Professional Documents

Culture Documents

Design Mix Computation Sheet

Design Mix Computation Sheet

Uploaded by

Ashutosh RawatCopyright:

Available Formats

You might also like

- IEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlDocument23 pagesIEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlJohn Bihag100% (1)

- DESIGN MIX OF CONCRETE - 4000psi PCDDocument6 pagesDESIGN MIX OF CONCRETE - 4000psi PCDJohn Archie Dela CruzNo ratings yet

- Concrete Mix DesignDocument10 pagesConcrete Mix Designkrishbist67% (3)

- DESIGN MIX OF CONCRETE - 6000psi PCDDocument6 pagesDESIGN MIX OF CONCRETE - 6000psi PCDJohn Archie Dela Cruz100% (2)

- Domino A Series Classic Spares Catalogue PDFDocument137 pagesDomino A Series Classic Spares Catalogue PDFprusikNo ratings yet

- Accessory Design Guidelines PDFDocument222 pagesAccessory Design Guidelines PDFYu MiNo ratings yet

- LP Separator SizingDocument81 pagesLP Separator SizingNadia BahloulNo ratings yet

- KEC Calculation Sheet SDCDocument10 pagesKEC Calculation Sheet SDCsubhaschandraNo ratings yet

- Concrete Mix DesignDocument58 pagesConcrete Mix Designharikan chaturvediNo ratings yet

- Concrete Mix Proportioning Annexure-A: Trial - 1 Trial-2 Trial-3 A-I Stipulations For ProportioningDocument11 pagesConcrete Mix Proportioning Annexure-A: Trial - 1 Trial-2 Trial-3 A-I Stipulations For ProportioningMr. Samuel BennettNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- Concrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDocument13 pagesConcrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDzey IsorenaNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- C - 25 Concrete Mix Design (Slab)Document14 pagesC - 25 Concrete Mix Design (Slab)Engineeri TadiyosNo ratings yet

- Report For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)Document9 pagesReport For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)artiNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix Designlewis kalataNo ratings yet

- C - 15 Concrete Mix Design CementDocument6 pagesC - 15 Concrete Mix Design CementEngineeri TadiyosNo ratings yet

- C - 35 Concrete Mix Design (Pipe Culvert)Document24 pagesC - 35 Concrete Mix Design (Pipe Culvert)Engineeri TadiyosNo ratings yet

- TM Concrete Mix Design M25PCCDocument11 pagesTM Concrete Mix Design M25PCCAnurag ChaturvediNo ratings yet

- DATE OF CASTING - 2/1/2022: Epc Contractor Representative Concessinoaire Independent EngineerDocument37 pagesDATE OF CASTING - 2/1/2022: Epc Contractor Representative Concessinoaire Independent Engineerjitendra dixitNo ratings yet

- MP Jal Nigam Tuv Sud M/s Larson and ToubroDocument4 pagesMP Jal Nigam Tuv Sud M/s Larson and Toubroprasant patelNo ratings yet

- Group 3Document10 pagesGroup 3Shivam SharmaNo ratings yet

- Mix Design of Class C-24 (3500psi) ConcreteDocument3 pagesMix Design of Class C-24 (3500psi) ConcreteMd. Mahmudle HassanNo ratings yet

- Design Mix of Concrete - Updated Is 10262-2019Document7 pagesDesign Mix of Concrete - Updated Is 10262-2019Raviteja MuralaNo ratings yet

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 pagesAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsNo ratings yet

- AW-1395 (Continuation Sheet)Document2 pagesAW-1395 (Continuation Sheet)udit shahNo ratings yet

- M30 Easycrete Mix DesignDocument3 pagesM30 Easycrete Mix Designabir senguptaNo ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodDocument4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodjaymarNo ratings yet

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirNo ratings yet

- Mix Design 2Document15 pagesMix Design 2partha_svnitNo ratings yet

- M 35 With FlyashDocument54 pagesM 35 With FlyashCIVIL ENGINEERINGNo ratings yet

- M30Pile Mix Design & Trial SheetDocument3 pagesM30Pile Mix Design & Trial Sheetabir senguptaNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- M 30 SFRSDocument2 pagesM 30 SFRSSudarsanan KNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- M40 Mix Design & Trial SheetDocument3 pagesM40 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Wakaaladda Horumarinta Wadooyinka: Free Zone ProjectDocument7 pagesWakaaladda Horumarinta Wadooyinka: Free Zone ProjectsacsewNo ratings yet

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarNo ratings yet

- Mix Design Details For 40 MPaDocument1 pageMix Design Details For 40 MPaTaposh PaulNo ratings yet

- M35 Revised Mix Design SheetDocument2 pagesM35 Revised Mix Design Sheetamol awateNo ratings yet

- Worksheet For Concrete Design MixDocument2 pagesWorksheet For Concrete Design MixJohn-jon LojicaNo ratings yet

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Is411 8Document1 pageIs411 8amoghimiNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix DesignWilliamray PabloNo ratings yet

- M-30 Mix Designs As Per Is-10262-2009Document4 pagesM-30 Mix Designs As Per Is-10262-2009Vinod BabhaleNo ratings yet

- Concrete Mix Design For - M5: (As Per IS 10262-2019)Document8 pagesConcrete Mix Design For - M5: (As Per IS 10262-2019)mahesh naikNo ratings yet

- M-25 Mix Designs As Per Is-10262-2009Document3 pagesM-25 Mix Designs As Per Is-10262-2009burhan.kanjeta1988No ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 3000 Psi at 28 Day 20 0.8 Good Mild 100 0.53 364Document4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 3000 Psi at 28 Day 20 0.8 Good Mild 100 0.53 364jaymarNo ratings yet

- Mix Design - M 20Document5 pagesMix Design - M 20Vijay Jamadar0% (1)

- Concrete Mixed Design For C30Document2 pagesConcrete Mixed Design For C30raju_420034520No ratings yet

- (As Per IS 10262-2019) : 1.stipulations For ProportioningDocument10 pages(As Per IS 10262-2019) : 1.stipulations For Proportioningmahesh naikNo ratings yet

- M30 Design CalculationDocument6 pagesM30 Design Calculationjeffkarthick1No ratings yet

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- Concrete Mixing DesignDocument15 pagesConcrete Mixing DesignChris ArtecoNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- 3.4 Concrete Mix Design Using ACI FormatDocument6 pages3.4 Concrete Mix Design Using ACI FormatHella SeyumNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Mix Design M45 PDFDocument6 pagesMix Design M45 PDFHarsh PatelNo ratings yet

- Filing of Resolutions and Agreements To The RegistrarDocument6 pagesFiling of Resolutions and Agreements To The RegistrarAshutosh RawatNo ratings yet

- Knowledge Sharing Session ON THE Topic OF "Statistical Quality Control Tools"Document14 pagesKnowledge Sharing Session ON THE Topic OF "Statistical Quality Control Tools"Ashutosh RawatNo ratings yet

- Data AnalysisDocument5 pagesData AnalysisAshutosh RawatNo ratings yet

- Elongation (MM) : Format No. T-1 Pull Out Test ISRM Document 2, Part 1 'Suggested Methods of Rockbolt Testing 'Document7 pagesElongation (MM) : Format No. T-1 Pull Out Test ISRM Document 2, Part 1 'Suggested Methods of Rockbolt Testing 'Ashutosh RawatNo ratings yet

- Technical Checks in P. Way Works Earthwork: Sl. No. DescriptionDocument4 pagesTechnical Checks in P. Way Works Earthwork: Sl. No. DescriptionAshutosh RawatNo ratings yet

- Technical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionDocument6 pagesTechnical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionAshutosh RawatNo ratings yet

- 7Ltwmkm - M: !V7T&TmDocument13 pages7Ltwmkm - M: !V7T&TmAshutosh RawatNo ratings yet

- Delvocrete Stabiliser v6Document2 pagesDelvocrete Stabiliser v6Ashutosh RawatNo ratings yet

- IS:1786 TMT BarDocument22 pagesIS:1786 TMT BarAshutosh RawatNo ratings yet

- Laboratory Exercise 2: Basic Logic GatesDocument5 pagesLaboratory Exercise 2: Basic Logic GatesSantiago EspitiaNo ratings yet

- 09 09 22 Rupert YoungerDocument1 page09 09 22 Rupert YoungerjordijaumaNo ratings yet

- Catalog of Throttle Body: Omp# Picture Oem No. Ref No. ApplicationDocument16 pagesCatalog of Throttle Body: Omp# Picture Oem No. Ref No. ApplicationLuiscas52No ratings yet

- Cara Program Security Alarm Merek AlboxDocument4 pagesCara Program Security Alarm Merek AlboxJhon LeoNo ratings yet

- TG SkripsiDocument138 pagesTG SkripsiYudanto SetyoNo ratings yet

- Error Detection and Correction CodesDocument36 pagesError Detection and Correction CodesSatyanarayana GarapatiNo ratings yet

- DFDDocument7 pagesDFDPramod KumarNo ratings yet

- VP Supply Chain Purchasing in Raleigh Greensboro NC Resume Jochen MeyerDocument2 pagesVP Supply Chain Purchasing in Raleigh Greensboro NC Resume Jochen MeyerJochenMeyer2No ratings yet

- Active Subwoofer 8": Order Ref: 170.190 User ManualDocument4 pagesActive Subwoofer 8": Order Ref: 170.190 User Manuallaur dafinNo ratings yet

- Moddingmorroblivion 1Document99 pagesModdingmorroblivion 1Deanna RussellNo ratings yet

- TSP P 15A Converted FileDocument76 pagesTSP P 15A Converted FileKyaw Win TunNo ratings yet

- Bolted, Sleeve-Type Couplings For Plain-End Pipe: Awwa StandardDocument28 pagesBolted, Sleeve-Type Couplings For Plain-End Pipe: Awwa Standardl_aguilar_m100% (1)

- Fi 05 Verkehrszeichen Engl 0510 30482Document13 pagesFi 05 Verkehrszeichen Engl 0510 30482Janki VernekarNo ratings yet

- Abstract - : (Type Text)Document43 pagesAbstract - : (Type Text)Roshanil kambleNo ratings yet

- Antenna QBDocument20 pagesAntenna QBMarcus McWile MorningstarNo ratings yet

- Read The Passage+a Suitable WordDocument3 pagesRead The Passage+a Suitable WordChi MinhNo ratings yet

- Department of The Navy: Approving Official (Ao) Citidirect Desk GuideDocument77 pagesDepartment of The Navy: Approving Official (Ao) Citidirect Desk GuideDavid GarciaNo ratings yet

- Clerk Mains Call Letter PDFDocument2 pagesClerk Mains Call Letter PDFhamesNo ratings yet

- IPT ReportDocument46 pagesIPT ReportSandeep Kumar YadlapalliNo ratings yet

- DataExplorer ManualDocument62 pagesDataExplorer ManualdanialalishahNo ratings yet

- SAP Solution Manager Service Level Reporting: Best Practice For E2E Solution OperationsDocument18 pagesSAP Solution Manager Service Level Reporting: Best Practice For E2E Solution Operationsamakr2010No ratings yet

- 7629Document125 pages7629Mark JohnsonNo ratings yet

- PGL-III-655: PGL-III-655 Is Made Features of Small Size, Drived by Battery, Special Safety Parts DesignDocument1 pagePGL-III-655: PGL-III-655 Is Made Features of Small Size, Drived by Battery, Special Safety Parts DesignSanjay PatilNo ratings yet

- Mounting On Concrete DSBDocument4 pagesMounting On Concrete DSBRolando AlvaradoNo ratings yet

- Daruma FrameworkDocument400 pagesDaruma FrameworkPietro BragaNo ratings yet

- UNSC - United States of America Position PaperDocument3 pagesUNSC - United States of America Position PaperemmaldavisNo ratings yet

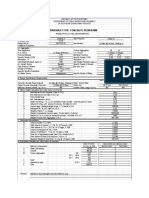

Design Mix Computation Sheet

Design Mix Computation Sheet

Uploaded by

Ashutosh RawatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Mix Computation Sheet

Design Mix Computation Sheet

Uploaded by

Ashutosh RawatCopyright:

Available Formats

Design stipulations for proportioning (M50 Grade)

As per IS 10262

A-1 Stipulations for Proportioning

a Grade designation M 50

b Type of cement OPC 53 S

c Max. nominal size of agg. 20

Minimum cement content Kg/cum 320

d

Maximum water cement ratio 0.45

Exposure condition Severe

e Workability mm 75 +/- 25

g Method of Concrete Placing Non Pumpable

Degree of Site Control Good

Crushed Angular

Type of agg. Aggregate

Maximum cement content Kg/cum 450

Super Plasticizer-

Chemical Admixture Type Normal

Type of Concrete PLAIN

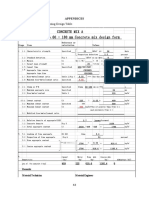

A-2 Test Data For Materials

a Cement Used

b Specific Gravity Of Cement 3.15

c Chemical Admixture

d Specific Gravity of

Coarse aggregate (at SSD) 2.83

Fine Aggregate (at SSD) 2.73

Chemical Admixture 1.11

e Water absorption

Coarse aggregate 1.57

Fine Aggregate 2.04

f Moisture content of Aggregate

Coarse aggregate Nil

Fine Aggregate Nil

A-3 Target Strength for Mix Proportioning

f( grade of

X (As per Table 1 of IS 10262:2019) 6.5 concrete)

f( grade of

S (As per Table 2 of IS 10262:2019) 5 concrete)

f'ck=fck+1.65S 58.25

f'ck=fck+X 56.5

Assumed Standard Deviation

(Clause 8.7.5.3) of IRS:CBC 7.4

Target Strength 62.21

Adopt f'ck (N/mm2) 62.21

A-4 Approximate Air Content

The approximate amount of entrapped air to be expected in normal

(non-air entrained) concrete (%) f( max. nominal

(As per Table 3 of IS 10262:2019) 1 size of aggregate

A-5 Selection of Water-Cement Ratio

f(exposure,grade,ty

Maximum Water cement ratio (As per Table 5 of IS:456) 0.45 pe of concrete)

f(grade,type of

The Free water cement ratio (As per Fig. 1 of IS 10262-2019) 0.39 cement)

Adopt Water cement ratio 0.34

A-6 Selection of Water Content

f( max. nominal

Water corresponding to 50mm slump 186 size of aggregate

Additional slump required 50

Water required for additional slump 11.16

Water content 197.16

Reduction of water content by using superplasticizer (%) 22.5 Assumed

Use of Plasticizer (by mass of cementitious material) 0.55

Water content 153

A-7 Calculation of Cement Content

Cement Content 450

f(exposure,grade,ty

Minimum Cement content 320 pe of concrete)

Adopt Cement Content 450

A-8 Proportion of Volume of Coarse Aggregate and Fine Aggregate

f(size of

aggrgate,Zone of

fine

aggregate,water

Volume of Coarse Aggregate (as per table 5 of IS:10262) 0.65 cement ratio)

Volume of Fine Aggregate 0.35

A-9 Mix Calculations

Total Volume cum 1

Volume of entrapped air in wet concrete cum 0.01

Volume of Cement cum 0.143

Volume of Water cum 0.153

Volume of Chemical admixture cum 0.002

Volume of all in aggregate cum 0.69

Mass of coarse aggregate kg 1269

Mass of Fine aggregate kg 651

A-10 Mix Proportions for Trial

Cement Kg/cum 450

Water Kg/cum 153

Fine Aggregate (SSD) Kg/cum 651

Coarse Aggregate (SSD) Kg/cum 1269

Chemical Admixture Kg/cum 2.475

Free Water Cement Ratio 0.34

Adjustment on water, Fine Aggregate and Coarse Aggregate (if the

A-11 coarse agggregate and Fine aggregate is in dry condition

Fine aggregate (Dry) 638

Coarse Aggregate (Dry) 1249

Water requirement 186

A-12 Mix Proportions after adjustment for Dry Aggregates

Cement Kg/cum 450

Water Kg/cum 186

Fine Aggregate (SSD) Kg/cum 638

Coarse Aggregate (SSD) Kg/cum 1249

Chemical Admixture Kg/cum 2.475

Free Water Cement Ratio 0.34

1269

651

You might also like

- IEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlDocument23 pagesIEEE Recommended Practice For Microprocessor-Based Protection Equipment Firmware ControlJohn Bihag100% (1)

- DESIGN MIX OF CONCRETE - 4000psi PCDDocument6 pagesDESIGN MIX OF CONCRETE - 4000psi PCDJohn Archie Dela CruzNo ratings yet

- Concrete Mix DesignDocument10 pagesConcrete Mix Designkrishbist67% (3)

- DESIGN MIX OF CONCRETE - 6000psi PCDDocument6 pagesDESIGN MIX OF CONCRETE - 6000psi PCDJohn Archie Dela Cruz100% (2)

- Domino A Series Classic Spares Catalogue PDFDocument137 pagesDomino A Series Classic Spares Catalogue PDFprusikNo ratings yet

- Accessory Design Guidelines PDFDocument222 pagesAccessory Design Guidelines PDFYu MiNo ratings yet

- LP Separator SizingDocument81 pagesLP Separator SizingNadia BahloulNo ratings yet

- KEC Calculation Sheet SDCDocument10 pagesKEC Calculation Sheet SDCsubhaschandraNo ratings yet

- Concrete Mix DesignDocument58 pagesConcrete Mix Designharikan chaturvediNo ratings yet

- Concrete Mix Proportioning Annexure-A: Trial - 1 Trial-2 Trial-3 A-I Stipulations For ProportioningDocument11 pagesConcrete Mix Proportioning Annexure-A: Trial - 1 Trial-2 Trial-3 A-I Stipulations For ProportioningMr. Samuel BennettNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- Concrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDocument13 pagesConcrete Mix Designs: Raw Materials Weight of Raw Materials Per Cubic Meter CMD-1 CMD-2 RemarksDzey IsorenaNo ratings yet

- Calculation of Design Mix: Fine Aggerates Coarse AggregatesDocument6 pagesCalculation of Design Mix: Fine Aggerates Coarse AggregatesVALIENT CANCERANNo ratings yet

- C - 25 Concrete Mix Design (Slab)Document14 pagesC - 25 Concrete Mix Design (Slab)Engineeri TadiyosNo ratings yet

- Report For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)Document9 pagesReport For Mix Design of Concrete Grade M-20: (With J.K.Lakshmi OPC 43G)artiNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix Designlewis kalataNo ratings yet

- C - 15 Concrete Mix Design CementDocument6 pagesC - 15 Concrete Mix Design CementEngineeri TadiyosNo ratings yet

- C - 35 Concrete Mix Design (Pipe Culvert)Document24 pagesC - 35 Concrete Mix Design (Pipe Culvert)Engineeri TadiyosNo ratings yet

- TM Concrete Mix Design M25PCCDocument11 pagesTM Concrete Mix Design M25PCCAnurag ChaturvediNo ratings yet

- DATE OF CASTING - 2/1/2022: Epc Contractor Representative Concessinoaire Independent EngineerDocument37 pagesDATE OF CASTING - 2/1/2022: Epc Contractor Representative Concessinoaire Independent Engineerjitendra dixitNo ratings yet

- MP Jal Nigam Tuv Sud M/s Larson and ToubroDocument4 pagesMP Jal Nigam Tuv Sud M/s Larson and Toubroprasant patelNo ratings yet

- Group 3Document10 pagesGroup 3Shivam SharmaNo ratings yet

- Mix Design of Class C-24 (3500psi) ConcreteDocument3 pagesMix Design of Class C-24 (3500psi) ConcreteMd. Mahmudle HassanNo ratings yet

- Design Mix of Concrete - Updated Is 10262-2019Document7 pagesDesign Mix of Concrete - Updated Is 10262-2019Raviteja MuralaNo ratings yet

- Aparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Document5 pagesAparna Enterprises Limited.: Vidya Nagar Cross (Bangalore)Kumar gsNo ratings yet

- AW-1395 (Continuation Sheet)Document2 pagesAW-1395 (Continuation Sheet)udit shahNo ratings yet

- M30 Easycrete Mix DesignDocument3 pagesM30 Easycrete Mix Designabir senguptaNo ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodDocument4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 1500 Psi at 28 Day 20 0.8 GoodjaymarNo ratings yet

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirNo ratings yet

- Mix Design 2Document15 pagesMix Design 2partha_svnitNo ratings yet

- M 35 With FlyashDocument54 pagesM 35 With FlyashCIVIL ENGINEERINGNo ratings yet

- M30Pile Mix Design & Trial SheetDocument3 pagesM30Pile Mix Design & Trial Sheetabir senguptaNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- M 30 SFRSDocument2 pagesM 30 SFRSSudarsanan KNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- SCC Class A G40 Concrete MixDocument1 pageSCC Class A G40 Concrete MixWunNaNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- M40 Mix Design & Trial SheetDocument3 pagesM40 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Wakaaladda Horumarinta Wadooyinka: Free Zone ProjectDocument7 pagesWakaaladda Horumarinta Wadooyinka: Free Zone ProjectsacsewNo ratings yet

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarNo ratings yet

- Mix Design Details For 40 MPaDocument1 pageMix Design Details For 40 MPaTaposh PaulNo ratings yet

- M35 Revised Mix Design SheetDocument2 pagesM35 Revised Mix Design Sheetamol awateNo ratings yet

- Worksheet For Concrete Design MixDocument2 pagesWorksheet For Concrete Design MixJohn-jon LojicaNo ratings yet

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Is411 8Document1 pageIs411 8amoghimiNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix DesignWilliamray PabloNo ratings yet

- M-30 Mix Designs As Per Is-10262-2009Document4 pagesM-30 Mix Designs As Per Is-10262-2009Vinod BabhaleNo ratings yet

- Concrete Mix Design For - M5: (As Per IS 10262-2019)Document8 pagesConcrete Mix Design For - M5: (As Per IS 10262-2019)mahesh naikNo ratings yet

- M-25 Mix Designs As Per Is-10262-2009Document3 pagesM-25 Mix Designs As Per Is-10262-2009burhan.kanjeta1988No ratings yet

- FFC-MBR-QC-CON-01 A Oct. 03, 2018: 3000 Psi at 28 Day 20 0.8 Good Mild 100 0.53 364Document4 pagesFFC-MBR-QC-CON-01 A Oct. 03, 2018: 3000 Psi at 28 Day 20 0.8 Good Mild 100 0.53 364jaymarNo ratings yet

- Mix Design - M 20Document5 pagesMix Design - M 20Vijay Jamadar0% (1)

- Concrete Mixed Design For C30Document2 pagesConcrete Mixed Design For C30raju_420034520No ratings yet

- (As Per IS 10262-2019) : 1.stipulations For ProportioningDocument10 pages(As Per IS 10262-2019) : 1.stipulations For Proportioningmahesh naikNo ratings yet

- M30 Design CalculationDocument6 pagesM30 Design Calculationjeffkarthick1No ratings yet

- Technical SPECIFICATION FOR PILESDocument13 pagesTechnical SPECIFICATION FOR PILESgopal sudhirNo ratings yet

- Concrete Mixing DesignDocument15 pagesConcrete Mixing DesignChris ArtecoNo ratings yet

- Img 20200831 0005Document1 pageImg 20200831 0005Aung Naing Latt AungNo ratings yet

- 3.4 Concrete Mix Design Using ACI FormatDocument6 pages3.4 Concrete Mix Design Using ACI FormatHella SeyumNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Mix Design M45 PDFDocument6 pagesMix Design M45 PDFHarsh PatelNo ratings yet

- Filing of Resolutions and Agreements To The RegistrarDocument6 pagesFiling of Resolutions and Agreements To The RegistrarAshutosh RawatNo ratings yet

- Knowledge Sharing Session ON THE Topic OF "Statistical Quality Control Tools"Document14 pagesKnowledge Sharing Session ON THE Topic OF "Statistical Quality Control Tools"Ashutosh RawatNo ratings yet

- Data AnalysisDocument5 pagesData AnalysisAshutosh RawatNo ratings yet

- Elongation (MM) : Format No. T-1 Pull Out Test ISRM Document 2, Part 1 'Suggested Methods of Rockbolt Testing 'Document7 pagesElongation (MM) : Format No. T-1 Pull Out Test ISRM Document 2, Part 1 'Suggested Methods of Rockbolt Testing 'Ashutosh RawatNo ratings yet

- Technical Checks in P. Way Works Earthwork: Sl. No. DescriptionDocument4 pagesTechnical Checks in P. Way Works Earthwork: Sl. No. DescriptionAshutosh RawatNo ratings yet

- Technical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionDocument6 pagesTechnical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionAshutosh RawatNo ratings yet

- 7Ltwmkm - M: !V7T&TmDocument13 pages7Ltwmkm - M: !V7T&TmAshutosh RawatNo ratings yet

- Delvocrete Stabiliser v6Document2 pagesDelvocrete Stabiliser v6Ashutosh RawatNo ratings yet

- IS:1786 TMT BarDocument22 pagesIS:1786 TMT BarAshutosh RawatNo ratings yet

- Laboratory Exercise 2: Basic Logic GatesDocument5 pagesLaboratory Exercise 2: Basic Logic GatesSantiago EspitiaNo ratings yet

- 09 09 22 Rupert YoungerDocument1 page09 09 22 Rupert YoungerjordijaumaNo ratings yet

- Catalog of Throttle Body: Omp# Picture Oem No. Ref No. ApplicationDocument16 pagesCatalog of Throttle Body: Omp# Picture Oem No. Ref No. ApplicationLuiscas52No ratings yet

- Cara Program Security Alarm Merek AlboxDocument4 pagesCara Program Security Alarm Merek AlboxJhon LeoNo ratings yet

- TG SkripsiDocument138 pagesTG SkripsiYudanto SetyoNo ratings yet

- Error Detection and Correction CodesDocument36 pagesError Detection and Correction CodesSatyanarayana GarapatiNo ratings yet

- DFDDocument7 pagesDFDPramod KumarNo ratings yet

- VP Supply Chain Purchasing in Raleigh Greensboro NC Resume Jochen MeyerDocument2 pagesVP Supply Chain Purchasing in Raleigh Greensboro NC Resume Jochen MeyerJochenMeyer2No ratings yet

- Active Subwoofer 8": Order Ref: 170.190 User ManualDocument4 pagesActive Subwoofer 8": Order Ref: 170.190 User Manuallaur dafinNo ratings yet

- Moddingmorroblivion 1Document99 pagesModdingmorroblivion 1Deanna RussellNo ratings yet

- TSP P 15A Converted FileDocument76 pagesTSP P 15A Converted FileKyaw Win TunNo ratings yet

- Bolted, Sleeve-Type Couplings For Plain-End Pipe: Awwa StandardDocument28 pagesBolted, Sleeve-Type Couplings For Plain-End Pipe: Awwa Standardl_aguilar_m100% (1)

- Fi 05 Verkehrszeichen Engl 0510 30482Document13 pagesFi 05 Verkehrszeichen Engl 0510 30482Janki VernekarNo ratings yet

- Abstract - : (Type Text)Document43 pagesAbstract - : (Type Text)Roshanil kambleNo ratings yet

- Antenna QBDocument20 pagesAntenna QBMarcus McWile MorningstarNo ratings yet

- Read The Passage+a Suitable WordDocument3 pagesRead The Passage+a Suitable WordChi MinhNo ratings yet

- Department of The Navy: Approving Official (Ao) Citidirect Desk GuideDocument77 pagesDepartment of The Navy: Approving Official (Ao) Citidirect Desk GuideDavid GarciaNo ratings yet

- Clerk Mains Call Letter PDFDocument2 pagesClerk Mains Call Letter PDFhamesNo ratings yet

- IPT ReportDocument46 pagesIPT ReportSandeep Kumar YadlapalliNo ratings yet

- DataExplorer ManualDocument62 pagesDataExplorer ManualdanialalishahNo ratings yet

- SAP Solution Manager Service Level Reporting: Best Practice For E2E Solution OperationsDocument18 pagesSAP Solution Manager Service Level Reporting: Best Practice For E2E Solution Operationsamakr2010No ratings yet

- 7629Document125 pages7629Mark JohnsonNo ratings yet

- PGL-III-655: PGL-III-655 Is Made Features of Small Size, Drived by Battery, Special Safety Parts DesignDocument1 pagePGL-III-655: PGL-III-655 Is Made Features of Small Size, Drived by Battery, Special Safety Parts DesignSanjay PatilNo ratings yet

- Mounting On Concrete DSBDocument4 pagesMounting On Concrete DSBRolando AlvaradoNo ratings yet

- Daruma FrameworkDocument400 pagesDaruma FrameworkPietro BragaNo ratings yet

- UNSC - United States of America Position PaperDocument3 pagesUNSC - United States of America Position PaperemmaldavisNo ratings yet