Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsWarehouse Operations Executive Inventory Management Executive

Warehouse Operations Executive Inventory Management Executive

Uploaded by

Quế SươngThe document provides a skills map for warehouse operations executives, inventory management executives, and warehouse assistant managers. It outlines their key responsibilities which include planning and implementing complex warehouse processes and operations. It also details their critical work functions such as performing warehousing tasks, business continuous improvement activities, cargo handling tasks, safety and health tasks, and technology application tasks. Their technical skills and competencies include automation design and leveraging data analytics to review efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Rita's Process Chart - 9th Edition: Initiating Executing Closing Planning Monitoring & ControllingDocument2 pagesRita's Process Chart - 9th Edition: Initiating Executing Closing Planning Monitoring & Controllingwinzylamb67% (3)

- Sap ActivateDocument10 pagesSap ActivatejsphdvdNo ratings yet

- CMMI v.2 0 Model Excerpt Estimating Practice Area ModelsDocument32 pagesCMMI v.2 0 Model Excerpt Estimating Practice Area ModelsNagini MNo ratings yet

- Hello Kitty in Chinese Zodiac Costume Dog: Amigurumi Doll PatternDocument11 pagesHello Kitty in Chinese Zodiac Costume Dog: Amigurumi Doll PatternEdith Raymundo Jara100% (1)

- 13 - Stakeholder Management - 11 PDFDocument24 pages13 - Stakeholder Management - 11 PDFAnonymous j19GEvKNNo ratings yet

- MNT - 036 - Configuration OverviewDocument50 pagesMNT - 036 - Configuration OverviewWael100% (1)

- Quality: Position DescriptionDocument6 pagesQuality: Position DescriptionalammasoodNo ratings yet

- PPt-OSCM-mg1 2020 AulaDocument21 pagesPPt-OSCM-mg1 2020 AulaSepta IkaNo ratings yet

- Week 9 EVEN - WorkBook2 - Designing Operations (Completed)Document22 pagesWeek 9 EVEN - WorkBook2 - Designing Operations (Completed)Vincentio WritingsNo ratings yet

- Module 2Document43 pagesModule 2KhushiNo ratings yet

- Paperrenjana PDFDocument17 pagesPaperrenjana PDFOner RenoNo ratings yet

- MPB 9 - Redesain Proses - Gasal120Document44 pagesMPB 9 - Redesain Proses - Gasal120iqbal aditamaNo ratings yet

- InitiatingDocument11 pagesInitiatingVirenDesaiNo ratings yet

- Bussys AnalystDocument5 pagesBussys AnalystTrish FaleganNo ratings yet

- Ewm CV Lakshminarasimha2024Document2 pagesEwm CV Lakshminarasimha2024Jallapuram Lakshmi NarasimhaNo ratings yet

- TSC OverviewSF BookletSF For Energy ChemicalsDocument9 pagesTSC OverviewSF BookletSF For Energy Chemicalsloli2323No ratings yet

- JSI Supply Chain Manager's Handbook Chpt.8 FinalDocument11 pagesJSI Supply Chain Manager's Handbook Chpt.8 FinalSwostik RoutNo ratings yet

- Rational Unified ProcessDocument45 pagesRational Unified ProcessLuis Miguel Carrillo HuancaNo ratings yet

- Apics Cpim: Certified in Planning & Inventory ManagementDocument8 pagesApics Cpim: Certified in Planning & Inventory ManagementMohamed El-sirNo ratings yet

- Inventory Control System PDFDocument2 pagesInventory Control System PDFAalif IbràhimNo ratings yet

- Overview of Technical Skills and CompetenciesDocument7 pagesOverview of Technical Skills and CompetenciesSekinat OdumosuNo ratings yet

- T1. 4. TerminologyDocument11 pagesT1. 4. TerminologyMarquise BelgradeNo ratings yet

- Skills Framework For Food Manufacturing Skills Map - Production ManagerDocument2 pagesSkills Framework For Food Manufacturing Skills Map - Production ManagerSamantha LeeNo ratings yet

- Krajewski Chapter 02Document25 pagesKrajewski Chapter 02Sergio MorenoNo ratings yet

- Curriculum Syllabus Template Level - 7 Retail Store ManagerDocument14 pagesCurriculum Syllabus Template Level - 7 Retail Store ManagerDinesh SharmaNo ratings yet

- PMP Process ChartDocument1 pagePMP Process ChartJennifer Hanks100% (1)

- Adobe Scan 03-Aug-2023Document3 pagesAdobe Scan 03-Aug-2023RajeshNo ratings yet

- Supply Chain Manager ResponsibilitiesDocument8 pagesSupply Chain Manager ResponsibilitiesvbadsNo ratings yet

- OM Group 04Document13 pagesOM Group 04Hassnain RiadNo ratings yet

- Introduction To Production and Operations ManagementDocument30 pagesIntroduction To Production and Operations ManagementReigneir PatotoyNo ratings yet

- Cbme 1Document3 pagesCbme 1cezarioNo ratings yet

- 4-5. PEC - PMP - PM Processes - Initiating Group PDFDocument16 pages4-5. PEC - PMP - PM Processes - Initiating Group PDFSyed Farhan EhteshamNo ratings yet

- Usaa Data EngineerDocument3 pagesUsaa Data EngineerluluNo ratings yet

- Procurement Coordination and Policy DevelopmentDocument2 pagesProcurement Coordination and Policy DevelopmentHana DwiNo ratings yet

- REPORTING - Function of Operation MNGTDocument16 pagesREPORTING - Function of Operation MNGTmarjorie.maraveNo ratings yet

- SAP Security Solutions: Is Your Business Protected?Document7 pagesSAP Security Solutions: Is Your Business Protected?maniNo ratings yet

- Production Effectiveness Is Achieved by Production Management While Production Efficiency Is Achieved Through Production SystemDocument1 pageProduction Effectiveness Is Achieved by Production Management While Production Efficiency Is Achieved Through Production SystemTiffany CorsinoNo ratings yet

- PG Operations ManagementDocument3 pagesPG Operations ManagementShajad AhmadNo ratings yet

- Project Charter - Group AssignmentDocument9 pagesProject Charter - Group Assignmentsuhasana0305No ratings yet

- 02SMR Ses2 Ver 1-2Document52 pages02SMR Ses2 Ver 1-2rajatgayal100% (1)

- Production-Operations Management ReviewerDocument3 pagesProduction-Operations Management ReviewerRicky RixNo ratings yet

- Project Management Process Chart: Initiating Planning Executing Monitoring & Control ClosingDocument1 pageProject Management Process Chart: Initiating Planning Executing Monitoring & Control ClosingPERVEZ AHMAD KHAN100% (1)

- Steelwedge Rapid Implementation MethodologyDocument13 pagesSteelwedge Rapid Implementation MethodologyNarayan SubramanianNo ratings yet

- ARC PresentationDocument19 pagesARC PresentationajayvgNo ratings yet

- Resume-Devendra PalDocument6 pagesResume-Devendra PalSV HealthcareNo ratings yet

- ALM PresentationDocument37 pagesALM Presentationrajesh1480No ratings yet

- Self-Assessment & Evaluation of Good Distribution & Storage Practices ImplementationDocument107 pagesSelf-Assessment & Evaluation of Good Distribution & Storage Practices ImplementationAmer RahmahNo ratings yet

- Lecture3 SDLCModelsDocument45 pagesLecture3 SDLCModelsnour313hakamNo ratings yet

- CM Saini 04.01.2022 PM IntroductionDocument44 pagesCM Saini 04.01.2022 PM IntroductionManish GuptaNo ratings yet

- Controlling 4ECEDocument23 pagesControlling 4ECEKeilla Romabiles LeopandoNo ratings yet

- 3LWDCDocument2 pages3LWDCBianchiNo ratings yet

- CMMI AwarenessDocument14 pagesCMMI Awarenessmadan1981No ratings yet

- Understanding Operations Management (OM) QDocument5 pagesUnderstanding Operations Management (OM) QaidynnNo ratings yet

- Balanced Scorecard & EVA - June 23, 2011Document47 pagesBalanced Scorecard & EVA - June 23, 2011aditprasNo ratings yet

- SCD3Document16 pagesSCD3Awais AliNo ratings yet

- Operations and Supply Chain Strategy: Mcgraw-Hill/IrwinDocument12 pagesOperations and Supply Chain Strategy: Mcgraw-Hill/IrwinVanessa Aulia PutriNo ratings yet

- Comprehensive and Integrated Approach To Project Management and Solution DeliveryDocument27 pagesComprehensive and Integrated Approach To Project Management and Solution DeliveryAlan McSweeneyNo ratings yet

- QAQC - Senior QAQC EngineerDocument2 pagesQAQC - Senior QAQC EngineerHammad AhmadNo ratings yet

- SAP776150 - ALP - SAP SuccessFactors Identify Grow Process - PUBLICDocument76 pagesSAP776150 - ALP - SAP SuccessFactors Identify Grow Process - PUBLICThuhira RamNo ratings yet

- Iso26262aspice enDocument4 pagesIso26262aspice enpece.o.rodiceNo ratings yet

- R5641062 G999000001 1887777 PDFDocument5 pagesR5641062 G999000001 1887777 PDFQuế SươngNo ratings yet

- DataDocument22 pagesDataQuế SươngNo ratings yet

- Server - Bien Ban Ban Giao Thiet Bi - Hvn-TrackifyDocument2 pagesServer - Bien Ban Ban Giao Thiet Bi - Hvn-TrackifyQuế SươngNo ratings yet

- McClellands Social MotivationsDocument6 pagesMcClellands Social MotivationsQuế SươngNo ratings yet

- R5642063 G999000003 1887758 PDFDocument5 pagesR5642063 G999000003 1887758 PDFQuế SươngNo ratings yet

- R564102WM G999000001 1962665 PDFDocument2 pagesR564102WM G999000001 1962665 PDFQuế SươngNo ratings yet

- AWVSU-184 Putaway Scan Storage Unit - Correct Location SuggestedDocument10 pagesAWVSU-184 Putaway Scan Storage Unit - Correct Location SuggestedQuế SươngNo ratings yet

- DataDocument8 pagesDataQuế SươngNo ratings yet

- DataDocument8 pagesDataQuế SươngNo ratings yet

- Default Branch Plant - 12122023Document3 pagesDefault Branch Plant - 12122023Quế SươngNo ratings yet

- AWVSU-88 Production Receive FP Products Labelled (GS1)Document11 pagesAWVSU-88 Production Receive FP Products Labelled (GS1)Quế SươngNo ratings yet

- DataDocument14 pagesDataQuế SươngNo ratings yet

- AWVSU-136 Production Last Single Pallet Move To Single MHADocument19 pagesAWVSU-136 Production Last Single Pallet Move To Single MHAQuế SươngNo ratings yet

- AWVSU-186 Production Receive FP Products Labelled (GS1)Document8 pagesAWVSU-186 Production Receive FP Products Labelled (GS1)Quế SươngNo ratings yet

- AWVSU-179 Putaway Change Location - Next Loc (System Suggest)Document7 pagesAWVSU-179 Putaway Change Location - Next Loc (System Suggest)Quế SươngNo ratings yet

- AWVSU-88 Production Receive FP Products Labelled (GS1) .1-2Document6 pagesAWVSU-88 Production Receive FP Products Labelled (GS1) .1-2Quế SươngNo ratings yet

- 50 Trends Influencing Europes Food SectorDocument44 pages50 Trends Influencing Europes Food SectorQuế SươngNo ratings yet

- No More War PDF - Pauling, Linus, 1901Document260 pagesNo More War PDF - Pauling, Linus, 1901pdf ebook free downloadNo ratings yet

- Hazardous Areas - Explosionproof Solenoids: Some HistoryDocument5 pagesHazardous Areas - Explosionproof Solenoids: Some HistoryShahram GhassemiNo ratings yet

- ThesisDocument129 pagesThesisOvaid MehmoodNo ratings yet

- CitoVac EnglishDocument32 pagesCitoVac EnglishJulio C. Sierra PalominoNo ratings yet

- CASE REPORT On OsteomyelitisDocument30 pagesCASE REPORT On OsteomyelitisNirbhay KatiyarNo ratings yet

- Simple Stress and Strain Relationship: Stress and Strain in Two Dimensions, Principal Stresses, Stress Transformation, Mohr's CircleDocument67 pagesSimple Stress and Strain Relationship: Stress and Strain in Two Dimensions, Principal Stresses, Stress Transformation, Mohr's CircleMushini NagabhushanNo ratings yet

- 06 - Heights and DistancesDocument2 pages06 - Heights and DistancesRekha BhasinNo ratings yet

- Composite EbookDocument285 pagesComposite Ebooksunilas218408100% (1)

- Chapter 03Document40 pagesChapter 03AC BañaresNo ratings yet

- Types of CrutchesDocument19 pagesTypes of CrutchesJOYCE ONYEAGORONo ratings yet

- Ray OpticsDocument6 pagesRay OpticsshardaviharphysicsNo ratings yet

- BFB2 PDFDocument4 pagesBFB2 PDFQuang HuyNo ratings yet

- Beyond The Brain - Text 1Document5 pagesBeyond The Brain - Text 1ivona0mati0No ratings yet

- 2015 - Soil Mechanics II - Final - enDocument7 pages2015 - Soil Mechanics II - Final - enjohn cambixNo ratings yet

- Blood of YahwehDocument22 pagesBlood of YahwehwilliamstewardNo ratings yet

- First Homework For Reservoir Rock and Fluid Properties LabDocument7 pagesFirst Homework For Reservoir Rock and Fluid Properties Labعامر ابراهيم0% (1)

- Irjet V3i4441 PDFDocument5 pagesIrjet V3i4441 PDFnisaNo ratings yet

- ESP Front Page Idea Aravinth 2Document10 pagesESP Front Page Idea Aravinth 2adcreation3696No ratings yet

- 0 - Ar - RavindraBhan LaDocument11 pages0 - Ar - RavindraBhan LaSuryNo ratings yet

- Electronics Interview QuestionsDocument8 pagesElectronics Interview QuestionsshyamNo ratings yet

- RPLL NewDocument74 pagesRPLL NewMeta learnNo ratings yet

- The Summer Internship at Limited: Hindustan AeronauticsDocument59 pagesThe Summer Internship at Limited: Hindustan AeronauticsAbhishek StarkNo ratings yet

- Putra, 003 - 3035 - I Wayan Adi Pranata - GalleyDocument7 pagesPutra, 003 - 3035 - I Wayan Adi Pranata - Galleyeunike jaequelineNo ratings yet

- 9865 0040 01 Cop 1838+ He+ Mux+ Hux+ BrochureDocument4 pages9865 0040 01 Cop 1838+ He+ Mux+ Hux+ BrochuresofrankxNo ratings yet

- 11thMachAutoExpo 2022Document112 pages11thMachAutoExpo 2022Priyanka KadamNo ratings yet

- Lab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyDocument39 pagesLab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyswatiNo ratings yet

- FungiDocument100 pagesFungibhanklhonkNo ratings yet

- Task 2 Overview and Instructions 2021Document3 pagesTask 2 Overview and Instructions 2021alindafitrotNo ratings yet

- WEEK 8 VentilationDocument39 pagesWEEK 8 VentilationNURIN ADLINA TAJULHALIMNo ratings yet

Warehouse Operations Executive Inventory Management Executive

Warehouse Operations Executive Inventory Management Executive

Uploaded by

Quế Sương0 ratings0% found this document useful (0 votes)

4 views1 pageThe document provides a skills map for warehouse operations executives, inventory management executives, and warehouse assistant managers. It outlines their key responsibilities which include planning and implementing complex warehouse processes and operations. It also details their critical work functions such as performing warehousing tasks, business continuous improvement activities, cargo handling tasks, safety and health tasks, and technology application tasks. Their technical skills and competencies include automation design and leveraging data analytics to review efficiency.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a skills map for warehouse operations executives, inventory management executives, and warehouse assistant managers. It outlines their key responsibilities which include planning and implementing complex warehouse processes and operations. It also details their critical work functions such as performing warehousing tasks, business continuous improvement activities, cargo handling tasks, safety and health tasks, and technology application tasks. Their technical skills and competencies include automation design and leveraging data analytics to review efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views1 pageWarehouse Operations Executive Inventory Management Executive

Warehouse Operations Executive Inventory Management Executive

Uploaded by

Quế SươngThe document provides a skills map for warehouse operations executives, inventory management executives, and warehouse assistant managers. It outlines their key responsibilities which include planning and implementing complex warehouse processes and operations. It also details their critical work functions such as performing warehousing tasks, business continuous improvement activities, cargo handling tasks, safety and health tasks, and technology application tasks. Their technical skills and competencies include automation design and leveraging data analytics to review efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

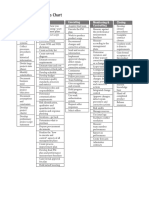

SKILLS FRAMEWORK FOR LOGISTICS

SKILLS MAP - WAREHOUSE OPERATIONS EXECUTIVE/INVENTORY MANAGEMENT EXECUTIVE/WAREHOUSE ASSISTANT MANAGER

Sector Logistics

Track Warehouse Management and Operations

Occupation Warehouse Operations Professional

Job Role Warehouse Operations Executive/Inventory Management Executive/Warehouse Assistant Manager

The Warehouse Operations Executive/Inventory Management Executive/Warehouse Assistant Manager is responsible for planning and implementing complex warehouse processes,

operations and technology. He/She is also responsible for developing plans to monitor and optimise storage utilisation levels, implementing quality programmes and using data analytics to

Job Role review efficiency of the warehouse storage and layout plans.

Description

Analytical and logical, he is required to explore solutions and analyse the feasibility of plans. He is also expected to coordinate closely with internal and external stakeholders to implement

processes and technology, and to assist in the management of the warehouse operations department.

Critical Work Functions Key Tasks

Perform Warehousing Tasks Develop warehouse planning methods, warehouse storage and layout plans

Develop warehouse storage, layout and material handling equipment (MHE) plans

Manage re-location of warehouses

Plan the information flow for end-to-end warehouse processes from order initiation to

receiving, handling, distribution and storage

Develop warehousing standards for quality management systems

Develop measures using quality management knowledge to enhance quality standards

Develop forecast planning of resources within business activities

Develop resource plans within business activities

Develop operational improvements based on performance measures

Perform Business Continuous Improvement Activities Formulate business process solutions to innovate current business processes

Analyse risks associated with different approaches of process changes

Define system scope and objectives aligned to business or contract requirements

Analyse business process improvements through workflow analysis methods to support

system development throughout project lifecycle

Adhere to corporate social responsibility policies for logistics operations

Implement advanced environmental protection policies and procedures

Formulate environmental protection policies and procedures

Perform Cargo and/or Material Handling and Delivery Tasks Select and deploy material handling systems

Critical Work

Manage cargo documentation process according to industry standards or sector

Functions and Key

requirements

Tasks

Manage supply chain security operations

Manage time and temperature-sensitive cargo operations

Review cargo consolidation plans to identify savings in space, cost and efficiency

Develop cargo-handling schedules that consider timeline and resource factors

Handle dangerous goods and hazardous materials

Perform Safety and Health Tasks Manage WSH activities to ensure department's compliance to requirements

Manage WSH solutioning discussions around suggestions to improve existing

processes

Perform safety and health risk assessment

Address WSH risks from assessment reports to determine hazards

Coordinate corrective actions to address areas of non-conformance to WSH standards

Review WSH reports to determine impact to work processes

Perform Technology Application Tasks Review latest technology trends for application to logistics business

Facilitate interactions between internal and external partners to design technology

projects

Facilitate interactions between internal and external partners to implement technology

projects

Review areas in logistics operations where technology can enhance processes

Integrate technology solutions and automations to replace inefficient processes

Leverage on data analytics to build insights on technology usage

Technical Skills and Competencies Generic Skills and Competencies (Top 5)

Automation Design Level 4 Resource Management Intermediate

Change Management Level 4 Communication Intermediate

Customer Management Level 4 Leadership Intermediate

Dangerous Goods (DG) Management Level 3 Problem Solving Intermediate

Financial Management Level 3 Decision Making Intermediate

Hazardous Materials Identification System (HMIS) Administration Level 3

Innovation Management Level 4

Logistics Solution Desig Thinking Level 4

Skills &

Process Improvement and Optimisation Level 4

Competencies

Risk Management and Administration Level 2

Shipment Load Planning and Palletisation/Consolidation Level 4

Warehous Automation Application Level 4

Warehous Layout Design Level 4

Warehouse Administration Level 4

Warehouse Inventory Control/Audit Level 4

Warehouse Management System (WMS) Administration Level 4

Warehouse Performance Measurement Level 4

Warehouse Space Utilisation Level 4

Programme Listing For a list of Training Programmes available for the Logistics sector, please visit: www.skillsfuture.sg/skills-framework/logistics

The information contained in this document serves as a guide.

© SkillsFuture Singapore

Effective date: September 2017, Version 1.1 Page 1 of 1

You might also like

- Rita's Process Chart - 9th Edition: Initiating Executing Closing Planning Monitoring & ControllingDocument2 pagesRita's Process Chart - 9th Edition: Initiating Executing Closing Planning Monitoring & Controllingwinzylamb67% (3)

- Sap ActivateDocument10 pagesSap ActivatejsphdvdNo ratings yet

- CMMI v.2 0 Model Excerpt Estimating Practice Area ModelsDocument32 pagesCMMI v.2 0 Model Excerpt Estimating Practice Area ModelsNagini MNo ratings yet

- Hello Kitty in Chinese Zodiac Costume Dog: Amigurumi Doll PatternDocument11 pagesHello Kitty in Chinese Zodiac Costume Dog: Amigurumi Doll PatternEdith Raymundo Jara100% (1)

- 13 - Stakeholder Management - 11 PDFDocument24 pages13 - Stakeholder Management - 11 PDFAnonymous j19GEvKNNo ratings yet

- MNT - 036 - Configuration OverviewDocument50 pagesMNT - 036 - Configuration OverviewWael100% (1)

- Quality: Position DescriptionDocument6 pagesQuality: Position DescriptionalammasoodNo ratings yet

- PPt-OSCM-mg1 2020 AulaDocument21 pagesPPt-OSCM-mg1 2020 AulaSepta IkaNo ratings yet

- Week 9 EVEN - WorkBook2 - Designing Operations (Completed)Document22 pagesWeek 9 EVEN - WorkBook2 - Designing Operations (Completed)Vincentio WritingsNo ratings yet

- Module 2Document43 pagesModule 2KhushiNo ratings yet

- Paperrenjana PDFDocument17 pagesPaperrenjana PDFOner RenoNo ratings yet

- MPB 9 - Redesain Proses - Gasal120Document44 pagesMPB 9 - Redesain Proses - Gasal120iqbal aditamaNo ratings yet

- InitiatingDocument11 pagesInitiatingVirenDesaiNo ratings yet

- Bussys AnalystDocument5 pagesBussys AnalystTrish FaleganNo ratings yet

- Ewm CV Lakshminarasimha2024Document2 pagesEwm CV Lakshminarasimha2024Jallapuram Lakshmi NarasimhaNo ratings yet

- TSC OverviewSF BookletSF For Energy ChemicalsDocument9 pagesTSC OverviewSF BookletSF For Energy Chemicalsloli2323No ratings yet

- JSI Supply Chain Manager's Handbook Chpt.8 FinalDocument11 pagesJSI Supply Chain Manager's Handbook Chpt.8 FinalSwostik RoutNo ratings yet

- Rational Unified ProcessDocument45 pagesRational Unified ProcessLuis Miguel Carrillo HuancaNo ratings yet

- Apics Cpim: Certified in Planning & Inventory ManagementDocument8 pagesApics Cpim: Certified in Planning & Inventory ManagementMohamed El-sirNo ratings yet

- Inventory Control System PDFDocument2 pagesInventory Control System PDFAalif IbràhimNo ratings yet

- Overview of Technical Skills and CompetenciesDocument7 pagesOverview of Technical Skills and CompetenciesSekinat OdumosuNo ratings yet

- T1. 4. TerminologyDocument11 pagesT1. 4. TerminologyMarquise BelgradeNo ratings yet

- Skills Framework For Food Manufacturing Skills Map - Production ManagerDocument2 pagesSkills Framework For Food Manufacturing Skills Map - Production ManagerSamantha LeeNo ratings yet

- Krajewski Chapter 02Document25 pagesKrajewski Chapter 02Sergio MorenoNo ratings yet

- Curriculum Syllabus Template Level - 7 Retail Store ManagerDocument14 pagesCurriculum Syllabus Template Level - 7 Retail Store ManagerDinesh SharmaNo ratings yet

- PMP Process ChartDocument1 pagePMP Process ChartJennifer Hanks100% (1)

- Adobe Scan 03-Aug-2023Document3 pagesAdobe Scan 03-Aug-2023RajeshNo ratings yet

- Supply Chain Manager ResponsibilitiesDocument8 pagesSupply Chain Manager ResponsibilitiesvbadsNo ratings yet

- OM Group 04Document13 pagesOM Group 04Hassnain RiadNo ratings yet

- Introduction To Production and Operations ManagementDocument30 pagesIntroduction To Production and Operations ManagementReigneir PatotoyNo ratings yet

- Cbme 1Document3 pagesCbme 1cezarioNo ratings yet

- 4-5. PEC - PMP - PM Processes - Initiating Group PDFDocument16 pages4-5. PEC - PMP - PM Processes - Initiating Group PDFSyed Farhan EhteshamNo ratings yet

- Usaa Data EngineerDocument3 pagesUsaa Data EngineerluluNo ratings yet

- Procurement Coordination and Policy DevelopmentDocument2 pagesProcurement Coordination and Policy DevelopmentHana DwiNo ratings yet

- REPORTING - Function of Operation MNGTDocument16 pagesREPORTING - Function of Operation MNGTmarjorie.maraveNo ratings yet

- SAP Security Solutions: Is Your Business Protected?Document7 pagesSAP Security Solutions: Is Your Business Protected?maniNo ratings yet

- Production Effectiveness Is Achieved by Production Management While Production Efficiency Is Achieved Through Production SystemDocument1 pageProduction Effectiveness Is Achieved by Production Management While Production Efficiency Is Achieved Through Production SystemTiffany CorsinoNo ratings yet

- PG Operations ManagementDocument3 pagesPG Operations ManagementShajad AhmadNo ratings yet

- Project Charter - Group AssignmentDocument9 pagesProject Charter - Group Assignmentsuhasana0305No ratings yet

- 02SMR Ses2 Ver 1-2Document52 pages02SMR Ses2 Ver 1-2rajatgayal100% (1)

- Production-Operations Management ReviewerDocument3 pagesProduction-Operations Management ReviewerRicky RixNo ratings yet

- Project Management Process Chart: Initiating Planning Executing Monitoring & Control ClosingDocument1 pageProject Management Process Chart: Initiating Planning Executing Monitoring & Control ClosingPERVEZ AHMAD KHAN100% (1)

- Steelwedge Rapid Implementation MethodologyDocument13 pagesSteelwedge Rapid Implementation MethodologyNarayan SubramanianNo ratings yet

- ARC PresentationDocument19 pagesARC PresentationajayvgNo ratings yet

- Resume-Devendra PalDocument6 pagesResume-Devendra PalSV HealthcareNo ratings yet

- ALM PresentationDocument37 pagesALM Presentationrajesh1480No ratings yet

- Self-Assessment & Evaluation of Good Distribution & Storage Practices ImplementationDocument107 pagesSelf-Assessment & Evaluation of Good Distribution & Storage Practices ImplementationAmer RahmahNo ratings yet

- Lecture3 SDLCModelsDocument45 pagesLecture3 SDLCModelsnour313hakamNo ratings yet

- CM Saini 04.01.2022 PM IntroductionDocument44 pagesCM Saini 04.01.2022 PM IntroductionManish GuptaNo ratings yet

- Controlling 4ECEDocument23 pagesControlling 4ECEKeilla Romabiles LeopandoNo ratings yet

- 3LWDCDocument2 pages3LWDCBianchiNo ratings yet

- CMMI AwarenessDocument14 pagesCMMI Awarenessmadan1981No ratings yet

- Understanding Operations Management (OM) QDocument5 pagesUnderstanding Operations Management (OM) QaidynnNo ratings yet

- Balanced Scorecard & EVA - June 23, 2011Document47 pagesBalanced Scorecard & EVA - June 23, 2011aditprasNo ratings yet

- SCD3Document16 pagesSCD3Awais AliNo ratings yet

- Operations and Supply Chain Strategy: Mcgraw-Hill/IrwinDocument12 pagesOperations and Supply Chain Strategy: Mcgraw-Hill/IrwinVanessa Aulia PutriNo ratings yet

- Comprehensive and Integrated Approach To Project Management and Solution DeliveryDocument27 pagesComprehensive and Integrated Approach To Project Management and Solution DeliveryAlan McSweeneyNo ratings yet

- QAQC - Senior QAQC EngineerDocument2 pagesQAQC - Senior QAQC EngineerHammad AhmadNo ratings yet

- SAP776150 - ALP - SAP SuccessFactors Identify Grow Process - PUBLICDocument76 pagesSAP776150 - ALP - SAP SuccessFactors Identify Grow Process - PUBLICThuhira RamNo ratings yet

- Iso26262aspice enDocument4 pagesIso26262aspice enpece.o.rodiceNo ratings yet

- R5641062 G999000001 1887777 PDFDocument5 pagesR5641062 G999000001 1887777 PDFQuế SươngNo ratings yet

- DataDocument22 pagesDataQuế SươngNo ratings yet

- Server - Bien Ban Ban Giao Thiet Bi - Hvn-TrackifyDocument2 pagesServer - Bien Ban Ban Giao Thiet Bi - Hvn-TrackifyQuế SươngNo ratings yet

- McClellands Social MotivationsDocument6 pagesMcClellands Social MotivationsQuế SươngNo ratings yet

- R5642063 G999000003 1887758 PDFDocument5 pagesR5642063 G999000003 1887758 PDFQuế SươngNo ratings yet

- R564102WM G999000001 1962665 PDFDocument2 pagesR564102WM G999000001 1962665 PDFQuế SươngNo ratings yet

- AWVSU-184 Putaway Scan Storage Unit - Correct Location SuggestedDocument10 pagesAWVSU-184 Putaway Scan Storage Unit - Correct Location SuggestedQuế SươngNo ratings yet

- DataDocument8 pagesDataQuế SươngNo ratings yet

- DataDocument8 pagesDataQuế SươngNo ratings yet

- Default Branch Plant - 12122023Document3 pagesDefault Branch Plant - 12122023Quế SươngNo ratings yet

- AWVSU-88 Production Receive FP Products Labelled (GS1)Document11 pagesAWVSU-88 Production Receive FP Products Labelled (GS1)Quế SươngNo ratings yet

- DataDocument14 pagesDataQuế SươngNo ratings yet

- AWVSU-136 Production Last Single Pallet Move To Single MHADocument19 pagesAWVSU-136 Production Last Single Pallet Move To Single MHAQuế SươngNo ratings yet

- AWVSU-186 Production Receive FP Products Labelled (GS1)Document8 pagesAWVSU-186 Production Receive FP Products Labelled (GS1)Quế SươngNo ratings yet

- AWVSU-179 Putaway Change Location - Next Loc (System Suggest)Document7 pagesAWVSU-179 Putaway Change Location - Next Loc (System Suggest)Quế SươngNo ratings yet

- AWVSU-88 Production Receive FP Products Labelled (GS1) .1-2Document6 pagesAWVSU-88 Production Receive FP Products Labelled (GS1) .1-2Quế SươngNo ratings yet

- 50 Trends Influencing Europes Food SectorDocument44 pages50 Trends Influencing Europes Food SectorQuế SươngNo ratings yet

- No More War PDF - Pauling, Linus, 1901Document260 pagesNo More War PDF - Pauling, Linus, 1901pdf ebook free downloadNo ratings yet

- Hazardous Areas - Explosionproof Solenoids: Some HistoryDocument5 pagesHazardous Areas - Explosionproof Solenoids: Some HistoryShahram GhassemiNo ratings yet

- ThesisDocument129 pagesThesisOvaid MehmoodNo ratings yet

- CitoVac EnglishDocument32 pagesCitoVac EnglishJulio C. Sierra PalominoNo ratings yet

- CASE REPORT On OsteomyelitisDocument30 pagesCASE REPORT On OsteomyelitisNirbhay KatiyarNo ratings yet

- Simple Stress and Strain Relationship: Stress and Strain in Two Dimensions, Principal Stresses, Stress Transformation, Mohr's CircleDocument67 pagesSimple Stress and Strain Relationship: Stress and Strain in Two Dimensions, Principal Stresses, Stress Transformation, Mohr's CircleMushini NagabhushanNo ratings yet

- 06 - Heights and DistancesDocument2 pages06 - Heights and DistancesRekha BhasinNo ratings yet

- Composite EbookDocument285 pagesComposite Ebooksunilas218408100% (1)

- Chapter 03Document40 pagesChapter 03AC BañaresNo ratings yet

- Types of CrutchesDocument19 pagesTypes of CrutchesJOYCE ONYEAGORONo ratings yet

- Ray OpticsDocument6 pagesRay OpticsshardaviharphysicsNo ratings yet

- BFB2 PDFDocument4 pagesBFB2 PDFQuang HuyNo ratings yet

- Beyond The Brain - Text 1Document5 pagesBeyond The Brain - Text 1ivona0mati0No ratings yet

- 2015 - Soil Mechanics II - Final - enDocument7 pages2015 - Soil Mechanics II - Final - enjohn cambixNo ratings yet

- Blood of YahwehDocument22 pagesBlood of YahwehwilliamstewardNo ratings yet

- First Homework For Reservoir Rock and Fluid Properties LabDocument7 pagesFirst Homework For Reservoir Rock and Fluid Properties Labعامر ابراهيم0% (1)

- Irjet V3i4441 PDFDocument5 pagesIrjet V3i4441 PDFnisaNo ratings yet

- ESP Front Page Idea Aravinth 2Document10 pagesESP Front Page Idea Aravinth 2adcreation3696No ratings yet

- 0 - Ar - RavindraBhan LaDocument11 pages0 - Ar - RavindraBhan LaSuryNo ratings yet

- Electronics Interview QuestionsDocument8 pagesElectronics Interview QuestionsshyamNo ratings yet

- RPLL NewDocument74 pagesRPLL NewMeta learnNo ratings yet

- The Summer Internship at Limited: Hindustan AeronauticsDocument59 pagesThe Summer Internship at Limited: Hindustan AeronauticsAbhishek StarkNo ratings yet

- Putra, 003 - 3035 - I Wayan Adi Pranata - GalleyDocument7 pagesPutra, 003 - 3035 - I Wayan Adi Pranata - Galleyeunike jaequelineNo ratings yet

- 9865 0040 01 Cop 1838+ He+ Mux+ Hux+ BrochureDocument4 pages9865 0040 01 Cop 1838+ He+ Mux+ Hux+ BrochuresofrankxNo ratings yet

- 11thMachAutoExpo 2022Document112 pages11thMachAutoExpo 2022Priyanka KadamNo ratings yet

- Lab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyDocument39 pagesLab File of Ad Hoc and Sensor Networks Lab (ETEC - 458) : Department of Information TechnologyswatiNo ratings yet

- FungiDocument100 pagesFungibhanklhonkNo ratings yet

- Task 2 Overview and Instructions 2021Document3 pagesTask 2 Overview and Instructions 2021alindafitrotNo ratings yet

- WEEK 8 VentilationDocument39 pagesWEEK 8 VentilationNURIN ADLINA TAJULHALIMNo ratings yet