Professional Documents

Culture Documents

371 Etch Primers

371 Etch Primers

Uploaded by

Haroon GorayaCopyright:

Available Formats

You might also like

- Doll Mabel PinesDocument12 pagesDoll Mabel PinesEurydice Suz100% (2)

- Coating Guide: Standards Contact UsDocument26 pagesCoating Guide: Standards Contact UsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Fundamentals of Stripe CoatingDocument164 pagesFundamentals of Stripe Coatinganangwahjudi100% (1)

- Tool and Die DesignDocument61 pagesTool and Die DesignAshley Kane P. Dumay100% (3)

- Etch Primers PDFDocument1 pageEtch Primers PDFBash MatNo ratings yet

- Painting GNDocument3 pagesPainting GNAd FwyNo ratings yet

- Organic and Inorganic Zinc Rich CoatingsDocument3 pagesOrganic and Inorganic Zinc Rich CoatingsEddy Norman Benites Delgado100% (6)

- Fan Protective Coatings ED400Document7 pagesFan Protective Coatings ED400arielNo ratings yet

- Cpei SopDocument5 pagesCpei SopCorrosion FactoryNo ratings yet

- PrimersDocument3 pagesPrimersDiya AwasthiNo ratings yet

- Coating For The Protection of Steel StructureDocument17 pagesCoating For The Protection of Steel StructureMohamed Abdel SamieNo ratings yet

- FE 400 Protective Coating Guide For FansDocument8 pagesFE 400 Protective Coating Guide For FansAvery OppegardNo ratings yet

- SSPC Tu 1Document3 pagesSSPC Tu 1Prashant PandeyNo ratings yet

- Thermal Spray Comparison To PaintingDocument1 pageThermal Spray Comparison To PaintingSunil GurubaxaniNo ratings yet

- OA 3957 Red Oxide Primer Product Data: (Exterior/InteriorDocument1 pageOA 3957 Red Oxide Primer Product Data: (Exterior/InteriortshawkyNo ratings yet

- Fundamentals of Offshore and On Shore CoatingsDocument12 pagesFundamentals of Offshore and On Shore CoatingsPravas PadhihariNo ratings yet

- Dental Cement 1Document5 pagesDental Cement 1eslamezzat21061990No ratings yet

- Paint SystemsDocument5 pagesPaint SystemsOmar DhiebNo ratings yet

- Coating FailureDocument14 pagesCoating FailureNnamdi Celestine NnamdiNo ratings yet

- Zinc Flake CoatingsDocument1 pageZinc Flake CoatingsDinh TuNo ratings yet

- General Knowledge of PCB OSP Surface FinishDocument5 pagesGeneral Knowledge of PCB OSP Surface FinishRennze Dominic De VeraNo ratings yet

- Paintmasterwbmetalprimer TDSDocument2 pagesPaintmasterwbmetalprimer TDSMichael JoudalNo ratings yet

- Cement Bases and Cavity LinersDocument8 pagesCement Bases and Cavity Linersمحمد احمد محمدNo ratings yet

- Paint SystemsDocument4 pagesPaint SystemsHung Mai VanNo ratings yet

- 2 - CementNotes2022-23Document7 pages2 - CementNotes2022-23Rana hasanaNo ratings yet

- All About Rust BulletDocument4 pagesAll About Rust BulletAan KhamaluddinNo ratings yet

- OA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)Document1 pageOA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)tshawkyNo ratings yet

- Rust Converted CoatingDocument80 pagesRust Converted Coatingalfan cita nyalaNo ratings yet

- NEI Anticorrosion Paints & Coatings BrochureDocument3 pagesNEI Anticorrosion Paints & Coatings Brochurefallen010% (1)

- Premium Zinc Coating: Corrosion Protection at All TimesDocument3 pagesPremium Zinc Coating: Corrosion Protection at All TimesJose JavierNo ratings yet

- Paint CoatDocument9 pagesPaint CoatAha AsaNo ratings yet

- Solvent Based PrimerDocument2 pagesSolvent Based PrimerLim Yong SiangNo ratings yet

- Painting of Hot-Dip Galvanized Steel - Duplex SystemsDocument5 pagesPainting of Hot-Dip Galvanized Steel - Duplex SystemsPrabath Nilan GunasekaraNo ratings yet

- Coating Failures: Richard W. DriskoDocument15 pagesCoating Failures: Richard W. DriskoAlejandro Expósito FernándezNo ratings yet

- Supplier of Zinc Phosphate in PakistanDocument3 pagesSupplier of Zinc Phosphate in PakistansdsdvsdvsdNo ratings yet

- Metallizing Process and Advantages MMPLDocument7 pagesMetallizing Process and Advantages MMPLCorrosion FactoryNo ratings yet

- VRM-Brochure IN AADocument2 pagesVRM-Brochure IN AApinasthika.timurNo ratings yet

- Corrosion: Corrosive Condition Description of EnvironmentDocument7 pagesCorrosion: Corrosive Condition Description of EnvironmentMaddyNo ratings yet

- VIVADocument15 pagesVIVAambiliNo ratings yet

- Inorganic Zinc Rich Paint PDFDocument2 pagesInorganic Zinc Rich Paint PDFarunrengaraj100% (1)

- Berger Paint CatalogDocument74 pagesBerger Paint Catalogdbehera0667% (3)

- Scotchkote FBEC BR 8086372Document16 pagesScotchkote FBEC BR 8086372ingrclNo ratings yet

- Fluoropolymer Coating BenefitsDocument8 pagesFluoropolymer Coating Benefitslamia97No ratings yet

- Protective CoatingsDocument8 pagesProtective CoatingsKakde Krushna LNo ratings yet

- How To Get The Greatest Possible Benefit From Shuttering PlywoodDocument1 pageHow To Get The Greatest Possible Benefit From Shuttering PlywoodRami JabadoNo ratings yet

- Brushbond RFXDocument2 pagesBrushbond RFXaneesh kapaNo ratings yet

- Brushbond RFXDocument2 pagesBrushbond RFXaneesh kapaNo ratings yet

- Brushbond RFX PDFDocument2 pagesBrushbond RFX PDFpiyu114No ratings yet

- VIVADocument16 pagesVIVAambiliNo ratings yet

- Offshore Eng PDFDocument8 pagesOffshore Eng PDFClintonDestinyNo ratings yet

- Epoxy Coating Guide For ConcreteDocument8 pagesEpoxy Coating Guide For ConcreteShepherd NhangaNo ratings yet

- 7 - Paint System - Ch-7Document4 pages7 - Paint System - Ch-7Manju JunoNo ratings yet

- Steelmaster 60WB: Technical Data Sheet Application GuideDocument10 pagesSteelmaster 60WB: Technical Data Sheet Application GuideyugandharNo ratings yet

- Doka SystemDocument47 pagesDoka SystembappanaduNo ratings yet

- Protective CoatingDocument6 pagesProtective CoatingPinaki RahaNo ratings yet

- Corrosion Removal: Before Starting Any Corrosion Removal, You Must Conduct An Inspection andDocument8 pagesCorrosion Removal: Before Starting Any Corrosion Removal, You Must Conduct An Inspection andHorhe TheGreatNo ratings yet

- New Polymer Technology Improves Durability and Constructability of Coatingfor Steel StructuresDocument4 pagesNew Polymer Technology Improves Durability and Constructability of Coatingfor Steel StructuresUsama Awad100% (1)

- Color Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueFrom EverandColor Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueNo ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Jde 10030Document3 pagesJde 10030X800XLNo ratings yet

- Grade 7-8 - Handicraft Q1 W1-W2Document30 pagesGrade 7-8 - Handicraft Q1 W1-W2Arlie Jean Bioneda AbilaNo ratings yet

- Amigurumi @crochetbykim ElefanteDocument11 pagesAmigurumi @crochetbykim Elefantesoraiathiago100% (2)

- Libble Eu PDFDocument25 pagesLibble Eu PDFFat CatNo ratings yet

- Macrame Bangle BraceletDocument6 pagesMacrame Bangle Braceletmahira_tippu100% (1)

- Christmas Granny Squares North Pole, Santa Claus & Grandma ClausDocument6 pagesChristmas Granny Squares North Pole, Santa Claus & Grandma ClausCarito Montenegro JiménezNo ratings yet

- SI Doris ENDocument2 pagesSI Doris ENnata westNo ratings yet

- Brocade: Uttar Pradesh O FDocument19 pagesBrocade: Uttar Pradesh O FNATASHA SAININo ratings yet

- Crafts Beautiful - Homeknits 2014Document164 pagesCrafts Beautiful - Homeknits 2014Bang Begs100% (4)

- Job Description FormDocument2 pagesJob Description FormJewel Hannah PatawaranNo ratings yet

- TolerancesDocument3 pagesTolerancesHenry Chrisnash SsenjuleNo ratings yet

- 1 Hummingbird PatternDocument3 pages1 Hummingbird Patternlittleburro1958No ratings yet

- GoldfishDocument7 pagesGoldfishSandra VeraNo ratings yet

- Catalogo TechcutDocument32 pagesCatalogo TechcutJavier GuevaraNo ratings yet

- BANCO CARPINTERO - Roubo Hobelbank Bauplan EnglishDocument42 pagesBANCO CARPINTERO - Roubo Hobelbank Bauplan Englishninon108100% (10)

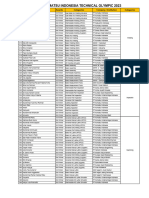

- 12th All Komatsu Indonesia Technical Olympic 2022 Official ResultDocument2 pages12th All Komatsu Indonesia Technical Olympic 2022 Official ResultMarchal KawengianNo ratings yet

- Daisy Turtle CrochetDocument6 pagesDaisy Turtle CrochetMarina ChouNo ratings yet

- Tropical Knitex LTD.: Sub: GSM CalculationDocument4 pagesTropical Knitex LTD.: Sub: GSM CalculationshponNo ratings yet

- Untitled 34Document4 pagesUntitled 34Fabiana Sarto Rasera100% (1)

- China Fastener Directory 2014 PLUS 1Document114 pagesChina Fastener Directory 2014 PLUS 1chinafastenerinfo100% (5)

- Buku Skrap Koleksi GambarDocument32 pagesBuku Skrap Koleksi GambardilasifNo ratings yet

- Penny The Doll: MaterialsDocument13 pagesPenny The Doll: MaterialsLeticia Glez100% (1)

- Kaia Crochet Pajama Party Bunny EngDocument13 pagesKaia Crochet Pajama Party Bunny EngNataly Diaz Salazar100% (2)

- Mini Kitten/Cat (Melis) : Let's Get Started With Someone Who Can Live in Our Doll House Melis The KittenDocument4 pagesMini Kitten/Cat (Melis) : Let's Get Started With Someone Who Can Live in Our Doll House Melis The KittenAn BnNo ratings yet

- Washcloth With Pocket Crochet PatternDocument3 pagesWashcloth With Pocket Crochet Patternlannecordier100% (1)

- Build A Plank On Frame Model ShipDocument77 pagesBuild A Plank On Frame Model Shipamauri bittencourtNo ratings yet

- American Glass GBDocument4 pagesAmerican Glass GBrazvicosteaNo ratings yet

- English KnottyDocument2 pagesEnglish Knottynehiltas2013No ratings yet

371 Etch Primers

371 Etch Primers

Uploaded by

Haroon GorayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

371 Etch Primers

371 Etch Primers

Uploaded by

Haroon GorayaCopyright:

Available Formats

WHAT ARE ETCH PRIMERS?

Etch Primers are single pack metal primers formulated with a

combination of resins to maximise adhesion to the various metal

surfaces on which they may be used. A low level of phosphoric acid

is present in these primers to etch the metal surface and improve

adhesion. The coatings also contain zinc phosphate anti-corrosion

pigment for steel surfaces. An important point to note is that they are

formulated with low volume solids so that film builds can be kept low

(10 - 15 m).

WHEN SHOULD THEY BE USED?

Etch Primers are intended for use as primers on new or relatively

sound ferrous and non-ferrous metal surfaces. Examples of the

types of surfaces on which these products would be used are light-

weight tubing or thin sheet metal surfaces that cannot be prepared

by abrasive blast cleaning. In such cases the combination

hand/power tool abrasion and acid present in the primer generally

provides sufficient adhesion to allow the use of thin film two-pack

finishes. Severely corroded surfaces or those that can be prepared

by abrasive blast cleaning would be better served by a surface-

tolerant or conventional two-pack epoxy primer, as these products

offer better long term corrosion protection than etch primers.

ADVANTAGES

The advantages of this type of product over other metal primers are

as follows:

Provides excellent adhesion over a variety of different metals.

Can be applied with minimal preparation (clean, degrease and abrade,

refer to data sheets).

Rapid cure, allowing overcoating with thin film topcoats in substantially

less than 1 hour.

Zinc phosphate pigmentation offers some degree of inhibitive corrosion

protection.

WHEN SHOULD THEY NOT BE USED?

When corrosion protection in coastal environments is required, etch

primers are not adequate. A zinc-rich primer should be used as part

of a heavy-duty, high build, two-pack system.

Etch primers work by acid etching the metal surface. Therefore they

have little effect on previously painted surfaces (including precoated Whilst the etch primer should be sprayed to ensure a

® thin, even film, the topcoat can be brushed.

sheet steel such as Colorbond ). In fact, the phosphoric acid present

in the etch primer may interfere with the adhesion of subsequent

coatings, causing delamination.

PRECAUTIONS

These precautions are typical of all single-pack etch primers:

The product is intended for use in thin film systems (50 – 100 m total

film thickness) and so cannot be expected to provide the level of

corrosion protection achievable with protective coating systems.

Higher than recommended film builds (usually around 10 m will risk

delamination of the coating.

Relatively short and restrictive recoat window may create difficulties for

larger jobs.

Brush and roller application are suitable for small areas only; the primer

should be sprayed to ensure a thin and even film build.

IN SUMMARY

Etch primers can be used across a range of metals

Etch primers are convenient for the priming of all types of metal that once corrosion and dirt have been removed.ensure

require a very quick turn-around time. They only require a very thin dissimilar metals are isolated from each other, or

corrosion will continue

coat in order to etch the metal surface and create a tenacious bond.

Zinc phosphate pigment offers some degree of corrosion protection.

The fast dry characteristics allow the topcoat to be applied shortly

after primer application.

The thin film limits application to metals in low corrosivity

environments and is unsuitable for heavy duty, high film build

intermediates and topcoats.

Etch primers are unsuitable for previously coated and/or non

Once the etch primer has dried, it is ready to paint.

For more information, please contact the Dulux Protective Coatings Technical

Consultant in your state.

You might also like

- Doll Mabel PinesDocument12 pagesDoll Mabel PinesEurydice Suz100% (2)

- Coating Guide: Standards Contact UsDocument26 pagesCoating Guide: Standards Contact UsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Fundamentals of Stripe CoatingDocument164 pagesFundamentals of Stripe Coatinganangwahjudi100% (1)

- Tool and Die DesignDocument61 pagesTool and Die DesignAshley Kane P. Dumay100% (3)

- Etch Primers PDFDocument1 pageEtch Primers PDFBash MatNo ratings yet

- Painting GNDocument3 pagesPainting GNAd FwyNo ratings yet

- Organic and Inorganic Zinc Rich CoatingsDocument3 pagesOrganic and Inorganic Zinc Rich CoatingsEddy Norman Benites Delgado100% (6)

- Fan Protective Coatings ED400Document7 pagesFan Protective Coatings ED400arielNo ratings yet

- Cpei SopDocument5 pagesCpei SopCorrosion FactoryNo ratings yet

- PrimersDocument3 pagesPrimersDiya AwasthiNo ratings yet

- Coating For The Protection of Steel StructureDocument17 pagesCoating For The Protection of Steel StructureMohamed Abdel SamieNo ratings yet

- FE 400 Protective Coating Guide For FansDocument8 pagesFE 400 Protective Coating Guide For FansAvery OppegardNo ratings yet

- SSPC Tu 1Document3 pagesSSPC Tu 1Prashant PandeyNo ratings yet

- Thermal Spray Comparison To PaintingDocument1 pageThermal Spray Comparison To PaintingSunil GurubaxaniNo ratings yet

- OA 3957 Red Oxide Primer Product Data: (Exterior/InteriorDocument1 pageOA 3957 Red Oxide Primer Product Data: (Exterior/InteriortshawkyNo ratings yet

- Fundamentals of Offshore and On Shore CoatingsDocument12 pagesFundamentals of Offshore and On Shore CoatingsPravas PadhihariNo ratings yet

- Dental Cement 1Document5 pagesDental Cement 1eslamezzat21061990No ratings yet

- Paint SystemsDocument5 pagesPaint SystemsOmar DhiebNo ratings yet

- Coating FailureDocument14 pagesCoating FailureNnamdi Celestine NnamdiNo ratings yet

- Zinc Flake CoatingsDocument1 pageZinc Flake CoatingsDinh TuNo ratings yet

- General Knowledge of PCB OSP Surface FinishDocument5 pagesGeneral Knowledge of PCB OSP Surface FinishRennze Dominic De VeraNo ratings yet

- Paintmasterwbmetalprimer TDSDocument2 pagesPaintmasterwbmetalprimer TDSMichael JoudalNo ratings yet

- Cement Bases and Cavity LinersDocument8 pagesCement Bases and Cavity Linersمحمد احمد محمدNo ratings yet

- Paint SystemsDocument4 pagesPaint SystemsHung Mai VanNo ratings yet

- 2 - CementNotes2022-23Document7 pages2 - CementNotes2022-23Rana hasanaNo ratings yet

- All About Rust BulletDocument4 pagesAll About Rust BulletAan KhamaluddinNo ratings yet

- OA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)Document1 pageOA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)tshawkyNo ratings yet

- Rust Converted CoatingDocument80 pagesRust Converted Coatingalfan cita nyalaNo ratings yet

- NEI Anticorrosion Paints & Coatings BrochureDocument3 pagesNEI Anticorrosion Paints & Coatings Brochurefallen010% (1)

- Premium Zinc Coating: Corrosion Protection at All TimesDocument3 pagesPremium Zinc Coating: Corrosion Protection at All TimesJose JavierNo ratings yet

- Paint CoatDocument9 pagesPaint CoatAha AsaNo ratings yet

- Solvent Based PrimerDocument2 pagesSolvent Based PrimerLim Yong SiangNo ratings yet

- Painting of Hot-Dip Galvanized Steel - Duplex SystemsDocument5 pagesPainting of Hot-Dip Galvanized Steel - Duplex SystemsPrabath Nilan GunasekaraNo ratings yet

- Coating Failures: Richard W. DriskoDocument15 pagesCoating Failures: Richard W. DriskoAlejandro Expósito FernándezNo ratings yet

- Supplier of Zinc Phosphate in PakistanDocument3 pagesSupplier of Zinc Phosphate in PakistansdsdvsdvsdNo ratings yet

- Metallizing Process and Advantages MMPLDocument7 pagesMetallizing Process and Advantages MMPLCorrosion FactoryNo ratings yet

- VRM-Brochure IN AADocument2 pagesVRM-Brochure IN AApinasthika.timurNo ratings yet

- Corrosion: Corrosive Condition Description of EnvironmentDocument7 pagesCorrosion: Corrosive Condition Description of EnvironmentMaddyNo ratings yet

- VIVADocument15 pagesVIVAambiliNo ratings yet

- Inorganic Zinc Rich Paint PDFDocument2 pagesInorganic Zinc Rich Paint PDFarunrengaraj100% (1)

- Berger Paint CatalogDocument74 pagesBerger Paint Catalogdbehera0667% (3)

- Scotchkote FBEC BR 8086372Document16 pagesScotchkote FBEC BR 8086372ingrclNo ratings yet

- Fluoropolymer Coating BenefitsDocument8 pagesFluoropolymer Coating Benefitslamia97No ratings yet

- Protective CoatingsDocument8 pagesProtective CoatingsKakde Krushna LNo ratings yet

- How To Get The Greatest Possible Benefit From Shuttering PlywoodDocument1 pageHow To Get The Greatest Possible Benefit From Shuttering PlywoodRami JabadoNo ratings yet

- Brushbond RFXDocument2 pagesBrushbond RFXaneesh kapaNo ratings yet

- Brushbond RFXDocument2 pagesBrushbond RFXaneesh kapaNo ratings yet

- Brushbond RFX PDFDocument2 pagesBrushbond RFX PDFpiyu114No ratings yet

- VIVADocument16 pagesVIVAambiliNo ratings yet

- Offshore Eng PDFDocument8 pagesOffshore Eng PDFClintonDestinyNo ratings yet

- Epoxy Coating Guide For ConcreteDocument8 pagesEpoxy Coating Guide For ConcreteShepherd NhangaNo ratings yet

- 7 - Paint System - Ch-7Document4 pages7 - Paint System - Ch-7Manju JunoNo ratings yet

- Steelmaster 60WB: Technical Data Sheet Application GuideDocument10 pagesSteelmaster 60WB: Technical Data Sheet Application GuideyugandharNo ratings yet

- Doka SystemDocument47 pagesDoka SystembappanaduNo ratings yet

- Protective CoatingDocument6 pagesProtective CoatingPinaki RahaNo ratings yet

- Corrosion Removal: Before Starting Any Corrosion Removal, You Must Conduct An Inspection andDocument8 pagesCorrosion Removal: Before Starting Any Corrosion Removal, You Must Conduct An Inspection andHorhe TheGreatNo ratings yet

- New Polymer Technology Improves Durability and Constructability of Coatingfor Steel StructuresDocument4 pagesNew Polymer Technology Improves Durability and Constructability of Coatingfor Steel StructuresUsama Awad100% (1)

- Color Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueFrom EverandColor Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueNo ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Jde 10030Document3 pagesJde 10030X800XLNo ratings yet

- Grade 7-8 - Handicraft Q1 W1-W2Document30 pagesGrade 7-8 - Handicraft Q1 W1-W2Arlie Jean Bioneda AbilaNo ratings yet

- Amigurumi @crochetbykim ElefanteDocument11 pagesAmigurumi @crochetbykim Elefantesoraiathiago100% (2)

- Libble Eu PDFDocument25 pagesLibble Eu PDFFat CatNo ratings yet

- Macrame Bangle BraceletDocument6 pagesMacrame Bangle Braceletmahira_tippu100% (1)

- Christmas Granny Squares North Pole, Santa Claus & Grandma ClausDocument6 pagesChristmas Granny Squares North Pole, Santa Claus & Grandma ClausCarito Montenegro JiménezNo ratings yet

- SI Doris ENDocument2 pagesSI Doris ENnata westNo ratings yet

- Brocade: Uttar Pradesh O FDocument19 pagesBrocade: Uttar Pradesh O FNATASHA SAININo ratings yet

- Crafts Beautiful - Homeknits 2014Document164 pagesCrafts Beautiful - Homeknits 2014Bang Begs100% (4)

- Job Description FormDocument2 pagesJob Description FormJewel Hannah PatawaranNo ratings yet

- TolerancesDocument3 pagesTolerancesHenry Chrisnash SsenjuleNo ratings yet

- 1 Hummingbird PatternDocument3 pages1 Hummingbird Patternlittleburro1958No ratings yet

- GoldfishDocument7 pagesGoldfishSandra VeraNo ratings yet

- Catalogo TechcutDocument32 pagesCatalogo TechcutJavier GuevaraNo ratings yet

- BANCO CARPINTERO - Roubo Hobelbank Bauplan EnglishDocument42 pagesBANCO CARPINTERO - Roubo Hobelbank Bauplan Englishninon108100% (10)

- 12th All Komatsu Indonesia Technical Olympic 2022 Official ResultDocument2 pages12th All Komatsu Indonesia Technical Olympic 2022 Official ResultMarchal KawengianNo ratings yet

- Daisy Turtle CrochetDocument6 pagesDaisy Turtle CrochetMarina ChouNo ratings yet

- Tropical Knitex LTD.: Sub: GSM CalculationDocument4 pagesTropical Knitex LTD.: Sub: GSM CalculationshponNo ratings yet

- Untitled 34Document4 pagesUntitled 34Fabiana Sarto Rasera100% (1)

- China Fastener Directory 2014 PLUS 1Document114 pagesChina Fastener Directory 2014 PLUS 1chinafastenerinfo100% (5)

- Buku Skrap Koleksi GambarDocument32 pagesBuku Skrap Koleksi GambardilasifNo ratings yet

- Penny The Doll: MaterialsDocument13 pagesPenny The Doll: MaterialsLeticia Glez100% (1)

- Kaia Crochet Pajama Party Bunny EngDocument13 pagesKaia Crochet Pajama Party Bunny EngNataly Diaz Salazar100% (2)

- Mini Kitten/Cat (Melis) : Let's Get Started With Someone Who Can Live in Our Doll House Melis The KittenDocument4 pagesMini Kitten/Cat (Melis) : Let's Get Started With Someone Who Can Live in Our Doll House Melis The KittenAn BnNo ratings yet

- Washcloth With Pocket Crochet PatternDocument3 pagesWashcloth With Pocket Crochet Patternlannecordier100% (1)

- Build A Plank On Frame Model ShipDocument77 pagesBuild A Plank On Frame Model Shipamauri bittencourtNo ratings yet

- American Glass GBDocument4 pagesAmerican Glass GBrazvicosteaNo ratings yet

- English KnottyDocument2 pagesEnglish Knottynehiltas2013No ratings yet