Professional Documents

Culture Documents

Ram 100

Ram 100

Uploaded by

MAT-LIONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ram 100

Ram 100

Uploaded by

MAT-LIONCopyright:

Available Formats

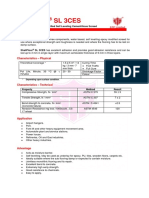

RAM-100®

ISO 9001:2008 CERTIFIED

ANTI-CORROSION COATING

(NMX-CC-9001-IMNC-2008)

LIQUID EPOXY

RAM-100 | RAM-100 SP PLUS

ANTI-CORROSIVE AND MECHANICAL PROTECTION FOR

PIPING AND SUPERFICIAL INFRASTRUCTURE

RAM-100® is a proprietary formula for a liquid epoxy coating for the repair and reinforcement of Oil & Gas piping and

other structures. RAM-100® is a cutting-edge thermosetting epoxy monolithic cement corrosion-protection agent for

steel or concrete pipes and existing oil structures that

are subject to attack by a variety of acids, corrosive

vapors, aggressive environments, micro-organisms,

thermal shock, salinity, humidity, and wear, caused by

friction or abrasion.

RAM-100® is formulated specifically for automated

application at the plant to new piping, or for manual

application on-site to active pipelines; its formula has

been successfully tested in its properties to provide

state of the art mechanical, anti-corrosive, and anti-

acid protection. It is also ideal for setting or joining

anti-acid and wall protection slabs, neutralization

basins, drains, trenches, doorposts, and concrete

pipes; that are exposed to severe corrosion conditions

and abrasive agents due to acids used in the oil

industry, chemical products, fertilizers, corrosive

vapors, hydrocarbons (crude and refined), water, or

aggressive agents. It is technically designed for

applications from 8 to 480 mils without losing its

protective properties.

RAM-100® is available in two presentations:

RAM-100 – original formula, and

RAM-100 SP PLUS – with a modified viscosity

for various applications

RAM-100® can be applied to:

Interior and exterior surfaces of new piping in

our automated plant located in Veracruz,

Mexico.

New or recovered pipes on-site with our

certified automated mobile plant.

Manually or by aspersion-based method on-

site to pipelines and operational structures

and/or facilities.

By high-pressure hoses for subsea

infrastructure.

Our proprietary formula is complemented with

aliphatic polyamide resins, reinforced with quartz and zirconium powders, intercalating inert plastic charges and

prepared in two components for an easy application.

TDS-RAM100 Rev 01 July 2014 Page 1 of 2

RAM-100® SP PLUS – Technical Data

Application Automated, Manual, by Aspersion, at the Manufacturing Plant, Mobile-Plant, or On-site

Installation Easy and fast installation on active pipelines and structures without interrupting the operations, in

a dry, humid, or wet environment

Durability Varies from 0.043 kg/m2 @ 1mils (0.0254 mm), and over 35 to 70% additional for spray application,

and depending on NPS, weather and surface conditions, and proper application and experience

by the user

Drying time 120 to 180 minutes @ 25°C (77°F)

Gel time 2 hours for water immersion / 24 hours for chemical operations

Service temperature -5°C to 145°C (23°F to 293°F)

Shelf life 60 months in a dry place in original sealed containers

Chemical resistance Excellent

Abrasion resistance High

Permeability 100% – antifouling

Dielectric resistance 440 V/mil

Warranty 20 years and up to 30 years of protective properties

Ballast application Directly on RAM-100® SP Plus coating

Additional information

RAM-100® SP PLUS (aspersion) Available in 20kg pails labeled for each component (A or BASE and B or CATALYST)

DQP-100 (modifier) Available in 20 liter pails or 200 liter drums

Time of application 30 – 45 minutes @ 24°C (75.2°F)

Application temperature -5°C (23°F) to 90°C (194°F)

Operating temperature -5°C (23°F) to 135°C (275°F)

Shelf life Up to 18 months from the date of manufacture stored in a shaded dry place, in the

original sealed containers

Thickness Varies depending on number of layers per application

Number of layers As required per each repair

Layer thickness 0.060 to 0.075 mm

Length 0.3 m (1 ft.) to the required length to repair the integrity deficiencies found

Geometry Easily applied to straight, bent, curved, and any shape required for the repair

UV finish For protection to UV ray exposure, apply a 3-5 mm layer of polyurethane finish

RAM-100® products are developed and manufactured exclusively by RAM-100 del Sureste, S.A. de C.V. using a

patented formula under Patent number 182885 and Trademark number 526546.

Contact us to obtain a quote, for additional details or specific questions:

TollPhone: 07 3161 6600 | Fax:

Free: (888)396-4128 (888)890-6011

Mobile: | Office:

0411 385 373 (832)917-1770

| Fax: 07 3910 1120

info@RAM100intl.com

Email: geoff@pipeserv.com Web: www.pipeserv.com

NORTHEAST SOUTH

11140 Rockville Pike, Suite 100-105 4822 N Sam Houston Pkwy W, Suite 100

Rockville, MD 20852

RAM-100 INTERNATIONAL, LLC Houston, TX 77086

TDS-RAM100 Rev 01 July 2014 Page 2 of 2

You might also like

- ASME - PCC-2 - Study - Guide - 510Document48 pagesASME - PCC-2 - Study - Guide - 510MAT-LION100% (2)

- Chapter 6 Risk Assessment 4 PipelinesDocument21 pagesChapter 6 Risk Assessment 4 PipelinesMAT-LIONNo ratings yet

- Systems Guide 2020 Edition: Compliant With Iso 12944-5:2018 Independently TestedDocument26 pagesSystems Guide 2020 Edition: Compliant With Iso 12944-5:2018 Independently TestedErnesto CascoNo ratings yet

- ASTM D5895 - 2020 Drying TimeDocument4 pagesASTM D5895 - 2020 Drying TimePablo OrtegaNo ratings yet

- Sikacem®-711 Elastic: Provisional Product Data SheetDocument4 pagesSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarNo ratings yet

- Ameron GRE Fabrication GuidelineDocument355 pagesAmeron GRE Fabrication GuidelineAbdul Hakam Mohamed Yusof100% (2)

- PIP CTSE1000 (Application of External Coatings)Document79 pagesPIP CTSE1000 (Application of External Coatings)이동욱No ratings yet

- Tensile Bond TestDocument14 pagesTensile Bond TestPanneer SelvamNo ratings yet

- VersaFlex FS45DC DatasheetDocument2 pagesVersaFlex FS45DC DatasheetShaheerKhaleequzzamanNo ratings yet

- Humiseal 1B73 TDSDocument2 pagesHumiseal 1B73 TDSKannanNo ratings yet

- Ps 700Document2 pagesPs 700Maurício LopesNo ratings yet

- Product Description: Epoxy Coating System, 100% SolidsDocument4 pagesProduct Description: Epoxy Coating System, 100% SolidsKatherine GonzalesNo ratings yet

- Anti Condensation CatalogueDocument8 pagesAnti Condensation CatalogueBoBo KyawNo ratings yet

- Strong Back BrochureDocument4 pagesStrong Back Brochurearifin rizalNo ratings yet

- REMALINE 60 The Lining For Protection From Impact WearDocument2 pagesREMALINE 60 The Lining For Protection From Impact WearCristian GaborNo ratings yet

- A65201880 - Instruction ManualDocument3 pagesA65201880 - Instruction ManualLubricants ServerNo ratings yet

- Catalogo General PolykenDocument9 pagesCatalogo General PolykenVinoth KumarNo ratings yet

- Barralastic AseanDocument2 pagesBarralastic AseanDonny Ari KusumaNo ratings yet

- Masterseal 540Document2 pagesMasterseal 540Nguyen Chi Thanh100% (1)

- Spikefast ET-75: Wood Tie Plugging MaterialDocument2 pagesSpikefast ET-75: Wood Tie Plugging MaterialdidbeauNo ratings yet

- Neocryl A-622 PdsDocument9 pagesNeocryl A-622 PdsLeandro EsvizaNo ratings yet

- Flowshield SL: Standard Colour ChartDocument2 pagesFlowshield SL: Standard Colour ChartManjunath HrmNo ratings yet

- Rhino Extreme 21-55 Dsheet - 5231Document2 pagesRhino Extreme 21-55 Dsheet - 5231Revestimento de PoliuretanoNo ratings yet

- Rex ThaneDocument4 pagesRex Thanesas999333No ratings yet

- Hyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane SealantDocument2 pagesHyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane Sealantsasikumar durairajanNo ratings yet

- Hyperseal 50 FCSDocument3 pagesHyperseal 50 FCSmeena nachiyarNo ratings yet

- Whitechem Polyurea Pa 1005-EnDocument4 pagesWhitechem Polyurea Pa 1005-EnBien PangilinanNo ratings yet

- Ecosafe Ro Membrane CatalogDocument11 pagesEcosafe Ro Membrane CatalogecosafeNo ratings yet

- Depliant - RECYCLING - New - ENG 2Document8 pagesDepliant - RECYCLING - New - ENG 2Ste Baccouche Negoce SbnNo ratings yet

- Tds CA 1000 Mastinox PPGDocument2 pagesTds CA 1000 Mastinox PPGAstari Putri NuarisaNo ratings yet

- Mobilfluid 125: Extra High Performance Power Transmission FluidDocument2 pagesMobilfluid 125: Extra High Performance Power Transmission FluidtribolasNo ratings yet

- GA-013 Functional Coatings BrochureDocument6 pagesGA-013 Functional Coatings Brochuregopinath87No ratings yet

- TDS - Masterpren TGE-FDocument2 pagesTDS - Masterpren TGE-FAlexi ALfred H. TagoNo ratings yet

- Vacuum SolutionsDocument20 pagesVacuum SolutionsRuben CandanosaNo ratings yet

- Liquid Applied, One Component Polyurethane Waterproofing MembraneDocument2 pagesLiquid Applied, One Component Polyurethane Waterproofing MembraneMazen OudNo ratings yet

- CSDS Stopaq FAST GRE V3Document2 pagesCSDS Stopaq FAST GRE V3AndyNo ratings yet

- Mobil Dte 20 SeriesDocument3 pagesMobil Dte 20 Seriessapu11jagat5855No ratings yet

- Data Sheet Sw30hrle-400Document2 pagesData Sheet Sw30hrle-400Alexis Antonio Jara VidalNo ratings yet

- TDS Total Rubia Fleet HD 300 15W40 enDocument2 pagesTDS Total Rubia Fleet HD 300 15W40 enthe anhNo ratings yet

- PDB VIASOL PU-L300MengDocument3 pagesPDB VIASOL PU-L300MengZeljkoNo ratings yet

- Ms 35Document7 pagesMs 35Omar AkramNo ratings yet

- PI - Ultramax HVLP 32 - 402 05aknlxnDocument2 pagesPI - Ultramax HVLP 32 - 402 05aknlxnNivardo Mendoza PintoNo ratings yet

- Enviroline 125LV Easy To Apply Epoxy Lining System BrochureDocument2 pagesEnviroline 125LV Easy To Apply Epoxy Lining System BrochureAhmed IbrahimNo ratings yet

- HT 521 86181 000 ENDocument6 pagesHT 521 86181 000 ENEdward AguillónNo ratings yet

- REMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesDocument16 pagesREMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesBaihaki StNo ratings yet

- Mapeflex Pu50 SLDocument4 pagesMapeflex Pu50 SLBarbara Ayub FrancisNo ratings yet

- Atlas E-Pro Patch PDSDocument2 pagesAtlas E-Pro Patch PDSuks444No ratings yet

- Chembloc Series 239Sc: Product ProfileDocument2 pagesChembloc Series 239Sc: Product ProfileSky MoonNo ratings yet

- Allegro Elastic Attachment NozzlesDocument2 pagesAllegro Elastic Attachment Nozzlesadel boukadoumNo ratings yet

- Acematt Ts 100 enDocument2 pagesAcematt Ts 100 enSeafar YachtingNo ratings yet

- 5 Star GroutDocument2 pages5 Star Groutchong pak limNo ratings yet

- Ucrete UD200: Heavy Duty Polyurethane Hybrid Flooring SystemDocument2 pagesUcrete UD200: Heavy Duty Polyurethane Hybrid Flooring Systemsyifa latifa zahidaNo ratings yet

- Tds Viacrete Pu Ud VMDocument3 pagesTds Viacrete Pu Ud VMSubrina IslamNo ratings yet

- Rapp-It Advantages FlyerDocument2 pagesRapp-It Advantages FlyerRafique AjmeriNo ratings yet

- Humiseal 1B18 Acrylic Conformal Coating Technical Data SheetDocument2 pagesHumiseal 1B18 Acrylic Conformal Coating Technical Data SheetDhamoNo ratings yet

- TDS - Masterpren HEDocument2 pagesTDS - Masterpren HEJaga NathNo ratings yet

- EPX RangeDocument2 pagesEPX RangecarmaNo ratings yet

- Viscopro 2100 Brochure A4 LRDocument4 pagesViscopro 2100 Brochure A4 LRLuz Stella Calixto GomezNo ratings yet

- TDS MY MacTex C2S July2013Document1 pageTDS MY MacTex C2S July2013Sherene HoNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- 21-Internal Inspection of Fired Heaters GuidelineDocument11 pages21-Internal Inspection of Fired Heaters GuidelineMAT-LIONNo ratings yet

- External Inspection of Fired Heaters GuidelineDocument7 pagesExternal Inspection of Fired Heaters GuidelineMAT-LIONNo ratings yet

- DownloadDocument17 pagesDownloadMAT-LIONNo ratings yet

- 17-Civil and Structural Inspection ProcedureDocument21 pages17-Civil and Structural Inspection ProcedureMAT-LIONNo ratings yet

- 6-Quality Assurance Audit Plan for Inspection-Testing Completion Verification of Tanks, Vessels, And Piping SystemsDocument4 pages6-Quality Assurance Audit Plan for Inspection-Testing Completion Verification of Tanks, Vessels, And Piping SystemsMAT-LIONNo ratings yet

- 6-Stationary Equipment Inspection Frequency GuidelineDocument14 pages6-Stationary Equipment Inspection Frequency GuidelineMAT-LIONNo ratings yet

- Infra Topic Paper 4-4 FINALDocument17 pagesInfra Topic Paper 4-4 FINALMAT-LIONNo ratings yet

- InTech-Evaluating The Integrity of Pressure Pipelines by Fracture MechanicsDocument28 pagesInTech-Evaluating The Integrity of Pressure Pipelines by Fracture MechanicsMAT-LIONNo ratings yet

- 2-Fired Heater External Inspection ChecklistDocument4 pages2-Fired Heater External Inspection ChecklistMAT-LIONNo ratings yet

- GFMAM Specification AM Maturity Assessor V1Document12 pagesGFMAM Specification AM Maturity Assessor V1MAT-LIONNo ratings yet

- APPENDIX B Laboratory and Field TestingDocument13 pagesAPPENDIX B Laboratory and Field TestingMAT-LIONNo ratings yet

- Chapter 5 How Do I Optimize An Internal CorrosionDocument40 pagesChapter 5 How Do I Optimize An Internal CorrosionMAT-LIONNo ratings yet

- Mechanical Clamp Baher 1650482617Document10 pagesMechanical Clamp Baher 1650482617MAT-LIONNo ratings yet

- Best Metallurgical PE Exam Study MaterialsDocument2 pagesBest Metallurgical PE Exam Study MaterialsMAT-LION100% (1)

- Appendix A Analysis ReportDocument5 pagesAppendix A Analysis ReportMAT-LIONNo ratings yet

- Wrninv 45 K Zhyt Bgro TTF9 X Le JT XCAVWEgf Ah IFn CDocument12 pagesWrninv 45 K Zhyt Bgro TTF9 X Le JT XCAVWEgf Ah IFn CMAT-LIONNo ratings yet

- SMiRT-23 Paper 093Document10 pagesSMiRT-23 Paper 093MAT-LIONNo ratings yet

- Chapter 11 Post Integrity Assessment Risk Analysis 464-471Document8 pagesChapter 11 Post Integrity Assessment Risk Analysis 464-471MAT-LIONNo ratings yet

- Program ObjectivesDocument1 pageProgram ObjectivesMAT-LIONNo ratings yet

- Chapter 13 Management Perspectivies 492-513Document22 pagesChapter 13 Management Perspectivies 492-513MAT-LIONNo ratings yet

- 1st QuestionDocument1 page1st QuestionMAT-LIONNo ratings yet

- PL RA CH 9-307-318Document12 pagesPL RA CH 9-307-318MAT-LIONNo ratings yet

- Fatigue of Materials Solved Problems UnlockedDocument20 pagesFatigue of Materials Solved Problems UnlockedMAT-LIONNo ratings yet

- Loss Prevention Accident Investigation 1660643140Document105 pagesLoss Prevention Accident Investigation 1660643140richardNo ratings yet

- Intergard 291Document4 pagesIntergard 291MohammadAseefNo ratings yet

- GRAUER & WEIL (INDIA) LTD PDFDocument2 pagesGRAUER & WEIL (INDIA) LTD PDFChoice OrganoNo ratings yet

- 39Document26 pages39supriyo1970No ratings yet

- Structural SteelworkDocument24 pagesStructural SteelworkJohnson SunderNo ratings yet

- Polymer Testing: Hafeezullah Memon, Yi Wei, Chengyan ZhuDocument20 pagesPolymer Testing: Hafeezullah Memon, Yi Wei, Chengyan ZhuMd. Abdur RashidNo ratings yet

- STP ShaliFloor SL 3CESDocument3 pagesSTP ShaliFloor SL 3CESRana MahatoNo ratings yet

- BS 812-113-1990 Testing Aggregates. Method For Determination of Aggregate Abrasion Value (AAV)Document11 pagesBS 812-113-1990 Testing Aggregates. Method For Determination of Aggregate Abrasion Value (AAV)Haris KyriazisNo ratings yet

- Mastertop 1210i M 12-04Document3 pagesMastertop 1210i M 12-04djrote4No ratings yet

- Chemistry and Technology: Uv&EbDocument8 pagesChemistry and Technology: Uv&EbjdcarnNo ratings yet

- C5Document31 pagesC5kouider100% (1)

- Fusion Bonded Steel - Is.13620.1993Document16 pagesFusion Bonded Steel - Is.13620.1993Srikanth BhaskaraNo ratings yet

- Resuline 2013 07Document2 pagesResuline 2013 07Alex BocicaNo ratings yet

- Care, Maintenance, and Testing OF Hot Line ToolsDocument20 pagesCare, Maintenance, and Testing OF Hot Line ToolsjosefmarqNo ratings yet

- Skiff Building InstructionsDocument30 pagesSkiff Building InstructionsTom Bee0% (2)

- Silquest A-1120 SILQUEST A-2120: and SilanesDocument4 pagesSilquest A-1120 SILQUEST A-2120: and SilanesPranshu JainNo ratings yet

- Epoxy Curing Agent BrochureDocument9 pagesEpoxy Curing Agent Brochureavinash3285No ratings yet

- Raychem Molded PartsDocument28 pagesRaychem Molded PartsAMNo ratings yet

- Innovative Lpe CoatingsDocument30 pagesInnovative Lpe CoatingsCarmen RusuNo ratings yet

- Composites: Part B: C.S. Verma, V.M. ChariarDocument7 pagesComposites: Part B: C.S. Verma, V.M. ChariarNeveRedNo ratings yet

- GP 3477 Epoxy Sealer Primer PDSDocument2 pagesGP 3477 Epoxy Sealer Primer PDSMarina AvNo ratings yet

- 1-Nitocote CM210Document4 pages1-Nitocote CM210Ahmed I. GhallabNo ratings yet

- 08chapter 3 FiberDocument8 pages08chapter 3 FiberAhmed AbdulazeezNo ratings yet

- Polydeck 3000: UV Stable Flexible Car Park Coating SystemDocument2 pagesPolydeck 3000: UV Stable Flexible Car Park Coating SystemAlexi ALfred H. TagoNo ratings yet

- 1 s2.0 S0266353805001193 MainDocument14 pages1 s2.0 S0266353805001193 MainDevan1984No ratings yet

- Rivertable 101 How To Build Rivertable PDFDocument14 pagesRivertable 101 How To Build Rivertable PDFMark ManzanoNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet