Professional Documents

Culture Documents

Ijaret 11 11 202

Ijaret 11 11 202

Uploaded by

Abhisekh PattanaikCopyright:

Available Formats

You might also like

- Free Google Slides Tesla TemplateDocument9 pagesFree Google Slides Tesla TemplateemmelinedouddouNo ratings yet

- FORD Motor Company - Case Study 1 For Term 3 - BS - Jun.2021 - Prof - Dr. Krishna Kumar V RaoDocument16 pagesFORD Motor Company - Case Study 1 For Term 3 - BS - Jun.2021 - Prof - Dr. Krishna Kumar V RaosatyavaniNo ratings yet

- Final Final Year Project ReportDocument53 pagesFinal Final Year Project Reportsehaj02843% (7)

- Siege Engine Electric Engine: NomenclatureDocument11 pagesSiege Engine Electric Engine: NomenclatureZülfüNo ratings yet

- Report On Six Stroke EnginDocument19 pagesReport On Six Stroke EnginBharathNo ratings yet

- Six Stroke Engines - Velozeta Mod 2018-2019Document19 pagesSix Stroke Engines - Velozeta Mod 2018-2019BharathNo ratings yet

- Seminar Powerpoint Presentation On 6 Stroke EnginesDocument31 pagesSeminar Powerpoint Presentation On 6 Stroke EnginesVijay ChauhanNo ratings yet

- Bahirdar University Bahirdar Institute of ThecnologyDocument6 pagesBahirdar University Bahirdar Institute of ThecnologyKaleab EndaleNo ratings yet

- Vinay SeminorDocument8 pagesVinay SeminorSyed Ateeb AhmedNo ratings yet

- Design and Analysis of Six Stroke Internal Combustion EngineDocument4 pagesDesign and Analysis of Six Stroke Internal Combustion Engineabhijith thankachanNo ratings yet

- Term Paper ON I C Engine ThermodynamicDocument14 pagesTerm Paper ON I C Engine ThermodynamicSuresh SharmaNo ratings yet

- Review Six Stroke EngineDocument7 pagesReview Six Stroke EngineSuhas G FADNISNo ratings yet

- PV 0001Document5 pagesPV 0001khih kvNo ratings yet

- Internal Combustion EngineDocument13 pagesInternal Combustion EngineNAITAJINo ratings yet

- Otto CyclePowePointDocument27 pagesOtto CyclePowePointVamsi KrishnaNo ratings yet

- Types of Six Stroke EngineDocument8 pagesTypes of Six Stroke EngineUmair SharifNo ratings yet

- Chapter OneDocument8 pagesChapter OneKaleab EndaleNo ratings yet

- The Internal Combustion EngineDocument8 pagesThe Internal Combustion EngineRiko AidaNo ratings yet

- Component Parts of Internal Combustion EnginesDocument26 pagesComponent Parts of Internal Combustion EnginesPeter AshrafNo ratings yet

- Compressed Air Engines SynopsisDocument6 pagesCompressed Air Engines Synopsisalfambar902100% (1)

- Performance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol EngineDocument8 pagesPerformance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol Engineashan19800217No ratings yet

- Concept of Six Stroke Engine-731Document4 pagesConcept of Six Stroke Engine-731Noman GhazaliNo ratings yet

- Hand Made CarDocument33 pagesHand Made CarSahil DhirNo ratings yet

- Six Stroke EngineDocument36 pagesSix Stroke EngineAmandeep Tanwar100% (2)

- KOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentDocument6 pagesKOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentArjun KhindreNo ratings yet

- Diesel EngineDocument3 pagesDiesel EngineHarpreet SinghNo ratings yet

- Project Study Diesel - EngineDocument21 pagesProject Study Diesel - EngineDovah KiinNo ratings yet

- Final AniketDocument18 pagesFinal AniketAniket BhaisareNo ratings yet

- Turbocharging of Ic EnginesDocument5 pagesTurbocharging of Ic EnginesKrishna MurthyNo ratings yet

- AEMSDocument28 pagesAEMSGARVIT SRIVASTAVANo ratings yet

- Refrig Vehi ElectrDocument11 pagesRefrig Vehi ElectrDaniel martínNo ratings yet

- Chapter 3Document29 pagesChapter 3Hasif EnazNo ratings yet

- Automotive EngineDocument4 pagesAutomotive Enginewilliameve2007No ratings yet

- 6 Stroke EngineDocument14 pages6 Stroke EngineMayank VyasNo ratings yet

- Diesel Power PlantDocument28 pagesDiesel Power PlantHassan MalghaniNo ratings yet

- Central RailwayDocument14 pagesCentral RailwayLazy ManNo ratings yet

- 6-Stroke Engine1Document22 pages6-Stroke Engine1KumarVidyadharNo ratings yet

- Development of High Efficiency Engine by Combining I. C. Engine and E C EngineDocument4 pagesDevelopment of High Efficiency Engine by Combining I. C. Engine and E C EngineMuhammad Rifqi PinandhitoNo ratings yet

- Advances in The Design of Two-Stroke, High Speed, Compression Ignition EnginesDocument34 pagesAdvances in The Design of Two-Stroke, High Speed, Compression Ignition EnginesenjpetNo ratings yet

- Exp #15Document14 pagesExp #15Eng TariqNo ratings yet

- Air Powered EngineDocument6 pagesAir Powered Engineolangocollins12No ratings yet

- Engine and Pump SpecificationDocument23 pagesEngine and Pump SpecificationRadamirNo ratings yet

- Comparision of Two Stroke, Four Stroke & Six Stroke Engine According To P-V & Valve Timing DiagramDocument3 pagesComparision of Two Stroke, Four Stroke & Six Stroke Engine According To P-V & Valve Timing DiagramBSAScitiNo ratings yet

- Aircraft SystemsDocument40 pagesAircraft SystemsRadu Andrei100% (1)

- ClasificationDocument30 pagesClasificationSanjay SwainNo ratings yet

- AkooDocument14 pagesAkooHASHIMU BWETENo ratings yet

- 6 Stroke Engine Literature ReviewDocument8 pages6 Stroke Engine Literature Reviewafdtakoea100% (1)

- Two Stroke AircraftDocument10 pagesTwo Stroke AircraftVinti Bhatia100% (1)

- Air and Water Cooled EngineDocument3 pagesAir and Water Cooled Engineneeraj0309No ratings yet

- Paper On Six Stroke EngineDocument8 pagesPaper On Six Stroke EngineAjinkya Deshpande0% (1)

- Automobile Air Conditioning Using Exhaust GasesDocument18 pagesAutomobile Air Conditioning Using Exhaust GasesniketanrNo ratings yet

- 6stroke EngineDocument5 pages6stroke EngineMitesh KumarNo ratings yet

- DGsetDocument14 pagesDGsetAntony HegdeNo ratings yet

- Razo, Alvin T - BSME3B - ME110 - RESEARCHDocument5 pagesRazo, Alvin T - BSME3B - ME110 - RESEARCHAlvin RazoNo ratings yet

- ART20181353Document3 pagesART20181353Abhisekh PattanaikNo ratings yet

- IOSRDocument6 pagesIOSRmuner886644No ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsFrom EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo ratings yet

- Eads CCQ QSTP-LLC Location MapDocument1 pageEads CCQ QSTP-LLC Location MapPinto CarlosNo ratings yet

- A HM 565 Fill Able FormsDocument54 pagesA HM 565 Fill Able FormsAnton Domin (Airport Manager)No ratings yet

- Online Public Auction Listing 20240417Document13 pagesOnline Public Auction Listing 20240417Che DeenNo ratings yet

- Buy DJI 2212 920KV Brushless DC Motor For Drone - CCW Rotation OnlineDocument1 pageBuy DJI 2212 920KV Brushless DC Motor For Drone - CCW Rotation OnlineRahul UpadhyayNo ratings yet

- Parts Manual: D10T2 Track-Type TractorDocument913 pagesParts Manual: D10T2 Track-Type TractorHaytham Maged0% (1)

- Schedule 5 PDFDocument2 pagesSchedule 5 PDFRahul KamtiNo ratings yet

- 2019-09-01 Racecar Engineering PDFDocument100 pages2019-09-01 Racecar Engineering PDFChedoki ChedokiNo ratings yet

- 423 - 2017 Traffic Code 2017Document38 pages423 - 2017 Traffic Code 2017Dulce TomotorgoNo ratings yet

- SD313-1 Mfi Control System (GSL M/T)Document5 pagesSD313-1 Mfi Control System (GSL M/T)Marcelo FasanandoNo ratings yet

- Activa Special BrochureDocument6 pagesActiva Special BrochureSibi SundarNo ratings yet

- File 4626Document3 pagesFile 4626jansjansNo ratings yet

- KSRTC Landline Nos EngDocument5 pagesKSRTC Landline Nos EngAbhishek KarnawatNo ratings yet

- Parts Book: TR35 Off-Highway TruckDocument348 pagesParts Book: TR35 Off-Highway TruckMartinezNo ratings yet

- Laguna Lakeshore Expressway and Dike Project (LLEDP)Document21 pagesLaguna Lakeshore Expressway and Dike Project (LLEDP)Diluc KaeyaNo ratings yet

- NCHRP RPT 301Document114 pagesNCHRP RPT 301KY PengNo ratings yet

- DVCA - 18022017 - Ver01.1 BOTTOMDocument1 pageDVCA - 18022017 - Ver01.1 BOTTOMcesvenegasNo ratings yet

- Route 198 Bocs (S) & Ubs: Weekdays Saturdays Sundays & Public HolidaysDocument70 pagesRoute 198 Bocs (S) & Ubs: Weekdays Saturdays Sundays & Public HolidaysWa WiNo ratings yet

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- Bumper and Fender 2017 Highlander SE AWDDocument5 pagesBumper and Fender 2017 Highlander SE AWDCole WalshNo ratings yet

- SP94-03 TG PTO Service PartsDocument24 pagesSP94-03 TG PTO Service PartsAlfredo GutierrezNo ratings yet

- Ar5321 - Advanced Architectural Integration: Tan Wenkai, Rafael A0166776LDocument8 pagesAr5321 - Advanced Architectural Integration: Tan Wenkai, Rafael A0166776LRafael TanNo ratings yet

- (CLA-VAL) Pantograph E-850GFDocument2 pages(CLA-VAL) Pantograph E-850GFKokodNo ratings yet

- FourStroke 40 60 HP Mercury Marine Network Yacht BrokersDocument5 pagesFourStroke 40 60 HP Mercury Marine Network Yacht BrokersDragan Melita CebicNo ratings yet

- Intersection ControlDocument12 pagesIntersection ControlMMAGNo ratings yet

- Battery Fuses Megane 2Document18 pagesBattery Fuses Megane 2osdasoNo ratings yet

- Government of West Bengal: Transport Department Islampur ARTO Form 23 Certificate of RegistrationDocument1 pageGovernment of West Bengal: Transport Department Islampur ARTO Form 23 Certificate of RegistrationAbhisek SarkarNo ratings yet

- Assignment SubmissionDocument40 pagesAssignment SubmissionFromDiGuyNo ratings yet

- Objective 1-100Document34 pagesObjective 1-100Abhishek Khobragade100% (1)

Ijaret 11 11 202

Ijaret 11 11 202

Uploaded by

Abhisekh PattanaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijaret 11 11 202

Ijaret 11 11 202

Uploaded by

Abhisekh PattanaikCopyright:

Available Formats

International Journal of Advanced Research in Engineering and Technology (IJARET)

Volume 11, Issue 11, November 2020, pp.2067-2073, Article ID: IJARET_11_11_202

Available online at http://iaeme.com/Home/issue/IJARET?Volume=11&Issue=11

ISSN Print: 0976-6480 and ISSN Online: 0976-6499

DOI: 10.34218/IJARET.11.11.2020.202

© IAEME Publication Scopus Indexed

A STUDY OF SIX STROKE ENGINE

Shivam Agarwal

Department of Mechanical Engineering, Sanskriti University,

Mathura, Uttar Pradesh, India.

ABSTRACT

The name itself shows that this engine is a cycle of six strokes where two strokes

are the power strokes. This is additionally a reciprocating sort of engine with twofold

progression of charge and it very well may be both internal and external ignition. It

totally differ with the 2 stroke and 4 stroke engine because of its thermodynamic cycle.

This type of engine consist of a “modified cylinder head” with “with two

supplementary chambers” one is combustion chamber and the other one is an air

heating chamber and both the chambers are totally independent from the cylinder.

The design analysis of this type of engine is quite easy because of separated cylinder

and combustion chamber.

In this type of engine two valves are added with comparison of four stroke engine

and both the valves are operated by an arrangement of piston. This engine is more

efficient thermodynamically because the volume change in power stroke is more than

the compression stroke and intake stroke. The leading advantage of this engine is “the

reduction in fuel consumption by 40%”, there are two power stroke in the cycle of six

strokes, and it is also less polluting type of engine. Six stroke engine's selection by the

vehicle industry would tremendously affect the earth and world economy.

Key words: Stroke, Engine, Efficiency, Fuel, Heat.

Cite this Article: Shivam Agarwal, A Study of Six Stroke Engine, International

Journal of Advanced Research in Engineering and Technology, 11(11), 2020, pp.

2067-2073.

http://iaeme.com/Home/issue/IJARET?Volume=11&Issue=11

1. INTRODUCTION

In inside ignition engine, working on various cycles have one regular element, burning

happening in the chamber after each compression, bringing about gas development that

demonstrations straightforwardly on the cylinder (work) and constrained to 180° of crankshaft

point.

As indicated by its mechanical structure, the six stroke engine[1] with internal and

external ignition what's more, twofold stream is like the real inner responding ignition engine.

In any case, it separates itself altogether, because of its thermodynamic cycle and an adjusted

chamber head with two advantageous chambers: Combustion, doesn't happen inside the

http://iaeme.com/Home/journal/IJARET 2067 editor@iaeme.com

A Study of Six Stroke Engine

chamber however in the advantageous burning chamber, doesn't act quickly on the cylinder,

and it's term is free from the 180° of crank shaft revolution that happens during the

development of the burning gases (work).

The burning chamber is completely encased inside the air-warming chamber. By heat

trade through the shining ignition chamber dividers, air pressure in the warming chamber

increases and create control for a valuable work stroke. A few favourable circumstances result

from this, one very significant being the expansion in warm effectiveness. In the

contemporary inside ignition engine, the vital cooling of the ignition chamber dividers

produce significant calorific losses. In the primary chamber, burning happens each turn as in a

two-stroke engine and oil as in a four-stroke engine.

Fuel injection can occur in the cylinder charger[2], in the gas move divert or in the

ignition chamber. It is likewise conceivable to charge two working chambers with one

cylinder charger. The blend of reduced plan for the burning chamber together with no loss of

fuel and air is professed to give the engine more power, more torque and better fuel

utilization.

In six strokes the motor catches the depleted warmth from the four stroke cycle and uses it

to get an extra power and fumes stroke of the cylinder in a similar chamber. This warmth is

utilized to produce the steam from the water which is additionally utilized as a working liquid

for the extra power stroke. This steam will powers the cylinder down. Just as extricating

power,

The extra stroke cools the motor by water and evacuates the requirement for a cooling

framework making the engine lighter.

2. LITERATURE REVIEW

2.1 Six Stroke Engine

This segment clarifies the valuable angles in a six stroke motor which doesn't exist in a 4

stroke engine. The significant contrasts between 4 are 6 stroke engine are the additional 2

strokes of which the fifth stroke is the power stroke. It is of 2 kinds recorded underneath:

2.1.1 Air Induction System

The six strokes engine as talked about before are fundamentally utilized for high efficiency

and high power output[3]. Noticeable all around acceptance system, the air from air channel is

then passed to the mass stream sensor. The mass wind stream sensor in the system shows the

wind stream though there is likewise an admission temperature sensor which helps in

deciding the temperature. As there is high power and efficiency, it will be in any case in

saying that there will be high compression proportion in the system. This prompts explosion

impact or pre-start in the system. This impact produces noises which is these days dispensed

with by utilizing a silencer. The air acceptance system therefore comprises of high

temperature admission air, as there are the turbochargers and superchargers in the engine

which give heat to the inlet air. This heat can additionally be disposed of by the intercoolers

which help in cooling the temperature of the hot packed air and hence decline its weight. This

expands the exhibition by dismissing heat into the climate. As it gives higher power and is

valuable in high burden limit motor, this system can be found in flying machines.

2.1.2 Water Injection

Water as it is known for its solid properties has a particular heat estimation of about 4.18 J/g

°C The vaporization of water or any fluid is considered by its property called as 'the idle heat

of vaporization'[4] which decides the adjustment in condition of water from fluid to vaporous

http://iaeme.com/Home/journal/IJARET 2068 editor@iaeme.com

Shivam Agarwal

state. As found in the 6 stroke engine, there is an additional power stroke separated from the

one existing force stroke in the four stroke motor. After the admission, compression, start and

exhaust strokes there is water infusion in the system. It is done so as to anticipate explosion in

the system. As the air is then input into the fifth stroke it prompts an exceptionally high

weight in the system which offers ascend to higher pressures.

These weights and temperatures lead to an unstable consuming of air which demonstrates

to be destructive for the motor. The water infusion system is introduced after the temperature

surpasses 40°C. It gives higher pressure proportions and along these lines gives antiknock

properties to the framework which help in shielding the framework from explosion just as

give an effective power stroke. Boeing B-52 at first utilized water infusion for departures as

these system are required for higher burden conveying limit vehicles. The water infusion

strategy is dared to be superior to air enlistment technique since water has a higher heat

injection limit than air likewise when air assimilates the warmth and extends in the fifth

stroke it produces high weights in the engine head prompting high weight on chamber.

2.2 Hybrid Technology

The gas electric crossover vehicle is exactly what it seems like - a hybrid between a gases

controlled vehicle and an electric vehicle[5]. A gas-controlled vehicle has a fuel tank, which

supplies gas to the engine. The engine at that point turns transmission, which turns the wheels.

The hybrid is a trade-off. It endeavours to fundamentally expand the mileage and diminish

the discharges of a gas-fueled vehicle while beating the weaknesses of an electric vehicle.

To be helpful to you or me, a vehicle must meet certain base prerequisites. The vehicle

ought to have the option to:

Drive at any rate 300 miles (482 km) before re-energizing.

Be refueled rapidly and effectively.

Keep up with the other traffic out and about.

A gas vehicle meets these prerequisites yet delivers a moderately huge measure of

contamination and for the most part gets poor gas mileage. An electric vehicle, in any case,

creates no contamination, yet it can just go 50 to 100 miles (80 to 161 km) between charges.

What's more, the issue has been that the electric vehicle is moderate and awkward to energize.

A fuel electric vehicle consolidates these two arrangements into one system that use the two

gas power and electric power. Fuel electric hybrid vehicles contain the accompanying parts:

Gasoline engine- the crossover vehicle has a gas engine a lot of like the one you will

discover on most autos. In any case, the engine on a hybrid is littler and utilizes cutting edge

innovations to diminish outflows and increment proficiency.

Fuel tank–The fuel tank in a hybrid is the vitality stockpiling gadget for the gas engine.

Gas has an a lot higher energy thickness than batteries do. For instance, it takes around 1,000

pounds of batteries to store as a lot of vitality as 1 gallon (7 pounds) of gas.

Electric engine[6]- the electric engine on a hybrid vehicle is modern. Propelled gadgets

enable it to go about as an engine just as a generator. For instance, when it needs to, it can

draw vitality from the batteries to quicken the vehicle. Be that as it may, going about as a

generator, it can back the vehicle off and return vitality to the batteries.

Generator–The generator is like an electric engine, however it acts just to deliver electrical

power. It is utilized for the most part on arrangement cross breeds.

Batteries–The batteries in a hybrid vehicle are the vitality stockpiling gadget[7] for the

electric engine. Dissimilar to the gas in the fuel tank, which can just power the gas motor, the

http://iaeme.com/Home/journal/IJARET 2069 editor@iaeme.com

A Study of Six Stroke Engine

electric engine on a hybrid vehicle can place vitality into the batteries just as draw vitality

from them.

Transmission–The transmission on a hybrid vehicle plays out a similar fundamental

capacity as the transmission on an ordinary vehicle. A few half and halves, similar to the

Honda Insight, have traditional transmissions. Others, similar to the Toyota Prius, have

profoundly various ones.

In this manner, the mix of six strokes and a hybrid vehicle would lead into an

unprecedented motor instrument, which won't just build the current eco-friendliness,

efficient[8] altogether of the framework with respect to its individual fuel efficiencies

however would likewise re- establish the whole framework regarding its mileage, power,

control yield and in particular its interest.

3. PRINCIPLE

A six stroke engine portrays various extraordinary approaches in the interior ignition engine

to catch the squander heat from the four stroke Otto cycle and use it to control an extra power

and exhaust stroke of the cylinder. Structures either use steam or air as the working liquid for

the extra power stroke. Just as removing power, the extra stroke cools the engine and expels

the requirement for a cooling system making the engine lighter and giving 40% expanded

productivity over the Otto Cycle. The cylinders in a six stroke motor go here and there

multiple times for each infusion of fuel.

The six stroke engine has 2 power strokes[9], one fuel, one steam or air. The right now

prominent six stroke engine structures incorporate “Crower's” six stroke motor, the “Bajulaz

engine” and the Six-stroke engine “The Beare Head engine[10]” is known as a six stroke by

its planner however stands separated from the others. It utilizes a second contradicted cylinder

in each chamber which moves at a large portion of the recurrent pace of the principle cylinder,

along these lines giving six cylinder developments for every cycle. It does not utilize any

extra working liquid. After the fumes stroke, rather than air/fuel blend (as if there should be

an occurrence of petroleum engine), outside air is sucked into the chamber from the air

channel, and is expelled during the 6th stroke. The valve covers have been expelled and the

extra two strokes have been accommodated better rummaging, utilizing air infusion. The

engine shows 40% decrease in fuel utilization and emotional decrease in contamination. Its

explicit power isn't not as much as that of a four-stroke oil engine. The engine can run on an

assortment of energizes, running from petroleum and diesel to LPG. An adjusted engine

shows a 65% decrease in CO contamination when contrasted and the four stroke engine from

which it was created.

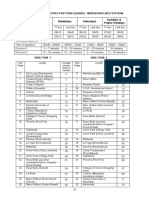

Table 1 Valve Timing Table for Six Stroke Engine

Degree of shaft Combustion Compressor QT chamber Combustion QT

rotation chamber Stroke 1&3/Stroke chamber 3& 4 chamber

1&3 2&4/Stroke

1 Discharge Compression Power Charge Exhaust

46 Discharge Intake Power Ignition Exhaust

91 Charge Compression Exhaust Discharge Power

136 Ignition Intake Exhaust Discharge Power

181 Discharge Compression Power Charge Exhaust

226 Discharge Intake Power Ignition Exhaust

271 Charge Compression Exhaust Discharge Power

316 Ignition Intake Exhaust Discharge Power

http://iaeme.com/Home/journal/IJARET 2070 editor@iaeme.com

Shivam Agarwal

4. WORKING

The workings of six stroke engine are as follows below-

First stroke (“suction stroke”) - During the principal stroke, the inlet valve opens and fuel-

air blend from carburetor is drawn into the chamber through the inlet chamber.

Figure 1 Suction Stroke of Six Stroke Engine

Second stroke (“compression stroke”) - During the subsequent stroke, cylinder moves

from BDC to TDC, both the inlet valve and fumes valves are shut and air-fuel blend is

compressed.

Figure 2 Compression Stroke of Six Stroke Engine

Third stroke (“fuel power stroke”) - During the third stroke, control is gotten from the

engine by lighting the air-fuel mixture utilizing a flash attachment. The two valves stay shut.

Cylinder moves from Top Dead Center to Base Dead Center.

Figure 3 Fuel Power Stroke of Six Stroke Engine

Fourth stroke (“recompression stroke”) - During the third stroke, cylinder moves from

Bottom Dead Focus to Top Dead Center. Both the inlet and the fumes valves are shut. When

http://iaeme.com/Home/journal/IJARET 2071 editor@iaeme.com

A Study of Six Stroke Engine

cylinder arrives at Top Perfectly focused, water injector infuses water which is then changed

over to steam.

Figure 4 Recompression Stroke of Six Stroke Engine

Fifth stroke (“steam power stroke”) - During the fifth stroke, the steam starts the

subsequent power stroke. The two valves stay shut. Cylinder moves from Top Dead Center to

Bottom Dead Center.

Figure 5 Steam Power Stroke of Six Stroke Engine

Sixth stroke (“Exhaust stroke”) - During the 6th stroke, cylinder moves from Bottom

Dead Center to Top Right on target. The inlet valve stays shut. The fumes valve opens and the

fumes gases are discharged.

Figure 6 Exhaust Stroke of Six Stroke Engine

5. CONCLUSION

From the above information the idea and working of the six-stroke engine can be

comprehended. Six stroke engine with all the ideal characteristics[11] as better from four

stroke engine will hit the market soon. Diminishing fuel utilization and contamination with no

impact on execution will reassessed the idea of car. Just enhancements of the present

http://iaeme.com/Home/journal/IJARET 2072 editor@iaeme.com

Shivam Agarwal

innovation can assist it with advancing inside sensible time and budgetary breaking points.

The six-stroke engine fits consummately into this view. Its reception by the car business

would have a decent sway on the earth and world economy.

REFERENCES

[1] R. Holkar and V. S. Jagadale, “Six Stroke Engine,” Int. J. Innov. Eng. Res. Technol., 2015.

[2] D. H. Qi, B. Chen, and D. Zhang, “Combustion and exhaust emissions characteristics of a

dual-fuel compression ignition engine operated with diesel fuel and liquefied petroleum gas,”

J. Energy Eng., vol. 142, no. 4, 2016.

[3] O. Doǧan, “The influence of n-butanol/diesel fuel blends utilization on a small diesel engine

performance and emissions,” Fuel, vol. 90, no. 7, pp. 2467–2472, 2011.

[4] C. Huh and M. Hwan, “Flow Boiling in an Asymmetrically Heated Single Rectangular

Microchannel,” in Evaporation, Condensation and Heat transfer, 2011.

[5] W. Liu, “Hybrid Electric Vehicle System Modeling,” in Hybrid Electric Vehicle System

Modeling and Control, 2017, pp. 38–96.

[6] R. C. Bansal, “Electric vehicles,” in Handbook of Automotive Power Electronics and Motor

Drives, 2017.

[7] J. Jaguemont, L. Boulon, and Y. Dubé, “A comprehensive review of lithium-ion batteries used

in hybrid and electric vehicles at cold temperatures,” Applied Energy. 2016.

[8] A. N. Toosi, A. H. Kakaee, and H. Ebne-Abbasi, “Exhaust gas heat recovery through

secondary expansion cylinder and water injection in an internal combustion engine,” Therm.

Sci., 2017.

[9] E. Arabaci and Y. İçingür, “Thermodynamic investigation of experimental performance

parameters of a water injection with exhaust heat recovery six-stroke engine,” J. Energy Inst.,

vol. 89, no. 4, pp. 569–577, 2016.

[10] “A REVIEW ON SIX STROKE INTERNAL COMBUSTION ENGINE,” Int. J. Adv. Eng.

Res. Dev., 2016.

[11] H. Chen et al., “A new six stroke single cylinder diesel engine referring Rankine cycle,”

Energy, 2015.

http://iaeme.com/Home/journal/IJARET 2073 editor@iaeme.com

You might also like

- Free Google Slides Tesla TemplateDocument9 pagesFree Google Slides Tesla TemplateemmelinedouddouNo ratings yet

- FORD Motor Company - Case Study 1 For Term 3 - BS - Jun.2021 - Prof - Dr. Krishna Kumar V RaoDocument16 pagesFORD Motor Company - Case Study 1 For Term 3 - BS - Jun.2021 - Prof - Dr. Krishna Kumar V RaosatyavaniNo ratings yet

- Final Final Year Project ReportDocument53 pagesFinal Final Year Project Reportsehaj02843% (7)

- Siege Engine Electric Engine: NomenclatureDocument11 pagesSiege Engine Electric Engine: NomenclatureZülfüNo ratings yet

- Report On Six Stroke EnginDocument19 pagesReport On Six Stroke EnginBharathNo ratings yet

- Six Stroke Engines - Velozeta Mod 2018-2019Document19 pagesSix Stroke Engines - Velozeta Mod 2018-2019BharathNo ratings yet

- Seminar Powerpoint Presentation On 6 Stroke EnginesDocument31 pagesSeminar Powerpoint Presentation On 6 Stroke EnginesVijay ChauhanNo ratings yet

- Bahirdar University Bahirdar Institute of ThecnologyDocument6 pagesBahirdar University Bahirdar Institute of ThecnologyKaleab EndaleNo ratings yet

- Vinay SeminorDocument8 pagesVinay SeminorSyed Ateeb AhmedNo ratings yet

- Design and Analysis of Six Stroke Internal Combustion EngineDocument4 pagesDesign and Analysis of Six Stroke Internal Combustion Engineabhijith thankachanNo ratings yet

- Term Paper ON I C Engine ThermodynamicDocument14 pagesTerm Paper ON I C Engine ThermodynamicSuresh SharmaNo ratings yet

- Review Six Stroke EngineDocument7 pagesReview Six Stroke EngineSuhas G FADNISNo ratings yet

- PV 0001Document5 pagesPV 0001khih kvNo ratings yet

- Internal Combustion EngineDocument13 pagesInternal Combustion EngineNAITAJINo ratings yet

- Otto CyclePowePointDocument27 pagesOtto CyclePowePointVamsi KrishnaNo ratings yet

- Types of Six Stroke EngineDocument8 pagesTypes of Six Stroke EngineUmair SharifNo ratings yet

- Chapter OneDocument8 pagesChapter OneKaleab EndaleNo ratings yet

- The Internal Combustion EngineDocument8 pagesThe Internal Combustion EngineRiko AidaNo ratings yet

- Component Parts of Internal Combustion EnginesDocument26 pagesComponent Parts of Internal Combustion EnginesPeter AshrafNo ratings yet

- Compressed Air Engines SynopsisDocument6 pagesCompressed Air Engines Synopsisalfambar902100% (1)

- Performance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol EngineDocument8 pagesPerformance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol Engineashan19800217No ratings yet

- Concept of Six Stroke Engine-731Document4 pagesConcept of Six Stroke Engine-731Noman GhazaliNo ratings yet

- Hand Made CarDocument33 pagesHand Made CarSahil DhirNo ratings yet

- Six Stroke EngineDocument36 pagesSix Stroke EngineAmandeep Tanwar100% (2)

- KOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentDocument6 pagesKOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentArjun KhindreNo ratings yet

- Diesel EngineDocument3 pagesDiesel EngineHarpreet SinghNo ratings yet

- Project Study Diesel - EngineDocument21 pagesProject Study Diesel - EngineDovah KiinNo ratings yet

- Final AniketDocument18 pagesFinal AniketAniket BhaisareNo ratings yet

- Turbocharging of Ic EnginesDocument5 pagesTurbocharging of Ic EnginesKrishna MurthyNo ratings yet

- AEMSDocument28 pagesAEMSGARVIT SRIVASTAVANo ratings yet

- Refrig Vehi ElectrDocument11 pagesRefrig Vehi ElectrDaniel martínNo ratings yet

- Chapter 3Document29 pagesChapter 3Hasif EnazNo ratings yet

- Automotive EngineDocument4 pagesAutomotive Enginewilliameve2007No ratings yet

- 6 Stroke EngineDocument14 pages6 Stroke EngineMayank VyasNo ratings yet

- Diesel Power PlantDocument28 pagesDiesel Power PlantHassan MalghaniNo ratings yet

- Central RailwayDocument14 pagesCentral RailwayLazy ManNo ratings yet

- 6-Stroke Engine1Document22 pages6-Stroke Engine1KumarVidyadharNo ratings yet

- Development of High Efficiency Engine by Combining I. C. Engine and E C EngineDocument4 pagesDevelopment of High Efficiency Engine by Combining I. C. Engine and E C EngineMuhammad Rifqi PinandhitoNo ratings yet

- Advances in The Design of Two-Stroke, High Speed, Compression Ignition EnginesDocument34 pagesAdvances in The Design of Two-Stroke, High Speed, Compression Ignition EnginesenjpetNo ratings yet

- Exp #15Document14 pagesExp #15Eng TariqNo ratings yet

- Air Powered EngineDocument6 pagesAir Powered Engineolangocollins12No ratings yet

- Engine and Pump SpecificationDocument23 pagesEngine and Pump SpecificationRadamirNo ratings yet

- Comparision of Two Stroke, Four Stroke & Six Stroke Engine According To P-V & Valve Timing DiagramDocument3 pagesComparision of Two Stroke, Four Stroke & Six Stroke Engine According To P-V & Valve Timing DiagramBSAScitiNo ratings yet

- Aircraft SystemsDocument40 pagesAircraft SystemsRadu Andrei100% (1)

- ClasificationDocument30 pagesClasificationSanjay SwainNo ratings yet

- AkooDocument14 pagesAkooHASHIMU BWETENo ratings yet

- 6 Stroke Engine Literature ReviewDocument8 pages6 Stroke Engine Literature Reviewafdtakoea100% (1)

- Two Stroke AircraftDocument10 pagesTwo Stroke AircraftVinti Bhatia100% (1)

- Air and Water Cooled EngineDocument3 pagesAir and Water Cooled Engineneeraj0309No ratings yet

- Paper On Six Stroke EngineDocument8 pagesPaper On Six Stroke EngineAjinkya Deshpande0% (1)

- Automobile Air Conditioning Using Exhaust GasesDocument18 pagesAutomobile Air Conditioning Using Exhaust GasesniketanrNo ratings yet

- 6stroke EngineDocument5 pages6stroke EngineMitesh KumarNo ratings yet

- DGsetDocument14 pagesDGsetAntony HegdeNo ratings yet

- Razo, Alvin T - BSME3B - ME110 - RESEARCHDocument5 pagesRazo, Alvin T - BSME3B - ME110 - RESEARCHAlvin RazoNo ratings yet

- ART20181353Document3 pagesART20181353Abhisekh PattanaikNo ratings yet

- IOSRDocument6 pagesIOSRmuner886644No ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsFrom EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo ratings yet

- Eads CCQ QSTP-LLC Location MapDocument1 pageEads CCQ QSTP-LLC Location MapPinto CarlosNo ratings yet

- A HM 565 Fill Able FormsDocument54 pagesA HM 565 Fill Able FormsAnton Domin (Airport Manager)No ratings yet

- Online Public Auction Listing 20240417Document13 pagesOnline Public Auction Listing 20240417Che DeenNo ratings yet

- Buy DJI 2212 920KV Brushless DC Motor For Drone - CCW Rotation OnlineDocument1 pageBuy DJI 2212 920KV Brushless DC Motor For Drone - CCW Rotation OnlineRahul UpadhyayNo ratings yet

- Parts Manual: D10T2 Track-Type TractorDocument913 pagesParts Manual: D10T2 Track-Type TractorHaytham Maged0% (1)

- Schedule 5 PDFDocument2 pagesSchedule 5 PDFRahul KamtiNo ratings yet

- 2019-09-01 Racecar Engineering PDFDocument100 pages2019-09-01 Racecar Engineering PDFChedoki ChedokiNo ratings yet

- 423 - 2017 Traffic Code 2017Document38 pages423 - 2017 Traffic Code 2017Dulce TomotorgoNo ratings yet

- SD313-1 Mfi Control System (GSL M/T)Document5 pagesSD313-1 Mfi Control System (GSL M/T)Marcelo FasanandoNo ratings yet

- Activa Special BrochureDocument6 pagesActiva Special BrochureSibi SundarNo ratings yet

- File 4626Document3 pagesFile 4626jansjansNo ratings yet

- KSRTC Landline Nos EngDocument5 pagesKSRTC Landline Nos EngAbhishek KarnawatNo ratings yet

- Parts Book: TR35 Off-Highway TruckDocument348 pagesParts Book: TR35 Off-Highway TruckMartinezNo ratings yet

- Laguna Lakeshore Expressway and Dike Project (LLEDP)Document21 pagesLaguna Lakeshore Expressway and Dike Project (LLEDP)Diluc KaeyaNo ratings yet

- NCHRP RPT 301Document114 pagesNCHRP RPT 301KY PengNo ratings yet

- DVCA - 18022017 - Ver01.1 BOTTOMDocument1 pageDVCA - 18022017 - Ver01.1 BOTTOMcesvenegasNo ratings yet

- Route 198 Bocs (S) & Ubs: Weekdays Saturdays Sundays & Public HolidaysDocument70 pagesRoute 198 Bocs (S) & Ubs: Weekdays Saturdays Sundays & Public HolidaysWa WiNo ratings yet

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- Bumper and Fender 2017 Highlander SE AWDDocument5 pagesBumper and Fender 2017 Highlander SE AWDCole WalshNo ratings yet

- SP94-03 TG PTO Service PartsDocument24 pagesSP94-03 TG PTO Service PartsAlfredo GutierrezNo ratings yet

- Ar5321 - Advanced Architectural Integration: Tan Wenkai, Rafael A0166776LDocument8 pagesAr5321 - Advanced Architectural Integration: Tan Wenkai, Rafael A0166776LRafael TanNo ratings yet

- (CLA-VAL) Pantograph E-850GFDocument2 pages(CLA-VAL) Pantograph E-850GFKokodNo ratings yet

- FourStroke 40 60 HP Mercury Marine Network Yacht BrokersDocument5 pagesFourStroke 40 60 HP Mercury Marine Network Yacht BrokersDragan Melita CebicNo ratings yet

- Intersection ControlDocument12 pagesIntersection ControlMMAGNo ratings yet

- Battery Fuses Megane 2Document18 pagesBattery Fuses Megane 2osdasoNo ratings yet

- Government of West Bengal: Transport Department Islampur ARTO Form 23 Certificate of RegistrationDocument1 pageGovernment of West Bengal: Transport Department Islampur ARTO Form 23 Certificate of RegistrationAbhisek SarkarNo ratings yet

- Assignment SubmissionDocument40 pagesAssignment SubmissionFromDiGuyNo ratings yet

- Objective 1-100Document34 pagesObjective 1-100Abhishek Khobragade100% (1)