Professional Documents

Culture Documents

Design Criteria For Structural FRP Composites

Design Criteria For Structural FRP Composites

Uploaded by

TS WongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Criteria For Structural FRP Composites

Design Criteria For Structural FRP Composites

Uploaded by

TS WongCopyright:

Available Formats

DESIGN CRITERIA FOR STRUCTURAL FRP COMPOSITES

The design of the fiberglass portions of these tanks follows guidance from the

American Society of Mechanical Engineers Standard. ASME-RTP-1-95

(REINFORCED THERMOSET PLASTIC CORROSION RESISTANT EQUIPMENT),

and ASTM-4097-95a (STANDARD SPECIFICATION FOR CONTACT-MOLDED

GLASS-FIBER-REINFORCED THERMOSET RESIN CORROSION RESISTANT

TANKS), as noted through out this document. These standards were written for the

design of large fiberglass tanks used for the storage of corrosive chemicals and are

considered very conservative by the fiberglass industry.

For all static, sustained load cases a margin of safety of 10 will be adhered to above

the laminates ultimate tensile strength as prescribed in ASTM-RTP-1, section 3A-

210. In general, this gives an allowable stress for sustained load cases of 1500 psi.

For transient, or live load situations a margin of 5 will be maintained above the

laminates ultimate tensile strength as prescribed in ASTM-RTP-1, section 3A-440. In

general this gives an allowable stress of 3000 psi for these cases. See Appendix A

for select information from these standards.

The deflection criteria which is used for the design of these tanks while under the

hydrostatic load are as follows:

A) A) For the design of the FRP panels and top flange a deflection

limit of L/300 is adhered to.

B) B) For the design of the perimeter of the window opening along

each span a deflection limit of L/300 is adhered to.

No deflection requirements are adhered to for the seismic load case.

The criteria for the steel stands are to have a maximum stress allowable of 22,000

psi in any member, for any load case.

MATERIAL PROPERTIES AND LAMINATES

The structural laminates considered in this analysis are of general-purpose ortho-

polyester resin with E-type fiberglass reinforcement. The laminates utilized in the

construction of these tanks will be of the Type II Laminates as given in ASTM-RTP-1,

table 2A-1, 3 (See appendix A). The thickness for different regions of the tanks are

as described in shop drawings for each individual tank, and are noted throughout this

report.

The laminate properties listed here along with the minimum thickness as described

herein are considered design minimums, which must be maintained during the

manufacturing of the tanks. Thicknesses are considered minimum structural

thicknesses. This thickness’ do not include any corrosion barrier or suffice finish

enhancement layers. These thicknesses’ can be increased at the discretion of the

manufacturer for reasons such as surface finish etc.

PROPERTY -------------------------------Type II Laminate = Alternate Layers 24

oz. WR, 1.5 oz. CSM

Density (lbs/cu.in.)----------------------.05 - .07

% fiber volume--------------------------30 or greater

Tensile modulus (psi)--------------------1.3 e6

Shear modulus (psi)---------------------0.40 e6

Ult. Tensile strength (psi)----------------15000

Ult. Compressive strength (psi)----------15000

Ult. Flexural strength (psi)---------------19000

Ult. Shear In-Plane (psi)-----------------7800

Interlaminar Shear (psi)------------------1500

The structural core to be used in the sandwich panel regions of the fiberglass tanks

will be of end grain balsa wood typically used in marine construction.

The density and mechanical properties of the cores used in this analysis are provided

below.

PROPERTY Balsa Properties

Density (lbs/cu.ft.) 7.5 min.

Shear strength (psi) 432

Shear modulus (psi) 23,100

Compressive modulus (psi) 590,000

You might also like

- Design of Penstock Pipe For A HydroelectDocument21 pagesDesign of Penstock Pipe For A Hydroelectjanardhana100% (1)

- NeopreneDocument15 pagesNeopreneEnriPatNo ratings yet

- Level 3 Assessment As Per API 579-1ASME FFS-1 For Pressure Vessel General Metal Loss by Using FEA Techniques by Kingston.RDocument21 pagesLevel 3 Assessment As Per API 579-1ASME FFS-1 For Pressure Vessel General Metal Loss by Using FEA Techniques by Kingston.Rkingston100% (1)

- FPR SpecificationsDocument15 pagesFPR SpecificationsHector Manuel Leon JimenezNo ratings yet

- ESPCI Design & Material Specs 102403 - LandscapeDocument1 pageESPCI Design & Material Specs 102403 - LandscapeAlin ApoNo ratings yet

- ASTM A779 - Steel StrandsDocument4 pagesASTM A779 - Steel StrandsberkdemirNo ratings yet

- Construction Standard: IPS-C-CE-200Document34 pagesConstruction Standard: IPS-C-CE-200lin xuNo ratings yet

- Book 1Document3 pagesBook 1charansalkutiNo ratings yet

- Welded Pressure Vessel CalculationDocument7 pagesWelded Pressure Vessel CalculationClark Ivan TorresNo ratings yet

- Chapter 2 - Post-Tensioning.Document13 pagesChapter 2 - Post-Tensioning.SaiMinMinNo ratings yet

- General Rubber 1100 Rej Specs PDFDocument6 pagesGeneral Rubber 1100 Rej Specs PDFRyan FisherNo ratings yet

- D 2310 - 97 - Rdizmtatukve PDFDocument4 pagesD 2310 - 97 - Rdizmtatukve PDFAndre CasteloNo ratings yet

- For Official Use Only DOC: WRD 14 (546) P: Preliminary Draft Indian StandardDocument8 pagesFor Official Use Only DOC: WRD 14 (546) P: Preliminary Draft Indian StandardSouvik DasNo ratings yet

- Diseno Con Hierro DuctilDocument9 pagesDiseno Con Hierro DuctilHarvey HernandezNo ratings yet

- Riveted Joints ASME IDocument7 pagesRiveted Joints ASME ICastoriadisNo ratings yet

- AISI CSP Durability GuideDocument4 pagesAISI CSP Durability Guiderhonald2000No ratings yet

- Astm D2996 17Document4 pagesAstm D2996 17Zakaria MOKARAMNo ratings yet

- BXUV.P264 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P264 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Pre-Stress Concrete Lab Report: Submitted by Bashir Ahmad (2020-MS-CES-108)Document9 pagesPre-Stress Concrete Lab Report: Submitted by Bashir Ahmad (2020-MS-CES-108)Mir MujeebNo ratings yet

- Pdvsa: Engineering Design ManualDocument7 pagesPdvsa: Engineering Design ManualAndresNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 pagesTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNo ratings yet

- Sec 1038Document4 pagesSec 1038Lauren BowenNo ratings yet

- D 3840 - 99 Rdm4ndatotkDocument9 pagesD 3840 - 99 Rdm4ndatotkHumberto GutierrezNo ratings yet

- Modern Armour Configurations Against 14.5 MM AP LASS 1999Document31 pagesModern Armour Configurations Against 14.5 MM AP LASS 1999spartha_beNo ratings yet

- Is 11639 - 2 Penstock BuriedDocument10 pagesIs 11639 - 2 Penstock BuriedVSMS8678100% (2)

- ADSS SpecificationDocument9 pagesADSS SpecificationSetfree NkomoNo ratings yet

- Alumina DaDocument7 pagesAlumina DaBurak GülenNo ratings yet

- Chrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai IndexDocument11 pagesChrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai IndexPACO PAQUETINESNo ratings yet

- Strength Calculation For ThermowellsDocument5 pagesStrength Calculation For ThermowellsTaylorNo ratings yet

- Astm A847Document5 pagesAstm A847Mohamed FaroukNo ratings yet

- Strength Calculation For Thermowells: ApplicationsDocument5 pagesStrength Calculation For Thermowells: ApplicationsPankaj BawariNo ratings yet

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- Wake Frequency CalcDocument4 pagesWake Frequency Calcteban09No ratings yet

- How To - Tech Data Sheet - Handrails BalustradesDocument4 pagesHow To - Tech Data Sheet - Handrails Balustradesomar9aNo ratings yet

- Fiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square Handrails Guard, Square Railing SystemsDocument10 pagesFiberglass (GRP) Pultruded Open-Weather Storm-And Guard-Square Handrails Guard, Square Railing SystemsDavid Drolet TremblayNo ratings yet

- Vessel Nozzle PDFDocument30 pagesVessel Nozzle PDFEugenia LorenzaNo ratings yet

- Rectangular Duct AtteDocument4 pagesRectangular Duct AtteShahrukh AnsariNo ratings yet

- Casing and TubingDocument13 pagesCasing and TubingHany AhmedNo ratings yet

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 3Document75 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 3Percy Romero Murillo100% (1)

- FGTankVes DesignDocument2 pagesFGTankVes Designagit pratamaNo ratings yet

- A 416 A416-M - 99Document5 pagesA 416 A416-M - 99Tan Tanju100% (1)

- F2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic PipeDocument8 pagesF2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic Pipemasoud132No ratings yet

- WIKA Thermowell Wake FrequencyDS IN0015 en Co 1353Document7 pagesWIKA Thermowell Wake FrequencyDS IN0015 en Co 1353Shameer MajeedNo ratings yet

- Bearing Design - Steel ReinforcementDocument10 pagesBearing Design - Steel ReinforcementRajesh SarswaNo ratings yet

- Esr 2408Document41 pagesEsr 2408rolandoriNo ratings yet

- Additional Requirements For Heavy Wall IP 5-1-2 Pressure Vessels, Thickness Over 2 InchesDocument5 pagesAdditional Requirements For Heavy Wall IP 5-1-2 Pressure Vessels, Thickness Over 2 Incheshcsharma1967No ratings yet

- DO - 007 - s2018 Standard Specifications For Item 1406, Rubber Dock FendersDocument11 pagesDO - 007 - s2018 Standard Specifications For Item 1406, Rubber Dock FendersanbertjonathanNo ratings yet

- DOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsDocument42 pagesDOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsRebaz A. OthmanNo ratings yet

- PPI Bridge Bearing Pads and StripsDocument7 pagesPPI Bridge Bearing Pads and StripsdineshweerasingheNo ratings yet

- American Institute of Timber Construction: AITC 402-2005Document6 pagesAmerican Institute of Timber Construction: AITC 402-2005jerchiNo ratings yet

- Strengthening of RC Chimneys With FRP Composites 0Document6 pagesStrengthening of RC Chimneys With FRP Composites 0andyhrNo ratings yet

- Tin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedDocument8 pagesTin Mill Products, Black Plate Electrolytic Chromium-Coated, Single and Double ReducedsamehNo ratings yet

- M203M-12 Especificacion Torones Trenzado Resistencia Aliviada Concreto PreesfuerzoDocument9 pagesM203M-12 Especificacion Torones Trenzado Resistencia Aliviada Concreto Preesfuerzodannychacon27No ratings yet

- SECTION 03 15 15 Elastomeric Bearing Pads: Part 1 - General 1.01 Section IncludesDocument0 pagesSECTION 03 15 15 Elastomeric Bearing Pads: Part 1 - General 1.01 Section IncludesLauren BowenNo ratings yet

- Apex Belting Conveyor HandbookDocument102 pagesApex Belting Conveyor Handbooksasha_seferovic1874No ratings yet

- Elastomeric Bearing 1 PDFDocument9 pagesElastomeric Bearing 1 PDFSuresh YedureswaramNo ratings yet

- Elastomeric Bearing 1Document9 pagesElastomeric Bearing 1Anonymous jLLjBdrNo ratings yet

- Section 5 Mechanical Standards Tema Class R C B: StyleDocument195 pagesSection 5 Mechanical Standards Tema Class R C B: StyleASI.KHMEDNo ratings yet

- Urban Desalination - Using Thickening Technologies Lime SaturatorsDocument6 pagesUrban Desalination - Using Thickening Technologies Lime SaturatorsTS WongNo ratings yet

- An Intro To Ozone GenerationDocument16 pagesAn Intro To Ozone GenerationTS WongNo ratings yet

- Water SecurityDocument310 pagesWater SecurityTS WongNo ratings yet

- Wet Scrubber For Exhaust Gas CleaningDocument4 pagesWet Scrubber For Exhaust Gas CleaningTS WongNo ratings yet

- Scrubbing For Clean AirDocument2 pagesScrubbing For Clean AirTS WongNo ratings yet

- Henry Law ConstantDocument8 pagesHenry Law ConstantTS WongNo ratings yet

- Lime For Dry ScrubbingDocument3 pagesLime For Dry ScrubbingTS WongNo ratings yet

- Engneering Guide BookDocument39 pagesEngneering Guide BookTS WongNo ratings yet

- What Is OzoneDocument26 pagesWhat Is OzoneTS WongNo ratings yet

- Case Study - Water Supply 2009Document133 pagesCase Study - Water Supply 2009TS WongNo ratings yet

- Bond Strength of FRPDocument7 pagesBond Strength of FRPTS WongNo ratings yet

- FRP Pipe AnalysisDocument4 pagesFRP Pipe AnalysisTS WongNo ratings yet

- Depth Efficiencies AerationDocument1 pageDepth Efficiencies AerationTS WongNo ratings yet

- Ozone Demand EffectDocument11 pagesOzone Demand EffectTS WongNo ratings yet

- Sterilization of HoneyDocument4 pagesSterilization of HoneyTS WongNo ratings yet

- GRP CoversDocument12 pagesGRP CoversTS WongNo ratings yet

- Strongest JointDocument5 pagesStrongest JointTS WongNo ratings yet

- CFRP Pipe Repair - How To Ensure SuccessDocument7 pagesCFRP Pipe Repair - How To Ensure SuccessTS WongNo ratings yet

- Joining Good Practice Guide - FINALDocument77 pagesJoining Good Practice Guide - FINALTS WongNo ratings yet

- FRP Pipes SpecificationsDocument1 pageFRP Pipes SpecificationsTS WongNo ratings yet

- Nitrate RemovalDocument1 pageNitrate RemovalTS WongNo ratings yet

- General Electrochemistry For Chlorine GenerationDocument9 pagesGeneral Electrochemistry For Chlorine GenerationTS WongNo ratings yet

- Specification For FRP Weir and Scum BafflesDocument4 pagesSpecification For FRP Weir and Scum BafflesTS WongNo ratings yet

- How Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingDocument4 pagesHow Long Should My Thermocouple Last - 2020-03-12 - Industrial HeatingTS WongNo ratings yet

- Injector Equipment SelectionDocument11 pagesInjector Equipment SelectionTS WongNo ratings yet

- Methods and Tools For Minimizing Heat Loss - 2020-11-10 - Process HeatingDocument7 pagesMethods and Tools For Minimizing Heat Loss - 2020-11-10 - Process HeatingTS WongNo ratings yet

- Launder Cover SpecificationsDocument4 pagesLaunder Cover SpecificationsTS WongNo ratings yet

- FRP Pipe Restraint DesignDocument2 pagesFRP Pipe Restraint DesignTS WongNo ratings yet

- Data Sheet: Karrasch & Eckert Karrasch & Eckert Karrasch & Eckert Karrasch & EckertDocument1 pageData Sheet: Karrasch & Eckert Karrasch & Eckert Karrasch & Eckert Karrasch & EckertTS WongNo ratings yet

- Transformer Oil Shell DIALA-S4-ZX-IGDocument3 pagesTransformer Oil Shell DIALA-S4-ZX-IGAsim IbrahimNo ratings yet

- Topic 1Document53 pagesTopic 1dixn__No ratings yet

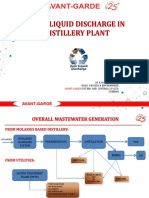

- Avant-Garde Mr. K Mohan KumarDocument46 pagesAvant-Garde Mr. K Mohan KumarSivakumar SelvarajNo ratings yet

- Part B: Stoichiometry: UNIT 4: Chemical Reactions, The Mole, Stoichiometry and ThermodynamicsDocument22 pagesPart B: Stoichiometry: UNIT 4: Chemical Reactions, The Mole, Stoichiometry and ThermodynamicsJacob MazzaNo ratings yet

- Chap 5: Separation of Substances: 6 (CBSE) Future Group Tuitions ScienceDocument2 pagesChap 5: Separation of Substances: 6 (CBSE) Future Group Tuitions ScienceSwapnil ChaudhariNo ratings yet

- Valvula Bola KT 585 580 UlDocument1 pageValvula Bola KT 585 580 UlOscar Fernandez SanchezNo ratings yet

- JATMv2n2 p169-182 Synthesis of A Boron Modified Phenolic ResinDocument14 pagesJATMv2n2 p169-182 Synthesis of A Boron Modified Phenolic ResinBình BeNo ratings yet

- Ohmic HeatingDocument5 pagesOhmic HeatingM.Hashir KhanNo ratings yet

- Unit 4 Basic Electronics: StructureDocument23 pagesUnit 4 Basic Electronics: StructureParminder singh parmarNo ratings yet

- Extracted Pages From Hygienic-Butterfly-Valves-F250-F251-Standard-Suedmo-Brochure-En5Document1 pageExtracted Pages From Hygienic-Butterfly-Valves-F250-F251-Standard-Suedmo-Brochure-En5Khairi NorzianNo ratings yet

- Co2 Capture PHD ThesisDocument5 pagesCo2 Capture PHD Thesisnibaditapalmerpaterson100% (2)

- Acrylock - Instructions For UseDocument2 pagesAcrylock - Instructions For UseZlatan DizdarevicNo ratings yet

- 2015 Experimental Research on the Electrochemical Machinability of Selected Γ-TiAl Alloys for the Manufacture of Future Aero Engine ComponentsDocument5 pages2015 Experimental Research on the Electrochemical Machinability of Selected Γ-TiAl Alloys for the Manufacture of Future Aero Engine Componentsomkar dadiNo ratings yet

- HMTDocument234 pagesHMTkanivelNo ratings yet

- GRDSLABDocument15 pagesGRDSLABmjlazo0% (1)

- Latent Heat of VaporizationDocument11 pagesLatent Heat of VaporizationEsther Faith GabrielNo ratings yet

- BSV Bspool 2019Document28 pagesBSV Bspool 2019juanldosNo ratings yet

- Raw Board Battle Round 2Document4 pagesRaw Board Battle Round 2Maridil Joy IsidroNo ratings yet

- Torrefaction Reactor Technologies StatusDocument52 pagesTorrefaction Reactor Technologies StatusHarish KumarNo ratings yet

- Denso Utility TapeDocument2 pagesDenso Utility TapeMark Darrel AranasNo ratings yet

- Production, Charecterisation and Process Optimization of Biodiesel From Hevea Brasiliensis and Waste Engine OilDocument14 pagesProduction, Charecterisation and Process Optimization of Biodiesel From Hevea Brasiliensis and Waste Engine OilGangaNo ratings yet

- Norma SAE J 306Document8 pagesNorma SAE J 306jizuNo ratings yet

- Earth Science Quarter 1Document222 pagesEarth Science Quarter 1Mickaella TaborlupaNo ratings yet

- Evaporation Vs BoilingDocument2 pagesEvaporation Vs BoilingJagdeep SekhonNo ratings yet

- Biomass Project ReportDocument11 pagesBiomass Project ReportRajeev Venegalla100% (4)

- Wire - Rope ExaminationDocument74 pagesWire - Rope ExaminationAyman6494% (17)

- PK0097PEN Mass Spectrometer OmniStarThermoStarDocument8 pagesPK0097PEN Mass Spectrometer OmniStarThermoStarSichem GuerreroNo ratings yet

- Thermolib UserManualDocument334 pagesThermolib UserManualFreeway SmileNo ratings yet

- Tunnel Design CriteriaDocument18 pagesTunnel Design Criteria티무르/학생/토목공학No ratings yet