Professional Documents

Culture Documents

URS-Capsule Filling Machine

URS-Capsule Filling Machine

Uploaded by

QAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

URS-Capsule Filling Machine

URS-Capsule Filling Machine

Uploaded by

QACopyright:

Available Formats

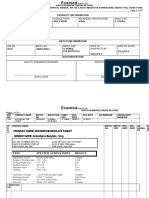

SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

USER REQUIREMENT

SPECIFICATION (URS)

NAME : CAPSULE FILLING MACHINE

USER DEPARTMENT : PRODUCTION (SUDAIR PLANT )

URS REFERENCE No. :

APPROVAL OF URS

In-Charge Name & Title Signature Date

Prepared By

Production Department Head

Reviewed By

Maintenance Department Head

Reviewed By

Validation Department Head

Reviewed By

Quality Assurance Department

Head

Approved By

Head – Quality & Technical Affairs

CONFIDENTIAL INFORMATION SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

NOT TO BE REPRODUCED / DISCLOSED WITHOUT PRIOR WRITTEN APPROVAL

Page 1 of 5

SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

USER REQUIREMENT SPECIFICATION

EQUIPMENT NAME CAPSULE FILLING MACHINE

URS REFERENCE No.

S.NO PARAMETER DETAILED DESCRIPTION OF THE SPECIFICATION

EQUIPMENT /

1 Capsule Filling Machine

MACHINE NAME

Capsule Filling Machine should be designed for high precision

Capsule Filling results in the process.

It should be Designed in compliance with the cGMP standard,

This equipment is design to create a uniform capsule filling process

with powder and granules

PURPOSE & Max output (capsules/hour): 90,000 / hr

2 GENERAL Filling percentage(accuracy ):99.7%

DESCRIPTION Vacuum: as per manufacturer recommendation

No. of die orifice: as per manufacturer recommendation and should

be in SS 316 quality.

Dimensions : as per manufacturer recommendation

It should be cGMP model, Complying to industrial standard and easy

to operate , clean

Capsule filling machine shall be installed at sudair plant of Production

INSTALLATION

3 section of Saudi Pharmaceutical Industries. Sudair site , Kingdom of

LOCATION

Saudi Arabia

Capsule Filling Machine should be made-up SS316L construction,

MATERIAL OF

4 All surfaces shall be smooth, crevice free and corrosive resistance.

CONSTRUCTION

All other accessories shall be industrial standards

The Capsule Filling Machine shall be designed with following features

Programmable control system, touch screen panel, speed-shift and

electronic automatic counter.

SPECIFIC Fully automatic, it can complete the actions of position, separation,

5

REQUIREMENTS filling and locking of capsules. It should be advanced high precision

tooling machines that guarantee reliable interchangeability of different

capsule models.

It should be suitable for pharmaceutical products such as powder,

pellets, and granules, even special products with sticky, abrasive,

fibrous or other properties.

CONFIDENTIAL INFORMATION SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

NOT TO BE REPRODUCED / DISCLOSED WITHOUT PRIOR WRITTEN APPROVAL

Page 2 of 5

SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

USER REQUIREMENT SPECIFICATION

EQUIPMENT NAME CAPSULE FILLING MACHINE

URS REFERENCE No.

It should be space-saving machine and should provides a

straightforward operation, format changeover

The housing and surface are covered with stainless steel 304. All

contact parts of medical powders are made from a corrosion resistant

stainless steel 316.

All parts are standardized and easy to substitute.

Capable of filling 6 capsules at a time with operation from 10 stations.

Accurate operation for orientation, opening, filling, joining and ejecting

of the capsules

Compulsory spiral feeding in the powder hopper to ensure powder

feeding and filling.

Dual capsule-opening design to ensure all capsules are opened.

Electrical impact protection device to prevent any further damage.

The machine should stop automatically in the event of collision.

Safety Sensing System to shut the machine down automatically in the

event of problems when no capsules, no powder, door is opened, and

abnormal load for the machine are detected.

Automatic vacuum removal of the air in the dosing tube to give more

accurate weight of the filled capsules.

Exclusive dosing tube system, temperature of the powder will not rise

during the filling process.

Adjustable compression piston in dosing tube to adjust the powder

volume without change parts.

Easy to changeable

Dosage accuracy.

Conforms to cGMP.

Flexible batch operations.

Easy to operate with a PLC system fully integrated with a HMI

Meets high quality testing standards (both EU and cGMP)

High production capacity and change parts for one years

Need capsule polisher

Cost competitive

high filling accuracy to the vertical-movement and the vacuum

assisted vacuum dosators

Quick format changes because only a very few format sets required

Statistical weight control system (CWC) for filled capsules

CONFIDENTIAL INFORMATION SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

NOT TO BE REPRODUCED / DISCLOSED WITHOUT PRIOR WRITTEN APPROVAL

Page 3 of 5

SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

USER REQUIREMENT SPECIFICATION

EQUIPMENT NAME CAPSULE FILLING MACHINE

URS REFERENCE No.

Optional automatic feed units for products and capsules

Automatic drug hopper in-feed mechanism to eliminate variations.

Guarantee high degree of accuracy and precision

Special purpose gauges are provided for quick and easy change over

Faulty capsule and filled capsule ejection stations with individual

air controls.

Adjustable gap between dosing disk and tamping plate ensures

minimum spillage of powder.

Automatic Capsule Filling Machine should be designed and

developed to fill hard / soft gelatin capsules with powder or pellets. It

is an extremely durable and reliable machine that fills dosages to the

highest accuracy. It can be applicable to the widest range of capsules

at all sizes and should guarantee the integrity of all capsules.

the empty capsules are fed from the storage hopper and through

rectifying unit, into the two piece filling ring

As the ring is rotated, a vacuum is applied on the outer side. This

vaccum seats the bodies into the lower half of the ring, while the caps

retained in the upper portion.

OPERATING The two pieces of the ring are separated, and the cap containing

6

PRINCIPLE portion is placed aside. The body containing portion of the ring is

placed on a variable speed turntable and is rotated mechanically

rotated under the powder hopper, which contains an auger for the

forced delivery of the powder.

After one complete rotation the powder hopper is removed, and the

two segments of the ring are rejoined.

The intact ring is positioned in front of the peg ring and the closing

plate is pivoted to 180 degrees.

Pneumatic pressure is applied to the peg ring, which forces the

capsules body into the cap and the closing plate.

Ejection of the capsules are collected through a chute

Emergency bottom shall be provided on the panel

Safety Sensing System to shut the machine down automatically in the

SAFETY event of problems when no capsules, no powder, door is opened, and

7

FEATURES abnormal load for the machine are detected.

Other features shall comply with industrial requirements

CONFIDENTIAL INFORMATION SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

NOT TO BE REPRODUCED / DISCLOSED WITHOUT PRIOR WRITTEN APPROVAL

Page 4 of 5

SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

USER REQUIREMENT SPECIFICATION

EQUIPMENT NAME CAPSULE FILLING MACHINE

URS REFERENCE No.

DATA & HMI screen shall be displayed all function like fill volume capsule

8

RPORTS counter , batch no. date and time option shall be provided

Test certificates of the different Materials used in the construction of

TEST the machine (MOC certificates).

9 CERTIFICATES Calibration certificates of the all the instruments

(Hard Copies) Data sheets of all major parts

One copy of operational , maintenance manuals in English

One copy of Functional specification in English

One copy of design specification created by vendor ( English )

One copy of validation document (DQ, IQ,OQ And PQ ) (optional)

DOCUMENTATI Data sheet for the all installed instruments

10

ON Machine mechanical , electrical diagrams

Change parts shall be provided as applicable

Spare part for first one year

P&ID , electrical drawing to be provided

Four levels ( operator , supervisor , Maintenance , admin) multi user

11 Passwords

password access to the HMI shall be provided

Start up & Required Start up & technical support on the user site during final

12

Technical support installation and qualification time.

Installation will be done at site by our Maintenance team.

Type of current –single phase , 220 Voltage and Frequency : 60 Hz

Energy / Utility or

13

Resources 3 phase supply,380 Voltage and Frequency :60 Hz

CONFIDENTIAL INFORMATION SAUDI PHARMACEUTICAL INDUSTRIES - RIYADH

NOT TO BE REPRODUCED / DISCLOSED WITHOUT PRIOR WRITTEN APPROVAL

Page 5 of 5

You might also like

- Area Qualification ProtocolDocument19 pagesArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- 2-E.BMR Liquid InjectionDocument28 pages2-E.BMR Liquid InjectionMohammed Zubair100% (7)

- Aphrin 500 MG Capsule BPR 2Document16 pagesAphrin 500 MG Capsule BPR 2ShagorShagor100% (2)

- 2 Facility Qualification UrsDocument3 pages2 Facility Qualification UrsDarlenis RodriguezNo ratings yet

- Protocol For The Conduct of Stability StudiesDocument4 pagesProtocol For The Conduct of Stability StudiesManish shankarpure100% (1)

- Validation ProtocolDocument9 pagesValidation ProtocolVikram ChhabraNo ratings yet

- Capsule Filler UrsDocument22 pagesCapsule Filler Urspham hoang quan100% (2)

- Aphrin 500 MG Capsule BPR 1Document12 pagesAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagorNo ratings yet

- Guide To Master Formulae Final 2012Document119 pagesGuide To Master Formulae Final 2012MohamedRefaatMohamedNo ratings yet

- Capsule Filling Machine OQDocument37 pagesCapsule Filling Machine OQvenki_bee76% (21)

- High Sheer Granulator URSDocument11 pagesHigh Sheer Granulator URSPépé Techopatham100% (1)

- Metformin FormulationDocument6 pagesMetformin Formulationsujit50% (2)

- Microbial Limit Test SOPDocument31 pagesMicrobial Limit Test SOPDipika Sunil Patel100% (5)

- cGMP Current Good Manufacturing Practices for PharmaceuticalsFrom EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsRating: 1 out of 5 stars1/5 (2)

- BPR - FP025-1 V-1Azinil 35ml PFSDocument17 pagesBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (1)

- BMR - Elfexo 120 TabletDocument13 pagesBMR - Elfexo 120 TabletShagorShagor100% (1)

- Tablet Tooling in Compression MachineDocument32 pagesTablet Tooling in Compression Machinesubirme0% (1)

- Sop For Cleaning Capsule Filling Machine C-14 in Capsulation Room 2Document5 pagesSop For Cleaning Capsule Filling Machine C-14 in Capsulation Room 2WANDERA ROBERTNo ratings yet

- Capsule FillingDocument23 pagesCapsule FillingErum ManzoorNo ratings yet

- Semi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationDocument9 pagesSemi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationGeotamNo ratings yet

- BMR SuspensionsDocument16 pagesBMR SuspensionsMohammed Zubair50% (2)

- 01 - Assay Procedure Development Protocol (APDP) of Celozin TabletDocument5 pages01 - Assay Procedure Development Protocol (APDP) of Celozin TabletShagorShagorNo ratings yet

- Actpro Al Drysyrup 3b001Document48 pagesActpro Al Drysyrup 3b001joerichladNo ratings yet

- List of Raw Material ActiveDocument11 pagesList of Raw Material ActiveShagorShagor0% (1)

- Prepared by Production: Approved by QA/QC:: TERASOL® 600 BolusDocument19 pagesPrepared by Production: Approved by QA/QC:: TERASOL® 600 BolusLegese HailuNo ratings yet

- Quality Dossier of Asmatab TabletDocument16 pagesQuality Dossier of Asmatab TabletShagorShagor100% (1)

- BMR Cephracap 500 Cap Checked 1Document16 pagesBMR Cephracap 500 Cap Checked 1jordan7half7don100% (2)

- URS 01 - Rotary Press Tablet Machine SPLDocument18 pagesURS 01 - Rotary Press Tablet Machine SPLrosy0171057% (7)

- CV Protocol-Coated TabletsDocument22 pagesCV Protocol-Coated Tabletsqaheadjml007No ratings yet

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Document5 pagesManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairNo ratings yet

- Xoxiban 10mg Tab VPDocument13 pagesXoxiban 10mg Tab VPziauddin bukhariNo ratings yet

- URS Lab Scale Counter Pressure Autoclave (Rev 1b)Document12 pagesURS Lab Scale Counter Pressure Autoclave (Rev 1b)puneetogupta100% (2)

- Prosses Validation Protocol For Albendazole SuspensionDocument25 pagesProsses Validation Protocol For Albendazole Suspensionمحمد عطاNo ratings yet

- User Requirement Specification For Weighing BalanceDocument12 pagesUser Requirement Specification For Weighing BalanceChandramauli MishraNo ratings yet

- Xrex 50mg CapDocument20 pagesXrex 50mg Capziauddin bukhariNo ratings yet

- Manufacturing Formula: Product: Univit SyrupDocument6 pagesManufacturing Formula: Product: Univit SyrupMohammed ZubairNo ratings yet

- SOP For Cleaning of Bottle Filling MachineDocument4 pagesSOP For Cleaning of Bottle Filling MachineSolomon0% (1)

- VAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleDocument3 pagesVAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleMarwa Ahmed100% (2)

- Validation of Equipment: Validation of Tablet Compression (Machine)Document20 pagesValidation of Equipment: Validation of Tablet Compression (Machine)Navdeep ChaudharyNo ratings yet

- Manufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Document6 pagesManufacturing Formula: PRODUCT: Neuropal Suspension (Pyritinol Dihydrochloride 100mg)Mohammed ZubairNo ratings yet

- Template Data PQR SANTA E 100Document124 pagesTemplate Data PQR SANTA E 100Dina FadillaNo ratings yet

- Sop For Operating Dry GranulatorDocument3 pagesSop For Operating Dry GranulatorsaimaNo ratings yet

- Cleaning Validation ProcessDocument11 pagesCleaning Validation Processsamia khan100% (1)

- BMR of Vericef 500capsuleDocument17 pagesBMR of Vericef 500capsuleShagorShagor100% (1)

- Site Master FileDocument16 pagesSite Master Fileshrikantmsd0% (1)

- Bulk Hold Time Study 1657011635Document6 pagesBulk Hold Time Study 1657011635Huỳnh Ngọc SángNo ratings yet

- Airlock SystemDocument15 pagesAirlock SystemKhalidaFaseehNo ratings yet

- Manufacturing Formula: Product: Ctzine SyrupDocument6 pagesManufacturing Formula: Product: Ctzine SyrupMohammed Zubair100% (1)

- Aphrin PFS BMR V-01Document13 pagesAphrin PFS BMR V-01ShagorShagorNo ratings yet

- Prepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusDocument17 pagesPrepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusLegese HailuNo ratings yet

- 10 - Design and Performance QualificationDocument8 pages10 - Design and Performance Qualificationsainzb83No ratings yet

- Cipro - MFR 500r1Document18 pagesCipro - MFR 500r1Anonymous IVUj0uiNo ratings yet

- SMP 200mgDocument7 pagesSMP 200mgTahir IbrahimNo ratings yet

- Process Validation GuidanceDocument11 pagesProcess Validation GuidancedutoitlouwNo ratings yet

- Performance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .Document14 pagesPerformance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .mehrdarou.qa100% (1)

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- Uv FormatDocument5 pagesUv FormatQANo ratings yet

- URS-Coating MachineDocument4 pagesURS-Coating MachineQA100% (1)

- URS-oct BlenderDocument4 pagesURS-oct BlenderQANo ratings yet

- URS-Fluid Bed Dryer-CancilledDocument4 pagesURS-Fluid Bed Dryer-CancilledQANo ratings yet