Professional Documents

Culture Documents

The Vital Role of Plant Maintenance in Modern Industry

The Vital Role of Plant Maintenance in Modern Industry

Uploaded by

SuhailShaikhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Vital Role of Plant Maintenance in Modern Industry

The Vital Role of Plant Maintenance in Modern Industry

Uploaded by

SuhailShaikhCopyright:

Available Formats

Title: The Vital Role of Plant Maintenance in Modern Industry

Introduction

Plant maintenance is a critical aspect of industrial operations that often goes unnoticed until

something goes wrong. It encompasses a wide range of activities aimed at preserving, repairing,

and enhancing the performance of machinery, equipment, and facilities within an industrial

plant. In today's highly competitive and technologically advanced industrial landscape, effective

plant maintenance has become indispensable for ensuring safety, reliability, efficiency, and

sustainability. This essay explores the significance of plant maintenance in modern industry, its

key components, and the benefits it brings to organizations.

The Significance of Plant Maintenance

1. Reliability and Availability: Reliability is a fundamental requirement in industrial settings.

Downtime due to equipment failure can result in substantial financial losses, decreased

productivity, and damage to a company's reputation. Effective plant maintenance helps ensure

that machinery and equipment operate reliably, minimizing unplanned downtime. This, in turn,

maximizes the availability of assets and the overall efficiency of the production process.

2. Safety: Safety is paramount in any industrial environment. Neglected maintenance can lead to

hazardous situations, equipment malfunctions, and accidents that may result in injuries or even

fatalities. Regular maintenance practices such as equipment inspections, safety audits, and

preventive maintenance routines help identify and mitigate potential safety risks, ensuring a

safer working environment for employees.

3. Cost Reduction: Properly planned and executed plant maintenance can lead to significant cost

savings. Preventive maintenance, for instance, helps detect and address issues before they

escalate into expensive breakdowns. Additionally, well-maintained equipment tends to have a

longer lifespan, reducing the need for frequent replacements and capital expenditures.

Key Components of Plant Maintenance

1. Preventive Maintenance: Preventive maintenance involves scheduled inspections, servicing, and

repairs to prevent equipment failures. This proactive approach helps identify and address

potential issues before they disrupt operations. Common preventive maintenance tasks include

lubrication, calibration, and equipment cleaning.

2. Predictive Maintenance: Predictive maintenance relies on data analysis and condition monitoring

to predict when equipment is likely to fail. Sensors and data analytics tools are used to detect

abnormalities in equipment performance, allowing for timely intervention and minimizing

unplanned downtime.

3. Corrective Maintenance: Corrective maintenance is performed in response to equipment failures

or breakdowns. While it is reactive in nature, it is essential to ensure prompt repairs and

minimize the impact on production. Quick response times and well-trained maintenance teams

are crucial for effective corrective maintenance.

4. Reliability-Centered Maintenance (RCM): RCM is a comprehensive maintenance strategy that

prioritizes critical equipment and assets based on their importance to the overall production

process. It involves a systematic analysis of failure modes and the development of tailored

maintenance plans to maximize reliability and minimize risks.

Benefits of Effective Plant Maintenance

1. Improved Efficiency: Efficiently maintained equipment operates at peak performance, leading to

increased production output and reduced energy consumption. This results in improved overall

operational efficiency and reduced operational costs.

2. Enhanced Asset Lifespan: Regular maintenance extends the lifespan of machinery and

equipment, postponing the need for costly replacements. This not only saves money but also

reduces the environmental impact of manufacturing through reduced waste and resource

consumption.

3. Regulatory Compliance: Many industries are subject to strict regulations regarding safety,

emissions, and environmental standards. Effective plant maintenance helps organizations meet

these regulatory requirements, avoiding fines and legal complications.

4. Employee Morale and Safety: A well-maintained plant creates a safer and more pleasant working

environment, leading to increased employee satisfaction and reduced turnover. A positive

workplace culture, in turn, contributes to better productivity and quality.

Conclusion

In the modern industrial landscape, plant maintenance is far more than a cost center; it is a

strategic imperative. Effective plant maintenance ensures the reliability, safety, and efficiency of

industrial operations. By embracing preventive, predictive, and corrective maintenance practices,

organizations can minimize downtime, reduce operational costs, and extend the lifespan of their

assets. In doing so, they not only safeguard their bottom line but also contribute to a

sustainable and responsible approach to industrial production. Plant maintenance is the invisible

force that keeps the wheels of industry turning smoothly, and its significance cannot be

overstated in today's competitive business environment.

You might also like

- Favoritism in The Workplace and Its Effect On The OrganizationDocument11 pagesFavoritism in The Workplace and Its Effect On The OrganizationSuhailShaikhNo ratings yet

- Culture of MaintenanceDocument4 pagesCulture of MaintenanceBoaz Otieno0% (1)

- Maintenance EngineeringDocument67 pagesMaintenance EngineeringV.Muthu KumarNo ratings yet

- TERNIDADocument10 pagesTERNIDADranreb Jazzver BautistaNo ratings yet

- Operations Management: (Shashank Tilak)Document7 pagesOperations Management: (Shashank Tilak)Vijay Singh ThakurNo ratings yet

- MaintenanceDocument2 pagesMaintenanceKarim Ahmed El SayedNo ratings yet

- Introduction To Maintenance and Replacement Models: Chapter - 1Document38 pagesIntroduction To Maintenance and Replacement Models: Chapter - 1engineer engrNo ratings yet

- Plant Maintenance EngineeringDocument7 pagesPlant Maintenance EngineeringSandeep Singh KharbNo ratings yet

- Maintenance Management CoolDocument56 pagesMaintenance Management CoolEmmanuel KutaniNo ratings yet

- PM and PDM ConceptsDocument6 pagesPM and PDM ConceptsMagoroku D. YudhoNo ratings yet

- MaintenanceDocument3 pagesMaintenancedineshkumarsavi2520No ratings yet

- Preventive Maintenance Part IDocument20 pagesPreventive Maintenance Part Ismodi20No ratings yet

- Q1 Final MaintenanceDocument4 pagesQ1 Final MaintenancejenankahNo ratings yet

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument19 pagesSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88Jj100% (1)

- Faizan MAINTENNANCEDocument13 pagesFaizan MAINTENNANCENoshad. ProcurementNo ratings yet

- STP 221 Lecture 1Document7 pagesSTP 221 Lecture 1oluwafolukemiakinseye2001No ratings yet

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument13 pagesSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88JjNo ratings yet

- Maintenance Work B.BDocument18 pagesMaintenance Work B.BMuhamad MhakimyNo ratings yet

- Tcoge - MaintananceDocument4 pagesTcoge - MaintananceamranimkurusuNo ratings yet

- Tema 1. What Is The Importance of Maintenance in IndustryDocument4 pagesTema 1. What Is The Importance of Maintenance in IndustryING. ANABELL COTA RAMÍREZNo ratings yet

- Preventive Maintenance Part IDocument21 pagesPreventive Maintenance Part IKABADDI RISINGNo ratings yet

- Maintenance Engineering (ME6012)Document68 pagesMaintenance Engineering (ME6012)ElementifyItNo ratings yet

- BLD304-BLD322 Reading Material 2Document6 pagesBLD304-BLD322 Reading Material 2oluwakoredeakinfolarinNo ratings yet

- Maintenance EngineeringDocument17 pagesMaintenance Engineeringmuhwezi collinsNo ratings yet

- Industrial SafetyDocument8 pagesIndustrial SafetyLyca GarciaNo ratings yet

- DiscussionDocument2 pagesDiscussionJuan GuerreroNo ratings yet

- Maintenance and Its Types-1Document33 pagesMaintenance and Its Types-1Xtylish RajpootNo ratings yet

- Module 2Document52 pagesModule 2Aditya ranjan BubunNo ratings yet

- Introduction To MaintenanceDocument38 pagesIntroduction To MaintenancemarianaNo ratings yet

- Met82 Maintenanceandsafetyengineering (3 0 0 3) Unit-IDocument51 pagesMet82 Maintenanceandsafetyengineering (3 0 0 3) Unit-IM.ThirunavukkarasuNo ratings yet

- MEP 283 Lecture NotesDocument57 pagesMEP 283 Lecture NotesPkay TandohNo ratings yet

- Maintenance Management: Assignment 1Document17 pagesMaintenance Management: Assignment 1Yogesh SharmaNo ratings yet

- The Purpose of Industrial Plant and Equipment MaintenanceDocument11 pagesThe Purpose of Industrial Plant and Equipment MaintenanceJJ MonroyNo ratings yet

- Maintenance ManagementDocument7 pagesMaintenance ManagementNadeemNo ratings yet

- Ce 2071 - Repair and Rehablitation of Structures (For Viii - Semester)Document15 pagesCe 2071 - Repair and Rehablitation of Structures (For Viii - Semester)Abera MamoNo ratings yet

- Ce 2071 - Repair and Rehablitation of Structures (For Viii - Semester)Document15 pagesCe 2071 - Repair and Rehablitation of Structures (For Viii - Semester)Charan Tej Rudrala100% (1)

- Plant Maintenance StrategyDocument8 pagesPlant Maintenance StrategyangphooiNo ratings yet

- Maintenance ManagementDocument20 pagesMaintenance ManagementRiya GuptaNo ratings yet

- Maintenance StrategyDocument15 pagesMaintenance StrategyNovi Wahyu Wulandari100% (1)

- Maintenance Management SrikanthDocument6 pagesMaintenance Management SrikanthSrikanth Prasanna BhaskarNo ratings yet

- Maintenance StrategiesDocument6 pagesMaintenance StrategiesarielsonNo ratings yet

- LeadershipDocument79 pagesLeadershipGaiusNo ratings yet

- Class NoteDocument2 pagesClass NoteDinuNo ratings yet

- Pme IntroductionDocument14 pagesPme IntroductionJITUMONI DekaNo ratings yet

- Mantenimiento Industrial (Ensayo en Ingles)Document2 pagesMantenimiento Industrial (Ensayo en Ingles)Jhonny Zurita GonzalesNo ratings yet

- Reliability and MaintenanceDocument77 pagesReliability and MaintenanceMitesh SharmaNo ratings yet

- Influence of Modification of Design Out Maintenance & Design Out Information System For Maintenance Cost Control & A Lucrative Business (With Case Study)Document9 pagesInfluence of Modification of Design Out Maintenance & Design Out Information System For Maintenance Cost Control & A Lucrative Business (With Case Study)seventhsensegroupNo ratings yet

- IP 5ME C Verosh Cantuba Equiz5Document6 pagesIP 5ME C Verosh Cantuba Equiz5ALDRICK JAYSON CADACIONo ratings yet

- BUS413 Maintenance PolicyDocument8 pagesBUS413 Maintenance PolicySeffaNo ratings yet

- MaintenanceDocument44 pagesMaintenanceLatifahabubakar Eifa100% (1)

- Maintenance ManagementDocument14 pagesMaintenance ManagementAasishPatilNo ratings yet

- SLIDES2Document20 pagesSLIDES2shahzad nasimNo ratings yet

- Total Preventive Maint.Document18 pagesTotal Preventive Maint.No HopeNo ratings yet

- Chapter 1 Maintenance Organization NewDocument49 pagesChapter 1 Maintenance Organization Newsofwanazmin100% (1)

- Maintenance NotesDocument51 pagesMaintenance NotesAlbert AwoponeNo ratings yet

- What Is Preventive Maintenance or Preventative Maintenance?Document5 pagesWhat Is Preventive Maintenance or Preventative Maintenance?Jevan CalqNo ratings yet

- Maintenance Chapter Two2Document23 pagesMaintenance Chapter Two2Football HDNo ratings yet

- Chemical IndustriesDocument10 pagesChemical IndustriessunliasNo ratings yet

- Maintenance System For Heavy Earth Moving EquipmentDocument7 pagesMaintenance System For Heavy Earth Moving Equipmentaguda samuel segunNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Management Science Its Historical DevelopmentDocument3 pagesManagement Science Its Historical DevelopmentSuhailShaikhNo ratings yet

- The Tools of Management ScienceDocument3 pagesThe Tools of Management ScienceSuhailShaikhNo ratings yet

- Applications of Industrial EngineeringDocument1 pageApplications of Industrial EngineeringSuhailShaikhNo ratings yet

- Production Management The Key To Efficient ManufacturingDocument2 pagesProduction Management The Key To Efficient ManufacturingSuhailShaikhNo ratings yet

- History and Development of Industrial EngineeringDocument2 pagesHistory and Development of Industrial EngineeringSuhailShaikhNo ratings yet

- The Concept of Industrial Engineering Enhancing Efficiency and ProductivityDocument2 pagesThe Concept of Industrial Engineering Enhancing Efficiency and ProductivitySuhailShaikhNo ratings yet

- The Art and Science of Decision-MakingDocument2 pagesThe Art and Science of Decision-MakingSuhailShaikhNo ratings yet

- Aina - e - Qismat October 2019Document60 pagesAina - e - Qismat October 2019SuhailShaikhNo ratings yet

- The Role of An Industrial EngineerDocument2 pagesThe Role of An Industrial EngineerSuhailShaikhNo ratings yet

- Online Restaurant Delivery Guide To Getting Started: Will You Deliver Yourself?Document1 pageOnline Restaurant Delivery Guide To Getting Started: Will You Deliver Yourself?SuhailShaikhNo ratings yet

- Welcome: A Guide To Accessibility ofDocument18 pagesWelcome: A Guide To Accessibility ofSuhailShaikhNo ratings yet

- Personnel Management Nurturing Human Capital For Organizational SuccessDocument2 pagesPersonnel Management Nurturing Human Capital For Organizational SuccessSuhailShaikhNo ratings yet

- Network Analysis Unveiling The Hidden Structures of Our Connected WorldDocument2 pagesNetwork Analysis Unveiling The Hidden Structures of Our Connected WorldSuhailShaikhNo ratings yet

- 7 Steps To Start Goat Farming Business For ProfitDocument8 pages7 Steps To Start Goat Farming Business For ProfitSuhailShaikhNo ratings yet

- Production and Productivity Driving Forces of Economic GrowthDocument2 pagesProduction and Productivity Driving Forces of Economic GrowthSuhailShaikhNo ratings yet

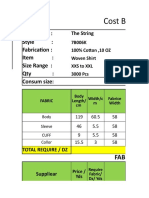

- Costing Sheet For Woven ShirtDocument9 pagesCosting Sheet For Woven ShirtSuhailShaikhNo ratings yet

- Performance Polos Classic PolosDocument37 pagesPerformance Polos Classic PolosSuhailShaikhNo ratings yet

- Welcome: A Guide To Accessibility ofDocument18 pagesWelcome: A Guide To Accessibility ofSuhailShaikhNo ratings yet

- Biogas Plant Sizes and DimensionsDocument7 pagesBiogas Plant Sizes and DimensionsSuhailShaikhNo ratings yet

- Profile To PrintDocument10 pagesProfile To PrintSuhailShaikhNo ratings yet

- Neha Chauhan (04) Bhawna Pandwar (30) : Presented byDocument47 pagesNeha Chauhan (04) Bhawna Pandwar (30) : Presented bySuhailShaikhNo ratings yet

- Frequently Asked Questions: RewardDocument6 pagesFrequently Asked Questions: RewardSuhailShaikhNo ratings yet