Professional Documents

Culture Documents

Valv

Valv

Uploaded by

sergio negreteCopyright:

Available Formats

You might also like

- Shitty First Drafts - Anne LamottDocument2 pagesShitty First Drafts - Anne LamottIllicitValentine100% (2)

- c200321 (WRFC E)Document2 pagesc200321 (WRFC E)María MarquinaNo ratings yet

- Reed Switch Magnetic Sensor For Airtec Slots Al 01Document1 pageReed Switch Magnetic Sensor For Airtec Slots Al 01ElectricalNo ratings yet

- Delta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30Document2 pagesDelta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30David SaymonNo ratings yet

- M1000120AC5MDocument1 pageM1000120AC5MEnrique MurgiaNo ratings yet

- AL 17 enDocument1 pageAL 17 enMoutaz IsmailNo ratings yet

- Satronix Three Phase Solid State Relay High VoltageDocument3 pagesSatronix Three Phase Solid State Relay High VoltagejbhupiNo ratings yet

- SPKT0031D0Document2 pagesSPKT0031D0Rafael CruzNo ratings yet

- 19 Technical Data Electromechanical Switching Relays and Installation ContactorsDocument1 page19 Technical Data Electromechanical Switching Relays and Installation ContactorsazNo ratings yet

- Skvc20a460c DatDocument2 pagesSkvc20a460c DatgusmilexaNo ratings yet

- Advanced Switching Solutions: 600+ Amp 12-800 VDC ContactorDocument4 pagesAdvanced Switching Solutions: 600+ Amp 12-800 VDC ContactorIndra FerdiansyahNo ratings yet

- Hirc63n PDFDocument3 pagesHirc63n PDFHenry RodriguezNo ratings yet

- Electromechanical Relays-Carlo GavazziDocument6 pagesElectromechanical Relays-Carlo Gavazzinour100% (2)

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- STE0363 - 92 Rev.06 - 22-07-2022Document22 pagesSTE0363 - 92 Rev.06 - 22-07-2022emunozNo ratings yet

- R15 473564 PDFDocument7 pagesR15 473564 PDFHENDER VILLEGASNo ratings yet

- 2 2 Way Poppet Valve MSVT 03Document5 pages2 2 Way Poppet Valve MSVT 03Dhanraj PatilNo ratings yet

- Catálogo de SeccionalizadorDocument19 pagesCatálogo de SeccionalizadorLuis LizárragaNo ratings yet

- High Speed Bi-Directional Circuit Breaker For DC ApplicationsDocument2 pagesHigh Speed Bi-Directional Circuit Breaker For DC ApplicationsagarwaalaaaaNo ratings yet

- SKN2000 SemikronDocument4 pagesSKN2000 SemikronEmerson G PinheiroNo ratings yet

- 240W DIN Rail Type DC-DC Converter: SeriesDocument9 pages240W DIN Rail Type DC-DC Converter: SeriesHasan MuftićNo ratings yet

- Lithium Datasheet SaDocument7 pagesLithium Datasheet SaArmin ZaimovićNo ratings yet

- HLD 65KDocument1 pageHLD 65KgilbertomjcNo ratings yet

- Omron Redundancy SMPSDocument14 pagesOmron Redundancy SMPSinstNo ratings yet

- Capacitor Duty ContactorsDocument3 pagesCapacitor Duty ContactorsYusuffNo ratings yet

- OLd Brochure Solar VT100 PV - CompressedDocument6 pagesOLd Brochure Solar VT100 PV - CompressedUmar RajputNo ratings yet

- C Elementar Vario MACRO Cube PDFDocument16 pagesC Elementar Vario MACRO Cube PDFWaleed El-azab100% (1)

- Carel Energy Meter PDFDocument1 pageCarel Energy Meter PDFElşən Yusifoğlu ƏsgərovNo ratings yet

- PN5 - PN7Document2 pagesPN5 - PN7cagv0202No ratings yet

- Etalko-Technical Data Electronic Impulse Switches Also For Central ControlDocument1 pageEtalko-Technical Data Electronic Impulse Switches Also For Central Controlbion.icleNo ratings yet

- Cosonic Series TableDocument2 pagesCosonic Series Tablejghjkhgkh87No ratings yet

- SD20N60Document10 pagesSD20N60Francisco LucenaNo ratings yet

- GV240 Series: Advanced Switching SolutionsDocument7 pagesGV240 Series: Advanced Switching SolutionsBiagio PadulaNo ratings yet

- Advanced Switching Solutions: FeaturesDocument4 pagesAdvanced Switching Solutions: Featuresraza239No ratings yet

- Screw Terminal Type, 105°C Standard: LNR LNUDocument6 pagesScrew Terminal Type, 105°C Standard: LNR LNUpo truongNo ratings yet

- 520 Pressure SensorDocument7 pages520 Pressure SensorDaveNo ratings yet

- EMRAX 188 Datasheet A00Document2 pagesEMRAX 188 Datasheet A00vicon16138No ratings yet

- 2 Vit Lbs CatalogDocument14 pages2 Vit Lbs CataloggeradakNo ratings yet

- 40Ω -10Ω Series Flow Control and ReliefDocument10 pages40Ω -10Ω Series Flow Control and ReliefMohamed FersiNo ratings yet

- PIX Catalog 2011-13-14Document2 pagesPIX Catalog 2011-13-146A EntertainmentNo ratings yet

- D3010 HSV600 ReducedDocument28 pagesD3010 HSV600 ReducedY.EbadiNo ratings yet

- CV & SV OLTC Operating Instruction-HM0.460.001Document31 pagesCV & SV OLTC Operating Instruction-HM0.460.001mudassar hussainNo ratings yet

- M Series Mobile Marine Intl Specsheet PDFDocument2 pagesM Series Mobile Marine Intl Specsheet PDFNguyễnThếAnhNo ratings yet

- Solenoid Control Valve: Product FeaturesDocument2 pagesSolenoid Control Valve: Product FeaturesXavierNo ratings yet

- ETEK Solar PV System 2023Document62 pagesETEK Solar PV System 2023ELECTROSTATIC SPRAYERS GREECENo ratings yet

- Nabm Series Ball Valve Actuator: Modulating Control 10 NMDocument5 pagesNabm Series Ball Valve Actuator: Modulating Control 10 NMHoàngViệtAnhNo ratings yet

- Sensor Magnetico Al 21r ShakoDocument1 pageSensor Magnetico Al 21r ShakoMantenimiento PuntoFlexNo ratings yet

- Vnso LiteratureDocument5 pagesVnso LiteraturepabloNo ratings yet

- F0303202 Data Sheet ENDocument1 pageF0303202 Data Sheet EN7 77No ratings yet

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90No ratings yet

- GROWATT Three Phase InverterDocument6 pagesGROWATT Three Phase InverterAlexandru ImrehNo ratings yet

- Chave de N¡vel Vibratoria - Nivoswith - R400-500Document2 pagesChave de N¡vel Vibratoria - Nivoswith - R400-500raphaelpessNo ratings yet

- IMI Hydronic Engineering TA-Slider 750 IMI TA AktuatorDocument12 pagesIMI Hydronic Engineering TA-Slider 750 IMI TA AktuatorMarko MarkovicNo ratings yet

- 520 Series CatalogueDocument9 pages520 Series CataloguenguyenmanhtuantlNo ratings yet

- MSP 2P & 4P Technical Specification 6-7-2019 (Rev 2)Document1 pageMSP 2P & 4P Technical Specification 6-7-2019 (Rev 2)ADE STORESNo ratings yet

- DDR 240 SpecDocument9 pagesDDR 240 Specb8f4fk5nqtNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Pembelajaran Literasi Membaca Di Pondok Pesantren Sidogiri Kraton PasuruanDocument17 pagesPembelajaran Literasi Membaca Di Pondok Pesantren Sidogiri Kraton Pasuruanpriyo hartantoNo ratings yet

- Lightolier Lytecaster 7-11 Downlights Brochure 1980Document8 pagesLightolier Lytecaster 7-11 Downlights Brochure 1980Alan MastersNo ratings yet

- Industrial Crops & ProductsDocument10 pagesIndustrial Crops & ProductsShield YggdrasilNo ratings yet

- Advancements in Concrete Design: Self-Consolidating/Self-Compacting ConcreteDocument4 pagesAdvancements in Concrete Design: Self-Consolidating/Self-Compacting ConcreteMikhaelo Alberti Dela CruzNo ratings yet

- SBARDocument2 pagesSBARNabiela Aswaty 2011125083No ratings yet

- C & C++ Interview Questions You'll Most Likely Be AskedDocument24 pagesC & C++ Interview Questions You'll Most Likely Be AskedVibrant PublishersNo ratings yet

- Manual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Document338 pagesManual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Joel Carvajal ArayaNo ratings yet

- Cultural Variations and Social Differences (Ethnicity)Document19 pagesCultural Variations and Social Differences (Ethnicity)Jomar TeofiloNo ratings yet

- Consequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniDocument21 pagesConsequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniSaraf KushalNo ratings yet

- Spill Kit ChecklistDocument1 pageSpill Kit Checklistmd rafiqueNo ratings yet

- Modern Business Statistics With Microsoft Office Excel 4Th Edition Anderson Solutions Manual Full Chapter PDFDocument47 pagesModern Business Statistics With Microsoft Office Excel 4Th Edition Anderson Solutions Manual Full Chapter PDFjerryholdengewmqtspaj100% (11)

- Wolfram Von Eschenbach - ParzivalDocument324 pagesWolfram Von Eschenbach - ParzivalStanley Castro100% (1)

- Project Management: Dan FleckDocument55 pagesProject Management: Dan FleckHamis Rabiam MagundaNo ratings yet

- LaGard LG Basic Manager InstructionsDocument2 pagesLaGard LG Basic Manager InstructionsGCNo ratings yet

- Database SecurityDocument19 pagesDatabase SecurityVinay VenkatramanNo ratings yet

- Diagrama 950H PDFDocument1 pageDiagrama 950H PDFDaniel Castillo PeñaNo ratings yet

- Lab 16 - Law of Definite CompositionDocument6 pagesLab 16 - Law of Definite CompositionMicah YapNo ratings yet

- Indirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractionDocument7 pagesIndirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractiondhanasundariNo ratings yet

- The Discriminant: Given A Quadratic Equation Use The Discriminant To Determine The Nature of The RootsDocument17 pagesThe Discriminant: Given A Quadratic Equation Use The Discriminant To Determine The Nature of The RootsdianneNo ratings yet

- Final Examination (Open Book) Koc3466 (Corporate Writing)Document9 pagesFinal Examination (Open Book) Koc3466 (Corporate Writing)Shar KhanNo ratings yet

- Be Project Work BookDocument44 pagesBe Project Work BookCASTING DEPARTMENTNo ratings yet

- Objective of ECO401 (1 22) Short NotesDocument11 pagesObjective of ECO401 (1 22) Short Notesmuhammad jamilNo ratings yet

- Wassp Handout F3 A4 4pp WebDocument2 pagesWassp Handout F3 A4 4pp WebLazy BearNo ratings yet

- Gestational Diabetes Diet - What To Eat For A Healthy Pregnancy PDFDocument9 pagesGestational Diabetes Diet - What To Eat For A Healthy Pregnancy PDFJibin John JacksonNo ratings yet

- Fyp PPT FinalDocument18 pagesFyp PPT FinalasadNo ratings yet

- 2volt Powerstack BatteriesDocument4 pages2volt Powerstack BatteriesYasirNo ratings yet

- Honeywell Actuator M7410EDocument6 pagesHoneywell Actuator M7410EFrinaru CiprianNo ratings yet

- Sooceal ProjectDocument40 pagesSooceal ProjectSushil ShresthaNo ratings yet

- Soft Cheese-Like Product Development Enriched With Soy ProteinDocument9 pagesSoft Cheese-Like Product Development Enriched With Soy ProteinJorge RamirezNo ratings yet

Valv

Valv

Uploaded by

sergio negreteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valv

Valv

Uploaded by

sergio negreteCopyright:

Available Formats

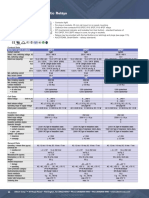

Proportional solenoid valve

21A2KCV15-10

2/2 way N.C. - Direct acting

PRESENTATION:

Solenoid valve designed for a fluid output proportional to

voltage change.

Minimum operational pressure is not required.

Mounting in any position.

Material used and tests carried out ensure reliability and long

life time.

TECHNICAL FEATURES:

Max. allowable pressure (PS) 40 bar

Ambient temperature:

with coils class F - 10°C + 60°C

with coil class H - 10°C + 80°C

Proportional response features:

Hysteresis < 5%

Repeatability < 3%

Sensitivity < 2%

Tensions range: 0-24 VDC

24 VDC impulse range modulation (600 ÷ 800 Hz),

(see general information:proportional S.V. operation).

These solenoid valves are not suitable for stagnating fluids, or

for fluids that being subject to evaporation may deposit solid,

calcareous or similar residues.

PIPES: G 1/4

COILS: 8W - Ø 13

BDA - BDS - BSA 155°C (class F)

BDF - BDV 180°C (class H)

12W - Ø 13

UDA 155°C (class F)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN MATERIAL.

Gaskets Temperature Medium

V=FKM Water, inert gas,

- 10°C +140°C

(fluoroelastomer) mineral oils (3°E), gasoline

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

8

G 1/4 21A2KCV15-10 21 ~3 1,5 1,4 0 - 10

12

SOLENOID VALVE CALIBRATED AT 10 bar - Flow rate in air

COIL 8W COIL 12W

9000 9000

8000 8000

7000 7000

6000 6000

5000

rate Nl/h

rate Nl/h

5000

Nl/h

Nl/h

4000 4000

Portata

Portata

Flow

Flow

3000 3000

2000 2000

1000 1000

0 0

0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100

Duty Cycle Duty Cycle

P= 10 bar P= 5 bar P= 1 bar

Note Also available with brass body without lead.

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

09-09-2010 ODE 21A2KCV15-10

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Spring Stainless steel AISI series 300

Ring guide PTFE

Orifice Brass - UNI EN 12165 CW617N

Seal V=FKM

Gasket V=FKM

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES:

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PART:

1. Coil:

See coils list

KIT:

KT130KCV55-I

DIMENSIONS:

POWER ABSORPTION DIMENSIONS

COIL

TYPE W D E F

mm mm mm

B 8 30 42 54

U 12 36 48 60

21A2KCV15-10 ODE 09-09-2010

Proportional solenoid valve

21A2KCV20-10

2/2 way N.C. - Direct acting

PRESENTATION:

Solenoid valve designed for a fluid output proportional to

voltage change.

Minimum operational pressure is not required.

Mounting in any position.

Material used and tests carried out ensure reliability and long

life time.

TECHNICAL FEATURES:

Max. allowable pressure (PS) 40 bar

Ambient temperature:

with coils class F - 10°C + 60°C

with coil class H - 10°C + 80°C

Proportional response features:

Hysteresis < 5%

Repeatability < 3%

Sensitivity < 2%

Tensions range: 0-24 VDC

24 VDC impulse range modulation (600 ÷ 800 Hz),

(see general information:proportional S.V. operation).

These solenoid valves are not suitable for stagnating fluids, or

for fluids that being subject to evaporation may deposit solid,

calcareous or similar residues.

PIPES: G 1/4

COILS: 8W - Ø 13

BDA - BDS - BSA 155°C (class F)

BDF - BDV 180°C (class H)

12W - Ø 13

UDA 155°C (class F)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN MATERIAL.

Gaskets Temperature Medium

V=FKM Water, inert gas,

- 10°C +140°C

(fluoroelastomer) mineral oils (3°E), gasoline

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

8

G 1/4 21A2KCV20-10 21 ~3 2 2 0 - 10

12

SOLENOID VALVE CALIBRATED AT 10 bar - Flow rate in air

COIL 8W COIL 12W

16000 16000

14000 14000

12000 12000

10000 10000

Flow rate Nl/h

Flow rate Nl/h

Nl/h

Nl/h

8000 8000

Portata

Portata

6000 6000

4000 4000

2000 2000

0 0

0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100

Duty Cycle Duty Cycle

P= 10 bar P= 5 bar P= 1 bar

Note Also available with brass body without lead.

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

09-09-2010 ODE 21A2KCV20-10

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Spring Stainless steel AISI series 300

Ring guide PTFE

Orifice Brass - UNI EN 12165 CW617N

Seal V=FKM

Gasket V=FKM

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES:

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PARTS:

1. Coil:

See coils list

KIT:

KT130KCV55-I

DIMENSIONS:

POWER ABSORPTION DIMENSIONS

COIL

TYPE W D E F

mm mm mm

B 8 30 42 54

U 12 36 48 60

21A2KCV20-10 ODE 09-09-2010

Proportional solenoid valve

21A2KCV25-08

2/2 way N.C. - Direct acting

PRESENTATION:

Solenoid valve designed for a fluid output proportional to

voltage change.

Minimum operational pressure is not required.

Mounting in any position.

Material used and tests carried out ensure reliability and long

life time.

TECHNICAL FEATURES:

Max. allowable pressure (PS) 40 bar

Ambient temperature:

with coils class F - 10°C + 60°C

with coil class H - 10°C + 80°C

Proportional response features:

Hysteresis < 5%

Repeatability < 3%

Sensitivity < 2%

Tensions range: 0-24 VDC

24 VDC impulse range modulation (600 ÷ 800 Hz),

(see general information:proportional S.V. operation).

These solenoid valves are not suitable for stagnating fluids, or

for fluids that being subject to evaporation may deposit solid,

calcareous or similar residues.

PIPES: G 1/4

COILS: 8W - Ø 13

BDA - BDS - BSA 155°C (class F)

BDF - BDV 180°C (class H)

12W - Ø 13

UDA 155°C (class F)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN MATERIAL.

Gaskets Temperature Medium

V=FKM Water, inert gas,

- 10°C +140°C

(fluoroelastomer) mineral oils (3°E), gasoline

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

8

G 1/4 21A2KCV25-08 21 ~3 2,5 3,2 0 - 8

12

SOLENOID VALVE CALIBRATED AT 8 bar - Flow rate in air

COIL 8W COIL 12W

16000 20000

14000 18000

16000

12000

14000

10000

12000

Nl/h

rate Nl/h

rate Nl/h

Nl/h

8000 10000

Portata

Portata

6000 8000

Flow

Flow

6000

4000

4000

2000

2000

0 0

0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100

Duty Cycle Duty Cycle

P= 8 bar P= 4 bar P= 1 bar

Note Also available with brass body without lead.

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

09-09-2010 ODE 21A2KCV25-08

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Spring Stainless steel AISI series 300

Ring guide PTFE

Orifice Brass - UNI EN 12165 CW617N

Seal V=FKM

Gasket V=FKM

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES:

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PARTS:

1. Coil:

See coils list

KIT:

KT130KCV55-I

DIMENSIONS:

POWER ABSORPTION DIMENSIONS

COIL

TYPE W D E F

mm mm mm

B 8 30 42 54

U 12 36 48 60

21A2KCV25-08 ODE 09-09-2010

Proportional solenoid valve

21A2KCV30-05

2/2 way N.C. - Direct acting

PRESENTATION:

Solenoid valve designed for a fluid output proportional to

voltage change.

Minimum operational pressure is not required.

Mounting in any position.

Material used and tests carried out ensure reliability and long

life time.

TECHNICAL FEATURES

Max. allowable pressure (PS) 40 bar

Ambient temperature:

with coil class F - 10°C + 60°C

with coil class H - 10°C + 80°C

Proportional response features:

Hysteresis < 5%

Repeatability < 3%

Sensitivity < 2%

Tensions range: 0-24 VDC

24 VDC impulse range modulation (600 ÷ 800 Hz),

(see general information:proportional S.V. operation).

These solenoid valves are not suitable for stagnating fluids, or

for fluids that being subject to evaporation may deposit solid,

calcareous or similar residues.

PIPES: G 1/4

COILS 8W - Ø 13

BDA - BDS - BSA 155°C (class F)

BDF - BDV 180°C (class H)

12W - Ø 13

UDA 155°C (class F)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN MATERIAL.

Gaskets Temperature Medium

V=FKM Water, inert gas,

- 10°C +140°C

(fluoroelastomer) mineral oils (3°E), gasoline

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

8

G 1/4 21A2KCV30-05 21 ~3 3 4 0 - 5

12

SOLENOID VALVE CALIBRATED AT 5 bar - Flow rate in air

COIL 8W COIL 12W

18000 25000

16000

14000 20000

12000

15000

10000

Nl/h

Flow rate Nl/h

Nl/h

rate Nl/h

8000

Portata

Portata

10000

Flow

6000

4000 5000

2000

0 0

0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100

Duty Cycle Duty Cycle

P= 5 bar P= 2,5 bar P= 1 bar

Note Also available with brass body without lead.

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

09-09-2010 ODE 21A2KCV30-05

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Spring Stainless steel AISI series 300

Ring guide PTFE

Orifice Brass - UNI EN 12165 CW617N

Seal V=FKM

Gasket V=FKM

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES:

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PARTS:

1. Coil:

See coils list

KIT:

KT130KCV55-I

DIMENSIONS:

POWER ABSORPTION DIMENSIONS

COIL

TYPE W D E F

mm mm mm

B 8 30 42 54

U 12 36 48 60

21A2KCV30-05 ODE 09-09-2010

Proportional solenoid valve

21A2KCV45-1X

2/2 way N.C. - Direct acting

PRESENTATION:

Solenoid valve designed for a fluid output proportional to

voltage change.

Minimum operational pressure is not required.

Mounting in any position.

Material used and tests carried out ensure reliability and long

life time.

TECHNICAL FEATURES:

Max. allowable pressure (PS) 40 bar

Ambient temperature:

with coils class F - 10°C + 60°C

with coil class H - 10°C + 80°C

Proportional response features:

Hysteresis < 5%

Repeatability < 3%

Sensitivity < 2%

Tensions range: 0-24 VDC

24 VDC impulse range modulation (600 ÷ 800 Hz),

(see general information:proportional S.V. operation).

These solenoid valves are not suitable for stagnating fluids, or

for fluids that being subject to evaporation may deposit solid,

calcareous or similar residues.

PIPES: G 1/4

COILS: 8W - Ø 13

BDA - BDS - BSA 155°C (class F)

BDF - BDV 180°C (class H)

12W - Ø 13

UDA 155°C (class F)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN MATERIAL.

Gaskets Temperature Medium

V=FKM Water, inert gas,

- 10°C +140°C

(fluoroelastomer) mineral oils (3°E), gasoline

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

8

G 1/4 21A2KCV45-1X 21 ~3 4,5 6,4 0 - 1,5

12

SOLENOID VALVE CALIBRATED AT 1,5 bar - Flow rate in air

COIL 8W COIL 12W

9000 14000

8000

12000

7000

10000

6000

8000

Nl/h

5000

Nl/h

rate Nl/h

rate Nl/h

4000

Portata

6000

Portata

Flow

3000

Flow

4000

2000

2000

1000

0 0

0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100

Duty Cycle Duty Cycle

P= 1,5 bar P= 1 bar

Note Also available with brass body without lead.

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

09-09-2010 ODE 21A2KCV45-1X

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Spring Stainless steel AISI series 300

Ring guide PTFE

Orifice Brass - UNI EN 12165 CW617N

Seal V=FKM

Gasket V=FKM

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES:

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PARTS:

1. Coil:

See coils list

KIT:

KT130KCV55-I

DIMENSIONS:

POWER ABSORPTION DIMENSIONS

COIL

TYPE W D E F

mm mm mm

B 8 30 42 54

U 12 36 48 60

21A2KCV45-1X ODE 09-09-2010

Proportional solenoid valve

21A2KCV55-01

2/2 way N.C. - Direct acting

PRESENTATION:

Solenoid valve designed for a fluid output proportional to

voltage change.

Minimum operational pressure is not required.

Mounting in any position.

Material used and tests carried out ensure reliability and long

life time.

TECHNICAL FEATURES:

Max. allowable pressure (PS) 40 bar

Ambient temperature: - 10°C + 60°C

Proportional response features:

Hysteresis < 5%

Repeatability < 3%

Sensitivity < 2%

Tensions range: 0-24 VDC

24 VDC impulse range modulation (600 ÷ 800 Hz),

(see general information:proportional S.V. operation).

These solenoid valves are not suitable for stagnating fluids, or

for fluids that being subject to evaporation may deposit solid,

calcareous or similar residues.

PIPES: G 1/4

COILS: 12W - Ø 13

UDA 155°C (class F)

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN

MATERIAL.

Gaskets Temperature Medium

V=FKM Water, inert gas,

- 10°C +140°C

(fluoroelastomer) mineral oils (3°E), gasoline

Ø Pressure

Pipe Max viscosity Kv Power

Code min M.O.P.D.

ISO 228/1

cSt °E mm l/mn (watt) bar AC bar DC bar

G 1/4 21A2KCV55-01 21 ~3 5,5 9 12 0 - 1

SOLENOID VALVE CALIBRATED AT 1 bar - Flow rate in air

COIL 12W

10000

9000

8000

7000

6000

rate Nl/h

Nl/h

5000

Portata

4000

Flow

3000

2000

1000

0

0 10 20 30 40 50 60 70 80 90 100

Duty Cycle

P= 1 bar P= 0,5 bar

Note Also available with brass body without lead.

The “ODE ” reserves the right to carry out technical and aesthetic modifications without prior notification.

09-09-2010 ODE 21A2KCV55-01

MATERIALS:

Body Brass - UNI EN 12165 CW617N

Armature tube Stainless steel AISI series 300

Fixed core Stainless steel AISI series 400

Plunger Stainless steel AISI series 400

Spring Stainless steel AISI series 300

Ring guide PTFE

Orifice Brass - UNI EN 12165 CW617N

Seal V=FKM

Gasket V=FKM

On request:

Connector Pg 9 or Pg 11

Connector conformity ISO 4400

FEATURES

Electrical conformity IEC 335

Protection degree IP 65 EN 60529 (DIN 40050)

with coil fitted by connector.

SPARE PARTS:

1. Coil:

See coils list

KIT:

KT130KCV55-I

DIMENSIONS:

POWER ABSORPTION DIMENSIONS

COIL

TYPE W D E F

mm mm mm

U 12 36 48 60

21A2KCV55-01 ODE 09-09-2010

You might also like

- Shitty First Drafts - Anne LamottDocument2 pagesShitty First Drafts - Anne LamottIllicitValentine100% (2)

- c200321 (WRFC E)Document2 pagesc200321 (WRFC E)María MarquinaNo ratings yet

- Reed Switch Magnetic Sensor For Airtec Slots Al 01Document1 pageReed Switch Magnetic Sensor For Airtec Slots Al 01ElectricalNo ratings yet

- Delta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30Document2 pagesDelta RPI-Commercial Series: RPI - M12 / M15A / M20A / M30David SaymonNo ratings yet

- M1000120AC5MDocument1 pageM1000120AC5MEnrique MurgiaNo ratings yet

- AL 17 enDocument1 pageAL 17 enMoutaz IsmailNo ratings yet

- Satronix Three Phase Solid State Relay High VoltageDocument3 pagesSatronix Three Phase Solid State Relay High VoltagejbhupiNo ratings yet

- SPKT0031D0Document2 pagesSPKT0031D0Rafael CruzNo ratings yet

- 19 Technical Data Electromechanical Switching Relays and Installation ContactorsDocument1 page19 Technical Data Electromechanical Switching Relays and Installation ContactorsazNo ratings yet

- Skvc20a460c DatDocument2 pagesSkvc20a460c DatgusmilexaNo ratings yet

- Advanced Switching Solutions: 600+ Amp 12-800 VDC ContactorDocument4 pagesAdvanced Switching Solutions: 600+ Amp 12-800 VDC ContactorIndra FerdiansyahNo ratings yet

- Hirc63n PDFDocument3 pagesHirc63n PDFHenry RodriguezNo ratings yet

- Electromechanical Relays-Carlo GavazziDocument6 pagesElectromechanical Relays-Carlo Gavazzinour100% (2)

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- STE0363 - 92 Rev.06 - 22-07-2022Document22 pagesSTE0363 - 92 Rev.06 - 22-07-2022emunozNo ratings yet

- R15 473564 PDFDocument7 pagesR15 473564 PDFHENDER VILLEGASNo ratings yet

- 2 2 Way Poppet Valve MSVT 03Document5 pages2 2 Way Poppet Valve MSVT 03Dhanraj PatilNo ratings yet

- Catálogo de SeccionalizadorDocument19 pagesCatálogo de SeccionalizadorLuis LizárragaNo ratings yet

- High Speed Bi-Directional Circuit Breaker For DC ApplicationsDocument2 pagesHigh Speed Bi-Directional Circuit Breaker For DC ApplicationsagarwaalaaaaNo ratings yet

- SKN2000 SemikronDocument4 pagesSKN2000 SemikronEmerson G PinheiroNo ratings yet

- 240W DIN Rail Type DC-DC Converter: SeriesDocument9 pages240W DIN Rail Type DC-DC Converter: SeriesHasan MuftićNo ratings yet

- Lithium Datasheet SaDocument7 pagesLithium Datasheet SaArmin ZaimovićNo ratings yet

- HLD 65KDocument1 pageHLD 65KgilbertomjcNo ratings yet

- Omron Redundancy SMPSDocument14 pagesOmron Redundancy SMPSinstNo ratings yet

- Capacitor Duty ContactorsDocument3 pagesCapacitor Duty ContactorsYusuffNo ratings yet

- OLd Brochure Solar VT100 PV - CompressedDocument6 pagesOLd Brochure Solar VT100 PV - CompressedUmar RajputNo ratings yet

- C Elementar Vario MACRO Cube PDFDocument16 pagesC Elementar Vario MACRO Cube PDFWaleed El-azab100% (1)

- Carel Energy Meter PDFDocument1 pageCarel Energy Meter PDFElşən Yusifoğlu ƏsgərovNo ratings yet

- PN5 - PN7Document2 pagesPN5 - PN7cagv0202No ratings yet

- Etalko-Technical Data Electronic Impulse Switches Also For Central ControlDocument1 pageEtalko-Technical Data Electronic Impulse Switches Also For Central Controlbion.icleNo ratings yet

- Cosonic Series TableDocument2 pagesCosonic Series Tablejghjkhgkh87No ratings yet

- SD20N60Document10 pagesSD20N60Francisco LucenaNo ratings yet

- GV240 Series: Advanced Switching SolutionsDocument7 pagesGV240 Series: Advanced Switching SolutionsBiagio PadulaNo ratings yet

- Advanced Switching Solutions: FeaturesDocument4 pagesAdvanced Switching Solutions: Featuresraza239No ratings yet

- Screw Terminal Type, 105°C Standard: LNR LNUDocument6 pagesScrew Terminal Type, 105°C Standard: LNR LNUpo truongNo ratings yet

- 520 Pressure SensorDocument7 pages520 Pressure SensorDaveNo ratings yet

- EMRAX 188 Datasheet A00Document2 pagesEMRAX 188 Datasheet A00vicon16138No ratings yet

- 2 Vit Lbs CatalogDocument14 pages2 Vit Lbs CataloggeradakNo ratings yet

- 40Ω -10Ω Series Flow Control and ReliefDocument10 pages40Ω -10Ω Series Flow Control and ReliefMohamed FersiNo ratings yet

- PIX Catalog 2011-13-14Document2 pagesPIX Catalog 2011-13-146A EntertainmentNo ratings yet

- D3010 HSV600 ReducedDocument28 pagesD3010 HSV600 ReducedY.EbadiNo ratings yet

- CV & SV OLTC Operating Instruction-HM0.460.001Document31 pagesCV & SV OLTC Operating Instruction-HM0.460.001mudassar hussainNo ratings yet

- M Series Mobile Marine Intl Specsheet PDFDocument2 pagesM Series Mobile Marine Intl Specsheet PDFNguyễnThếAnhNo ratings yet

- Solenoid Control Valve: Product FeaturesDocument2 pagesSolenoid Control Valve: Product FeaturesXavierNo ratings yet

- ETEK Solar PV System 2023Document62 pagesETEK Solar PV System 2023ELECTROSTATIC SPRAYERS GREECENo ratings yet

- Nabm Series Ball Valve Actuator: Modulating Control 10 NMDocument5 pagesNabm Series Ball Valve Actuator: Modulating Control 10 NMHoàngViệtAnhNo ratings yet

- Sensor Magnetico Al 21r ShakoDocument1 pageSensor Magnetico Al 21r ShakoMantenimiento PuntoFlexNo ratings yet

- Vnso LiteratureDocument5 pagesVnso LiteraturepabloNo ratings yet

- F0303202 Data Sheet ENDocument1 pageF0303202 Data Sheet EN7 77No ratings yet

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90No ratings yet

- GROWATT Three Phase InverterDocument6 pagesGROWATT Three Phase InverterAlexandru ImrehNo ratings yet

- Chave de N¡vel Vibratoria - Nivoswith - R400-500Document2 pagesChave de N¡vel Vibratoria - Nivoswith - R400-500raphaelpessNo ratings yet

- IMI Hydronic Engineering TA-Slider 750 IMI TA AktuatorDocument12 pagesIMI Hydronic Engineering TA-Slider 750 IMI TA AktuatorMarko MarkovicNo ratings yet

- 520 Series CatalogueDocument9 pages520 Series CataloguenguyenmanhtuantlNo ratings yet

- MSP 2P & 4P Technical Specification 6-7-2019 (Rev 2)Document1 pageMSP 2P & 4P Technical Specification 6-7-2019 (Rev 2)ADE STORESNo ratings yet

- DDR 240 SpecDocument9 pagesDDR 240 Specb8f4fk5nqtNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Pembelajaran Literasi Membaca Di Pondok Pesantren Sidogiri Kraton PasuruanDocument17 pagesPembelajaran Literasi Membaca Di Pondok Pesantren Sidogiri Kraton Pasuruanpriyo hartantoNo ratings yet

- Lightolier Lytecaster 7-11 Downlights Brochure 1980Document8 pagesLightolier Lytecaster 7-11 Downlights Brochure 1980Alan MastersNo ratings yet

- Industrial Crops & ProductsDocument10 pagesIndustrial Crops & ProductsShield YggdrasilNo ratings yet

- Advancements in Concrete Design: Self-Consolidating/Self-Compacting ConcreteDocument4 pagesAdvancements in Concrete Design: Self-Consolidating/Self-Compacting ConcreteMikhaelo Alberti Dela CruzNo ratings yet

- SBARDocument2 pagesSBARNabiela Aswaty 2011125083No ratings yet

- C & C++ Interview Questions You'll Most Likely Be AskedDocument24 pagesC & C++ Interview Questions You'll Most Likely Be AskedVibrant PublishersNo ratings yet

- Manual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Document338 pagesManual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Joel Carvajal ArayaNo ratings yet

- Cultural Variations and Social Differences (Ethnicity)Document19 pagesCultural Variations and Social Differences (Ethnicity)Jomar TeofiloNo ratings yet

- Consequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniDocument21 pagesConsequences of Stress: Kushaal Saraf Luv Kumar Jain Shivank Kedia Himashu RawtaniSaraf KushalNo ratings yet

- Spill Kit ChecklistDocument1 pageSpill Kit Checklistmd rafiqueNo ratings yet

- Modern Business Statistics With Microsoft Office Excel 4Th Edition Anderson Solutions Manual Full Chapter PDFDocument47 pagesModern Business Statistics With Microsoft Office Excel 4Th Edition Anderson Solutions Manual Full Chapter PDFjerryholdengewmqtspaj100% (11)

- Wolfram Von Eschenbach - ParzivalDocument324 pagesWolfram Von Eschenbach - ParzivalStanley Castro100% (1)

- Project Management: Dan FleckDocument55 pagesProject Management: Dan FleckHamis Rabiam MagundaNo ratings yet

- LaGard LG Basic Manager InstructionsDocument2 pagesLaGard LG Basic Manager InstructionsGCNo ratings yet

- Database SecurityDocument19 pagesDatabase SecurityVinay VenkatramanNo ratings yet

- Diagrama 950H PDFDocument1 pageDiagrama 950H PDFDaniel Castillo PeñaNo ratings yet

- Lab 16 - Law of Definite CompositionDocument6 pagesLab 16 - Law of Definite CompositionMicah YapNo ratings yet

- Indirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractionDocument7 pagesIndirani College of Nursing: Level of Student - B.SC (N) Ii Yrs TractiondhanasundariNo ratings yet

- The Discriminant: Given A Quadratic Equation Use The Discriminant To Determine The Nature of The RootsDocument17 pagesThe Discriminant: Given A Quadratic Equation Use The Discriminant To Determine The Nature of The RootsdianneNo ratings yet

- Final Examination (Open Book) Koc3466 (Corporate Writing)Document9 pagesFinal Examination (Open Book) Koc3466 (Corporate Writing)Shar KhanNo ratings yet

- Be Project Work BookDocument44 pagesBe Project Work BookCASTING DEPARTMENTNo ratings yet

- Objective of ECO401 (1 22) Short NotesDocument11 pagesObjective of ECO401 (1 22) Short Notesmuhammad jamilNo ratings yet

- Wassp Handout F3 A4 4pp WebDocument2 pagesWassp Handout F3 A4 4pp WebLazy BearNo ratings yet

- Gestational Diabetes Diet - What To Eat For A Healthy Pregnancy PDFDocument9 pagesGestational Diabetes Diet - What To Eat For A Healthy Pregnancy PDFJibin John JacksonNo ratings yet

- Fyp PPT FinalDocument18 pagesFyp PPT FinalasadNo ratings yet

- 2volt Powerstack BatteriesDocument4 pages2volt Powerstack BatteriesYasirNo ratings yet

- Honeywell Actuator M7410EDocument6 pagesHoneywell Actuator M7410EFrinaru CiprianNo ratings yet

- Sooceal ProjectDocument40 pagesSooceal ProjectSushil ShresthaNo ratings yet

- Soft Cheese-Like Product Development Enriched With Soy ProteinDocument9 pagesSoft Cheese-Like Product Development Enriched With Soy ProteinJorge RamirezNo ratings yet