Professional Documents

Culture Documents

Plastic Material Properties Table

Plastic Material Properties Table

Uploaded by

Joy's MavunguOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastic Material Properties Table

Plastic Material Properties Table

Uploaded by

Joy's MavunguCopyright:

Available Formats

Plastic

material properties table pdf

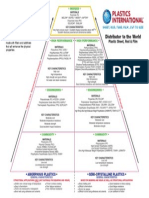

Sort, compare, and find the plastic material suited for your application * View additional table for data – click material name Properties for some of the materials above represent a specific grade, formulation, specification, or brand including the following: Acetal (Homopolymer), Acrylic (Continuously Processed), DuPont™ Vespel® Polyimide

(Vespel® SP-1), ECTFE (Halar® 901), ETFE (Tefzel® HT-2183), Expanded PVC (Celtec® 3mm-12mm thickness), KYDEX® Thermoplastic Sheet (KYDEX® 100), Noryl® (Modified PPO), Nylon (6/6 Extruded), PET (Semicrystalline), Polycarbonate Film (Makrofol® DE 1-1), Polyester Film (Skyrol® SH82 .005" thickness), Polypropylene (Homopolymer),

PPSU (Radel® R), PVDF (Homopolymer). All statements, technical information, and recommendations contained in this publication are for informational purposes only. Curbell Plastics, Inc. does not guarantee the accuracy or completeness of any information contained herein and it is the customer’s responsibility to conduct its own review and make

its own determination regarding the suitability of specific products for any given application. Hardness, Izod impact, light transmittance, tensile strength and more. Degree to which a plastic resists sliding against another material. A lower number indicates more slippery. Degree to which a plastic changes size due temperature change. High number

indicates more growth when heated. The load at which a plastic test specimen fails in compression. A measure of the voltage required to puncture a plastic insulating material. A measure of the flexural stiffness of a plastic prior to breaking or permanently deforming. The load at which a plastic test specimen fails in flexure. The resistance of a plastic

material to indentation. The degree to which a transparent plastic material appears cloudy. The temperature at which a plastic test specimen will bend a specified distance under a specified load. The energy that it takes to break a plastic test specimen. An indication of the toughness of a material. The ability of a plastic to transmit light.

A higher number indicates greater transparency. An approximate temperature above which a plastic material will be more likely to fail. The density of a plastic compared with the density of water. A higher number indicates a denser plastic.

The degree to which a plastic test specimen can be stretched under a tensile load prior to failure. A measure of the tensile (pulling) stiffness of a plastic material prior to breaking or permanently deforming. The load at which a plastic test specimen fails when it is pulled from both ends. The % increase in the weight of a plastic when it is immersed in

water for a specified period of time.

You might also like

- BS 8571-2018Document30 pagesBS 8571-2018mithilesh100% (2)

- Fortron PPS Material SpecDocument59 pagesFortron PPS Material Specranjan_ganapathiNo ratings yet

- Material PropertiesDocument3 pagesMaterial PropertiesmialitaNo ratings yet

- Material Selection Guide PDFDocument86 pagesMaterial Selection Guide PDFstaticfactory9281100% (2)

- Chemistry 9th Fbise PDFDocument211 pagesChemistry 9th Fbise PDFtala khole50% (6)

- Thermoplastics Selection GuideDocument1 pageThermoplastics Selection GuidelokomundoNo ratings yet

- Hytrel Product Reference GuideDocument4 pagesHytrel Product Reference GuideashkansoheylNo ratings yet

- Miscellaneous StorageDocument1 pageMiscellaneous StorageSamson ArayanNo ratings yet

- Material Selection: 800-877-ALRODocument18 pagesMaterial Selection: 800-877-ALROdiadam07No ratings yet

- Classification of ThermoplasticsDocument9 pagesClassification of ThermoplasticsJoe JoeNo ratings yet

- Ethylene Vinyl AcetateDocument5 pagesEthylene Vinyl AcetateAli RazuNo ratings yet

- Plastic Properties HandbookDocument15 pagesPlastic Properties HandbookguilloteARGNo ratings yet

- Classification of ThermoplasticsDocument9 pagesClassification of ThermoplasticsEd Willis100% (1)

- Lecture 4Document16 pagesLecture 4Rahmeh EL saaiedehNo ratings yet

- Plastic Material Selection GuideDocument7 pagesPlastic Material Selection Guide1000kyNo ratings yet

- 012 Additional AlroDocument18 pages012 Additional AlroPartagon PowNo ratings yet

- Film and Flexible Packaging Materials CharacterizationDocument5 pagesFilm and Flexible Packaging Materials CharacterizationsggdgdNo ratings yet

- FoodProcessing HandlingBrochure2011Document8 pagesFoodProcessing HandlingBrochure2011Wm BatzNo ratings yet

- Derakane 411 350 Tds PDFDocument5 pagesDerakane 411 350 Tds PDFRuth MillerNo ratings yet

- Dylite-Eps Guide Amer enDocument21 pagesDylite-Eps Guide Amer enAjay IyerNo ratings yet

- General Properties of PetDocument3 pagesGeneral Properties of PetpavithraNo ratings yet

- Overmolding GuidelinesDocument18 pagesOvermolding GuidelinesRJCIIINo ratings yet

- Hetron CR 197Document3 pagesHetron CR 197Faidhi SobriNo ratings yet

- Ptfe Datasheet CurbellDocument1 pagePtfe Datasheet CurbellAbohicham AbhNo ratings yet

- (C H) CH OH (Mixed Isomers) : Primary Amyl AlcoholDocument3 pages(C H) CH OH (Mixed Isomers) : Primary Amyl AlcoholFredy CastillejoNo ratings yet

- Polymer Additive Reference StandardsDocument36 pagesPolymer Additive Reference Standardsvasucristal100% (1)

- Manufacturers Plastic Materials Generics: DisadvantagesDocument1 pageManufacturers Plastic Materials Generics: DisadvantagesNevin BakrNo ratings yet

- Fluoro GE 125Document1 pageFluoro GE 125Virender KumarNo ratings yet

- Vespel S Parts Shapes PropertiesDocument18 pagesVespel S Parts Shapes PropertiesVinaya Almane DattathreyaNo ratings yet

- Hytel Product GuideDocument15 pagesHytel Product GuidewantamanualNo ratings yet

- Spaceloft DS 1.1Document1 pageSpaceloft DS 1.1raeggaemanNo ratings yet

- ThermoplasticDocument10 pagesThermoplasticvaniakash294No ratings yet

- XXXXXX XXXXXXXXXXX XXXXXXX XXXXXXXXXXXX XXXXXXXXX: Dowlex™ Pe-Rt FaqDocument6 pagesXXXXXX XXXXXXXXXXX XXXXXXX XXXXXXXXXXXX XXXXXXXXX: Dowlex™ Pe-Rt Faqdiadam07No ratings yet

- Physical and Chemical Properties: ECTFE (Ethylene Chlorotrifluoroethlyene) Is ADocument3 pagesPhysical and Chemical Properties: ECTFE (Ethylene Chlorotrifluoroethlyene) Is ASurajPachhadeNo ratings yet

- Techtron HPVDocument3 pagesTechtron HPVwillys8No ratings yet

- PV Specificna Velicina Za PA6 Plastiku - QUADRANT-Products - Applications - GuideDocument44 pagesPV Specificna Velicina Za PA6 Plastiku - QUADRANT-Products - Applications - Guide022freeNo ratings yet

- CrastinSK603NC010 CompleteDocument6 pagesCrastinSK603NC010 Completerajcoep88No ratings yet

- Gamma Compatible Materials ListDocument4 pagesGamma Compatible Materials ListGilbert WongNo ratings yet

- Honam Honam: DescriptionDocument1 pageHonam Honam: Descriptionsirartur5No ratings yet

- Ramakrishna2001 (Unlocked by WWW - Freemypdf.com)Document36 pagesRamakrishna2001 (Unlocked by WWW - Freemypdf.com)testerNo ratings yet

- Tensile Properties (Sheet) ASTM D882Document3 pagesTensile Properties (Sheet) ASTM D882info100% (1)

- P35 UNI Datasheet S2013Document2 pagesP35 UNI Datasheet S2013mallenman640No ratings yet

- High Density Polyethylene (HDPE) Resins: Product Safety AssessmentDocument7 pagesHigh Density Polyethylene (HDPE) Resins: Product Safety Assessmentngocthang7117No ratings yet

- Technical Data Sheet: Subject: The Peak A59 Safety HatDocument2 pagesTechnical Data Sheet: Subject: The Peak A59 Safety HatErika Patricia Donado CaamañoNo ratings yet

- Peek - and - Pekk - Applicationin - Dentistry (3) (AutoRecovered)Document14 pagesPeek - and - Pekk - Applicationin - Dentistry (3) (AutoRecovered)dr.leena7amid8690No ratings yet

- PolymersDocument35 pagesPolymersYash AwatadeNo ratings yet

- PolymersDocument35 pagesPolymersYash Awatade100% (1)

- Rotating: EquipmentDocument36 pagesRotating: EquipmentBureau VeritasNo ratings yet

- Food Pharma GBDocument32 pagesFood Pharma GBjosvangompelNo ratings yet

- Gasket BrochureDocument26 pagesGasket BrochureAreeb KhanNo ratings yet

- Matrix Material SelectionDocument3 pagesMatrix Material SelectionDevendra BangarNo ratings yet

- Tony Whelan, John Goff (auth.) - Injection Molding of Thermoplastics Materials β€" 1-Springer US (1990)Document167 pagesTony Whelan, John Goff (auth.) - Injection Molding of Thermoplastics Materials β€" 1-Springer US (1990)Constantinus InFleshNo ratings yet

- Mechanical Properties of Polyamide Versus Different PMMA Denture Base MaterialsDocument4 pagesMechanical Properties of Polyamide Versus Different PMMA Denture Base MaterialsThi LiemNo ratings yet

- Vistalon™ 878P: Ethylene Propylene Copolymer RubberDocument1 pageVistalon™ 878P: Ethylene Propylene Copolymer RubberMaram YasserNo ratings yet

- ZAT146 Catalog REV10 WEBDocument132 pagesZAT146 Catalog REV10 WEBgsheetslogisticsNo ratings yet

- PPA Fact SheetDocument4 pagesPPA Fact SheetBilly FowlerNo ratings yet

- One Vendor Complete List of Materials Available For Plastic Nuts and BoltsDocument5 pagesOne Vendor Complete List of Materials Available For Plastic Nuts and BoltsChristopher HartmanNo ratings yet

- PolymersDocument35 pagesPolymersYash AwatadeNo ratings yet

- Mechanical Properties of Drilling Mud Waste-Filled Low Density Polyethylene CompositesDocument9 pagesMechanical Properties of Drilling Mud Waste-Filled Low Density Polyethylene Compositesgplese0No ratings yet

- PlasticDocument55 pagesPlasticdtaneja11100% (1)

- Ms-215 Max-Tek™ Signs & Tags: DescriptionDocument2 pagesMs-215 Max-Tek™ Signs & Tags: DescriptionSayarLinnNo ratings yet

- HW 01 Solutions Spring 2012 ThermodynamicsDocument5 pagesHW 01 Solutions Spring 2012 ThermodynamicsGabito EssienNo ratings yet

- Pesticide Biodegradation: Mechanisms, Genetics and Strategies To Enhance The ProcessDocument39 pagesPesticide Biodegradation: Mechanisms, Genetics and Strategies To Enhance The ProcessLia MaldivesNo ratings yet

- Sigma FG 10 PDFDocument4 pagesSigma FG 10 PDFdhanu2399No ratings yet

- AISI SAE 4130 Product Datasheet D.A.Cooper SonsDocument1 pageAISI SAE 4130 Product Datasheet D.A.Cooper SonsHaris AliNo ratings yet

- Technozen Quiz MaterialDocument35 pagesTechnozen Quiz MaterialKarthi100% (1)

- Boyle'S Law: Driving Question - ObjectiveDocument6 pagesBoyle'S Law: Driving Question - ObjectiveSherif AyantayoNo ratings yet

- 96719302871Document41 pages96719302871yourmomstitsNo ratings yet

- Quantitative Analysis of Vitamin B1 With Alkalimetry MethodDocument3 pagesQuantitative Analysis of Vitamin B1 With Alkalimetry MethodFitri SamiaNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationNileshNo ratings yet

- s.3 Is-Bio Ch.2 WsDocument13 pagess.3 Is-Bio Ch.2 WsChris WongNo ratings yet

- ES 3 Envi Chem - LECTURE SYLLABUSDocument3 pagesES 3 Envi Chem - LECTURE SYLLABUSAtlas CerboNo ratings yet

- Development and Characterization of A Wood Adhesive Using Bagasse LigninDocument9 pagesDevelopment and Characterization of A Wood Adhesive Using Bagasse Ligninfaiz ismaNo ratings yet

- Specification For Valves P-09-1001 Rev0Document29 pagesSpecification For Valves P-09-1001 Rev0Anonymous H8EsgFCXjWNo ratings yet

- Chapter TwoDocument14 pagesChapter TwoEboO QQNo ratings yet

- Four Steps To Effective Pigment Dispersions Jadel Baptista DCC LanscoDocument5 pagesFour Steps To Effective Pigment Dispersions Jadel Baptista DCC LanscoEyad AlsheiikhNo ratings yet

- Blood and PH BalanceDocument28 pagesBlood and PH Balancesamia75% (4)

- Testing Mixer PerformanceDocument4 pagesTesting Mixer PerformanceAnsariNo ratings yet

- Chapter01 PDFDocument16 pagesChapter01 PDFnirattisaikulNo ratings yet

- Terpenes and Terpenoids: Principles of Biochemistry BIOC-301 Dr. Gull-E-FaranDocument10 pagesTerpenes and Terpenoids: Principles of Biochemistry BIOC-301 Dr. Gull-E-FaranFahad NaeemNo ratings yet

- A4 CLASSIC PINK (@wonrika On TWT) GDocs Notes Upated TemplateDocument3 pagesA4 CLASSIC PINK (@wonrika On TWT) GDocs Notes Upated TemplateJheryn May BulagaoNo ratings yet

- Part Design ThermoformingDocument34 pagesPart Design ThermoformingSampanna Aware100% (1)

- Handbook Mechanical Engeneering PDFDocument88 pagesHandbook Mechanical Engeneering PDFRafaelGloriaPereiraNo ratings yet

- The Drying of Apples in A Laboratory Tray Drier PDFDocument12 pagesThe Drying of Apples in A Laboratory Tray Drier PDFgauri guptaNo ratings yet

- Document of Analyst ChemicalDocument3 pagesDocument of Analyst ChemicalHoang BuiNo ratings yet

- SfmsdsDocument5 pagesSfmsdsapi-263411629No ratings yet

- ARBDocument27 pagesARBApurba Sarker ApuNo ratings yet

- Revision Notes On Chemical ThermodynamicsDocument6 pagesRevision Notes On Chemical ThermodynamicsManish SainiNo ratings yet