Professional Documents

Culture Documents

Caps & Plugs

Caps & Plugs

Uploaded by

Rida AltafCopyright:

Available Formats

You might also like

- ENACb 1Document166 pagesENACb 1DarrylpnzNo ratings yet

- Beko WTL84111B Wtl84151b, Wtl84141w, Wtl84111w, Wtl84151w, Wtl84131w, Wtl84141. User ManualDocument32 pagesBeko WTL84111B Wtl84151b, Wtl84141w, Wtl84111w, Wtl84151w, Wtl84131w, Wtl84141. User Manualnadaljoachim77No ratings yet

- RMU Test ReportDocument3 pagesRMU Test ReportGANESH K75% (4)

- IADC Well Sharp WireLine UpdatedDocument143 pagesIADC Well Sharp WireLine UpdatedEmad ZakiNo ratings yet

- Sop AutoclavingDocument4 pagesSop AutoclavingXiang LiuNo ratings yet

- Washing Machine Lavadora: User's Manual Manual Del UsuarioDocument19 pagesWashing Machine Lavadora: User's Manual Manual Del Usuariosinisterleft100% (1)

- Tutorial Chapter 1 - 0 ThermodynamicDocument2 pagesTutorial Chapter 1 - 0 ThermodynamicSufferedMuchNo ratings yet

- EASA Part-66 Exam Questions of Module 01 - Part IIDocument24 pagesEASA Part-66 Exam Questions of Module 01 - Part IISteven J. Selcuk100% (2)

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Vitamins SpreadsheetDocument6 pagesVitamins SpreadsheetB-Rock Daniels100% (1)

- 2011 10 Beacon SDocument1 page2011 10 Beacon SDiego DavidNo ratings yet

- Double Block and BleedDocument1 pageDouble Block and BleedRMG0512No ratings yet

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishManish ChandaniNo ratings yet

- Well Completion & Reservoir StimulationDocument14 pagesWell Completion & Reservoir StimulationPhước LêNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-19Document2 pages01.hazards of Trapped Pressure & Vacuum-19rahulNo ratings yet

- Ecoline User Guide 25-300Document8 pagesEcoline User Guide 25-300eduardo roqueNo ratings yet

- Vulnerable Piping (Pipa Yang Rentan) : Aerial ViewDocument2 pagesVulnerable Piping (Pipa Yang Rentan) : Aerial ViewAgus RamdhaniNo ratings yet

- Warning-Signs April 12Document4 pagesWarning-Signs April 12Tyron FrancisNo ratings yet

- Shop Vacuum ProceduresDocument2 pagesShop Vacuum ProceduresRoland von KurnatowskiNo ratings yet

- Beacon - Corrosion Under InsulationDocument1 pageBeacon - Corrosion Under Insulationkave4923No ratings yet

- Positive & Safe Isolation MethodDocument118 pagesPositive & Safe Isolation MethodRahul S. Chandrawar100% (1)

- OT HowTo f02Document4 pagesOT HowTo f02iwancoc15100% (1)

- Confidence Testing For Fire Hydrants: A Guide To The Maintenance, Testing, and Marking of Private Fire HydrantsDocument13 pagesConfidence Testing For Fire Hydrants: A Guide To The Maintenance, Testing, and Marking of Private Fire HydrantsImdad PeshimamNo ratings yet

- What Went Wrong: TopicDocument35 pagesWhat Went Wrong: Topickara_25No ratings yet

- Septic InspectingDocument37 pagesSeptic InspectingpersonaNo ratings yet

- Fire Hydrant SpecsDocument14 pagesFire Hydrant SpecsGie Mak100% (2)

- Tcs 220Document3 pagesTcs 220yeralNo ratings yet

- SOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Document4 pagesSOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Kimia AsikNo ratings yet

- EF6100+ - Manual de Utilizare PDFDocument32 pagesEF6100+ - Manual de Utilizare PDFdanythe007No ratings yet

- Washing Machine User's Manual Masina de Spalat Automata Manual de UtilizareDocument32 pagesWashing Machine User's Manual Masina de Spalat Automata Manual de UtilizarecaprismadaNo ratings yet

- Iom Gate Valves Fig. 291 Rev1Document4 pagesIom Gate Valves Fig. 291 Rev1linh phamNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-41Document2 pages01.hazards of Trapped Pressure & Vacuum-41rahulNo ratings yet

- 1.0 Sanitation System NotesDocument21 pages1.0 Sanitation System Notesdhevashini narayananNo ratings yet

- Lesson 2: 2.1. Safety Precautions in Plumbing Works and Plumbing InstrumentsDocument2 pagesLesson 2: 2.1. Safety Precautions in Plumbing Works and Plumbing InstrumentsYandi TVNo ratings yet

- Day 11Document3 pagesDay 11Rapha MontereyNo ratings yet

- Getting Started?: EasyDocument36 pagesGetting Started?: EasyThe secret TDMerNo ratings yet

- Lab Vacuum Use ProcedureDocument3 pagesLab Vacuum Use ProceduretrucbeoNo ratings yet

- Top 15 Plumber Interview QuestionsDocument4 pagesTop 15 Plumber Interview QuestionsNwachukwu UmehNo ratings yet

- Washing Machine Beko WTIK72151Document40 pagesWashing Machine Beko WTIK72151Jalil BouhdidNo ratings yet

- Manual de Servicio LK-C090BC00Document35 pagesManual de Servicio LK-C090BC00jose antonio100% (1)

- Washing Machine: Owner'S ManualDocument25 pagesWashing Machine: Owner'S ManualSamorai KazaNo ratings yet

- 201906beaconenglish-Corrosion Under InsulationDocument1 page201906beaconenglish-Corrosion Under InsulationguhadebasisNo ratings yet

- Um DEDocument68 pagesUm DEYasminSolbergNo ratings yet

- Beko WMB 51021 ManualDocument20 pagesBeko WMB 51021 ManualPero PerićNo ratings yet

- Guia de Instalacion de La LavadoraDocument64 pagesGuia de Instalacion de La LavadoraRonald MedinaNo ratings yet

- Double Block and Bleed: What Can You Do?Document1 pageDouble Block and Bleed: What Can You Do?Triod jacksonNo ratings yet

- Washing Machine (PW-F85-W)Document33 pagesWashing Machine (PW-F85-W)JoeNo ratings yet

- Probationary Firefighters ManualDocument45 pagesProbationary Firefighters ManualHualy DelgadoNo ratings yet

- On-Stream Leak Repair Techniques - Part 2Document2 pagesOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- The Plumbing BasicsDocument36 pagesThe Plumbing BasicsDewmabel BaconawaNo ratings yet

- SF 28 22Document5 pagesSF 28 22Shivkumar JadhavNo ratings yet

- WD32HBB101 User ManualDocument82 pagesWD32HBB101 User ManualAixy RiveraNo ratings yet

- Washing Machine User's Manual: 2820523376 - EN / Document NumberDocument65 pagesWashing Machine User's Manual: 2820523376 - EN / Document Numberskole75No ratings yet

- Altus 5100 Washing MachineDocument40 pagesAltus 5100 Washing MachineVuk PanonskiNo ratings yet

- DWD Ld1411 ManualDocument32 pagesDWD Ld1411 Manualsarvaanyaa100% (1)

- TWM50FBM User ManualDocument28 pagesTWM50FBM User ManualhamorcomNo ratings yet

- Instruction Manual: 7" Widescreen TFT LCD Digital Photo Frame With Video and Music PlaybackDocument36 pagesInstruction Manual: 7" Widescreen TFT LCD Digital Photo Frame With Video and Music PlaybackjohnynNo ratings yet

- Sa 11 24Document1 pageSa 11 24Imran A. KhanNo ratings yet

- KUKJE-44 문서번호 CWROM-1606-00087 Order No. MFL67870415 P/No. 최종 컨펌일자: 작업자 연구실 담당자 황종현 안성주Document24 pagesKUKJE-44 문서번호 CWROM-1606-00087 Order No. MFL67870415 P/No. 최종 컨펌일자: 작업자 연구실 담당자 황종현 안성주ALVARO LEALNo ratings yet

- MFL68525412 170721 PDFDocument59 pagesMFL68525412 170721 PDFdalmohvacNo ratings yet

- Beko Wmy - 91443 - lb1Document41 pagesBeko Wmy - 91443 - lb1Bjorn SammutNo ratings yet

- Zvlhčovač Boneco - User GuideDocument18 pagesZvlhčovač Boneco - User Guidevtp4qcv26pNo ratings yet

- 42TVU010 012 018 Manual PDFDocument8 pages42TVU010 012 018 Manual PDFArvin Randy TeoNo ratings yet

- TvattadDocument80 pagesTvattadyepiwip390No ratings yet

- Ultimate Guide: Plumbing, 4th Updated EditionFrom EverandUltimate Guide: Plumbing, 4th Updated EditionRating: 4 out of 5 stars4/5 (1)

- Transport Phenomena: τ =μ dv dyDocument2 pagesTransport Phenomena: τ =μ dv dySYED ASGHAR ALI SULTANNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

- MG 2 - TEMA 1 Limba EnglezaDocument4 pagesMG 2 - TEMA 1 Limba Englezamimi12345678910No ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Amina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionDocument1 pageAmina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionFïzã PäthäñNo ratings yet

- Directory of SMEs in India-2012 EditionDocument7,115 pagesDirectory of SMEs in India-2012 EditionNilesh RanaNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Federal MogulDocument277 pagesFederal Mogulعبدالغني القباطي100% (1)

- NASA NOAA Earth Sciences Letter To TrumpDocument6 pagesNASA NOAA Earth Sciences Letter To TrumpMelissa Meehan BaldwinNo ratings yet

- Autonomous University of Baja California: Faculty of Engineering Aerospace EngineeringDocument18 pagesAutonomous University of Baja California: Faculty of Engineering Aerospace EngineeringOscar Oreste Salvador CarlosNo ratings yet

- Costing By-Product and Joint ProductsDocument36 pagesCosting By-Product and Joint ProductseltantiNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- Thermit WeldingDocument52 pagesThermit WeldingAssistant Engineer100% (1)

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Lecture 4Document24 pagesLecture 4Geeta AroraNo ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- CESCCommunityProjectPlan Brgy - MacarioDaconDocument6 pagesCESCCommunityProjectPlan Brgy - MacarioDaconKennedy BalmoriNo ratings yet

- Catalogo ColonneDocument140 pagesCatalogo Colonneapi-18378576No ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- (HMI-LP-RT30 + R131-A - User Manual) A06 - ENDocument110 pages(HMI-LP-RT30 + R131-A - User Manual) A06 - ENrehanNo ratings yet

- Plant Hormones PDFDocument5 pagesPlant Hormones PDFYASHNo ratings yet

Caps & Plugs

Caps & Plugs

Uploaded by

Rida AltafOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caps & Plugs

Caps & Plugs

Uploaded by

Rida AltafCopyright:

Available Formats

This Issue Sponsored by

www.iomosaic.com

Messages for Manufacturing Personnel

http://www.aiche.org/CCPS/Publications/Beacon/index.aspx December 2011

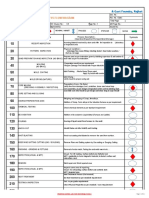

Caps and Plugs - One Day You Will Miss Them

A piece of debris fell from temporary scaffolding used to support

people and material. It hit the straight handle of a quarter-turn ball

valve that served a ¾-in. (about 20 mm) vent on a large process pipe.

The falling debris caused the vent valve to open. The pipe contained

flammable material, which was released through the vent. The released

material ignited, and the resulting fire killed one contract worker and

seriously burned two others.

When the incident occurred, there was no cap or plug on the vent

line from the process pipe. The quarter-turn ball valve was the only

thing preventing a hazardous release of flammable material.

This incident occurred because something fell onto the valve and

opened it. Can you think of other ways this valve might have leaked or

been accidentally opened?

Did You Know? What Can You Do?

• You should have more than one • Always replace all caps and plugs on vent pipes, drain pipes, or sample

barrier between a hazardous material pipes, or other caps/plugs that you need to remove to do a job. The job is

and the outside environment or the not finished until you return all equipment to its original condition.

workplace. A single leaking or • Look for missing or damaged plugs and caps on pipe connections in your

accidentally opened valve should plant, and make sure they are replaced or repaired.

not be able to result in a dangerous • Don’t forget that some vent valves are intended to be open (not plugged

release of hazardous material. or capped) — for example, the vent on a double block-and-bleed isolation

• It is easy to forget to replace caps device. If you are not sure whether a cap or plug is needed, ask somebody

and plugs on vents or drains from who understands the design of the piping.

process pipes. Usually the person • Look for places where a single leaking or accidentally opened valve could

who removes the cap or plug intends result in a hazardous release of material or pressure. Report them and make

to return and replace it later, but sure that some kind of backup is provided — for example, a cap, plug, blind,

people working in a process plant or a second isolation valve.

are very busy, and can forget. • Consider alternative placement of the valve handles on vents or drains

• There can be a dangerous release so they cannot be accidentally opened by leaning or stepping on them.

of hazardous, flammable or toxic • Consider another type of vent valve instead of quarter-turn ball or plug

material through a very small pipe. valves — for example, diaphragm, globe, or gate valves, which are less

likely to be opened accidentally.

• Be sure to do a management-of-change review before making any

modifications to a drain or vent.

Don’t let a single failure cause a serious incident!

AIChE © 2011. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of

resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 646-495-1371.

The Beacon is usually available in Afrikaans, Arabic, Chinese, Danish, Dutch, English, French, German, Greek, Gujarati, Hebrew, Hindi,

Italian, Japanese, Korean, Malay, Marathi, Persian, Polish, Portuguese, Romanian, Russian, Spanish, Swedish, Telugu, Thai, Turkish and Vietnamese.

Circle 103 on p. 63 for a free electronic subscription to the Beacon.

CEP December 2011 www.aiche.org/cep 15

You might also like

- ENACb 1Document166 pagesENACb 1DarrylpnzNo ratings yet

- Beko WTL84111B Wtl84151b, Wtl84141w, Wtl84111w, Wtl84151w, Wtl84131w, Wtl84141. User ManualDocument32 pagesBeko WTL84111B Wtl84151b, Wtl84141w, Wtl84111w, Wtl84151w, Wtl84131w, Wtl84141. User Manualnadaljoachim77No ratings yet

- RMU Test ReportDocument3 pagesRMU Test ReportGANESH K75% (4)

- IADC Well Sharp WireLine UpdatedDocument143 pagesIADC Well Sharp WireLine UpdatedEmad ZakiNo ratings yet

- Sop AutoclavingDocument4 pagesSop AutoclavingXiang LiuNo ratings yet

- Washing Machine Lavadora: User's Manual Manual Del UsuarioDocument19 pagesWashing Machine Lavadora: User's Manual Manual Del Usuariosinisterleft100% (1)

- Tutorial Chapter 1 - 0 ThermodynamicDocument2 pagesTutorial Chapter 1 - 0 ThermodynamicSufferedMuchNo ratings yet

- EASA Part-66 Exam Questions of Module 01 - Part IIDocument24 pagesEASA Part-66 Exam Questions of Module 01 - Part IISteven J. Selcuk100% (2)

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Vitamins SpreadsheetDocument6 pagesVitamins SpreadsheetB-Rock Daniels100% (1)

- 2011 10 Beacon SDocument1 page2011 10 Beacon SDiego DavidNo ratings yet

- Double Block and BleedDocument1 pageDouble Block and BleedRMG0512No ratings yet

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishManish ChandaniNo ratings yet

- Well Completion & Reservoir StimulationDocument14 pagesWell Completion & Reservoir StimulationPhước LêNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-19Document2 pages01.hazards of Trapped Pressure & Vacuum-19rahulNo ratings yet

- Ecoline User Guide 25-300Document8 pagesEcoline User Guide 25-300eduardo roqueNo ratings yet

- Vulnerable Piping (Pipa Yang Rentan) : Aerial ViewDocument2 pagesVulnerable Piping (Pipa Yang Rentan) : Aerial ViewAgus RamdhaniNo ratings yet

- Warning-Signs April 12Document4 pagesWarning-Signs April 12Tyron FrancisNo ratings yet

- Shop Vacuum ProceduresDocument2 pagesShop Vacuum ProceduresRoland von KurnatowskiNo ratings yet

- Beacon - Corrosion Under InsulationDocument1 pageBeacon - Corrosion Under Insulationkave4923No ratings yet

- Positive & Safe Isolation MethodDocument118 pagesPositive & Safe Isolation MethodRahul S. Chandrawar100% (1)

- OT HowTo f02Document4 pagesOT HowTo f02iwancoc15100% (1)

- Confidence Testing For Fire Hydrants: A Guide To The Maintenance, Testing, and Marking of Private Fire HydrantsDocument13 pagesConfidence Testing For Fire Hydrants: A Guide To The Maintenance, Testing, and Marking of Private Fire HydrantsImdad PeshimamNo ratings yet

- What Went Wrong: TopicDocument35 pagesWhat Went Wrong: Topickara_25No ratings yet

- Septic InspectingDocument37 pagesSeptic InspectingpersonaNo ratings yet

- Fire Hydrant SpecsDocument14 pagesFire Hydrant SpecsGie Mak100% (2)

- Tcs 220Document3 pagesTcs 220yeralNo ratings yet

- SOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Document4 pagesSOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Kimia AsikNo ratings yet

- EF6100+ - Manual de Utilizare PDFDocument32 pagesEF6100+ - Manual de Utilizare PDFdanythe007No ratings yet

- Washing Machine User's Manual Masina de Spalat Automata Manual de UtilizareDocument32 pagesWashing Machine User's Manual Masina de Spalat Automata Manual de UtilizarecaprismadaNo ratings yet

- Iom Gate Valves Fig. 291 Rev1Document4 pagesIom Gate Valves Fig. 291 Rev1linh phamNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-41Document2 pages01.hazards of Trapped Pressure & Vacuum-41rahulNo ratings yet

- 1.0 Sanitation System NotesDocument21 pages1.0 Sanitation System Notesdhevashini narayananNo ratings yet

- Lesson 2: 2.1. Safety Precautions in Plumbing Works and Plumbing InstrumentsDocument2 pagesLesson 2: 2.1. Safety Precautions in Plumbing Works and Plumbing InstrumentsYandi TVNo ratings yet

- Day 11Document3 pagesDay 11Rapha MontereyNo ratings yet

- Getting Started?: EasyDocument36 pagesGetting Started?: EasyThe secret TDMerNo ratings yet

- Lab Vacuum Use ProcedureDocument3 pagesLab Vacuum Use ProceduretrucbeoNo ratings yet

- Top 15 Plumber Interview QuestionsDocument4 pagesTop 15 Plumber Interview QuestionsNwachukwu UmehNo ratings yet

- Washing Machine Beko WTIK72151Document40 pagesWashing Machine Beko WTIK72151Jalil BouhdidNo ratings yet

- Manual de Servicio LK-C090BC00Document35 pagesManual de Servicio LK-C090BC00jose antonio100% (1)

- Washing Machine: Owner'S ManualDocument25 pagesWashing Machine: Owner'S ManualSamorai KazaNo ratings yet

- 201906beaconenglish-Corrosion Under InsulationDocument1 page201906beaconenglish-Corrosion Under InsulationguhadebasisNo ratings yet

- Um DEDocument68 pagesUm DEYasminSolbergNo ratings yet

- Beko WMB 51021 ManualDocument20 pagesBeko WMB 51021 ManualPero PerićNo ratings yet

- Guia de Instalacion de La LavadoraDocument64 pagesGuia de Instalacion de La LavadoraRonald MedinaNo ratings yet

- Double Block and Bleed: What Can You Do?Document1 pageDouble Block and Bleed: What Can You Do?Triod jacksonNo ratings yet

- Washing Machine (PW-F85-W)Document33 pagesWashing Machine (PW-F85-W)JoeNo ratings yet

- Probationary Firefighters ManualDocument45 pagesProbationary Firefighters ManualHualy DelgadoNo ratings yet

- On-Stream Leak Repair Techniques - Part 2Document2 pagesOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- The Plumbing BasicsDocument36 pagesThe Plumbing BasicsDewmabel BaconawaNo ratings yet

- SF 28 22Document5 pagesSF 28 22Shivkumar JadhavNo ratings yet

- WD32HBB101 User ManualDocument82 pagesWD32HBB101 User ManualAixy RiveraNo ratings yet

- Washing Machine User's Manual: 2820523376 - EN / Document NumberDocument65 pagesWashing Machine User's Manual: 2820523376 - EN / Document Numberskole75No ratings yet

- Altus 5100 Washing MachineDocument40 pagesAltus 5100 Washing MachineVuk PanonskiNo ratings yet

- DWD Ld1411 ManualDocument32 pagesDWD Ld1411 Manualsarvaanyaa100% (1)

- TWM50FBM User ManualDocument28 pagesTWM50FBM User ManualhamorcomNo ratings yet

- Instruction Manual: 7" Widescreen TFT LCD Digital Photo Frame With Video and Music PlaybackDocument36 pagesInstruction Manual: 7" Widescreen TFT LCD Digital Photo Frame With Video and Music PlaybackjohnynNo ratings yet

- Sa 11 24Document1 pageSa 11 24Imran A. KhanNo ratings yet

- KUKJE-44 문서번호 CWROM-1606-00087 Order No. MFL67870415 P/No. 최종 컨펌일자: 작업자 연구실 담당자 황종현 안성주Document24 pagesKUKJE-44 문서번호 CWROM-1606-00087 Order No. MFL67870415 P/No. 최종 컨펌일자: 작업자 연구실 담당자 황종현 안성주ALVARO LEALNo ratings yet

- MFL68525412 170721 PDFDocument59 pagesMFL68525412 170721 PDFdalmohvacNo ratings yet

- Beko Wmy - 91443 - lb1Document41 pagesBeko Wmy - 91443 - lb1Bjorn SammutNo ratings yet

- Zvlhčovač Boneco - User GuideDocument18 pagesZvlhčovač Boneco - User Guidevtp4qcv26pNo ratings yet

- 42TVU010 012 018 Manual PDFDocument8 pages42TVU010 012 018 Manual PDFArvin Randy TeoNo ratings yet

- TvattadDocument80 pagesTvattadyepiwip390No ratings yet

- Ultimate Guide: Plumbing, 4th Updated EditionFrom EverandUltimate Guide: Plumbing, 4th Updated EditionRating: 4 out of 5 stars4/5 (1)

- Transport Phenomena: τ =μ dv dyDocument2 pagesTransport Phenomena: τ =μ dv dySYED ASGHAR ALI SULTANNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

- MG 2 - TEMA 1 Limba EnglezaDocument4 pagesMG 2 - TEMA 1 Limba Englezamimi12345678910No ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Amina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionDocument1 pageAmina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionFïzã PäthäñNo ratings yet

- Directory of SMEs in India-2012 EditionDocument7,115 pagesDirectory of SMEs in India-2012 EditionNilesh RanaNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Federal MogulDocument277 pagesFederal Mogulعبدالغني القباطي100% (1)

- NASA NOAA Earth Sciences Letter To TrumpDocument6 pagesNASA NOAA Earth Sciences Letter To TrumpMelissa Meehan BaldwinNo ratings yet

- Autonomous University of Baja California: Faculty of Engineering Aerospace EngineeringDocument18 pagesAutonomous University of Baja California: Faculty of Engineering Aerospace EngineeringOscar Oreste Salvador CarlosNo ratings yet

- Costing By-Product and Joint ProductsDocument36 pagesCosting By-Product and Joint ProductseltantiNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- Thermit WeldingDocument52 pagesThermit WeldingAssistant Engineer100% (1)

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Lecture 4Document24 pagesLecture 4Geeta AroraNo ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- CESCCommunityProjectPlan Brgy - MacarioDaconDocument6 pagesCESCCommunityProjectPlan Brgy - MacarioDaconKennedy BalmoriNo ratings yet

- Catalogo ColonneDocument140 pagesCatalogo Colonneapi-18378576No ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- (HMI-LP-RT30 + R131-A - User Manual) A06 - ENDocument110 pages(HMI-LP-RT30 + R131-A - User Manual) A06 - ENrehanNo ratings yet

- Plant Hormones PDFDocument5 pagesPlant Hormones PDFYASHNo ratings yet