Professional Documents

Culture Documents

Whitepaper - Is Your Dry Storage J-Standard Compliant From ECD

Whitepaper - Is Your Dry Storage J-Standard Compliant From ECD

Uploaded by

Adair NettoCopyright:

Available Formats

You might also like

- Individual FEA ReportDocument12 pagesIndividual FEA ReportShahmeer KhalidNo ratings yet

- How To Mothball and Decommission Industrial PlantsDocument4 pagesHow To Mothball and Decommission Industrial Plantswholenumber100% (3)

- Intan Moisture Sensitive Device GuideDocument1 pageIntan Moisture Sensitive Device GuideAdair NettoNo ratings yet

- FG00212 Cashbox Cleaning ProceduresDocument2 pagesFG00212 Cashbox Cleaning ProceduresHansel Manuel Torres EyssericNo ratings yet

- Moisture Sensitive Devices (MSD) / Moisture Sensitivity Levels (MSL)Document16 pagesMoisture Sensitive Devices (MSD) / Moisture Sensitivity Levels (MSL)Muneendra Sharma100% (1)

- Ucts/? Gclid Cnxxzflmhascfyd66Wod - 0oe0 Q Ers/02 - Cleaning PDFDocument8 pagesUcts/? Gclid Cnxxzflmhascfyd66Wod - 0oe0 Q Ers/02 - Cleaning PDFkahani20099731No ratings yet

- Mothballing Requires More Than Idle ThoughtDocument4 pagesMothballing Requires More Than Idle Thoughtfawmer61No ratings yet

- Megayacht Imperial Antifouling DataDocument3 pagesMegayacht Imperial Antifouling DatakormatekNo ratings yet

- Case For Contamination Control PDFDocument12 pagesCase For Contamination Control PDFchanayireNo ratings yet

- Managing Moisture Damage in PCBs 1Document4 pagesManaging Moisture Damage in PCBs 1Adair NettoNo ratings yet

- MSD ProcedureeDocument22 pagesMSD Procedureeram dhukeNo ratings yet

- Mothballing GuideDocument8 pagesMothballing GuideJasper MaraisNo ratings yet

- Cold Warehouse NMMDocument5 pagesCold Warehouse NMMRana JahanzaibNo ratings yet

- Assignment ATFDocument2 pagesAssignment ATFduafareed711No ratings yet

- Some Recent Advances in Drying Technologies To Produce Particulate SolidsDocument15 pagesSome Recent Advances in Drying Technologies To Produce Particulate Solidsconker4No ratings yet

- Süd-Chemie BDocument3 pagesSüd-Chemie BJose VegaNo ratings yet

- 7 Steps To Selecting A Quality DesiccantDocument2 pages7 Steps To Selecting A Quality DesiccantMohammed AlShammasiNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Solutions For Long-Term Storage of Electronic Components and CompositionsDocument3 pagesSolutions For Long-Term Storage of Electronic Components and CompositionsJoão Pedro AlmeidaNo ratings yet

- Loctite MR 5923™: Technical Data SheetDocument2 pagesLoctite MR 5923™: Technical Data Sheetraffabox84yahoo.itNo ratings yet

- Some Recent Advances in Drying Technologies To Produce Particulate SolidsDocument15 pagesSome Recent Advances in Drying Technologies To Produce Particulate Solidsambrosio85No ratings yet

- Penguard Express ZPDocument5 pagesPenguard Express ZPMustafa Al-YasseriNo ratings yet

- Az 6600 Series (For HW 1)Document4 pagesAz 6600 Series (For HW 1)Max LiaoNo ratings yet

- Storage and Handling: Excessive HeatDocument4 pagesStorage and Handling: Excessive HeatMike MotariNo ratings yet

- Masterclass 52 - DemudificationDocument7 pagesMasterclass 52 - DemudificationsofyangunawanNo ratings yet

- Jet Mastic 800Document3 pagesJet Mastic 800jopersa9No ratings yet

- DryKeep BrochureWEBDocument16 pagesDryKeep BrochureWEBRichard SyNo ratings yet

- Anhydro Spray Bed Dryer: ForproductionofdustfreepowdersDocument8 pagesAnhydro Spray Bed Dryer: ForproductionofdustfreepowdersMilos MijatovicNo ratings yet

- Hardtop CA Technical Data Sheet JotunDocument5 pagesHardtop CA Technical Data Sheet JotunSam JoseNo ratings yet

- Preservation Procedure For Material Under Stand StillDocument7 pagesPreservation Procedure For Material Under Stand StillsvvsnrajuNo ratings yet

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- The Screw and Barrel SystemDocument31 pagesThe Screw and Barrel SystemAnonymous oyUAtpKNo ratings yet

- Modulyo Freeze Dryers: Delivering Maximum Flexibility For Life Science ApplicationsDocument16 pagesModulyo Freeze Dryers: Delivering Maximum Flexibility For Life Science ApplicationsJose luisNo ratings yet

- SD Freeze Drying BrochureDocument8 pagesSD Freeze Drying BrochureSNS EnerjiNo ratings yet

- Barrier 80Document5 pagesBarrier 80adeoye_okunoyeNo ratings yet

- The Misconceptions of Silica GelDocument6 pagesThe Misconceptions of Silica GelShofi MuktianaNo ratings yet

- Jotaguard 630Document4 pagesJotaguard 630Christine HermawanNo ratings yet

- Zentrifix F 92Document2 pagesZentrifix F 92Roberto_PrrNo ratings yet

- Glass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Document18 pagesGlass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Syed Arsalan Afsar100% (2)

- MBCC Masterseal 345 Tds v4Document2 pagesMBCC Masterseal 345 Tds v4shashikantNo ratings yet

- Dimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsDocument4 pagesDimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsYokesh Anand RNo ratings yet

- Dow Corning RTV InfoDocument20 pagesDow Corning RTV InfoLevent ÖnderNo ratings yet

- Leaflet D 40 Storage Conditions For Aeronautical SuppliesDocument17 pagesLeaflet D 40 Storage Conditions For Aeronautical SuppliesAraNo ratings yet

- Intergard 986Document4 pagesIntergard 986Ashta VakrNo ratings yet

- CO2 DatasheetDocument8 pagesCO2 DatasheetAwad BasyounyNo ratings yet

- A Guide To Gland Packing, Selection of Gland Packing, Standard SizesDocument15 pagesA Guide To Gland Packing, Selection of Gland Packing, Standard SizesFakhreddine ZahiNo ratings yet

- MSL3 Guideline 1Document3 pagesMSL3 Guideline 1Alex GarciaNo ratings yet

- Megayacht Royal AntifoulingDocument3 pagesMegayacht Royal Antifoulingasjoben1002No ratings yet

- Lithium Battery (SMK)Document3 pagesLithium Battery (SMK)HemonNo ratings yet

- FTA129eng Pharm GuidelinesDocument8 pagesFTA129eng Pharm GuidelinesNaser JahangiriNo ratings yet

- 10 Goldenrules in Eco-DesignDocument25 pages10 Goldenrules in Eco-Design1861969No ratings yet

- Rotary Dryer ThesisDocument8 pagesRotary Dryer Thesisafkoierfb100% (2)

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Document4 pagesTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNo ratings yet

- 2016 03 BINDER Climate Chamber Norm ENDocument2 pages2016 03 BINDER Climate Chamber Norm ENJoan Ferrao GenescàNo ratings yet

- Wet Lay Up in BoilerDocument5 pagesWet Lay Up in BoilersprotkarNo ratings yet

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- Jotun Pioner Topcoat Application Guide - AlkideDocument4 pagesJotun Pioner Topcoat Application Guide - AlkideChaerul AnwarNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Cold chain Business Planning and Strategy: Design, Retrofit And Maintenance Of Cold Storages And Pack Houses: Business strategy books, #3From EverandCold chain Business Planning and Strategy: Design, Retrofit And Maintenance Of Cold Storages And Pack Houses: Business strategy books, #3No ratings yet

- GTI Cobar Xray Article 061421Document4 pagesGTI Cobar Xray Article 061421Adair NettoNo ratings yet

- Concepts and Terminology Used in Printed Circuit Boards (PCB) - Electrosoft EngineeringDocument6 pagesConcepts and Terminology Used in Printed Circuit Boards (PCB) - Electrosoft EngineeringAdair NettoNo ratings yet

- An Engineer S Guide To Component Re-Conditioning Using The RHSD ProcessDocument6 pagesAn Engineer S Guide To Component Re-Conditioning Using The RHSD ProcessAdair NettoNo ratings yet

- IMC Thickness StatsDocument6 pagesIMC Thickness StatsAdair NettoNo ratings yet

- Counterfeit Integrated CircuitsDocument15 pagesCounterfeit Integrated CircuitsAdair NettoNo ratings yet

- Component Level Reliability For High Temperature Power ComputingDocument7 pagesComponent Level Reliability For High Temperature Power ComputingAdair NettoNo ratings yet

- SMT Apr2018Document94 pagesSMT Apr2018Adair NettoNo ratings yet

- Moisture Measurement in Pcbs IpcDocument10 pagesMoisture Measurement in Pcbs IpcAdair NettoNo ratings yet

- SMT007 Dec2020Document100 pagesSMT007 Dec2020Adair NettoNo ratings yet

- Intan Moisture Sensitive Device GuideDocument1 pageIntan Moisture Sensitive Device GuideAdair NettoNo ratings yet

- SMT - TODAY 34-dlDocument60 pagesSMT - TODAY 34-dlAdair NettoNo ratings yet

- SMT007 July2021Document110 pagesSMT007 July2021Adair NettoNo ratings yet

- Flux and CleaningDocument2 pagesFlux and CleaningAdair NettoNo ratings yet

- Three Ways Ai Helps You Hit Your Sales Goals: EbookDocument9 pagesThree Ways Ai Helps You Hit Your Sales Goals: EbookAdair NettoNo ratings yet

- Academic CalendarDocument16 pagesAcademic CalendarSanttosh Kummar AgathamudiNo ratings yet

- Learning Unit 03Document9 pagesLearning Unit 03Lucky Lehlohonolo ChakaNo ratings yet

- A New Method For Learning Decision Trees From Rules: Amany Abdelhalim, Issa TraoreDocument6 pagesA New Method For Learning Decision Trees From Rules: Amany Abdelhalim, Issa TraoreRV SreehariNo ratings yet

- Технический мануал ProoneDocument200 pagesТехнический мануал ProoneAIDNo ratings yet

- Daa C6Document14 pagesDaa C6amanterefe99No ratings yet

- Single Line SKF GreeaseDocument204 pagesSingle Line SKF GreeaseNakul RNo ratings yet

- Activity 3 - Dorado, VDocument4 pagesActivity 3 - Dorado, VVenus Bacaro DoradoNo ratings yet

- Casio FX 3800PDocument6 pagesCasio FX 3800PRamiroRinconSuarezNo ratings yet

- Types of Educational PlanningDocument35 pagesTypes of Educational PlanningJuju Zenemij91% (11)

- New Fire Water System Project Bontang Kalimantan Timur: Site Inspection and Test Plan (ITP) For Fire Water Tank WorksDocument34 pagesNew Fire Water System Project Bontang Kalimantan Timur: Site Inspection and Test Plan (ITP) For Fire Water Tank WorksTim JalurNo ratings yet

- Eligible Participants For CertificateDocument112 pagesEligible Participants For Certificate001srvnNo ratings yet

- Pneumatic PumpDocument4 pagesPneumatic PumpMuchlis MuchlisNo ratings yet

- SS Lab Manual (Ar20) 2022-23Document53 pagesSS Lab Manual (Ar20) 2022-23Shankar0% (1)

- 700T Extrusion Press - Back Loading - Long Stroke 240407Document9 pages700T Extrusion Press - Back Loading - Long Stroke 240407amitsehgal9No ratings yet

- Bill of Quantity Schedule For Boiler SystemDocument4 pagesBill of Quantity Schedule For Boiler SystemshakibNo ratings yet

- Multi TenantDocument5 pagesMulti TenantRobbyandi PerdanaNo ratings yet

- Intrusive vs. Non-Intrusive Electric Actuators: Which Option Is Right For Your Installation?Document8 pagesIntrusive vs. Non-Intrusive Electric Actuators: Which Option Is Right For Your Installation?Thanachai TengjirathanapaNo ratings yet

- How To Boot From A USB Flash Drive in VirtualBox Pen Drive LinuxDocument7 pagesHow To Boot From A USB Flash Drive in VirtualBox Pen Drive Linuxفارس فارسNo ratings yet

- Keywords: Time of Provision, Delay in Medical RecordsDocument10 pagesKeywords: Time of Provision, Delay in Medical RecordsnabilaNo ratings yet

- Industrial Automation: Gravity Roller ConveyorsDocument3 pagesIndustrial Automation: Gravity Roller ConveyorsRudresh RakeshNo ratings yet

- Flat Cool Pipes / MHP Series: FeaturesDocument3 pagesFlat Cool Pipes / MHP Series: Featuresmcyt harmonyNo ratings yet

- School of Engineering Technology and Applied Science (SETAS) Advanced Manufacturing and Automation Technology (AMAT)Document6 pagesSchool of Engineering Technology and Applied Science (SETAS) Advanced Manufacturing and Automation Technology (AMAT)anmol singhNo ratings yet

- Purposive CommunicationDocument8 pagesPurposive CommunicationBorgonia, Khryzlin May C.No ratings yet

- Extech 407764 DatasheetDocument1 pageExtech 407764 Datasheetbo cephusNo ratings yet

- MDSReport 6799005210A4Document3 pagesMDSReport 6799005210A4abinayaNo ratings yet

- XI CS Sample PaperDocument5 pagesXI CS Sample PaperPapanhiManege100% (1)

- Assignment 1Document4 pagesAssignment 1Orhan KhanNo ratings yet

- Transformer Wiring QuoteDocument2 pagesTransformer Wiring QuoteOkhwa WangilaNo ratings yet

- MOLEX AssociateManagerSoftwareTesting JDDocument2 pagesMOLEX AssociateManagerSoftwareTesting JDYenumula SaicharanNo ratings yet

Whitepaper - Is Your Dry Storage J-Standard Compliant From ECD

Whitepaper - Is Your Dry Storage J-Standard Compliant From ECD

Uploaded by

Adair NettoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Whitepaper - Is Your Dry Storage J-Standard Compliant From ECD

Whitepaper - Is Your Dry Storage J-Standard Compliant From ECD

Uploaded by

Adair NettoCopyright:

Available Formats

Is Your Dry Storage J-Standard Compliant?

Learn more about J-STD Compliance and Why it’s

Important for Product Quality

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Overview

What is J-Standard compliance and why should you care? Is your operation in full compliance? Is your team adopting

practices that may be sacrificing compliance? What’s your confidence level that moisture sensitive components have

been stored correctly?

With the abundance of misleading information, outdated practices, and simple lack of understanding, you may be at risk

of unintentionally producing suspect assemblies.

Key Learning Points:

✔ #1 Understand what J-STD compliance is and is not

✔ #2 Tools and techniques used to get and maintain compliance and the pros/cons of each

✔ #3 Common misconceptions about MSLs that may impact product quality

Is your Operation J-STD Compliant?

What is J-STD 033 compliance and why should you care? What does being in – or out – of compliance mean for your

business and your customers?

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

First Things First…Definitions and Why you it Matters

The misconception that placing components in dry storage will reset their floor life is worth mentioning, and is a good

opportunity to distinguish between pausing versus resetting components’ floor life. It is understood that baking a set of

components at sufficient temperature for the appropriate length of time will reset their floor life clock. The schedule for

performing a compliant bake is detailed in Table 4-1 of J-STD-033D and provides bake temperatures of 40° C, 90° C, and

125° C.

A dry cabinet, on the other hand (unless it has a baking feature), will simply pause the floor life clock for a given reel or

tray of components. Once a component has exceeded its floor life exposure time, there is no schedule for how long it

would take for it to be reset in a dry (<5% RH) environment.

While it is true that the standard does have a provision for resetting components via a dry cabinet after short exposure

times, it necessitates placing them in the dry environment for five or ten times the length of the short-term exposure (less

than 12 hours for MSL levels 2, 2a, and 3; and less than 8 hours for MSL levels 4, 5, and 5a).

This means that simply storing the parts overnight in a dry cabinet after a day on the floor will not reset them for use the

following day. For example, an MSL 2, 2a, or 3 component that spends eight hours on the floor would require 40 hours in

a dry cabinet to reset; and an MSL 4, 5, and 5a component with eight hours exposure time would require 80 hours in a dry

cabinet to reset.

This is the only way a dry cabinet can be used to “re-dry” parts, if the exposure times are short. This adds to the intricacy

of dry storage logistics and often contributes to the impulse to bake everything.

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Introduction to Moisture Sensitivity Levels (MSL)

Moisture sensitivity level (MSL) describes how sensitive a given component is to absorbing ambient moisture at ambient

humidity conditions (anything above 5% relative humidity[rH]). This floor life clock is the amount of time a given

component can be on the manufacturing floor before it absorbs a threshold of moisture that puts it at risk for defects such

as popcorning or other moisture-related defects that can occur during manufacturing. Some of these defects are invisible

to the naked eye and can pass initial quality inspection, but fail prematurely in the field.

The floor life clock is determined by the MSL of the component and ranges from MSL 1, which allows for unlimited floor

time, to MSL 6, which requires mandatory baking prior to use 100% of the time. For this reason, the discussion herein

focuses on MSL 2-5, where some limited amount of floor time is allowed without having to bake the component. In general,

the higher the number, the more sensitive to moisture the component is. Some of these levels have subcategories,

delineated as an ‘a’ suffix, which indicates a higher level of moisture sensitivity. For example, an MSL 2 component will

allow for a floor time of 365 days, whereas an MSL 2a component will allow for just 28 days of floor time, and an MSL 3

component allows for 7 days.

Maintaining Compliance

Maintaining compliance is a matter of ensuring MSD parts are not exposed to ambient humidity levels -- or any humidity

levels exceeding 5% rH -- for longer than their specified floor life clock. If they do use up their floor life timer, maintaining

compliance requires baking these components to reset their floor life timer before they are used in manufacturing.

So how do you ensure compliance with this standard in the normal storage of moisture sensitive devices (MSD)? It is

important to set quality procedures and tracking around these J-STD MSL schedules, which can be achieved using various

methods. Below are some storage methods for compliance, each with pros and cons:

Moisture Barrier Bags (MBBs)

Moisture barrier bags (MBBs) are sealable bags made of polyethylene and polyester or aluminum film which protect

against moisture penetrating the bag while it is sealed. MBBs are used in conjunction with Humidity Indicator Cards (HICs)

to notify anyone handling the component if the seal has been compromised or if moisture has otherwise reached the

component. MBBs must be packaged in a dry room, or more commonly with a desiccant packet, so the interior of the

sealed bag is dry at the outset.

Benefits of MBBs used with HICs include convenience, ease-of-use, and low acquisition cost. The drawbacks of MBB use

are increased man-hours for packaging and the residual cost of consuming the bags and cards over time. MBBs are also a

one-time use solution, as once the MBB is opened it must go through the sealing procedure again and requires a new

desiccant packet.

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Dry Storage Solutions

Nitrogen (N2) Cabinet

A nitrogen cabinet is what often comes to mind when considering a desiccator cabinet. This is a clear, polyester or

polycarbonate cabinet with connections for nitrogen drip or nitrogen purge functionality. These cabinets supply a

continuous flow of nitrogen to maintain low humidity.

Pros of N2 cabinets include their ability to provide low humidity and inert (prevention of oxidation). By filling the

compartment with nitrogen, oxygen is forced out. This is very helpful in preventing oxidation of metal component leads

that can lead to solderability issues. These are often utilized in clean rooms, as they do not produce any particulates.

Some of cons include the expense of nitrogen supply and the risk of nitrogen being out of compliance with the J-STD

depending on the grade of nitrogen used, as humidity of the nitrogen itself may exceed the 5% requirement. Nitrogen

supplies can range from as low as 3% rH to as high as 8% rH.

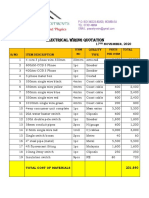

And example of cost comparison over time:

To calculator your own cost savings, use our free cost savings calculator tool here.

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Desiccant Cabinets

A typical desiccant cabinet is made of metal construction with glass windows on the doors, and integrates dryer modules

which are used to regenerate molecular-sieve desiccant beads such as zeolite. They allow air molecules to pass through,

but trap the larger water molecules. Once the desiccant is saturated, the moisture is removed by heating the beads to

evaporate the moisture. The minimum rH% attainable with molecular-sieve desiccant is 0.5% rH (not zero).

Benefits of a micro-sieve desiccant cabinet include the ability to maintain <5% rH for long-term storage of components.

However, they are not as adept at inerting as N2 cabinets, and also produce particulates which are not suitable for

cleanroom use. Cabinet accessibility (how often the door can be opened) can also be a hindrance, as some desiccant

cabinets take 30-45 minutes to recover to <5% rH to be in compliance again with the J-STD. This means cabinet access

more than once an hour would risk compliance.

Next-generation Desiccant Cabinets

A modern desiccant cabinet uses molecular-sieve (zeolite) as well, and has improved construction and performance with

electronics manufacturing specifically in mind. This may include ESD protective surfaces, improved recovery time

technology for greater accessibility, automatic data logging for audits and reports, or optional N2 plumbing for applications

that need to chemically inert.

Benefits of modern desiccant cabinets include their ability to comply with J-STD, recovering to <5% rH in under 5

minutes in some cases. Many newer solutions also offer automatic data logging and visible status lighting which is

helpful for compliance purposes. One drawback is that they are not as adept at inerting as N2 cabinets unless they have

the option for nitrogen.

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Common Misconceptions

One of the more common misconceptions is that parts can simply be placed in dry storage for a given amount of time to

reset their floor life clock. It’s important to remember that placing components in dry storage will pause the floor life clock,

but does not reset it. To reset the floor life clock, MSD components must be baked according to a J-STD-033 bake schedule,

which will be discussed in the following section.

Another fallacy is that a custom bake schedule will be synonymous with an approved J-STD bake schedule. For example,

assuming a bake can be performed at a hotter temperature like 140° C instead of the maximum approved temperature of

125° C to cut down the needed bake time is a common misconception. In short, unapproved bake schedules produce

unapproved and unknown results.

Baking (schedules, resetting floor life clock)

Baking of components is required once the component’s floor life clock has expired, as in the case of MSL 6 components.

J-STD-033 lays out specific bake schedules, which vary in time for a given MSL part, and provides three different

temperatures at which these parts can be baked: 40° C, 90° C, and 125° C. In general, baking at higher temperatures will

allow for a faster bake, which is convenient as some bake times can extend for days -- or even weeks -- depending on the

thickness and MSL of the component. However, one must be conscious of the packaging, as temperatures of 125° C, or

even 90° C, can damage component packaging, including tapes, trays and reels. If the packaging becomes warped or

deformed, this can cause other problems in pick and place and assembly preparation.

In general, it is best to refer to Table 4-1 of your copy of J-STD-033 for ‘Reference Conditions for Drying Mounted or

Unmounted SMD Packages’. This provides the appropriate time and temperature of the bake for the MSL part, which can

be referenced against the manufacturer specification for the maximum package temperature exposure prior to production.

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Why is J-STD compliance important?

Risk of component failure or field failure due to invisible defects are significant problems. As mentioned previously, some

manufacturing defects due to moisture exposure can be caused by micro-fractures inside a component package, not

simply popcorning failures that are visible to the naked eye. This makes it difficult for automated optical inspection (AOI)

systems and other quality management technologies to trigger a flag in production, and can result in entire lots of products

reaching the field where failures may not be immediate.

For customers in high-reliability industries such as defense, aerospace, automotive, and medical, this simply isn’t an option.

The manufacture of missile guidance systems, anti-lock brake controllers, self-driving technology, or pacemakers require

fail-safe quality and control. There are countless examples of faulty airbags in cars, or anti-lock brake malfunction or

airbag deployment mistakes that have resulted in injury, lost revenue and lawsuits far exceeding the cost of implementing

a quality, standard-compliant manufacturing process. It is with these realities in mind that evaluation of quality processes,

and a determination of the need for J-STD compliance is highly encouraged.

Want to Learn More?

If you would like to dive deeper into the topic of dry storage please have a look at another recent article, ‘Dispelling Dry

Storage Myths’, available here: https://smartdry.ecd.com/downloads.aspx.

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

References:

• Whitepaper “Why Bake” by ECD

• “MSD-ESD Guide” by ECD

• SmartDRY product Data Sheet

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-06

Guided by Quality, Driven by Passion - www.ecd.com © 2020

Notes:

WORLD HEADQUARTERS ASIA EMEA

ECD North & South America ECD Asia/Pacific ECD Europe/Africa/Middle East

4287-B SE International Way Singapore Office UK Office

Milwaukie, Oregon 97222-8825 U.S.A. Mobile: +65 9692 6822 Mobile: +44 (0) 7903 252560

Tel: +1 503 659 6100/+1 800 323 4548 E-Mail: ecd.asia@ecd.com E-Mail: ecd.europe@ecd.com

Fax: +1 503 659 4422

E-Mail: sales@ecd.com | Web: www.ecd.com

• Award winning products, service & software • No-cost ECD Online Training •

Accredited Labs Member of Awards Social Networks

Pioneers of SmartDRY™ Intelligent Dry Storage 2020-05

Guided by Quality, Driven by Passion - www.ecd.com © 2020

You might also like

- Individual FEA ReportDocument12 pagesIndividual FEA ReportShahmeer KhalidNo ratings yet

- How To Mothball and Decommission Industrial PlantsDocument4 pagesHow To Mothball and Decommission Industrial Plantswholenumber100% (3)

- Intan Moisture Sensitive Device GuideDocument1 pageIntan Moisture Sensitive Device GuideAdair NettoNo ratings yet

- FG00212 Cashbox Cleaning ProceduresDocument2 pagesFG00212 Cashbox Cleaning ProceduresHansel Manuel Torres EyssericNo ratings yet

- Moisture Sensitive Devices (MSD) / Moisture Sensitivity Levels (MSL)Document16 pagesMoisture Sensitive Devices (MSD) / Moisture Sensitivity Levels (MSL)Muneendra Sharma100% (1)

- Ucts/? Gclid Cnxxzflmhascfyd66Wod - 0oe0 Q Ers/02 - Cleaning PDFDocument8 pagesUcts/? Gclid Cnxxzflmhascfyd66Wod - 0oe0 Q Ers/02 - Cleaning PDFkahani20099731No ratings yet

- Mothballing Requires More Than Idle ThoughtDocument4 pagesMothballing Requires More Than Idle Thoughtfawmer61No ratings yet

- Megayacht Imperial Antifouling DataDocument3 pagesMegayacht Imperial Antifouling DatakormatekNo ratings yet

- Case For Contamination Control PDFDocument12 pagesCase For Contamination Control PDFchanayireNo ratings yet

- Managing Moisture Damage in PCBs 1Document4 pagesManaging Moisture Damage in PCBs 1Adair NettoNo ratings yet

- MSD ProcedureeDocument22 pagesMSD Procedureeram dhukeNo ratings yet

- Mothballing GuideDocument8 pagesMothballing GuideJasper MaraisNo ratings yet

- Cold Warehouse NMMDocument5 pagesCold Warehouse NMMRana JahanzaibNo ratings yet

- Assignment ATFDocument2 pagesAssignment ATFduafareed711No ratings yet

- Some Recent Advances in Drying Technologies To Produce Particulate SolidsDocument15 pagesSome Recent Advances in Drying Technologies To Produce Particulate Solidsconker4No ratings yet

- Süd-Chemie BDocument3 pagesSüd-Chemie BJose VegaNo ratings yet

- 7 Steps To Selecting A Quality DesiccantDocument2 pages7 Steps To Selecting A Quality DesiccantMohammed AlShammasiNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Solutions For Long-Term Storage of Electronic Components and CompositionsDocument3 pagesSolutions For Long-Term Storage of Electronic Components and CompositionsJoão Pedro AlmeidaNo ratings yet

- Loctite MR 5923™: Technical Data SheetDocument2 pagesLoctite MR 5923™: Technical Data Sheetraffabox84yahoo.itNo ratings yet

- Some Recent Advances in Drying Technologies To Produce Particulate SolidsDocument15 pagesSome Recent Advances in Drying Technologies To Produce Particulate Solidsambrosio85No ratings yet

- Penguard Express ZPDocument5 pagesPenguard Express ZPMustafa Al-YasseriNo ratings yet

- Az 6600 Series (For HW 1)Document4 pagesAz 6600 Series (For HW 1)Max LiaoNo ratings yet

- Storage and Handling: Excessive HeatDocument4 pagesStorage and Handling: Excessive HeatMike MotariNo ratings yet

- Masterclass 52 - DemudificationDocument7 pagesMasterclass 52 - DemudificationsofyangunawanNo ratings yet

- Jet Mastic 800Document3 pagesJet Mastic 800jopersa9No ratings yet

- DryKeep BrochureWEBDocument16 pagesDryKeep BrochureWEBRichard SyNo ratings yet

- Anhydro Spray Bed Dryer: ForproductionofdustfreepowdersDocument8 pagesAnhydro Spray Bed Dryer: ForproductionofdustfreepowdersMilos MijatovicNo ratings yet

- Hardtop CA Technical Data Sheet JotunDocument5 pagesHardtop CA Technical Data Sheet JotunSam JoseNo ratings yet

- Preservation Procedure For Material Under Stand StillDocument7 pagesPreservation Procedure For Material Under Stand StillsvvsnrajuNo ratings yet

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- The Screw and Barrel SystemDocument31 pagesThe Screw and Barrel SystemAnonymous oyUAtpKNo ratings yet

- Modulyo Freeze Dryers: Delivering Maximum Flexibility For Life Science ApplicationsDocument16 pagesModulyo Freeze Dryers: Delivering Maximum Flexibility For Life Science ApplicationsJose luisNo ratings yet

- SD Freeze Drying BrochureDocument8 pagesSD Freeze Drying BrochureSNS EnerjiNo ratings yet

- Barrier 80Document5 pagesBarrier 80adeoye_okunoyeNo ratings yet

- The Misconceptions of Silica GelDocument6 pagesThe Misconceptions of Silica GelShofi MuktianaNo ratings yet

- Jotaguard 630Document4 pagesJotaguard 630Christine HermawanNo ratings yet

- Zentrifix F 92Document2 pagesZentrifix F 92Roberto_PrrNo ratings yet

- Glass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Document18 pagesGlass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Syed Arsalan Afsar100% (2)

- MBCC Masterseal 345 Tds v4Document2 pagesMBCC Masterseal 345 Tds v4shashikantNo ratings yet

- Dimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsDocument4 pagesDimetcote 6: Inorganic Zinc Silicate Coating Product Data/ Application InstructionsYokesh Anand RNo ratings yet

- Dow Corning RTV InfoDocument20 pagesDow Corning RTV InfoLevent ÖnderNo ratings yet

- Leaflet D 40 Storage Conditions For Aeronautical SuppliesDocument17 pagesLeaflet D 40 Storage Conditions For Aeronautical SuppliesAraNo ratings yet

- Intergard 986Document4 pagesIntergard 986Ashta VakrNo ratings yet

- CO2 DatasheetDocument8 pagesCO2 DatasheetAwad BasyounyNo ratings yet

- A Guide To Gland Packing, Selection of Gland Packing, Standard SizesDocument15 pagesA Guide To Gland Packing, Selection of Gland Packing, Standard SizesFakhreddine ZahiNo ratings yet

- MSL3 Guideline 1Document3 pagesMSL3 Guideline 1Alex GarciaNo ratings yet

- Megayacht Royal AntifoulingDocument3 pagesMegayacht Royal Antifoulingasjoben1002No ratings yet

- Lithium Battery (SMK)Document3 pagesLithium Battery (SMK)HemonNo ratings yet

- FTA129eng Pharm GuidelinesDocument8 pagesFTA129eng Pharm GuidelinesNaser JahangiriNo ratings yet

- 10 Goldenrules in Eco-DesignDocument25 pages10 Goldenrules in Eco-Design1861969No ratings yet

- Rotary Dryer ThesisDocument8 pagesRotary Dryer Thesisafkoierfb100% (2)

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Document4 pagesTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNo ratings yet

- 2016 03 BINDER Climate Chamber Norm ENDocument2 pages2016 03 BINDER Climate Chamber Norm ENJoan Ferrao GenescàNo ratings yet

- Wet Lay Up in BoilerDocument5 pagesWet Lay Up in BoilersprotkarNo ratings yet

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- Jotun Pioner Topcoat Application Guide - AlkideDocument4 pagesJotun Pioner Topcoat Application Guide - AlkideChaerul AnwarNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Cold chain Business Planning and Strategy: Design, Retrofit And Maintenance Of Cold Storages And Pack Houses: Business strategy books, #3From EverandCold chain Business Planning and Strategy: Design, Retrofit And Maintenance Of Cold Storages And Pack Houses: Business strategy books, #3No ratings yet

- GTI Cobar Xray Article 061421Document4 pagesGTI Cobar Xray Article 061421Adair NettoNo ratings yet

- Concepts and Terminology Used in Printed Circuit Boards (PCB) - Electrosoft EngineeringDocument6 pagesConcepts and Terminology Used in Printed Circuit Boards (PCB) - Electrosoft EngineeringAdair NettoNo ratings yet

- An Engineer S Guide To Component Re-Conditioning Using The RHSD ProcessDocument6 pagesAn Engineer S Guide To Component Re-Conditioning Using The RHSD ProcessAdair NettoNo ratings yet

- IMC Thickness StatsDocument6 pagesIMC Thickness StatsAdair NettoNo ratings yet

- Counterfeit Integrated CircuitsDocument15 pagesCounterfeit Integrated CircuitsAdair NettoNo ratings yet

- Component Level Reliability For High Temperature Power ComputingDocument7 pagesComponent Level Reliability For High Temperature Power ComputingAdair NettoNo ratings yet

- SMT Apr2018Document94 pagesSMT Apr2018Adair NettoNo ratings yet

- Moisture Measurement in Pcbs IpcDocument10 pagesMoisture Measurement in Pcbs IpcAdair NettoNo ratings yet

- SMT007 Dec2020Document100 pagesSMT007 Dec2020Adair NettoNo ratings yet

- Intan Moisture Sensitive Device GuideDocument1 pageIntan Moisture Sensitive Device GuideAdair NettoNo ratings yet

- SMT - TODAY 34-dlDocument60 pagesSMT - TODAY 34-dlAdair NettoNo ratings yet

- SMT007 July2021Document110 pagesSMT007 July2021Adair NettoNo ratings yet

- Flux and CleaningDocument2 pagesFlux and CleaningAdair NettoNo ratings yet

- Three Ways Ai Helps You Hit Your Sales Goals: EbookDocument9 pagesThree Ways Ai Helps You Hit Your Sales Goals: EbookAdair NettoNo ratings yet

- Academic CalendarDocument16 pagesAcademic CalendarSanttosh Kummar AgathamudiNo ratings yet

- Learning Unit 03Document9 pagesLearning Unit 03Lucky Lehlohonolo ChakaNo ratings yet

- A New Method For Learning Decision Trees From Rules: Amany Abdelhalim, Issa TraoreDocument6 pagesA New Method For Learning Decision Trees From Rules: Amany Abdelhalim, Issa TraoreRV SreehariNo ratings yet

- Технический мануал ProoneDocument200 pagesТехнический мануал ProoneAIDNo ratings yet

- Daa C6Document14 pagesDaa C6amanterefe99No ratings yet

- Single Line SKF GreeaseDocument204 pagesSingle Line SKF GreeaseNakul RNo ratings yet

- Activity 3 - Dorado, VDocument4 pagesActivity 3 - Dorado, VVenus Bacaro DoradoNo ratings yet

- Casio FX 3800PDocument6 pagesCasio FX 3800PRamiroRinconSuarezNo ratings yet

- Types of Educational PlanningDocument35 pagesTypes of Educational PlanningJuju Zenemij91% (11)

- New Fire Water System Project Bontang Kalimantan Timur: Site Inspection and Test Plan (ITP) For Fire Water Tank WorksDocument34 pagesNew Fire Water System Project Bontang Kalimantan Timur: Site Inspection and Test Plan (ITP) For Fire Water Tank WorksTim JalurNo ratings yet

- Eligible Participants For CertificateDocument112 pagesEligible Participants For Certificate001srvnNo ratings yet

- Pneumatic PumpDocument4 pagesPneumatic PumpMuchlis MuchlisNo ratings yet

- SS Lab Manual (Ar20) 2022-23Document53 pagesSS Lab Manual (Ar20) 2022-23Shankar0% (1)

- 700T Extrusion Press - Back Loading - Long Stroke 240407Document9 pages700T Extrusion Press - Back Loading - Long Stroke 240407amitsehgal9No ratings yet

- Bill of Quantity Schedule For Boiler SystemDocument4 pagesBill of Quantity Schedule For Boiler SystemshakibNo ratings yet

- Multi TenantDocument5 pagesMulti TenantRobbyandi PerdanaNo ratings yet

- Intrusive vs. Non-Intrusive Electric Actuators: Which Option Is Right For Your Installation?Document8 pagesIntrusive vs. Non-Intrusive Electric Actuators: Which Option Is Right For Your Installation?Thanachai TengjirathanapaNo ratings yet

- How To Boot From A USB Flash Drive in VirtualBox Pen Drive LinuxDocument7 pagesHow To Boot From A USB Flash Drive in VirtualBox Pen Drive Linuxفارس فارسNo ratings yet

- Keywords: Time of Provision, Delay in Medical RecordsDocument10 pagesKeywords: Time of Provision, Delay in Medical RecordsnabilaNo ratings yet

- Industrial Automation: Gravity Roller ConveyorsDocument3 pagesIndustrial Automation: Gravity Roller ConveyorsRudresh RakeshNo ratings yet

- Flat Cool Pipes / MHP Series: FeaturesDocument3 pagesFlat Cool Pipes / MHP Series: Featuresmcyt harmonyNo ratings yet

- School of Engineering Technology and Applied Science (SETAS) Advanced Manufacturing and Automation Technology (AMAT)Document6 pagesSchool of Engineering Technology and Applied Science (SETAS) Advanced Manufacturing and Automation Technology (AMAT)anmol singhNo ratings yet

- Purposive CommunicationDocument8 pagesPurposive CommunicationBorgonia, Khryzlin May C.No ratings yet

- Extech 407764 DatasheetDocument1 pageExtech 407764 Datasheetbo cephusNo ratings yet

- MDSReport 6799005210A4Document3 pagesMDSReport 6799005210A4abinayaNo ratings yet

- XI CS Sample PaperDocument5 pagesXI CS Sample PaperPapanhiManege100% (1)

- Assignment 1Document4 pagesAssignment 1Orhan KhanNo ratings yet

- Transformer Wiring QuoteDocument2 pagesTransformer Wiring QuoteOkhwa WangilaNo ratings yet

- MOLEX AssociateManagerSoftwareTesting JDDocument2 pagesMOLEX AssociateManagerSoftwareTesting JDYenumula SaicharanNo ratings yet