Professional Documents

Culture Documents

MAT 402-Syllabus-Spring2021

MAT 402-Syllabus-Spring2021

Uploaded by

Liang FrankOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAT 402-Syllabus-Spring2021

MAT 402-Syllabus-Spring2021

Uploaded by

Liang FrankCopyright:

Available Formats

MAT 402 Polymer Engineering II

Instructor: Dr. Ozge Akbulut,

TA:

Course meeting times: Tue: 2:40–4:30 pm, Fri: 3:40–4:30. There are no recitations for

this class, but you are encouraged to make use of the Instructor's office hours for assistance.

Scope:

The aim of the class is to equip students with 1) polymer processing techniques and the

effect of these processing techniques on polymer structure, 2) aspects of designing

polymeric devices and polymer additives, 3) the properties of reinforced polymers and

related reinforcement methods. Students are assumed to have basic knowledge on polymer

structure-property relationship from Polymer Engineering I and/or ENS 205 classes. The

target audience is materials science and engineering, industrial engineering, and

mechatronics majors.

Learning outcomes:

1. Describe how polymers are processed in industry

2. Describe how processing affects internal microstructure and thus polymer properties

3. Use this understanding in the design of commercial processes for polymer-based objects

4. Apply principles of polymer processing and knowledge on the microstructure of

polymers to define properties and functionality for commercial items

5. Use theory in the design of polymeric products and manufacturing processes

6. Specify suitable manufacturing processes for a range of commercial items

Recommended reading:

McCrum, N. G., Buckley, C.P. and Bucknall, C.B. The Principles of Polymer Engineering, 2nd ed.;

Oxford University Press: Oxford, New York, Tokyo, 1997.

Ashby, M. F. Materials Selection in Mechanical Design, 2nd ed.; Butterworth-Heinemann:

Oxford, Boston, 1999. (This book is also available as an electronic resource in IC Database)

Grading: The grading will be based on one term exam (25%), one group project (20%),

homework (25%), and a final (30%).

Three site visits to (We will discuss how to carry these out online):

Farplas: Injection molding, extrusion, thermoforming

AKSA: Fiber production

Fark Labs: Product design, entrepreneurship

Group project: Students are expected to analyze the manufacturing of a plastic product in

three steps:

1) Specification of the product

• Its function, drawings, expected performance, conditions of use and cost,

market.

2) Specification of the process

• Process type, flow map, and conditions.

3) Specification of the equipment

• Technical specifications, price offers, other products that can be made with

that equipment

4) Presentation

Week 1

Introductory lectures (Background on polymers)

Week 2

Use of polymers in daily life and high-technology products (e.g., in textile and civil

engineering)

Introduction to the Design Project

Industry 4.0, multifunctionality, custom-design, economy

Week 3

Flow properties of polymer melts

Week 4

Extrusion process I

Week 5

Extrusion process II

Student presentations

Week 6

Polymer film production (Blown film, cast film)

Week 7

Injection molding

Mold and process design

Week 8

Thermoforming, blow molding, compression and transfer molding

Week 9

Fabrication of reinforced plastics

Week 10

Micro/nanofabrication methods involving polymers

Week 11

Silicone-based products and their fabrication

Student presentations

Week 12 and 13

Design for manufacture, design for strength, design for toughness and design for X.

Week 14

Student presentations and wrap up

You might also like

- Chapters 1 To 4Document108 pagesChapters 1 To 4Andreu1287100% (1)

- ROland BergerDocument72 pagesROland BergeryssahuNo ratings yet

- Case Study: Non-Metallic ProcessesDocument1 pageCase Study: Non-Metallic ProcessesAmirul FahmieNo ratings yet

- MCE 552 Powder Metallurgy 2018Document6 pagesMCE 552 Powder Metallurgy 2018KEHINDE BABALOLANo ratings yet

- Mechanical Engineering, Course Descriptions Autumn 2013-2014Document11 pagesMechanical Engineering, Course Descriptions Autumn 2013-2014Shah Jehan HanifNo ratings yet

- AeronsyllDocument208 pagesAeronsylljayanth sNo ratings yet

- Module Description 2021 11Document21 pagesModule Description 2021 11PAVAN KUMAR THATANo ratings yet

- Diary: Student DetailsDocument3 pagesDiary: Student DetailsNanditaNo ratings yet

- AeroDocument217 pagesAeroDemo UserNo ratings yet

- L0 MEC205 Zero Lecture UpdatedDocument42 pagesL0 MEC205 Zero Lecture UpdatedJames PrakashNo ratings yet

- Quezon City University: Industrial Engineering DepartmentDocument7 pagesQuezon City University: Industrial Engineering DepartmentJhun Jhunniee CapiliNo ratings yet

- PDFDocument4 pagesPDFGeorge CamachoNo ratings yet

- Mech Pso PDFDocument14 pagesMech Pso PDFMeer Mustafa AliNo ratings yet

- MA2004 Engineering Materials and Manufacturing Processes 23082021Document7 pagesMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNo ratings yet

- Course Description Polymer ProcessingDocument3 pagesCourse Description Polymer ProcessingarobaidiNo ratings yet

- Department: Production Engineering LaboratoryDocument70 pagesDepartment: Production Engineering LaboratorySourabh PradhanNo ratings yet

- Foundry and Forging Laboratory ManualDocument110 pagesFoundry and Forging Laboratory Manualvampiredraak2712No ratings yet

- Materials Lab 28072023Document38 pagesMaterials Lab 28072023ShemelsNo ratings yet

- Mce 653 Advanced Manufacturing TechnologyDocument1 pageMce 653 Advanced Manufacturing TechnologypathakatulNo ratings yet

- Master of Science in Sustainable Materials Engineering: 120 Ects Credits - Language: EnglishDocument4 pagesMaster of Science in Sustainable Materials Engineering: 120 Ects Credits - Language: Englishmuhammad adnanNo ratings yet

- PHD Programme in Mechanical EngineeringDocument7 pagesPHD Programme in Mechanical EngineeringAshok BodaNo ratings yet

- BESCK104DDocument4 pagesBESCK104DNithin Gowdru0% (1)

- BESCK104DDocument4 pagesBESCK104Dyukthareddy.2605No ratings yet

- Emg 4102 CN 1Document3 pagesEmg 4102 CN 1MaxwellNo ratings yet

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesDocument23 pagesBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuNo ratings yet

- Visvesvaraya Technological University, BelgaumDocument41 pagesVisvesvaraya Technological University, BelgaumBen GeorgeNo ratings yet

- MEC 322 OutlineDocument3 pagesMEC 322 OutlineBob jonesNo ratings yet

- Production and Industrial EngimeeringDocument47 pagesProduction and Industrial Engimeeringrathish14uNo ratings yet

- Course File EditED 1.1.1...Document54 pagesCourse File EditED 1.1.1...jyothi bogaNo ratings yet

- OR Assignment 2022-23Document22 pagesOR Assignment 2022-23Pratham DakoriaNo ratings yet

- 2nd Sem PDM SyllabusDocument11 pages2nd Sem PDM SyllabusVinay AlagundiNo ratings yet

- Production EngineeringDocument39 pagesProduction EngineeringkeepingbusyNo ratings yet

- EMM2512 AssignmentDocument4 pagesEMM2512 AssignmentVenkatesh GangadharNo ratings yet

- An Industry Perspective On Polymer Process Modeling: February 2002Document12 pagesAn Industry Perspective On Polymer Process Modeling: February 2002Esfand DNo ratings yet

- Additive Manufacturing PrintableDocument42 pagesAdditive Manufacturing Printablechahira DNo ratings yet

- Tribology NotesDocument70 pagesTribology NotesPRAVIN PATOLE100% (2)

- Fitting ManualDocument72 pagesFitting Manualayush bindalNo ratings yet

- Course - Outline Tex 209 - Fall-2020Document6 pagesCourse - Outline Tex 209 - Fall-2020naimur.7566No ratings yet

- Ptam CP 25.7.22Document8 pagesPtam CP 25.7.22SAMUEL SANJAY RAJA R MECHNo ratings yet

- 22ESC144Document4 pages22ESC144Naveen S BasandiNo ratings yet

- M - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem)Document105 pagesM - SC Garment Manufacturing Technology (GMT) (Scheme & Syllabus 1st To 4th Sem)Mohammad Zahirul IslamNo ratings yet

- OUHK TM1220 Building Practices and NDTDocument19 pagesOUHK TM1220 Building Practices and NDTMichael ChungNo ratings yet

- Materials of Construction, Operation and Maintenance in The Chemical Process IndustriesDocument37 pagesMaterials of Construction, Operation and Maintenance in The Chemical Process IndustriesNam SanchunNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- Manufacturing TechnologyDocument34 pagesManufacturing TechnologyGeorge OliverNo ratings yet

- BEMEM103Document4 pagesBEMEM103Keerti HulakantanavarNo ratings yet

- PP-I Syllabus (SH2019)Document2 pagesPP-I Syllabus (SH2019)Vishwa RohindNo ratings yet

- Brochure ICMEDocument3 pagesBrochure ICMEkumar deepakNo ratings yet

- Integrated Design Methods For The Simulation of Fibre Based StructuresDocument10 pagesIntegrated Design Methods For The Simulation of Fibre Based StructuresThao HoangNo ratings yet

- Workshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadDocument28 pagesWorkshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadECE 33 Sahil ManglaNo ratings yet

- SSRN-id4072720 EXEMPLODocument6 pagesSSRN-id4072720 EXEMPLOAdriano FlorencioNo ratings yet

- Course Outline MEFB213Document10 pagesCourse Outline MEFB213lucasNo ratings yet

- Elements of Mechanical Engineering: Course Learning ObjectivesDocument5 pagesElements of Mechanical Engineering: Course Learning ObjectivesSudheer Kini KNo ratings yet

- Become What You Want To Be: Unit GuideDocument6 pagesBecome What You Want To Be: Unit GuideMq SharozNo ratings yet

- Manufact Engg FDocument31 pagesManufact Engg FtskcbeNo ratings yet

- Introduction To Composite MaterialsDocument3 pagesIntroduction To Composite Materialsvenugopal_aeroNo ratings yet

- Mechainical EngineeringDocument12 pagesMechainical Engineeringsai thesisNo ratings yet

- MQF Level 3: Diploma in Mechanical EngineeringDocument9 pagesMQF Level 3: Diploma in Mechanical EngineeringA SNo ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- 2021 - Nat Comm - Art - Mn-PEPI Organic Barrier LocDocument8 pages2021 - Nat Comm - Art - Mn-PEPI Organic Barrier LocLiang FrankNo ratings yet

- 2022-J. Am. Chem. Soc.-Mechanically Interlocked VitrimersDocument11 pages2022-J. Am. Chem. Soc.-Mechanically Interlocked VitrimersLiang FrankNo ratings yet

- 2019 - JACS - Art - Bismuth Pero EPRDocument22 pages2019 - JACS - Art - Bismuth Pero EPRLiang FrankNo ratings yet

- 2011 - JMR - Art - From First Harmonic To First DerivativeDocument5 pages2011 - JMR - Art - From First Harmonic To First DerivativeLiang FrankNo ratings yet

- 2014 - JPCL - Art - Perovskite Charge Trapping EPRDocument6 pages2014 - JPCL - Art - Perovskite Charge Trapping EPRLiang FrankNo ratings yet

- CD 01 - MDSP Aug 2019 FinalDocument5 pagesCD 01 - MDSP Aug 2019 FinalMaki DizonNo ratings yet

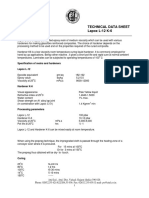

- Lapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingDocument2 pagesLapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingMadhu Bilugali MahadevaswamyNo ratings yet

- "Grdslab" - Concrete Slab On Grade Analysis: Program DescriptionDocument4 pages"Grdslab" - Concrete Slab On Grade Analysis: Program DescriptionAlexi Milan0% (1)

- Science Fest Script 3Document9 pagesScience Fest Script 3vaibhavi singhNo ratings yet

- C649Document18 pagesC649Gato SesaNo ratings yet

- Reinforced Earth StructuresDocument19 pagesReinforced Earth StructuresRohit ChaurasiaNo ratings yet

- Heat Treatment Notes PDFDocument10 pagesHeat Treatment Notes PDFSushilNo ratings yet

- Scaffolding PropDocument6 pagesScaffolding Propwaquarshai100% (1)

- ShaliFloor SL TC 4EDocument3 pagesShaliFloor SL TC 4EPrashant BaruaNo ratings yet

- Eg244 Assignment 2Document5 pagesEg244 Assignment 2Anthony MubangaNo ratings yet

- ISO Bearing Damage Classification & TerminologyDocument63 pagesISO Bearing Damage Classification & Terminologykcp1986100% (3)

- Selection of Materials For Cutting ToolsDocument21 pagesSelection of Materials For Cutting ToolsKarthick NNo ratings yet

- Vinnapas® Ep 400: Product DescriptionDocument2 pagesVinnapas® Ep 400: Product DescriptionrjmscNo ratings yet

- Constant Head PermeabilityDocument1 pageConstant Head PermeabilityDr Wong Kim YuenNo ratings yet

- EG-180 Past Exam PaperDocument3 pagesEG-180 Past Exam PaperAndrew BeadleNo ratings yet

- KIRAN PPT-unit 3Document54 pagesKIRAN PPT-unit 3RED EYENo ratings yet

- 202004032240236827nksingh Polymer ProcessingDocument9 pages202004032240236827nksingh Polymer ProcessingMuhammad Umair Akbar GujjarNo ratings yet

- Structure BasedDocument36 pagesStructure BasedsggdgdNo ratings yet

- Exercise 1Document6 pagesExercise 1Sunny KashyapNo ratings yet

- Underpinning NotesDocument3 pagesUnderpinning NotesJon 'Bionic-Kidd' FarquharsonNo ratings yet

- Shafts and Shaft Components: Machine Design IIDocument48 pagesShafts and Shaft Components: Machine Design IIEngr Aleem AmjadNo ratings yet

- Spur Gear) SoluctionDocument7 pagesSpur Gear) Soluctionrip111176No ratings yet

- Various Data On Pulveriser MachineDocument3 pagesVarious Data On Pulveriser Machine19ME056 PATEL JAY DALSUKHBHAINo ratings yet

- Bonding Effectiveness of Contemporary Composite Cements To Dentin After 6 Month Water StorageDocument7 pagesBonding Effectiveness of Contemporary Composite Cements To Dentin After 6 Month Water Storageerma gusmayantiNo ratings yet

- An Application of Chaboche Model To Predict Uniaxial and Multiaxial RatchetingDocument10 pagesAn Application of Chaboche Model To Predict Uniaxial and Multiaxial RatchetingKamel FedaouiNo ratings yet

- Murali - Metrology & Measurements Lab ManualDocument30 pagesMurali - Metrology & Measurements Lab ManualsubhashNo ratings yet

- Irc Gov in 083-2 2018Document52 pagesIrc Gov in 083-2 2018manupriyaNo ratings yet

- WHY STUDY Phase Transformations?Document21 pagesWHY STUDY Phase Transformations?Rowen PratherNo ratings yet

- 8-6 Fits and AllowancesDocument15 pages8-6 Fits and AllowancesshivendrakumarNo ratings yet

- 3 Phase ModelsDocument24 pages3 Phase Modelsfaroukm91No ratings yet