Professional Documents

Culture Documents

Cap 12a Understanding Const Draw

Cap 12a Understanding Const Draw

Uploaded by

Leyla Moran0 ratings0% found this document useful (0 votes)

80 views11 pagesOriginal Title

CAP 12A UNDERSTANDING CONST DRAW

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

80 views11 pagesCap 12a Understanding Const Draw

Cap 12a Understanding Const Draw

Uploaded by

Leyla MoranCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 11

Understanding

for Housing and Small Buildings

v

FR 2onT ELEY

eT oh is

we 1 #4 The Building Envelope

LEARNING OBJECTIVES

After completing this chapter, you will be able to:

* Read and interpret drawings for

information related to the building

envelope.

‘+ Explain the qualities of an air barrier.

+ Explain the qualities of @ vapour

retarder (barrier)

+ Interpret detail drawings regarding

the placement of the air and vapour

retarders

* Describe the placement of the air/

vapour barrier around the structure,

INTRODUCTION

This chapter introduces you to the building enve-

lope, which consists of all sides of the building

that directly separate the inside environment

from the outside environment. This includes all

exterior facing walls including foundation walls,

ceilings, and floors (e.g., the basement floor slab).

THE BUILDING

ENVELOPE

Historically buildings were not insulated or kept

airtight. However, buildings today are increas-

ingly airtight due to higher energy costs. As a

result, much greater care has to be taken

regarding how the building is sealed. Besides

lowering energy costs and providing a very com-

fortable dwelling, a tighter building envelope

can also bring with it an array of other chal

lenges such as control of indoor moisture. For

example, a tight envelope means reduced air

leakage and that humidity generated by people

living in the home remains inside. Other con

cerns also arise regarding indoor air quality and

pollutants.

Programs such as the R2000 program

Energuide for New Houses and Energy Star for

New Houses have helped place Canada on the

leading edge of energy efficiency. These pro-

grams and certifications place very stringent

requirements (higher requirements than the cur

rent NBC) on home building design and con.

struction. While most homes are not yet con:

structed to these high standards, many of the

improvements to the NBC over the last 20 years

have been and continue to be a result of

adopting a number of best practices from these

and similar-type programs (refer to Division B

Part 9.25 of the NBC}. Several provincial codes

are adopting standards such as Energy Star for

New Homes and will be phasing them in over

the coming years. There is an ongoing debate as

to how high the NBC standards should be and

how higher standards may affect affordability.

Heat Flow

Heat moves from warm to cold, so in winter

warm inside air moves through the envelope

toward the cold outside air. In summer the

reverse is true; hot outside air moves toward the

cooler inside air.

There are three methods of heat transfer:

+ Conduction: The transfer of heat through a

solid from a higher temperature to a lower

temperature. Heat will flow through mate:

rials at different rates. A material’s capacity

to resist conductive heat flow is measured

by R value in imperial measurement and by

RSI value for metric measurement. Insulating

materials such as fibreglass will have an R

and RSI value labelled on the package when it

arrives on site. The NBC designates minimum.

263

264 —_UNDISTANDING CONSTRUCTION DRAWINGS FOR HOUSING AND SMALL EULDINGS

acceptable standards of RSI value for the

building envelope, and provincial codes may

adopt further standards based on regional

climatic conditions. The construction draw-

ings will specify the type of insulation and

the R or RSI value required for installation.

This information is usually found in the con-

struction notes or specifications.

The term thermal bridging describes the

movement of heat across a solid. The effects

of thermal bridging can be offset by applying

extruded Styrofoam to the outside of the

frame wall as discussed in Chapter 8. For

example, studs and plates constructed out of

wood form a better thermal bridge than insu:

lation placed in a wall; therefore, if Styrofoam

is placed over the entire surface area of a

wall it will greatly reduce the thermal bridge

through the wood, making a more energy

efficient wall

Refer to Table 12.1 for a listing of R and RSI

values for different materials. Notice that the

R value of wood is much lower (1.3 per inch)

than the R value of fibreglass insulation (3.2

per inch). Interpreting this information with an

understanding of heat transfer helps you to

understand why the building envelope needs

to be designed with consideration of the com-

ponents and their placement in the envelope.

FIGURE 12.1

Methods of heat transfer

TABLE 12.1

‘Thermal Resistance Table

CoE [So

_Shest stool Ns Ns

oot a

nos 13

Gypsum board 0.006 09

Plywood 009 13

0sB 0.008 13

Insulating fibreboard 0017 25

Cavity Insulation

Fibreglass oon 32

Mineral fibre 0.024 35

Cellulose (blown in) 0.025 36

Urethane foam (sprayed) 081 60

Board Insulation

Rigid fibreglass 0.029 a2

Extruded polystyrene 034 50

ATypes Wi) —

Polysocyanurate nse 8

Polyurethane aos 60

NS = no significant resistance

Source: CMHC Best Practice Guide: Wood Frame Envelopes,

Table 31, Thermal Resistance

(becomes less dense) and

rises—drawing more coo!

fir in from the sides to be outside inside

heated up

{eold)_—_twarm)

yh

* 6

ae?

*

*

*

Gendustion

*

‘energy (sunlight)

+ Convection: The transfer of heat in a liquid or

gas by upward movement of the heated

medium. Similar to a forced-air furnace

system, warm air will rise and then fall as it

cools. Convection currents within a wall

cavity will increase the rate of heat transfer.

Therefore it is important that insulation fills

all cavities and that there are no spaces

between the insulation and vapour retarder

for convection loops to form. The insulation

must not be overly compressed, otherwise it

will lose R value.

+ Radiation: The transfer of heat by rays, such

as that given off from the sun or other means

such as a fireplace. This type of heat transfer

heats objects instead of heating air, pro

viding a very comfortable heat that does not

seem drafty for the occupants.

Moisture Movement

Moisture moves in and out of a building in three

main ways:

+ Air leakage: Caused by moisture-laden air

moving through a building and possibly con:

densing in a wall cavity. When moisture:

laden air reaches the dew point it will

condense. (The dew point occurs when the

relative humidity level [RH] reaches 100%.)

+ Vapour diffusion: The transfer of moisture

through materials. The rate of moisture

movement depends on the permeability of

the material

+ Rain penetration: Can occur through the

exterior cladding or any of the junctions and

intersections of materials in the building

envelope. Moisture may also enter through

capillary action (the effect of being sucked in

or sucked up) from contaet at grade level.

Air Barriers

An air barrier reduces air leakage (which is diffi

cult to totally eliminate) from the structure. The

air barrier system must be continuous and as air-

tight as possible. Air barriers can be used on the

inside or outside of a structure. An air/vapour

barrier used on the inside (generally the most

popular method) uses a 6 mil polyethylene sheet

material that is approved for use as a vapour

retarder to provide a continuous seal around all

walls and the ceiling. With this method it is

important to seal all penetrations including

CHAPTER 2 THEGUILOING ENVELOPE = 265

around electrical boxes, and holes made through

plates for wiring and plumbing vent stacks. A

spun-bonded olefin header wrap (usually

‘Tyvek®, or Typar® building wrap) is used at floor

level to ensure the integrity of the air barrier

around the joists.

Another method of creating an air barrier

uses @ spun-bonded olefin wrap applied contin-

uously to the outside walls and connected to the

vapour retarder on the ceiling. Itis important that

air barriers (known as building wraps) applied to

the outside of the wall are constructed from a

material that breathes so as to allow any mois-

ture that collects inside the wall to dry out. A

building wrap acting as an air barrier is a much

more energy efficient alternative to regular

building paper (also referred to as tar paper),

which is used to keep moisture out but does not

act as an air barrier.

Vapour Retarder

The vapour retarder prevents moisture from dif-

fusing through materials into the wall. The vapour

retarder is placed on the warm side of the wall; in

Canada the warm side of the wall is on the interior

of the house. The type of vapour retarder depends

on the materials used in the wall assembly. The

most common method of installing a vapour

retarder is to apply a 6 mil polyethylene to the

interior wall on top of the studs.

While conventional theory stresses the impor-

tance of a tight vapour retarder to the envelope,

it is actually the air barrier that needs to form the

tightest seal. If large amounts of air flow through

any openings in the envelope, large amounts of

‘moisture-laden air can condense at the dew point

within the wall, causing localized problems (e.g.,

mould and rot). However, this can be prevented

when the air/vapour barriers are part of a com-

bined system. A combined system is one in which

the polyethelene acts as both an air and vapour

barrier on the walls, forming a continuous seal,

while at the floor a header wrap acts as an air bar-

rier on the outside, and poly cut and placed

between the joists covering the fibreglass insula-

tion acts as the vapour barrier on the inside (refer

to Figure 12.4 for more detail). The addition of a

building wrap to the outside of the entire wall

‘surface will provide a higher level of protection

(best practice, not a NBC requirement).

266 —_UNDERSTANONNG CONSTRUCTION DRAWINGS FOR HOUSING AND SMALL BUILDINGS

Caulks and Sealants

Caulks and sealants are used to seal any points

where moisture or air leakages might occur (e.9.,

around windows, doors, flashings, and at joints

in the air/vapour barrier). Caulks and sealants

include acrylic, butyl rubber, latex, polyurethane,

and silicone. Caulks and sealants have different

uses (e.g., acoustic sealant is used extensively in

sealing joints in polyethylene because it remains

highly flexible). Outside silicone and latex caulks

are very popular because of their resistance to

freeze-thaw cycles and their expansion and con-

traction qualities. Where large beads of caulking

are required the joint should be filled with a

backer rod to avoid the caulking adhering to

more than two surfaces at once, which can lead

to premature failure.

Ventilation

Ventilation is required in attic space to ensure

that any moisture:laden air that condenses in the

attic can dry out. The NBC requires that ventila-

tion be provided in attic space at a ratio of at

FIGURE 12.2

least 1:300. This means if there is 300 square feet

of ceiling area that at minimum 1 square foot of

ventilation must be provided. This is most effec-

tively accomplished by providing a combination

of soffit and roof vents.

Older buildings have envelopes that leak

excessively compared to new buildings, so fresh

indoor air is not an issue in these buildings.

However, in new tightly sealed buildings fresh

air must be brought in from outside; this can be

accomplished by exhausting inside air out with

the use of exhaust fans or by simply opening a

window. Unfortunately, both defeat the purpose

of building energy efficient. A better solution is

to incorporate a heat recovery ventilator (HRV)

into the HVAC system. An HRV will remove stale

indoor air and exhaust it out after transferring

much of the heat to thin metal plates that then

transfer the heat to new fresh air being brought

in at the same time on the other side of the plate.

This greatly improves the quality of air in the

building while maintaining the energy efficien-

cies gained by a tight envelope.

Examples of two- and three-surface bonds, and the advantage of using backer rod

‘TWO-SURFACE BOND

on 4 Fein :

Ss —

BACKER ea *

foo

THREE-SURFACE BOND

eevee on a

——- SS Soe

> +> <>

MATERIAL MOVEMENT

MATERIAL MOVEMENT

MATERIAL MOVEMENT

CHAPTER 12. THEGULDINGENVELORE = 267

FIGURE 12.3

Ventilation provided in the soffit and by a ridge vent installed along the ridge; alternatively, individual roof

vents could have been placed at a few points in the roof

CAP SHINGLES

RIDGE Vent. /

POSITIVE

VENTILATION

CHUTE

AIR.INSULATION,

/ DAM

'\ venTED SOFFIT

AVR MOVEMENT

POSITIVE VENTILATION CHUTE

FIGURE 12.4

ection detail showing how a heat recovery ventilator (HRV) works

Components of an HRV

Controls INTERIOR ou;

NTERION TDOORS

Screen

Exhaust

airoutlet

Fresh air

to

Holise

Stale air

‘rom

House dhs

resh air

intake

Soaten

cision pie

with water

(Note: All the parts shown here may not be found on all HRVs.)

268 —_ UNDERSTANDING CONSTRUCTION DRAWINGS FOR HOUSING AND SMALL BULOINGS

FIGURE 12.5

Building envelope detail for foundation intersection from CMHC Best Practice Guide: Wood Frame

Envelopes

—ALvanizen arcK TIE

SALED Info ‘STUD

laRIck VENEER

138 mm (11/2 In.) AIR SPACE

PERFORATED 15 LB. ASPHALT

JBULDING PAPER (WOISTURE

BARRIER (MB)

[13'mm (7/16 in.) OSB SHEATHING

J38 x 140 mm (NOMINAL 2 x 6

fn) wooo STUDS AT 400 mm (16

fn.) 06. 08 600 mm (24"Tn)

‘SEALANT | ma

IRS! 3.52 (R=20) BATT INSULATION

10.15. mm (6 mil) POLYETHYLENE.

(48 AND VR)

2.7 mm (1/2 in.) GYPSUM

BOARD

BATT INSULATION

I POLYETHYLENE

PiuLow, “Friction

FIT IN PLACE (VRQ)

I |___ sPUNBONDED OLEFIN (AB)

Vises |AT 600 mm (24 in) OC.

GALVANIZED METAL FLASHING

wi DP eboe

c+

eters

[0.15 mm (6 il)

[OKMPPROOFING TO GRADE

) POURED

[CONCRETE FOUNDATION WALL

I Teens", (W.8.)

[PERFORATED ABOVE GRADE

[RSI 2.11 (R12) BATT INSULATION

10.05 mm (2 nil)

[POLYETHYLENE (48) AND VR)

112.7 mm (1/2 in.) GYPSUM

lsoaRD

BRICK VENEER WALL AT FOUNDATION G)

SCALE: 1:5 BASIC POLYETHYLENE STUD WALL (WALL ASSEMBLY A)

CHAPTER 12 THEGULONGEWHLOR =: 26O

FIGURE 12.6

Building envelope detail for intersection of first-floor walls, second floor, and second-floor walls at bathtub

from CMHC Best Practice Guide: Wood Frame Envelopes

TLE BACKER BOARD

OR MOSTURE RESISTANT

Crest BOARD

aaTua.

CONTINUOUS GYPSUM BOARD

| _— petinD eaTiTUs

BRICK VENEER 38 mm (1 1/2 in)

AIRSPACE.

PERFORATED 15 &, ASPHALT BUILDING

lpaPeR (WE)

1 mm (7/16 i) 058 SHEATHING

f 138 x 140 mm (NOMINAL 2 x 6 in)

18 mm (5/0 in) [wooo STUDS’ AT’ 490 mm (16: in.)

TONGUE AND GROW) lo.c. OR 600 mm (24"%n) OG

PLrwoOD. SHEATHIN: [RSI 3.52 (R-20) BATT INSULATION

[0.15 ram (6 mil) POLYETHYLENE (AB

[AND VR)

12.7 mm (1/2 in.) GYPSUM BOARD

SSPUNBONDED OLEFIN

| SHEATHING. MEMBRANE.

BATE INSULATION

IN PoleraVtENe 8)

PILLOW, FRICTION-FIT

IN PLAGE (Wa)

— GaLvanizen RieK ‘TI

NAILED INTO STUD

SENANT I

IH

! 1

BRICK VENEER WALL AT HEADER

SCALE: 1:5 BASIC POLYETHYLENE STUD WALL (WALL ASSEMBLY A)

270 UNDERSTANDING CONSTRUCTION DRAWINGS FOR HOUSING AND SMALL BULOINGS

FIGURE 12.7

Building envelope detail for roof, exterior wall, and ceiling intersection from CMHC Best Practice Guide.

Wood Frame Envelopes

ROOANG SHINGLES.

SELF SEALING” MEMBRANE—TYPE GAVE

PROTECTION (1 200 mm [48 in] HIGH

Nin.)

12.7 mm (1/2 in.) PLYWOOD SHEATHING

H curs

PRE-ENGINEERED WOOD TRUSSES

RSI 7.0 (R40) BATT INSULATION

0.15. mm (6 mil) POLYETHYLENE (AB

/AND VR)

9.x 66 mm (NOMINAL 3/4 x 3 in)

]WoOD FURRING

112.7 mm (1/2 in.) GYPSUM BOARD

PREFORMED VENTILATION SPACER

BLOWN-IN INSULATION

MANTAIN' MINIMUM THICKNESS OF ROOF

INSULATION EQUAL TO THE VALUE OF

}WALL INSULATION OVER EXTERIOR WALL.

RAISED HEEL TRUSS

FAVE PROTECTION To EXTEND

MIN. 300" men (12 in) BEYOND

INSIDE FACE "OF EXTERIOR WALL

e ! PREFINISHED FASCIA

= pero aun

} SOFFIT

Povveriruene (va)

SEALANT (AB)

38 x 89 mm (2 X 4 in.)

wood ‘sTu0'

———— rea. interior

PARTIMON

INTERIOR PARTITION, HORIZONTAL SECTION

SCALE: 1:5 BASIC POLYETHYLENE STUD WALL (WALL ASSEMBLY A)

272 —_unoeestannevs cons RJCTION RAHN FoR HOUSING AND SMALL BUILDINGS

FIGURE 12.9

Electrical box on an exterior wall wrapped with

6 mil polyethylene as part of a continuous air/

vapour barrier

FIGURE 12.10

Electrical box sealed to air/vapour barrier; notice

how the air/vapour barrier wraps around the box

FIGURE 12.11

A specially designed electrical box to be used on

outside walls where the air/vapour barrier can be

sealed to the extended lip around the box

FIGURE 12.12

Bathroom exhaust fan covered with 6 mil polyeth-

ylene. The poly will be sealed to the polyethylene

sheeting that covers the whole ceiling. Notice the

black insulation covering the exhaust duct. This will

be pulled down to prevent moisture-laden air from

both condensing an the duct as warm inside air

flows through it in the colder months of the year,

and causing moisture prablems in the atic

FIGURE 12.13

Acoustic caulking applied to holes made by wiring

through top plate, which will prevent air leakage

through the air barrier. All protrusions of the air bar

rier must be sealed to prevent air leakage.

FIGURE 12.14

This photo taken from the Doncaster house

shows fibreglass insulation installed in the wall

and between joists with 6 mil aiflvapour barrier

installed on top of insulation. Notice the header

wrap {the white material just under the floor joists)

which is providing the tight seal required for the

air barrier, while the polyethylene is providing the

vapour retarder between the joists. It would be

very difficult to provide the tight seal required for

the air barrier if the header wrap were not used.

FIGURE 12.15

Basement foundation wall insulated to 2’ below

grade with vapour retarder on warm side of wall

‘A number of provinces have adopted full-height

basement insulation as a minimum building code

requirement

CHAPTER 12 THEBULONGEWELORE = - 273.

FIGURE 12.16

This photo taken from the Doncaster house

ensuite bathroom shows that all joints in air/vapour

barrier not occurring over studs or plates are

sealed with appropriate tape or acoustic caulking;

notice that the 6 mil polyethelene extends behind

the tub and meets with the header wrap to form a

continuous seal

FIGURE 12.17

This photo is taken from the living room of the

Doncaster house living room; notice that the

ceiling insulation and air/vapour barrier stop

halfway because the roof extends out aver the

front portion of the house, and that section must

be insulated,

274 —_UNOERSTANOING CONSTRUCTION DRAWINGS FOR HOUSING AND SMALL BUILDINGS

FIGURE 12.18

Laundry room air/vapour barrier being prepared,

notice all the protrusions through the barrier,

including the header wrap, intersecting wall, dryer

vent, dryer outlet, washer outlet, and window, and

how they have to be sealed. Note that it is best

practice to seal all joints with acoustic caulking or

sheathing tape (red tape, e.g., Tuck Tape)

FIGURE 12.19

Indication for inspector of approved vapour retarder

being used

KEY TERMS

Building envelope (p. 263)

Conduction (p. 263)

R value (p. 263)

RSI value (p. 263)

Thermal bridging (p. 264)

Convection (p. 265)

Radiation (p. 265)

Dew point (p. 265)

Vapour diffusion (p. 265)

Air barrier (p. 265)

Building wrap (p. 265)

Vapour retarder (p. 265)

Heat recovery ventilator (HRV) (p. 266)

CHAPTER 12

ASSIGNMENT: BUILDING

ENVELOPE AND

DONCASTER DRAWINGS

Answer questions 1 to 7 using the material in this

chapter, and answer questions 8 to 15 using the

Doncaster drawings. Identify the letter that best

completes the statement or answers the question.

1. The vapour barrier requires a tighter seal

than the air barrier.

a. True

b. False

2. The transference of heat is caused by

‘a. Convection

b. Radiation

©. Conduetion

d. Allof the above

3. From Table 12.1, what is the R value per

inch for lumber?

a 2

b 5

e 13

4d. None of the above

4. Moisture moves into and out of a building

by ey

a. Air leakage

b. Rain penetration

©. Vapour diffusion

d. Allof the above

5, From a technical perspective the header

wrap is part of the _

a. Air barrier

b. Vapour retarder

c. Both aandb

d. None of the above

6. Convection currents in an insulated wall can

be caused by compressing fibreglass insula-

tion too much,

a. True

b. False

7. When installing an air/vapour barrier,

a, Joints that don't occur over a solid

surface must be sealed with acoustic

sealant.

10.

1".

12.

3.

CHAPTER 12 THE GUILOING ENWOPE = 275

b. It is best practice to seal all joints with

acoustic caulk or approved tape.

c. Only an approved 6 mil polyethylene is

to be used as a vapour retarder.

d. All of the above are correct.

From the drawings you can see the main

floor walls use ___

a. Styrofoam insulation

b. Fibreglass insulation

©. Cellulose insulation

d. None of the above

. From the drawings you can see the R value

required for the insulation in the walls is

R12

a

b. R19

ce. R32

d. R20

From the drawings you can see the RSI

value required for the insulation in the walls

is

a, RSI3.25

b. RSI19

c. RSIS

d. RSI6

From the drawings you can see the R value

required for the insulation in the ceiling is

a. R40

b. R32

ce R31

d. R19

From the drawings you can see the RSI

value of the ceiling insulation is

a. RSI31

b. RSI5.4

c. RSI6

d. RSL.

From the drawings you can see the R value

for the foundation insulation is

a R21

b. R12

ce. R19

d. R31

276

14, From the drawings you can see the founda

tion insulation must be placed

a. To 2' below grade

b. To 3! below grade

c. To the basement floor slab

d. None of the above

[UNDERSTANDING CONSTRUCTION ORAWINGS FOR HOUSING AND SMALL BUILDINGS

15, The insulation placed between the ceiling of

the garage and the bedroom above must

have an R value of

a. R40

b. R31

c. R25

d. R19

CHAPTER 12 Quiz

REVIEW: BUILDING

ENVELOPE USING

WHITTINGTON

DRAWINGS

Answer the questions below using the Whit-

tington drawings at the back of the text. Identify

the letter that best completes the statement or

answers the question,

1. From the drawings what must be placed

between the insulation and the foundation

wall?

a. 6 mil poly

b. No. 15 building paper

c. OSB

d. None of the above

2. From the drawings you can see building

wrap (Tyvek*) is indicated for all of the

framed exterior walls.

a. Tue

b. False

3. From the drawings you can see the exterior

frame walls have

@. 6 mil airivapour barrier placed on the

inside

b. Building wrap placed on the outside

©. Building wrap placed on the inside

d. None of the above

4. From the drawings you can see

a. Building wrap is placed on the outside

of the frame walls.

b. No. 15 building paper is placed on the

outside of the frame walls,

©. Vapour retarder is placed on the outside

of the frame walls.

d. All of the above are correct.

5. From the drawings you can see there is a

ventilation requirement of 1:200 for the

attic.

a. True

b. False

6. From the drawings you can see the attic

ventilation is to be installed to provide 50%

ventilation at the eaves and therefore

50% ventilation on the roof.

a. True

b. False

7. From the drawings what spe

10.

1.

12,

CHAPTER 2 THE SULOINGENVELOPE = 277

require-

‘ment must the door to the house from the

garage have?

a. Adoor closer

b. Weather stripping to gas proof

c. Awindow

4. Both aandb

From the drawings, you can see the vapour

retarder

a. Is not required in the basement

b. Is required on the warm side (interior)

of the foundation wall

©. Is constructed using 6 mil poly

d, Both b andc

. From the drawings you can see the dryer

vent would need to be sealed where it

Penetrates air/vapour barrier in the

Roof

Rear elevation

Front elevation

pegs

The drawings do not indicate where the

vent penetrates the air/vapour barrier,

From the drawings you can see

The living room ceiling must be insu-

lated completely.

b. The living room ceiling requires insula-

tion from the beam toward the windows.

©. The living room ceiling is inside the

house; therefore, it does not require

insulation,

d. None of the above are correct.

From the drawings you can see

a, The attic access hatch is 20” x 28”,

b. The attic access hatch requires weather-

stripping,

¢. The attic access hatch requires insulation,

d. Alll of the above are correct.

From the drawings you can see

There is a ridge vent specified

throughout.

b. There is no mention of the method used

to vent the attic,

©. There is a soffit vent specified.

4d. None of the above are correct

278

[UNDERSTANDING CONSTRUCTION DRAWINGS FOR HOUSING AND SMALL BUILDINGS

13. From the drawings you can see

e.

The ceiling in the garage is dropped.

The insulation in the garage ceiling is

placed lower than the second floor (in

the dropped portion).

The vapour retarder in the garage is

placed between the drywall and insula~

tion inside the garage.

All of the above are correct.

Both a and b are correct.

14. The drawings call for an HRV.

a, True

b. False

16. From the drawings you can see the exterior

frame wall construction consists of

2" x 4” with 1” styrofoam on the outside

2" < 6" with R19 fibreglass insulation

2° x 4" with R19 fibreglass insulation

None of the above

aege

Understanding

CONSTRUCTION DRAWINGS

for Housing and Small Buildings

Tere Reeder a Tae Oe ee ea Te ea

first Canadian textbook designed to help you learn to read the drawings that are

Pee Renee Cu ee a oe ee Ce ec

HVAC installer, electrician, or general contractor, you must be able to understand

construction drawings. An ability to efficiently locate information in different parts

ie Wi Uc Ree ee ECC acme)

RR ced Net etree eae cm eat er

Cee Coen Cee

ete rs

Se Cee untae se Ue eR Ceti)

STE

Seer eC Rem ee TT)

Cau TE kee aera CERO tue

Geet ee nc ee RR CMC CCU aren

Peto ne ew iurery

For additional resources and information that enhance this book, be sure to visit:

www.stephensonte.nelson.com

Ca ra aoa

NELSON

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- OBC-SB-3-Supplementary StandardDocument110 pagesOBC-SB-3-Supplementary StandardLeyla Moran100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Level 3 MEP ServicesDocument2 pagesLevel 3 MEP ServicesLeyla MoranNo ratings yet

- OBC-SB1-Suppl Std-Climatic and Seismic DataDocument26 pagesOBC-SB1-Suppl Std-Climatic and Seismic DataLeyla MoranNo ratings yet

- Cap 4 - Understanding Const DrawDocument13 pagesCap 4 - Understanding Const DrawLeyla MoranNo ratings yet

- FINAL EXAM ENVIRO 2 LMoranDocument4 pagesFINAL EXAM ENVIRO 2 LMoranLeyla MoranNo ratings yet

- Cap 2 - Understanding Const DrawDocument11 pagesCap 2 - Understanding Const DrawLeyla MoranNo ratings yet

- A2-PANEL Tyler LeylaDocument1 pageA2-PANEL Tyler LeylaLeyla MoranNo ratings yet

- I Am Leyla MoranDocument1 pageI Am Leyla MoranLeyla MoranNo ratings yet

- A2-Panel 2Document2 pagesA2-Panel 2Leyla MoranNo ratings yet

- Nudo de Corbata-ManualDocument1 pageNudo de Corbata-ManualLeyla MoranNo ratings yet

- Environmental Course by LMCDocument10 pagesEnvironmental Course by LMCLeyla MoranNo ratings yet

- L MORAN Portfolio 2020 EngDocument18 pagesL MORAN Portfolio 2020 EngLeyla MoranNo ratings yet

- A2 Panel 2Document2 pagesA2 Panel 2Leyla MoranNo ratings yet

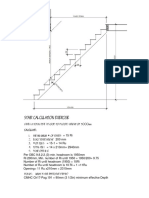

- ARC8421-260 LMoran As4-StairsDocument1 pageARC8421-260 LMoran As4-StairsLeyla MoranNo ratings yet

- Lady Chair - ZanusoKDocument1 pageLady Chair - ZanusoKLeyla MoranNo ratings yet

- ARC421-260 - LMoran - Assignment 1Document4 pagesARC421-260 - LMoran - Assignment 1Leyla MoranNo ratings yet

- ARC8421-260 LMoran As3-RoofsDocument1 pageARC8421-260 LMoran As3-RoofsLeyla MoranNo ratings yet

- ARC8421 260 LMoran - FoundationDocument1 pageARC8421 260 LMoran - FoundationLeyla MoranNo ratings yet

- Assignment 1Document3 pagesAssignment 1Leyla MoranNo ratings yet

- ChildhoodDocument2 pagesChildhoodLeyla MoranNo ratings yet

- FINAL TERM - HIS8482-260 LMoranDocument1 pageFINAL TERM - HIS8482-260 LMoranLeyla MoranNo ratings yet

- ARC8402-mora0190-SITE PLAN-F-ArchCDocument1 pageARC8402-mora0190-SITE PLAN-F-ArchCLeyla MoranNo ratings yet

- 2013dec-052-059 - Building-Sciences DuctosDocument7 pages2013dec-052-059 - Building-Sciences DuctosLeyla MoranNo ratings yet