetArindam SarkarNo ratings yet

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelNo ratings yet

- Technical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksDocument3 pagesTechnical Note TN 105 Asphalt Surfacing of Concrete Bridge DecksSpiros LicoudisNo ratings yet

- PDS Sika ChapdurDocument3 pagesPDS Sika ChapdurMuhammad Nurul FajryNo ratings yet

- (Sika) Sika Monotop 612Document5 pages(Sika) Sika Monotop 612_at_to_No ratings yet

- (Sika) Sikatop 122hbDocument5 pages(Sika) Sikatop 122hb_at_to_No ratings yet

- Chem Poxy Grout E999 Tds Am22319Document2 pagesChem Poxy Grout E999 Tds Am22319Navid HashemiNo ratings yet

- DR Fixit Piditop 333 105 1Document3 pagesDR Fixit Piditop 333 105 1hunky11No ratings yet

- Profi FOOD - CTP Bucharest ParkDocument26 pagesProfi FOOD - CTP Bucharest ParkGaftoi TicaNo ratings yet

- Low Modulus 1 Part Polyurethane SealantDocument2 pagesLow Modulus 1 Part Polyurethane SealantVietpapayaNo ratings yet

- CGBM Revised NoteDocument10 pagesCGBM Revised NoteSunil Bose100% (2)

- PDS - Sika Chapdur - 20190416 - 221102 - 110241Document4 pagesPDS - Sika Chapdur - 20190416 - 221102 - 110241Andre SitumeangNo ratings yet

- Sika Chapdur CorondumDocument4 pagesSika Chapdur CorondumTolga YazanNo ratings yet

- Preprufe 300R & 160R PDFDocument6 pagesPreprufe 300R & 160R PDForlandomcortezNo ratings yet

- Terrace Water ProofingDocument3 pagesTerrace Water ProofingKvrd PrasadNo ratings yet

- Launch FRPDocument6 pagesLaunch FRPRana MahatoNo ratings yet

- Pavement Materials: AggregatesDocument41 pagesPavement Materials: AggregatesSri Bindu KajaNo ratings yet

- RAF026-SiKA QUARTZTOPDocument11 pagesRAF026-SiKA QUARTZTOPEmil ElkinNo ratings yet

- Speaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadDocument38 pagesSpeaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadRainakNo ratings yet

- PDS Sika Chapdur 2019.04.16Document3 pagesPDS Sika Chapdur 2019.04.16Ahmad aliNo ratings yet

- Emaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion InhibitorDocument4 pagesEmaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion Inhibitormohamed ayadNo ratings yet

- Plio CureDocument2 pagesPlio Curepravi3434No ratings yet

- Renderoc S: Constructive SolutionsDocument2 pagesRenderoc S: Constructive SolutionsMuhammad.FaisalNo ratings yet

- WorkTip 11 Bituminous Surfacing CharacteristicsDocument3 pagesWorkTip 11 Bituminous Surfacing CharacteristicsLa FoliakNo ratings yet

- MASTERFLEX 700i v4Document2 pagesMASTERFLEX 700i v4RUDRA KARMAKARNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- SSPC Paint ComDocument10 pagesSSPC Paint ComanoopkumarNo ratings yet

- Interthane 990 HS DatasheetDocument4 pagesInterthane 990 HS DatasheetBalasubramanian Ananth100% (1)

- PlastijointDocument2 pagesPlastijointzeroicesnowNo ratings yet

- Samsung Hdc6d90tg Hdc6d90ug Hdc9d90tg Hdc9d90ug Hdc6c55tx Hdc6c55ux Hdc9c55tx Hdc9c55ux Hdc6a90tx Hdc6a90ux Hdc9a90tx Hdc9a90ux Hdc9a90ux Eur Hdc6c55uDocument3 pagesSamsung Hdc6d90tg Hdc6d90ug Hdc9d90tg Hdc9d90ug Hdc6c55tx Hdc6c55ux Hdc9c55tx Hdc9c55ux Hdc6a90tx Hdc6a90ux Hdc9a90tx Hdc9a90ux Hdc9a90ux Eur Hdc6c55usgraureNo ratings yet

- Fosroc Cemtop 200: Constructive SolutionsDocument4 pagesFosroc Cemtop 200: Constructive SolutionsVincent JavateNo ratings yet

- Panavia v5 Ifu PDFDocument2 pagesPanavia v5 Ifu PDFdajfldsaljNo ratings yet

- Protective & Marine Coatings: Zinc Clad IVDocument4 pagesProtective & Marine Coatings: Zinc Clad IVJoseph Cristian Cruz LuqueNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158gstketutNo ratings yet

- Masterseal SP120Document2 pagesMasterseal SP120Shahsoor Shah MajeedNo ratings yet

- CIKOcrete Micro HSDocument3 pagesCIKOcrete Micro HSMuhammathu Anver AbdullahNo ratings yet

- Sikaflex® Precast: Product Data SheetDocument4 pagesSikaflex® Precast: Product Data SheetRoyce MarchaNo ratings yet

- Basf Masterkure 181 TdsDocument2 pagesBasf Masterkure 181 Tdssirui xuNo ratings yet

- Sigmazinc 109hs PDFDocument5 pagesSigmazinc 109hs PDFAneesh Lie A YoungNo ratings yet

- Tds-Uk-699vz (Seajet 023 Teichi) - 09-03-2021Document2 pagesTds-Uk-699vz (Seajet 023 Teichi) - 09-03-2021Ben Abdelkader MehdiNo ratings yet

- HPSR Building2009Document467 pagesHPSR Building2009Mandeep Singh100% (7)

- Hi Pon 20 01 Epoxy Primer Ver 8.0Document4 pagesHi Pon 20 01 Epoxy Primer Ver 8.0PushpendraNo ratings yet

- Mil C 53072Document43 pagesMil C 53072Valerie Schmid BurnsNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Zainal ArifinNo ratings yet

- MIL-DTL-53072D With Amendment 1Document38 pagesMIL-DTL-53072D With Amendment 1pmicjenNo ratings yet

- DOWSIL™ 896 PanelFixDocument7 pagesDOWSIL™ 896 PanelFixChris Hung WeiNo ratings yet

- Epilux 78Document2 pagesEpilux 78MuthuKumar100% (1)

- Fosroc Nitoproof 800HT System: Liquid Applied Waterproofing SystemDocument5 pagesFosroc Nitoproof 800HT System: Liquid Applied Waterproofing SystemVincent JavateNo ratings yet

- Resist 65: Technical Data SheetDocument5 pagesResist 65: Technical Data Sheetchristian210789No ratings yet

- Mastertop P10 TDSDocument2 pagesMastertop P10 TDSطه اللوذعيNo ratings yet

- 701 Construction Manual Intro 18pages PDFDocument18 pages701 Construction Manual Intro 18pages PDFPanosNo ratings yet

- SHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationDocument42 pagesSHAHEEN-COM-PS-BQR-006 - 070 Attachment - Cleaning Management RecommendationOliver JimmyNo ratings yet

- Method Statement of Steel Structures (TS TRUSS SDN BHD)Document21 pagesMethod Statement of Steel Structures (TS TRUSS SDN BHD)Calvin OhNo ratings yet

- Question Bank - 1: ApixamsDocument24 pagesQuestion Bank - 1: ApixamsChabdi EssenzNo ratings yet

- Hempel Paints (Qatar) WLLDocument36 pagesHempel Paints (Qatar) WLLmimrusfan100% (1)