Professional Documents

Culture Documents

Oniondrying Rev1610-03

Oniondrying Rev1610-03

Uploaded by

Thein Tun AungCopyright:

Available Formats

You might also like

- Mushroom Storage and ProcessingDocument5 pagesMushroom Storage and ProcessingKho Siong Thong80% (5)

- Automated Electronic Evaporative Cooling and Fogging System For MushroomDocument14 pagesAutomated Electronic Evaporative Cooling and Fogging System For MushroomElijahx San JoseNo ratings yet

- Unit 3 Dehydration and ConcentrationDocument62 pagesUnit 3 Dehydration and ConcentrationHayati SofiyahNo ratings yet

- You Raise Me UpDocument1 pageYou Raise Me UpJoseph Jecong100% (1)

- Potato Storage PDFDocument3 pagesPotato Storage PDFUFITABE MANASSENo ratings yet

- FNH-00745 Drying Fruits and VegetablesDocument4 pagesFNH-00745 Drying Fruits and VegetablesChristinah Maheritiana ANDRIAMANANTSOANo ratings yet

- Alaska Root CellarDocument4 pagesAlaska Root CellarREBogart100% (3)

- Guide To Drying Fruits and VeggiesDocument12 pagesGuide To Drying Fruits and VeggiesphoboscaNo ratings yet

- Harvesting Practices of Various CropsDocument21 pagesHarvesting Practices of Various CropsNemie Rex Sukil-ap Guerzon100% (1)

- KOUSIK - GHOSHMushroom Storage2020-05-03MUSHROOMSTORAGEDocument5 pagesKOUSIK - GHOSHMushroom Storage2020-05-03MUSHROOMSTORAGEgeetavaddar2006atNo ratings yet

- I2433e10 PDFDocument48 pagesI2433e10 PDFDinesh PatilNo ratings yet

- Plagiarism Scan Report: Date Exclude URLDocument5 pagesPlagiarism Scan Report: Date Exclude URLmerry sheeryNo ratings yet

- Drying and Dehydration HRT 321 OnlineDocument41 pagesDrying and Dehydration HRT 321 OnlineNisarga T DaryaNo ratings yet

- DehydratingDocument10 pagesDehydratingRyza MartizanoNo ratings yet

- Onion Storage and Dryer: Solimar F.Moradas, Elmer S.SealongoDocument6 pagesOnion Storage and Dryer: Solimar F.Moradas, Elmer S.SealongoJemimah NatividadNo ratings yet

- 2IJEAB 10720201 HydroponicDocument8 pages2IJEAB 10720201 HydroponicraxiblairNo ratings yet

- Vegetable Storage in Root CellarsDocument4 pagesVegetable Storage in Root CellarsVassile Rossi100% (1)

- Different Ways of Storing VegetablesDocument6 pagesDifferent Ways of Storing VegetablesVia ValderamaNo ratings yet

- FinalDocument6 pagesFinalMarlene SambasNo ratings yet

- Fabrication of Solar Food Dryer Using Parabolic ReflectorDocument7 pagesFabrication of Solar Food Dryer Using Parabolic ReflectorannamalaiNo ratings yet

- Dehydration (Fo-Wps OfficeDocument3 pagesDehydration (Fo-Wps OfficeArielBallasoNo ratings yet

- Principles and Methods of PreservationbydryingDocument29 pagesPrinciples and Methods of PreservationbydryingVinodNo ratings yet

- Food PreservationDocument4 pagesFood Preservationalifriamae478No ratings yet

- Storage: Primary Aims of StorageDocument7 pagesStorage: Primary Aims of StorageAlpheccaNo ratings yet

- Grain and Soybean Drying On Georgia FarmsDocument13 pagesGrain and Soybean Drying On Georgia FarmsjimNo ratings yet

- Food DehydratorDocument11 pagesFood Dehydratorjimmycrackcorn100100% (1)

- Seed DryingDocument10 pagesSeed DryingJack Ethan Dean B. CamiadorNo ratings yet

- Tray Dryer ExperimentDocument13 pagesTray Dryer Experimentgeek311295% (37)

- Reading Mat PhoDocument9 pagesReading Mat PhoLadyliza Martinez NazaroNo ratings yet

- Potato StorageDocument3 pagesPotato StorageSanjeev Gautam100% (1)

- FLORABANK GUIDELINES - Native Seed StorageDocument6 pagesFLORABANK GUIDELINES - Native Seed StorageCeobahn WebberNo ratings yet

- FFT April 19 Drying DehydrationDocument6 pagesFFT April 19 Drying DehydrationMaLyn MaravillaNo ratings yet

- Herb Dryer Leaflet PDFDocument8 pagesHerb Dryer Leaflet PDFpandaypiraNo ratings yet

- Laboratory Exercise No. 3 Drying of Durable Crops (Corn)Document5 pagesLaboratory Exercise No. 3 Drying of Durable Crops (Corn)JojenNo ratings yet

- LAS Cookery 10week 7 8Document14 pagesLAS Cookery 10week 7 8jon pantzNo ratings yet

- LAS Cookery 10week 7 8Document14 pagesLAS Cookery 10week 7 8jon pantzNo ratings yet

- KhanDocument4 pagesKhanirfan hilmanNo ratings yet

- Drying Process Ppt. AmenDocument18 pagesDrying Process Ppt. AmenCherry ObiasNo ratings yet

- MushroomDocument21 pagesMushroomKEVIN MANALONo ratings yet

- 1 s2.0 S0925521413002779 Main PDFDocument6 pages1 s2.0 S0925521413002779 Main PDFSukma FirdausNo ratings yet

- Alternatives To Refrigerated StorageDocument2 pagesAlternatives To Refrigerated StorageHoney de la TorreNo ratings yet

- Dehydration ProcessDocument7 pagesDehydration ProcessSunil BarnwalNo ratings yet

- Storage of FruitsDocument7 pagesStorage of FruitsNoor AlaswadNo ratings yet

- Module Week 12 Basic StocksDocument9 pagesModule Week 12 Basic StocksJayson TaytingNo ratings yet

- Chilling and Respiration of Fruits and VegetablesDocument8 pagesChilling and Respiration of Fruits and VegetablesPaul Laurence Bondoc100% (1)

- Fot Assin 1Document10 pagesFot Assin 1RishavNo ratings yet

- Bhople Et Al (2019)Document3 pagesBhople Et Al (2019)amelia arum ramadhaniNo ratings yet

- DK2869 CH22Document21 pagesDK2869 CH22Duy NguyenNo ratings yet

- Glak - Q2 - WK 6-8Document35 pagesGlak - Q2 - WK 6-8Lucille PaglingayenNo ratings yet

- Safe Storage Conditions Part 3Document10 pagesSafe Storage Conditions Part 35vuoupu4kNo ratings yet

- Study of The Solar Drying of Grapes by Three Different ProcessesDocument7 pagesStudy of The Solar Drying of Grapes by Three Different ProcessesAhamed AhamadNo ratings yet

- Chapter 7 - Drying - Part 2Document16 pagesChapter 7 - Drying - Part 221129847No ratings yet

- Oyster Mushroom Cultivation - Unidad 2 PDFDocument14 pagesOyster Mushroom Cultivation - Unidad 2 PDFSandra Milena VelandiaNo ratings yet

- ROOT CELLARING FOR PREPPERS: A Prepper's Guide to Root Cellaring: Essential Skills for Sustainable LivingFrom EverandROOT CELLARING FOR PREPPERS: A Prepper's Guide to Root Cellaring: Essential Skills for Sustainable LivingNo ratings yet

- CO2IncubatorCare BestPracticesDocument1 pageCO2IncubatorCare BestPracticesAsistencia TécnicaNo ratings yet

- Storage PHTDocument20 pagesStorage PHTGalano, Hana MarieNo ratings yet

- No Refrigeration VDocument2 pagesNo Refrigeration Vapi-655937126No ratings yet

- Potato Storage Management Fact Sheet English FinalDocument9 pagesPotato Storage Management Fact Sheet English FinalDiego RuedaNo ratings yet

- Grain Aeration: January 2012Document15 pagesGrain Aeration: January 2012Marie Cris Gajete MadridNo ratings yet

- ROOT CELLARING FOR PREPPERS: Root Cellaring Techniques for Preserving Harvests and Building Self-RelianceFrom EverandROOT CELLARING FOR PREPPERS: Root Cellaring Techniques for Preserving Harvests and Building Self-RelianceNo ratings yet

- ROOT CELLARING FOR PREPPERS: Food Security for Preppers: Storing Fresh Produce All Year RoundFrom EverandROOT CELLARING FOR PREPPERS: Food Security for Preppers: Storing Fresh Produce All Year RoundNo ratings yet

- On Tap Viet Lai CauDocument4 pagesOn Tap Viet Lai CauHoàng Minh ChâuNo ratings yet

- Quizizz: The WeatherDocument13 pagesQuizizz: The WeatherValeria LurquinNo ratings yet

- The Dry Grass Sings MemoDocument2 pagesThe Dry Grass Sings Memocarabritz25No ratings yet

- Masterprotect 300 Tds PDFDocument3 pagesMasterprotect 300 Tds PDFSedki AlashkarNo ratings yet

- Week 7 Disaster and Disaster RiskDocument3 pagesWeek 7 Disaster and Disaster RiskAilyn Uy Laparan DiolataNo ratings yet

- Prova de Inglês 2005 EfommDocument6 pagesProva de Inglês 2005 EfommGabriel CastilloNo ratings yet

- Air Environment: What Are The Main Sources of Air Pollution?Document8 pagesAir Environment: What Are The Main Sources of Air Pollution?Erika EludoNo ratings yet

- A Descriptive Text ExampleDocument10 pagesA Descriptive Text ExampleCehep CehepNo ratings yet

- Physical Geography of AfricaDocument23 pagesPhysical Geography of AfricaFalilou100% (1)

- NOVA-Rise of The Superstorms Video Questions KeyDocument2 pagesNOVA-Rise of The Superstorms Video Questions KeyANDREEA MALNo ratings yet

- Des CPDocument29 pagesDes CPjeromerantsNo ratings yet

- Tenagashaw2022 Article LandUseAndClimateChangeImpactsDocument15 pagesTenagashaw2022 Article LandUseAndClimateChangeImpactsAbdusalam IdirisNo ratings yet

- Week 13 (21st Century Lit)Document11 pagesWeek 13 (21st Century Lit)aimee almario100% (1)

- Air Pollution (Grade 8) - Free Printable Tests and WorksheetsDocument2 pagesAir Pollution (Grade 8) - Free Printable Tests and WorksheetsBảo NhiNo ratings yet

- Integers and The Coordinate PlaneDocument46 pagesIntegers and The Coordinate PlaneAnyapat (Bouquet) SivapornratNo ratings yet

- Universidad Privada Franz Tamayo Facultad de Ciencias Económicas Y EmpresarialesDocument4 pagesUniversidad Privada Franz Tamayo Facultad de Ciencias Económicas Y EmpresarialesJOSE MARIA RODRIGUEZ RIOSNo ratings yet

- Haki Universal: User S ManualDocument36 pagesHaki Universal: User S ManualTaeseung KimNo ratings yet

- DRRR PointersDocument12 pagesDRRR PointersI Don't KnowNo ratings yet

- Overview of World GeographyDocument367 pagesOverview of World Geographysai skNo ratings yet

- Science 8 Quarter 2 Week 4Document4 pagesScience 8 Quarter 2 Week 4Black VenusNo ratings yet

- Bahasa Inggris Paket BDocument8 pagesBahasa Inggris Paket BPic JhoeNo ratings yet

- The Weather Report: Activity TypeDocument3 pagesThe Weather Report: Activity TypeSara Saavedra100% (1)

- METAR1Document3 pagesMETAR1Trz CoordinatorNo ratings yet

- biên dịch 1Document112 pagesbiên dịch 1Thành TàiNo ratings yet

- Programmation AnglaisDocument4 pagesProgrammation AnglaisErell PétillonNo ratings yet

- Site Memo CHC - SM - 008Document2 pagesSite Memo CHC - SM - 008Park ParkNo ratings yet

- Module 1 - A Geographer's WorldDocument36 pagesModule 1 - A Geographer's WorldRayna Wacha0% (1)

- Ray's Short Sory The Old Man and The SparrowDocument3 pagesRay's Short Sory The Old Man and The SparrowKovacs ZsokaNo ratings yet

- SV Tài liệu ôn T3.2024 - ListeningDocument12 pagesSV Tài liệu ôn T3.2024 - ListeningCương Lỗ thanhNo ratings yet

Oniondrying Rev1610-03

Oniondrying Rev1610-03

Uploaded by

Thein Tun AungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oniondrying Rev1610-03

Oniondrying Rev1610-03

Uploaded by

Thein Tun AungCopyright:

Available Formats

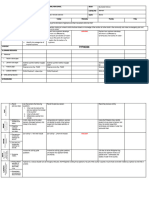

Dehumidification Application

The choice for

desiccant dehumidification®

® and ™ Trademarks of Bry-Air (Asia) Pvt. Ltd.

Desiccant

Dehumidification

in Onion Drying

Bry-Air environmental control

systems allow for consistent and

quality products to be produced

efficiently with dry air.

Photo Courtesy of MCT Direct Photos

I

n the process of drying onions, In most cases, 100% outside the onions may decay or begin to

a drying oven (such as a Proctor air is pre-cooled, dehumidified sprout. The ideal storage condition

Schwartz) is commonly used and delivered to the final stage for onions is 32°F at a relative

in conjunction with a desiccant (commonly known as the D-stage) humidity of 65 - 70%. In order to

dehumidifying system. The at a condition of less than 100°F maintain this temperature, the coil

dehumidifier is usually applied in at 15 gr/lb or lower (approximately temperature will be well below

the final stage in which very dry 4-7% RH). freezing. A desiccant dehumidifier

air is required. If this drying were can control the humidity and

attempted only with heat, the onions Storage Conditions eliminate the need for defrost

would be damaged and unfit for cycles, allowing the cooling system

consumption. The dehumidifier In order to store onions for any to maintain a steady temperature.

supplies cooler, drier air which length of time, it is necessary These conditions will ensure

ensures that the onions will be dried to keep them in a cool, dry that the onions remain dormant.

without the damage associated with environment. When humidity levels Refrigerated storage is often used

high temperatures. and temperatures are too high to hold onions for approximately six

months.

Onions to be kept in cold storage

should be placed there immediately

following the curing process. The

temperature of 32° F will keep

the onions dormant and free from

decay, provided the onions are

sound and properly cured prior to

storage. Sprout growth can indicate

that the’ storage temperature is too

high, the bulbs are poorly cured or

that they are immature bulbs. Root

growth can indicate that the relative

humidity is too high.

Photo Courtesy of MCT Direct Photos

Storage Procedure In the case of onion storage the

permeation load is, by far, the

Onions should be adequately cured largest load to consider. In most

either in the field, in open sheds, or cases the other parameters are

by artificial means before or during minimal or nonexistent.

storage. The most common method

of curing is natural or forced air One of the factors which directly

ventilation. Onions are considered affects the permeation load is the

to be cured when the necks are tight vapor barrier. The better the vapor

and the outer scales are dried until barrier in the storage area the lower

they rustle. If not properly cured, the permeation load which results

the onions are likely to decay in in a more satisfactory storage

the form of a gray mold rot which condition. The correct application of

occurs at the top of the bulb. This is a desiccant dehumidifier will ensure

commonly known in the industry as humidity control and successful

“neck rot”. storage of the onions. In most cases

the increase in yield of onions

When onions are removed covers the initial cost of the drying

from storage in warm weather, system within the first season.

condensation may form as they

are exposed to the warmer Bry-Air desiccant dehumidifiers

temperatures and higher humidity. have been utilized in hundreds

This, in turn, can lead to decay of of applications for the drying and

the product. The solution to this storage of onions. Whether they

problem is to allow the onions to are in bulk, flake or powdered

warm gradually until they reach form, onion drying and storage is

equilibrium with the surrounding air. important to ensure that the product

reaches the consumer in good

Storage Capacity and Basis of condition and taste.

Design

The quantity of onions that can be

stored will depend on whether they

are stored in bags, crates, pallet

boxes or storage bins. A general rule

of thumb is to figure on the basis

of between 90 to 110 cubic feet of

space required per ton of onions.

The majority of the moisture load

which will be removed by the

dehumidifier is a sum of:

1. Permeation as a result of vapor

pressure differential inside and

outside of the storage space.

2. Door openings per hour.

3. Fresh air required.

4. Conveyor openings.

5. Number of people working in

the space.

6. Product load.

For more information on Bry-Air’s products and services please visit www.bry-air.com

Bry-Air, Inc. - 10793 St. Rt. 37 W. Sunbury, Ohio 43074 - P: 740.965.2974 - F: 740.965.5470 - E: bryair1@bry-air.com

Rev. 1610-03

You might also like

- Mushroom Storage and ProcessingDocument5 pagesMushroom Storage and ProcessingKho Siong Thong80% (5)

- Automated Electronic Evaporative Cooling and Fogging System For MushroomDocument14 pagesAutomated Electronic Evaporative Cooling and Fogging System For MushroomElijahx San JoseNo ratings yet

- Unit 3 Dehydration and ConcentrationDocument62 pagesUnit 3 Dehydration and ConcentrationHayati SofiyahNo ratings yet

- You Raise Me UpDocument1 pageYou Raise Me UpJoseph Jecong100% (1)

- Potato Storage PDFDocument3 pagesPotato Storage PDFUFITABE MANASSENo ratings yet

- FNH-00745 Drying Fruits and VegetablesDocument4 pagesFNH-00745 Drying Fruits and VegetablesChristinah Maheritiana ANDRIAMANANTSOANo ratings yet

- Alaska Root CellarDocument4 pagesAlaska Root CellarREBogart100% (3)

- Guide To Drying Fruits and VeggiesDocument12 pagesGuide To Drying Fruits and VeggiesphoboscaNo ratings yet

- Harvesting Practices of Various CropsDocument21 pagesHarvesting Practices of Various CropsNemie Rex Sukil-ap Guerzon100% (1)

- KOUSIK - GHOSHMushroom Storage2020-05-03MUSHROOMSTORAGEDocument5 pagesKOUSIK - GHOSHMushroom Storage2020-05-03MUSHROOMSTORAGEgeetavaddar2006atNo ratings yet

- I2433e10 PDFDocument48 pagesI2433e10 PDFDinesh PatilNo ratings yet

- Plagiarism Scan Report: Date Exclude URLDocument5 pagesPlagiarism Scan Report: Date Exclude URLmerry sheeryNo ratings yet

- Drying and Dehydration HRT 321 OnlineDocument41 pagesDrying and Dehydration HRT 321 OnlineNisarga T DaryaNo ratings yet

- DehydratingDocument10 pagesDehydratingRyza MartizanoNo ratings yet

- Onion Storage and Dryer: Solimar F.Moradas, Elmer S.SealongoDocument6 pagesOnion Storage and Dryer: Solimar F.Moradas, Elmer S.SealongoJemimah NatividadNo ratings yet

- 2IJEAB 10720201 HydroponicDocument8 pages2IJEAB 10720201 HydroponicraxiblairNo ratings yet

- Vegetable Storage in Root CellarsDocument4 pagesVegetable Storage in Root CellarsVassile Rossi100% (1)

- Different Ways of Storing VegetablesDocument6 pagesDifferent Ways of Storing VegetablesVia ValderamaNo ratings yet

- FinalDocument6 pagesFinalMarlene SambasNo ratings yet

- Fabrication of Solar Food Dryer Using Parabolic ReflectorDocument7 pagesFabrication of Solar Food Dryer Using Parabolic ReflectorannamalaiNo ratings yet

- Dehydration (Fo-Wps OfficeDocument3 pagesDehydration (Fo-Wps OfficeArielBallasoNo ratings yet

- Principles and Methods of PreservationbydryingDocument29 pagesPrinciples and Methods of PreservationbydryingVinodNo ratings yet

- Food PreservationDocument4 pagesFood Preservationalifriamae478No ratings yet

- Storage: Primary Aims of StorageDocument7 pagesStorage: Primary Aims of StorageAlpheccaNo ratings yet

- Grain and Soybean Drying On Georgia FarmsDocument13 pagesGrain and Soybean Drying On Georgia FarmsjimNo ratings yet

- Food DehydratorDocument11 pagesFood Dehydratorjimmycrackcorn100100% (1)

- Seed DryingDocument10 pagesSeed DryingJack Ethan Dean B. CamiadorNo ratings yet

- Tray Dryer ExperimentDocument13 pagesTray Dryer Experimentgeek311295% (37)

- Reading Mat PhoDocument9 pagesReading Mat PhoLadyliza Martinez NazaroNo ratings yet

- Potato StorageDocument3 pagesPotato StorageSanjeev Gautam100% (1)

- FLORABANK GUIDELINES - Native Seed StorageDocument6 pagesFLORABANK GUIDELINES - Native Seed StorageCeobahn WebberNo ratings yet

- FFT April 19 Drying DehydrationDocument6 pagesFFT April 19 Drying DehydrationMaLyn MaravillaNo ratings yet

- Herb Dryer Leaflet PDFDocument8 pagesHerb Dryer Leaflet PDFpandaypiraNo ratings yet

- Laboratory Exercise No. 3 Drying of Durable Crops (Corn)Document5 pagesLaboratory Exercise No. 3 Drying of Durable Crops (Corn)JojenNo ratings yet

- LAS Cookery 10week 7 8Document14 pagesLAS Cookery 10week 7 8jon pantzNo ratings yet

- LAS Cookery 10week 7 8Document14 pagesLAS Cookery 10week 7 8jon pantzNo ratings yet

- KhanDocument4 pagesKhanirfan hilmanNo ratings yet

- Drying Process Ppt. AmenDocument18 pagesDrying Process Ppt. AmenCherry ObiasNo ratings yet

- MushroomDocument21 pagesMushroomKEVIN MANALONo ratings yet

- 1 s2.0 S0925521413002779 Main PDFDocument6 pages1 s2.0 S0925521413002779 Main PDFSukma FirdausNo ratings yet

- Alternatives To Refrigerated StorageDocument2 pagesAlternatives To Refrigerated StorageHoney de la TorreNo ratings yet

- Dehydration ProcessDocument7 pagesDehydration ProcessSunil BarnwalNo ratings yet

- Storage of FruitsDocument7 pagesStorage of FruitsNoor AlaswadNo ratings yet

- Module Week 12 Basic StocksDocument9 pagesModule Week 12 Basic StocksJayson TaytingNo ratings yet

- Chilling and Respiration of Fruits and VegetablesDocument8 pagesChilling and Respiration of Fruits and VegetablesPaul Laurence Bondoc100% (1)

- Fot Assin 1Document10 pagesFot Assin 1RishavNo ratings yet

- Bhople Et Al (2019)Document3 pagesBhople Et Al (2019)amelia arum ramadhaniNo ratings yet

- DK2869 CH22Document21 pagesDK2869 CH22Duy NguyenNo ratings yet

- Glak - Q2 - WK 6-8Document35 pagesGlak - Q2 - WK 6-8Lucille PaglingayenNo ratings yet

- Safe Storage Conditions Part 3Document10 pagesSafe Storage Conditions Part 35vuoupu4kNo ratings yet

- Study of The Solar Drying of Grapes by Three Different ProcessesDocument7 pagesStudy of The Solar Drying of Grapes by Three Different ProcessesAhamed AhamadNo ratings yet

- Chapter 7 - Drying - Part 2Document16 pagesChapter 7 - Drying - Part 221129847No ratings yet

- Oyster Mushroom Cultivation - Unidad 2 PDFDocument14 pagesOyster Mushroom Cultivation - Unidad 2 PDFSandra Milena VelandiaNo ratings yet

- ROOT CELLARING FOR PREPPERS: A Prepper's Guide to Root Cellaring: Essential Skills for Sustainable LivingFrom EverandROOT CELLARING FOR PREPPERS: A Prepper's Guide to Root Cellaring: Essential Skills for Sustainable LivingNo ratings yet

- CO2IncubatorCare BestPracticesDocument1 pageCO2IncubatorCare BestPracticesAsistencia TécnicaNo ratings yet

- Storage PHTDocument20 pagesStorage PHTGalano, Hana MarieNo ratings yet

- No Refrigeration VDocument2 pagesNo Refrigeration Vapi-655937126No ratings yet

- Potato Storage Management Fact Sheet English FinalDocument9 pagesPotato Storage Management Fact Sheet English FinalDiego RuedaNo ratings yet

- Grain Aeration: January 2012Document15 pagesGrain Aeration: January 2012Marie Cris Gajete MadridNo ratings yet

- ROOT CELLARING FOR PREPPERS: Root Cellaring Techniques for Preserving Harvests and Building Self-RelianceFrom EverandROOT CELLARING FOR PREPPERS: Root Cellaring Techniques for Preserving Harvests and Building Self-RelianceNo ratings yet

- ROOT CELLARING FOR PREPPERS: Food Security for Preppers: Storing Fresh Produce All Year RoundFrom EverandROOT CELLARING FOR PREPPERS: Food Security for Preppers: Storing Fresh Produce All Year RoundNo ratings yet

- On Tap Viet Lai CauDocument4 pagesOn Tap Viet Lai CauHoàng Minh ChâuNo ratings yet

- Quizizz: The WeatherDocument13 pagesQuizizz: The WeatherValeria LurquinNo ratings yet

- The Dry Grass Sings MemoDocument2 pagesThe Dry Grass Sings Memocarabritz25No ratings yet

- Masterprotect 300 Tds PDFDocument3 pagesMasterprotect 300 Tds PDFSedki AlashkarNo ratings yet

- Week 7 Disaster and Disaster RiskDocument3 pagesWeek 7 Disaster and Disaster RiskAilyn Uy Laparan DiolataNo ratings yet

- Prova de Inglês 2005 EfommDocument6 pagesProva de Inglês 2005 EfommGabriel CastilloNo ratings yet

- Air Environment: What Are The Main Sources of Air Pollution?Document8 pagesAir Environment: What Are The Main Sources of Air Pollution?Erika EludoNo ratings yet

- A Descriptive Text ExampleDocument10 pagesA Descriptive Text ExampleCehep CehepNo ratings yet

- Physical Geography of AfricaDocument23 pagesPhysical Geography of AfricaFalilou100% (1)

- NOVA-Rise of The Superstorms Video Questions KeyDocument2 pagesNOVA-Rise of The Superstorms Video Questions KeyANDREEA MALNo ratings yet

- Des CPDocument29 pagesDes CPjeromerantsNo ratings yet

- Tenagashaw2022 Article LandUseAndClimateChangeImpactsDocument15 pagesTenagashaw2022 Article LandUseAndClimateChangeImpactsAbdusalam IdirisNo ratings yet

- Week 13 (21st Century Lit)Document11 pagesWeek 13 (21st Century Lit)aimee almario100% (1)

- Air Pollution (Grade 8) - Free Printable Tests and WorksheetsDocument2 pagesAir Pollution (Grade 8) - Free Printable Tests and WorksheetsBảo NhiNo ratings yet

- Integers and The Coordinate PlaneDocument46 pagesIntegers and The Coordinate PlaneAnyapat (Bouquet) SivapornratNo ratings yet

- Universidad Privada Franz Tamayo Facultad de Ciencias Económicas Y EmpresarialesDocument4 pagesUniversidad Privada Franz Tamayo Facultad de Ciencias Económicas Y EmpresarialesJOSE MARIA RODRIGUEZ RIOSNo ratings yet

- Haki Universal: User S ManualDocument36 pagesHaki Universal: User S ManualTaeseung KimNo ratings yet

- DRRR PointersDocument12 pagesDRRR PointersI Don't KnowNo ratings yet

- Overview of World GeographyDocument367 pagesOverview of World Geographysai skNo ratings yet

- Science 8 Quarter 2 Week 4Document4 pagesScience 8 Quarter 2 Week 4Black VenusNo ratings yet

- Bahasa Inggris Paket BDocument8 pagesBahasa Inggris Paket BPic JhoeNo ratings yet

- The Weather Report: Activity TypeDocument3 pagesThe Weather Report: Activity TypeSara Saavedra100% (1)

- METAR1Document3 pagesMETAR1Trz CoordinatorNo ratings yet

- biên dịch 1Document112 pagesbiên dịch 1Thành TàiNo ratings yet

- Programmation AnglaisDocument4 pagesProgrammation AnglaisErell PétillonNo ratings yet

- Site Memo CHC - SM - 008Document2 pagesSite Memo CHC - SM - 008Park ParkNo ratings yet

- Module 1 - A Geographer's WorldDocument36 pagesModule 1 - A Geographer's WorldRayna Wacha0% (1)

- Ray's Short Sory The Old Man and The SparrowDocument3 pagesRay's Short Sory The Old Man and The SparrowKovacs ZsokaNo ratings yet

- SV Tài liệu ôn T3.2024 - ListeningDocument12 pagesSV Tài liệu ôn T3.2024 - ListeningCương Lỗ thanhNo ratings yet