Professional Documents

Culture Documents

Getting Start of Dispensing-180713

Getting Start of Dispensing-180713

Uploaded by

Tuyên VũOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Getting Start of Dispensing-180713

Getting Start of Dispensing-180713

Uploaded by

Tuyên VũCopyright:

Available Formats

TAEHA

Dispensing

Getting Start

Core Development Production Division

July. 10, 2018

TAEHA BASIC DISPENSING SYSTEM(AIR)

Barrel (Syringe) Needle Compression Air Controller

Research & Development Department 2

TAEHA BASIC DISPENSING SYSTEM(AIR)

Combine Dispensing system Using Compression Air

Research & Development Department 3

TAEHA THE KIND OF MATERIAL

Epoxy(1K/2K) Thermal conductive / grease

Epoxy (Dual Cartridge)

Silicone (1K/2K/RTV) Urethane (2K)

• Epoxy : Amine

• Urethane : Iso-cya-nate

• Acryl : Methyl Methacrylate

• Silicone : Amine, Oxim

• Silicone RTV : Moisture

Research & Development Department 4

TAEHA WHAT IS THE VISCOSITY (FLOWABILITY)

The flowability is different / like ink and honey

• Viscosity unit : cp = cps = mpa.s

Research & Development Department 5

TAEHA WHAT IS THE THIXOTROPY (STICKY)

Grease - Viscosity high, Thixotropy low Honey - Viscosity low, Thixotropy high

• Dispensing is easy than • Dispensing is hard than

Research & Development Department 6

TAEHA WHAT IS THE SPECIFIC GRAVITY(WEIGHT)

• Specific gravity = density of material / density of water

* Density of water is ‘1’ when temp. 4°C , 1atm

No filler material - specific gravity : 0.98 ~ 1.0 (normally) filler material - specific gravity : 1.1 ~ 3.5 (normally)

• Filler material – alumina, metal filler

• Filler size – 5 ~ 20μ

Research & Development Department 7

TAEHA THE KIND OF MATERIAL

MATERIAL VISCOSITY(CPS) SPECIFIC GRAVITY

FLUX, IPA, PRIMER 0.5 0.98

ANAEROBIC 1.0 - 50 0.98

ACIDIC 1.0 0.98

SILICONE 1K, 2K (CIPG, FIPG) 50 – 50,000 0.98

CONFORMAL COATING 100 – 500 0.98

UV 1,000 – 50,000 1.0

EPOXY 1K, 2K 3,000 – 50,000 1.0

PUR 2K (CIPG, FIPG) 1 – 20,000 1.0

ACRYL (MMA) 50 – 40,000 0.98

FILLER MATERIAL 10,000 – PASTE 1.1 – 2.5

THERMAL CONDUCTIVE ADHESIVE(2K) 20,000 – 80,000 1.1 - 1.5

SOLDER CREAME 50,000 – 100,000 2.0

GRASE 100,000 – 300,000 1.0

SILICONE RTV 100,000 – PASTE 1.0 – 1.5

SILICONE / EPOXY PASTE PASTE 1.0

THERMAL GREASE PASTE 2.5 - 3.5

Normally, These material have viscosity & specific gravity like that

Research & Development Department 8

TAEHA THE DISPENSING SYSTEM

(ONE COMPONENT)

• Material supply part

• Material Dispensing(Dosing) part

Normally, All kind of Application follow this formation

Research & Development Department 9

TAEHA THE DISPENSING SYSTEM

(TWO COMPONENT)

Resin(A) Hardner(B)

• Material supply part

• Material Dispensing & Mixing part

Normally, All kind of Application follow this formation

Research & Development Department 10

TAEHA MATERIAL SUPPLY PART

Barrel Tank

Cartridge Can pump

MSIV (Material Supply System In vacuum) MSS (Material Supply System In air) Pro Can pump

Research & Development Department 11

TAEHA MATERIAL DISPENSING PART

Barrel

Cartridge Valve Jetting Valve

Pro Duo pump

Pro pump

Research & Development Department 12

TAEHA BARREL SYSREM (SPEC-1)

Combine Dispensing system Using Compression Air

Research & Development Department 13

TAEHA CARTRIDGE SYSREM (SPEC-2)

Sealant Cartridge(340cc)

Research & Development Department 14

TAEHA VALVE & CARTRIDGE/BARREL SYSREM

(SPEC-3)

Research & Development Department 15

TAEHA VALVE & TANK SYSREM (SPEC-4)

Research & Development Department 16

TAEHA ACCESSORY

• Standard part • UV Material / Heating option

Research & Development Department 17

TAEHA ACCESSORY

• Precision Nozzle

• One inlet Multi outlet

Research & Development Department 18

TAEHA ACCESSORY

Research & Development Department 19

TAEHA HOW ARE DIFFERENT THE VALVE AND

PUMP

Valve

• Control Flow

Pump

• Can’t make pressure

• Make flow

• Can make pressure by oneself

Research & Development Department 20

TAEHA CAN PUMP

TCP-100(1L – 5L)

TCP-1800(18L)

• Outlet Pressure : 50bar

Research & Development Department 21

TAEHA SPRAY VALVE

Research & Development Department 22

TAEHA PROPUMP/PRODUOPUMP

Research & Development Department 23

TAEHA PROPUMP/PRODUOPUMP

• DISPLACEMENT : 15CC/REV.

• DOSING MAX. PRESSURE : 20BAR

• MOTOR : 400W (AC SERVO)

• CONTROLLER : PROCON-1000

PCP-5000

MODEL STATUS

PCP-1500 ON SALE

PCP-2000 ON SALE

PCP-5000 ON SALE

PCP-15000 ON DEVELOP

PCP-15000

Research & Development Department 24

TAEHA JETTING VALVE (PROJET)

Research & Development Department 25

TAEHA JETTING VALVE (PROJET)

• PRODOT-100

LAB UPGRADE

• PRODOT-200

LAB UPGRADE

• PRODOT-250

FIELD UPGRADE

• PRODOT-1000

LAB DEVELOPMENT

PRODOT-100 PRODOT-200 PRODOT-250 PRODOT-1000

Zoom In picture

Korea Hosiden Electronic

Research & Development Department 26

TAEHA PRO CAN PUMP

PRO-CP05

PRO-CP20

Research & Development Department 27

TAEHA PLUNGER PUMP & VALVE(PPV)

SPECIFIC PRO

MODEL(1K) MODEL(2K) SIZE MATERIAL VISCOSITY(CPS) PRO-JET PPV

GRAVITY PUMP

PPV-015 PPDV-015 FLUX, IPA, PRIMER 0.5 0.98 ● ●

PPV-050 PPDV-050 ANAEROBIC 1.0 - 50 0.98 ● ● ●

28MM

PPV-150 PPDV-150 ACIDIC 1.0 0.98 ● ●

PPV-500 PPDV-500 SILICONE 1K, 2K (CIPG, FIPG) 50 – 50K 0.98 ● ● ●

PPV-1000 PPDV-1000 CONFORMAL COATING 100 – 500 0.98 ● ● ●

35MM

PPV-5000 PPDV-5000 UV 1K – 50K 1.0 ● ● ●

PPV-10000 EPOXY 1K, 2K 3K – 50K 1.0 ● ● ●

45MM

PPV-20000 PUR 2K (CIPG, FIPG) 1 – 20K 1.0 ● ●

ACRYL (MMA) 50 – 40K 0.98 ● ●

FILLER MATERIAL 10K - PASTE 1.1 – 2.5 ● ●

THERMAL CONDUCTIVE

20K - 80K 1.1 - 1.5 ● ●

ADHESIVE(2K)

SOLDER CREAME 50K – 100K 2.0 ● ●

GRASE 100K – 300K 1.0 ● ● ●

SILICONE RTV 100K – PASTE 1.0 – 1.5 ● ●

SILICONE / EPOXY PASTE PASTE 1.0 ● ●

THERMAL GREASE PASTE 2.5 - 3.5 ●

PPV-20000 ● : VERY GOOD, ● : AVAILABLE, BLANK : UNABLE

THERMAL GREASE

Research & Development Department 28

TAEHA THE SYSTEM OF DISPENSING

• Material : Silicone HTV

• Processor : CIPG (Curing in place gasket)

• Viscosity : 1,000,000cp

• Specific gravity : 1.3

• System of Dispensing :

> Pro-cp20

> Pro pump (pcp-150)

> Desktop robot (jr 3303)

> Work table

> Line heating

Research & Development Department 29

TAEHA THE SYSTEM OF DISPENSING

• Material : Silicone RTV

• Processor : Solar cell frame Sealing

• Viscosity : Paste

• Specific gravity : 1.1

• System of Dispensing :

> 200 liter Rampump

> Pro pump (pcp-5000)

> Distance of line : 8meter

> Flowrate 3g/3sec

> Pressure of line : 250bar

Research & Development Department 30

TAEHA THE SYSTEM OF DISPENSING

• Material : Thermal conductive(2k)

• Processor : Automobile PTC heater

• Viscosity : Paste

• Specific gravity : 1.6

• System of Dispensing :

> Can pump (TCP-105)

> Pro duo pump (pdp-500)

> Nozzle : Flat nozzle

> Robot : Desk top 300 x 300 x 100

> Head : Dual head

Research & Development Department 31

TAEHA THE SYSTEM OF DISPENSING

Research & Development Department 32

TAEHA Corporation

Core Development Production Division

July. 10, 2018

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- TDS - Etersol 6512af-1Document3 pagesTDS - Etersol 6512af-1Helmi Rizki Hayati100% (1)

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- Robert Donington - Interpretation of Early Music PDFDocument616 pagesRobert Donington - Interpretation of Early Music PDFandres bonilla torres100% (10)

- Fluvial Depositional Systems 2014 - Andrew Miall PDFDocument322 pagesFluvial Depositional Systems 2014 - Andrew Miall PDFdenis andriyani100% (3)

- Derakane 411 Momentum TDSDocument6 pagesDerakane 411 Momentum TDSAnindya Paul ChowdhuryNo ratings yet

- Technical Data Sheet (TDS) PDFDocument3 pagesTechnical Data Sheet (TDS) PDFSabuj SaikiaNo ratings yet

- Ecoalube642TDS PDFDocument2 pagesEcoalube642TDS PDFDkC gunsNo ratings yet

- Derakane 8084 TdsDocument4 pagesDerakane 8084 TdsPecel LeleNo ratings yet

- Lavacrete Series 489Document2 pagesLavacrete Series 489Dumbledore The 3rdNo ratings yet

- PET Processing V4 1 PDFDocument48 pagesPET Processing V4 1 PDFwoongs73100% (1)

- Multimedia Filter and Activated Carbon Filter Pilot Test StudyDocument10 pagesMultimedia Filter and Activated Carbon Filter Pilot Test StudyHedi Ben MohamedNo ratings yet

- Everlube 620 ATDSDocument2 pagesEverlube 620 ATDSValentinNo ratings yet

- TPS Eva 3641 2Document1 pageTPS Eva 3641 2Juthi RahmanNo ratings yet

- Getting Start of Pro Can Pump-181103Document24 pagesGetting Start of Pro Can Pump-181103Tuyên VũNo ratings yet

- About SSPDocument5 pagesAbout SSPmmozupurNo ratings yet

- Derakane 8084Document4 pagesDerakane 8084willNo ratings yet

- Ashland - Data Sheet For DERAKANE 411-350Document5 pagesAshland - Data Sheet For DERAKANE 411-350Muhamed JhabeerNo ratings yet

- Ashland, Technical Data SheetDocument5 pagesAshland, Technical Data Sheetyasi heeruNo ratings yet

- C100E Resin PUROLITEDocument3 pagesC100E Resin PUROLITEmilaNo ratings yet

- C100EDocument3 pagesC100ESatrio NugrohoNo ratings yet

- Aesthetic Topcoat Guide SWDocument8 pagesAesthetic Topcoat Guide SWjennifergiannouNo ratings yet

- 3d Printing Materials PropertiesDocument51 pages3d Printing Materials PropertiesAmy GaoNo ratings yet

- Derakane Momentum 411-350 TDSDocument5 pagesDerakane Momentum 411-350 TDSGautamNo ratings yet

- Pall Profile Coreless FilterDocument2 pagesPall Profile Coreless FilterMustafa DaoudNo ratings yet

- IDS 302 1001 002 General Purpose MEK BlackDocument3 pagesIDS 302 1001 002 General Purpose MEK BlackFarid DiazNo ratings yet

- PCTEP PercoTop EP 2K Epoxy Topcoat-ENDocument5 pagesPCTEP PercoTop EP 2K Epoxy Topcoat-ENadfaNo ratings yet

- Electrodes For Hollow Perforated ElectrodesDocument14 pagesElectrodes For Hollow Perforated ElectrodesPraful N KNo ratings yet

- Factors Influencing The Flocculation Process in Silica-Reinforced Natural Rubber CompoundsDocument16 pagesFactors Influencing The Flocculation Process in Silica-Reinforced Natural Rubber Compoundsdong maiNo ratings yet

- C100EDocument3 pagesC100EsivaNo ratings yet

- C100EDocument3 pagesC100Eatlantic.int25No ratings yet

- Key Products : The Steak !!!Document88 pagesKey Products : The Steak !!!stevenNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- Assignment No.4 - PEP Elective - Spring 2017Document2 pagesAssignment No.4 - PEP Elective - Spring 2017Dr-Adel SalemNo ratings yet

- Flo Pac Plus Filter Cartridge - Data Sheet - IPF NADocument2 pagesFlo Pac Plus Filter Cartridge - Data Sheet - IPF NAashfaqsaiyadNo ratings yet

- Din 1048 Permeability Testing-Report ConfidentialDocument2 pagesDin 1048 Permeability Testing-Report ConfidentialEros Setyo AndoroNo ratings yet

- Everlube 9002 TDSDocument2 pagesEverlube 9002 TDSValentin100% (1)

- Overdenture Brochure ENGDocument10 pagesOverdenture Brochure ENGEmanuel RosuNo ratings yet

- FluidsDocument13 pagesFluidslelekunNo ratings yet

- Parker Chomerics CHO-FOIL-CHO-FAB Conductive TapeDocument2 pagesParker Chomerics CHO-FOIL-CHO-FAB Conductive TapeAlexandreNo ratings yet

- Purolite C100: Product Data SheetDocument3 pagesPurolite C100: Product Data SheetStella Avinca TantraNo ratings yet

- Adeka Nol Uh-450Vf: o o o oDocument5 pagesAdeka Nol Uh-450Vf: o o o oLong An ĐỗNo ratings yet

- TDS en Primer Ep 1040Document3 pagesTDS en Primer Ep 1040AzifahNo ratings yet

- Miramer M600 TDS - Rev1.1Document1 pageMiramer M600 TDS - Rev1.1Adesh GurjarNo ratings yet

- AffcvDocument2 pagesAffcvValentinNo ratings yet

- Yacht - Pro Catalogue - 2022-2023 - EN - UKDocument31 pagesYacht - Pro Catalogue - 2022-2023 - EN - UKghyd artiagaNo ratings yet

- Online Course - Petrosoftware: Basic Information Course ObjectivesDocument67 pagesOnline Course - Petrosoftware: Basic Information Course ObjectivesAli maghrbiNo ratings yet

- Siap PrintDocument243 pagesSiap Printgubruriteibi-1990No ratings yet

- Eutectic 25030Document2 pagesEutectic 25030Simelemon TolomeoNo ratings yet

- BoltDocument4 pagesBoltShilpa DhanureNo ratings yet

- 1402-00 Simazinc EP PrimerDocument2 pages1402-00 Simazinc EP PrimerMuhammad Mulya JatiNo ratings yet

- Plastic Primer - 0Document4 pagesPlastic Primer - 0محمدرفیع احمدیانNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- 1 s2.0 S0301679X20301432 MainDocument11 pages1 s2.0 S0301679X20301432 MaindharamuuNo ratings yet

- Toray RO TM800KDocument2 pagesToray RO TM800KsreerajNo ratings yet

- Techtron PPS HPV & Ketron PEEK HPV SpecificationsDocument3 pagesTechtron PPS HPV & Ketron PEEK HPV SpecificationsPeterWayNo ratings yet

- Macropoxy 400Document2 pagesMacropoxy 400nellyNo ratings yet

- Tospearl 120FL, 130FL, 145FL, 1100FL: Technical Data SheetDocument7 pagesTospearl 120FL, 130FL, 145FL, 1100FL: Technical Data SheetarslanNo ratings yet

- File 1495037066Document4 pagesFile 1495037066Paul WheelerNo ratings yet

- New PTFE-based Material For Hydraulic Seal ApplicationsDocument6 pagesNew PTFE-based Material For Hydraulic Seal ApplicationsjojoNo ratings yet

- Purolite A300: Product Data SheetDocument2 pagesPurolite A300: Product Data SheetCah Logoe DewweNo ratings yet

- THV-D1912001 - 4PE - Hang .Document1 pageTHV-D1912001 - 4PE - Hang .Tuyên VũNo ratings yet

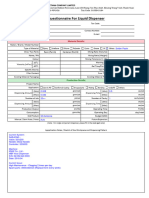

- Dispenser RFQ Questionnaire Form (KMW) 1Document1 pageDispenser RFQ Questionnaire Form (KMW) 1Tuyên VũNo ratings yet

- Hoenle (1) - MinDocument32 pagesHoenle (1) - MinTuyên VũNo ratings yet

- TAEHA - SPEC-H - Barrel Heating SystemDocument1 pageTAEHA - SPEC-H - Barrel Heating SystemTuyên VũNo ratings yet

- TAEHA MSIV (2액형) 리플렛 engDocument1 pageTAEHA MSIV (2액형) 리플렛 engTuyên VũNo ratings yet

- Taeha Nano - PenDocument1 pageTaeha Nano - PenTuyên VũNo ratings yet

- Part Number Revision Iss Date Drawn by Checked by Simon Martin A BDocument1 pagePart Number Revision Iss Date Drawn by Checked by Simon Martin A BTuyên VũNo ratings yet

- TAEHA - PRO-CP20 - Pro Can PumpDocument1 pageTAEHA - PRO-CP20 - Pro Can PumpTuyên VũNo ratings yet

- RSP 1000 Spec 1511917Document9 pagesRSP 1000 Spec 1511917Tuyên VũNo ratings yet

- Janome - JR3000시리즈 - 제품사양서 (ENG) 0517Document8 pagesJanome - JR3000시리즈 - 제품사양서 (ENG) 0517Tuyên VũNo ratings yet

- UV Design InstrumentsDocument4 pagesUV Design InstrumentsTuyên VũNo ratings yet

- PSP 1000 Spec 1179932Document3 pagesPSP 1000 Spec 1179932Tuyên VũNo ratings yet

- UV HF NT INK (영문)Document2 pagesUV HF NT INK (영문)Tuyên VũNo ratings yet

- Yq Light-UvDocument12 pagesYq Light-UvTuyên VũNo ratings yet

- Jueun Uv Tech 카다로그 KrenchDocument20 pagesJueun Uv Tech 카다로그 KrenchTuyên VũNo ratings yet

- 758 SignedDocument8 pages758 SignedTuyên VũNo ratings yet

- (NEW) TAEHA COMPANY PROFILE (해외영업)Document33 pages(NEW) TAEHA COMPANY PROFILE (해외영업)Tuyên VũNo ratings yet

- MES Test UV Strip PI EDocument4 pagesMES Test UV Strip PI ETuyên VũNo ratings yet

- UV Head - Awill VDocument2 pagesUV Head - Awill VTuyên VũNo ratings yet

- Theimer Lamp Equival 2014Document37 pagesTheimer Lamp Equival 2014Tuyên VũNo ratings yet

- Indium8.9HFG Pb-Free Solder Paste - MSDS (Viet) - 20181201 - N20190917 (Stamp)Document9 pagesIndium8.9HFG Pb-Free Solder Paste - MSDS (Viet) - 20181201 - N20190917 (Stamp)Tuyên VũNo ratings yet

- Indium8.9HFG Pb-Free Solder Paste - MSDS (Viet) - 20181201 - N20190917 (Stamp) ADocument9 pagesIndium8.9HFG Pb-Free Solder Paste - MSDS (Viet) - 20181201 - N20190917 (Stamp) ATuyên VũNo ratings yet

- FireEdge FE400 PLC Interface Tech NoteDocument2 pagesFireEdge FE400 PLC Interface Tech NoteTuyên VũNo ratings yet

- FireEdge FE400 User ManualDocument53 pagesFireEdge FE400 User ManualTuyên VũNo ratings yet

- Bai Giang - CT361 - Chuong 4 (PDF - Io)Document18 pagesBai Giang - CT361 - Chuong 4 (PDF - Io)Nghiệp Nguyễn ThànhNo ratings yet

- SM-G935F Tshoo 7 PDFDocument56 pagesSM-G935F Tshoo 7 PDFhernanNo ratings yet

- 1ST Periodical Exam Sci. 8Document5 pages1ST Periodical Exam Sci. 8richardsamranoNo ratings yet

- The Names of The Tithis Are Given Below:: TithiDocument7 pagesThe Names of The Tithis Are Given Below:: TithiLuciana Lôbo CardosoNo ratings yet

- Volume 2 Construction For Bore Well 2 Nos at IIM Indore2Document3 pagesVolume 2 Construction For Bore Well 2 Nos at IIM Indore2Abir SenguptaNo ratings yet

- NEPP BOK 2016 GRC Boomer SiC TN35760Document28 pagesNEPP BOK 2016 GRC Boomer SiC TN35760shriram1082883No ratings yet

- Fdocuments - in Chapter 1 Introduction Utoledo Wevanschap1spdfthe Machine Tool and AutomotiveDocument27 pagesFdocuments - in Chapter 1 Introduction Utoledo Wevanschap1spdfthe Machine Tool and AutomotiveFoo BrandonNo ratings yet

- Gesture Timbre Space CMMR LNCSDocument24 pagesGesture Timbre Space CMMR LNCSmichaelzedNo ratings yet

- S2R PM-WP02-D-S2R-001-01 - D2.1 Modelling Guidelines and Moving Block Use Cases CharacterizationDocument150 pagesS2R PM-WP02-D-S2R-001-01 - D2.1 Modelling Guidelines and Moving Block Use Cases CharacterizationIvan RisticNo ratings yet

- Mmse and MseDocument3 pagesMmse and Mse황춘히No ratings yet

- Keepers Smart Contracts Audit v0.1 GingerSecDocument60 pagesKeepers Smart Contracts Audit v0.1 GingerSecAbhishek ShuklaNo ratings yet

- Lab6a 2-Out-Of-5 To BCD Code Converter and Display CircuitDocument11 pagesLab6a 2-Out-Of-5 To BCD Code Converter and Display CircuitMustafaAsimNo ratings yet

- Optimization With Scilab: Michaël BAUDIN & Vincent COUVERTDocument52 pagesOptimization With Scilab: Michaël BAUDIN & Vincent COUVERTLazNgcengulaNo ratings yet

- Freebsd Firewall and DMZDocument7 pagesFreebsd Firewall and DMZAlex AmorNo ratings yet

- Passive Solar Design ReportDocument24 pagesPassive Solar Design ReportManish100% (1)

- Design Calculation Sheet - HoodDocument4 pagesDesign Calculation Sheet - HoodSumanth GundetiNo ratings yet

- Ca1 PDocument2 pagesCa1 PYash jangidNo ratings yet

- bullion-HT003 PCIe Adapter Firmware Updatev2Document14 pagesbullion-HT003 PCIe Adapter Firmware Updatev2Fabrice PLATELNo ratings yet

- Electric Vehicles Standards Charging InfDocument27 pagesElectric Vehicles Standards Charging InfPedrito OrangeNo ratings yet

- Geometry Basics VocabularyDocument39 pagesGeometry Basics VocabularyIsrael Jimenez FelixNo ratings yet

- Photovoltaic Systems Engineering 4th Messenger Solution ManualDocument12 pagesPhotovoltaic Systems Engineering 4th Messenger Solution ManualJesus Carter100% (41)

- Catalytic Wet Air OxidationDocument10 pagesCatalytic Wet Air OxidationAman PrasadNo ratings yet

- Driveline: SectionDocument345 pagesDriveline: SectionLuis BarriosNo ratings yet

- GTSTRUDL 32 - Student Edition 13: Quick-Start InstructionsDocument3 pagesGTSTRUDL 32 - Student Edition 13: Quick-Start InstructionsVimalan KannanNo ratings yet

- Laboratory Science High School Sultan Kudarat State UniversityDocument5 pagesLaboratory Science High School Sultan Kudarat State UniversityCezarNo ratings yet

- Class IX Chemistry Chapter 04Document13 pagesClass IX Chemistry Chapter 04Sam FisherNo ratings yet

- Asat Paper (Iq) Series (Easy) (11 To 12) : A. B. C. DDocument7 pagesAsat Paper (Iq) Series (Easy) (11 To 12) : A. B. C. DAbhijeet Singh PanwarNo ratings yet

- Numericals On CVP AnalysisDocument2 pagesNumericals On CVP AnalysisAmil SaifiNo ratings yet