Professional Documents

Culture Documents

40211-40412 - 663011 Pre-Molded Straight Joint Kit For XLPE Insulated Cable - 002

40211-40412 - 663011 Pre-Molded Straight Joint Kit For XLPE Insulated Cable - 002

Uploaded by

Mohamed AhmiedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40211-40412 - 663011 Pre-Molded Straight Joint Kit For XLPE Insulated Cable - 002

40211-40412 - 663011 Pre-Molded Straight Joint Kit For XLPE Insulated Cable - 002

Uploaded by

Mohamed AhmiedCopyright:

Available Formats

GES 40211~40412

Technical Specification of GECOL

Pre-molded Straight Joint Kit for

XLPE Insulated Cable (11kV, 30kV, 66kV)

(Revision history)

- Issued on: Jan. 01, 2007

- Amended on: Jan.01, 2013

General Electricity Company of Libya

Contents

1 SCOPE AND SERVICE CONDITIONS.............................................................................................. 4

1.1 SCOPE .................................................................................................................................................. 4

1.2 SERVICE CONDITIONS ........................................................................................................................... 4

1.2.1 Normal service conditions ......................................................................................................... 4

1.2.2 Unusual service conditions ........................................................................................................ 4

2 NORMATIVE REFERENCES ............................................................................................................. 4

3 DEFINITIONS ....................................................................................................................................... 5

3.1 STRAIGHT JOINT ................................................................................................................................... 5

3.2 EXTRUDED ........................................................................................................................................... 5

3.3 PREMOLDED ......................................................................................................................................... 5

4 KINDS AND RATINGS......................................................................................................................... 5

4.1 KINDS .................................................................................................................................................. 5

4.2 RATING ................................................................................................................................................ 6

4.2.1 Voltage and frequency................................................................................................................ 6

4.2.2 Current and temperature ........................................................................................................... 6

4.2.3 Earthing ..................................................................................................................................... 6

4.2.4 Dimensions of cables ................................................................................................................. 6

5 REQUIREMENTS ................................................................................................................................. 7

5.1 GENERAL REQUIREMENTS .................................................................................................................... 7

5.2 KIT COMPONENTS ................................................................................................................................ 8

5.3 REQUIRED CHARACTERISTICS .............................................................................................................. 8

5.3.1 Temperature ............................................................................................................................... 8

5.3.2 Joint housing ............................................................................................................................. 8

5.3.3 Conductor connector ................................................................................................................. 8

5.3.4 Screen rebuilding metallic material for tape screened cable ..................................................... 9

5.3.5 Mechanical screen connector for wire screened cable .............................................................. 9

5.3.6 Armor restoration component .................................................................................................... 9

5.3.7 Rejaketing tube .......................................................................................................................... 9

5.3.8 Special tools and equipment required for jointing work ............................................................ 9

5.4 ELECTRICAL REQUIREMENTS ............................................................................................................... 9

5.4.1 AC withstand voltage ................................................................................................................. 9

5.4.2 DC withstand voltage .............................................................................................................. 10

2/17 Amended on Jan. 2013

5.4.3 Partial discharge voltage......................................................................................................... 10

5.4.4 Impulse voltage withstand ....................................................................................................... 10

5.4.5 Thermal cycling characteristics ............................................................................................... 11

5.4.6 Thermal short circuit current withstand of screen connector ................................................... 11

5.4.7 Thermal short circuit current withstand of conductor connector ............................................ 12

5.4.8 Dynamic short circuit current withstand ................................................................................. 12

6 TESTS ................................................................................................................................................... 12

6.1 TYPE TESTS ........................................................................................................................................ 12

6.2 ROUTINE TESTS .................................................................................................................................. 12

6.3 ACCEPTANCE TESTS ........................................................................................................................... 12

7 MARKING ........................................................................................................................................... 12

8 PACKING AND DELIVERY .............................................................................................................. 13

9 DOCUMENT AND CERTIFICATE .................................................................................................. 13

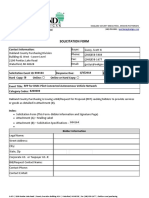

9.1 INFORMATION TO BE PROVIDED WITH THE BID .................................................................................. 14

9.2 DOCUMENTS TO BE APPROVED BY GECOL ........................................................................................ 14

9.3 DOCUMENTATION ............................................................................................................................... 14

10 WARRANTY ........................................................................................................................................ 15

3/17 Amended on Jan. 2013

GES (Technical Specification of GECOL)

Pre-molded Straight Joint Kit for XLPE Insulated Cable

(11kV, 30kV, 66kV)

1 Scope and service conditions

1.1 Scope

The specification covers the pre-molded polymeric straight cable joint kits for armored/

non-armored, single/three core(s) stranded conductor, extruded dielectric shielded, XLPE

insulated cables rated in preferred voltage of 11kV, 30kV and 66kV on distribution system

in Libya.

1.2 Service conditions

1.2.1 Normal service conditions

Cable joints shall be suitable for use under the following service conditions:

(a) In air, including expose to direct sunlight

(b) Directly buried in earth

(c) Intermittently or continuously submerged in water at a depth not exceeding 7m

(d) Environmental temperatures within the range of –10°C to +50°C

(e) Installed in cable conduits or underground chambers or tunnels or vaults

1.2.2 Unusual service conditions

Condition other than those listed in 1.2.1 for cable joints are considered to be unusual.

The manufacturer should discuss with GECOL for the unusual service conditions.

2 Normative references

The cable joints shall confirm to the latest edition of following international standards:

(a) IEC 60228: Conductors of insulated cables

(b) IEC 60502: Power cables with extruded insulation and their accessories for rated

voltage from 1kV (Um=1.2kV) up to 30kV (Um=36kV)

(c) IEC 60502-2: Power cables with extruded insulation and their accessories for rated

voltages from 1kV up to 30kV, Part 2 : Cables for rated voltage from 6kV up to 30kV

(d) IEC 60502-4: Test requirements on accessories for cables with rated voltage from 1kV

(Um=1.2kV) up to 30kV (Um=36kV)

(e) IEC 60840: Power cables with extruded insulation and their accessories for rated

voltages above 30 kV (Um = 36 kV) up to 150 kV (Um = 170 kV) - Test methods and

requirements

4/17 Amended on Jan. 2013

(f) IEC 61442: Electric cables – Test methods for accessories for power cables with rated

voltage from 6kV (Um=7.2kV) up to 30kV *Um=36kV)

(g) IEEE Std 404: Extruded and laminated dielectric shielded cable joints rated 2,500V to

500,000V

3 Definitions

3.1 Straight joint

Accessory making a connection between two cables to form a continuous circuit

3.2 Extruded

A joint in which both cables are insulated with extruded dielectric materials rated 2.5kV

to 500kV.

3.3 Premolded

A joint that is factory molded in the shape that it will take when installed. Installation is

performed by sliding the joint over the cable.

4 Kinds and ratings

4.1 Kinds

Kinds of the joint are determined by kinds of cables to be applied as listed in Table 1 of

this specification.

Table 1 – Kinds of straight joints

Specification Nominal No. of Cross Sectional

Armor Screen

No. Voltage (kV) Core(s) Area (mm2)

4021118 240

Al Wire Cu Tape

4021120 400

1

4021218 240

Non Cu Tape

4021220 11 400

4023116 150

4023117 3 Steel Tape Cu Tape 185

4023118 240

Specification Nominal No. of Cross Sectional

Armor Screen

No. Voltage (kV) Core(s) Area (mm2)

5/17 Amended on Jan. 2013

4031120 400

Al Wire Cu Wire

4031122 630

1

4031220 400

30 Non Cu Wire

4031222 630

4033116 150

3 Steel Tape Cu Tape

4033118 240

4041120 400

4041121 Al Wire Cu Wire 500

4041122 630

66 1

4041220 400

4041221 Non Cu Wire 500

4041222 630

4.2 Rating

The normal rating specified shall be the continuous rating under the worst temperature

and geographical conditions encountered in Libya.

4.2.1 Voltage and frequency

(a) The nominal system phase to phase voltage shall be 11kV, 30kV and 66kV.

(b) The system highest voltage for equipment shall be 17.5kV, 36kV, 72.5kV respectively.

(c) The voltage rating of joints shall be 8.7/15kV, 18/30kV and 36/66kV respectively.

(d) The system frequency shall be 50Hz.

4.2.2 Current and temperature

The current and temperature ratings of the cable joint shall be equal to or greater than

those of the cable for which it is designed as verified in GES 17200~17401.

4.2.3 Earthing

11kV system is effectively earthed system and no earthing on the line. 30kV system is

low resistance earthed system and no earthing on the line. 66kV system is effectively

earthed system and no earthing on the line.

4.2.4 Dimensions of cables

The joints shall comply with the cable dimensions listed in Table 2 of this specification.

Table 2 - Dimensions of cables

6/17 Amended on Jan. 2013

Rated No. of Cross Sectional Approx. Diameter (mm)

Armor Screen 2

Voltage Core(s) Area (mm ) Conductor Insulation Overall

240 18 29 43

Al Wire Cu Tape

400 23 34 49

1

240 18 29 36

Non Cu Tape

8.7/15kV 400 23 34 43

150 14 25 70

Steel

3 Cu Tape 185 16 27 74

Tape

240 18 29 80

400 23 40 59

Al Wire Cu Wire

630 31 48 66

1

400 23 40 54

18/30kV Non Cu Wire

630 31 48 60

Steel 150 14 32 93

3 Cu Tape

Tape 240 18 36 104

400 23 48 70

Al Wire Cu Wire 500 26 51 74

630 31 52 77

36/66kV 1

400 23 48 59

Non Cu Wire 500 26 51 62

630 31 52 66

5 Requirements

5.1 General requirements

Joints shall be factory engineered kits and shall be the product of one manufacturer.

Joints shall be fully shielded, suitable for use on 11kV, 30kV and 66kV distribution

systems of Libya. The joint kit and its material shall be appropriate for each cable size and

applicable voltage.

The joints shall be easily adapted to accommodate XLPE cables. The joints shall be

capable of tolerating any variance in the manufactured dimension of the cable such as oval,

out of round, sectored or oversize cable cores.

The joint kit shall contain all necessary components for stress relief, conductor

7/17 Amended on Jan. 2013

connection, and reinstatement of cable insulation and sealing.

The entire joint shall be suitable for continuous operation under water. The joint shall be

capable of immediate energizing at once after installation of all components.

The pre-molded straight joints shall meet the requirements of the latest edition of IEC

60502-4, IEC 60840 and related international standards.

5.2 Kit components

The joints kit shall contain all necessary components to reinstate the cable insulation,

metallic shielding, armor, over sheath of each core, etc.

The straight joint kits shall include following components:

(a) Joint housing(s)

(b) Shear off Connector(s) suitable for both copper and aluminum conductors.

(c) Screen rebuilding metallic material(s) for tape screened cables

(d) Mechanical screen connector(s) for wire screened cables

(e) Armor restoration component(s) for armored cables

(f) Rejaketing tube(s)

(g) Sufficient lubricants, cleaning material and cleaning cloth

(h) Installation instruction

(i) Component list

(j) All other items necessary to complete the joint

5.3 Required characteristics

5.3.1 Temperature

The joints and its components shall have equal or greater temperature endurance ability

than the insulation material of conductors to be jointed.

5.3.2 Joint housing

The joint housing shall be of one piece type and shall be of reasonable size to

accommodate cables easily. The housing shall be capable of proper sealing, sufficient

strength, robustness and impact resistance. Joint housing shall be able to smooth the

electrical field over the connector and cable screen ends. Heat transfer sleeve could be

applied, if necessary.

5.3.3 Conductor connector

The conductors connector(s) shall be Shear off type suitable for both copper and

aluminum conductors, and have good conductivity and mechanical strength. The material

shall not make galvanic corrosion with conductors.

8/17 Amended on Jan. 2013

5.3.4 Screen rebuilding metallic material for tape screened cable

Screen rebuilding metallic material shall ensure the correct screen connection across the

joint area and make electrical contact for tape screened cables with the outer screen of the

joint. The screen rebuilding material shall be copper.

5.3.5 Mechanical screen connector for wire screened cable

Mechanical screen connector cable shall ensure the correct screen connection across the

joint area and make electrical contact for wire screened cables with the outer screen of the

joint. The material of screen rebuilding connector shall copper.

5.3.6 Armor restoration component

Quick installable armor restoration component shall be provided for armored cables. The

material of armor restoration component shall not make galvanic corrosion with armor of

cables.

5.3.7 Rejaketing tube

The rejaketing tube shall provide mechanical impact and chemical resistance as

expected from cable over sheaths. The entire joint shall be environmentally sealed with a

heat activated tube which shall be adhesive and capable of prevention the ingress of

external moisture and contamination.

5.3.8 Special tools and equipment required for jointing work

The joint shall require the fewest special tools or equipment for jointing work. But if any

special tool and equipment is needed for the jointing work, full details shall be included in

the offer as separate items and with individual prices.

5.4 Electrical requirements

5.4.1 AC withstand voltage

The joints shall withstand following test voltage without breakdown or flashover for the

time specified in Table 3 of this specification.

9/17 Amended on Jan. 2013

Table 3 - AC withstand voltage and duration

Rated voltage of joint AC test voltage

Duration

(kV) (kV rms, dry)

8.7/15 39 5 min

18/30 81 5 min

36/66 90 15 min

5.4.2 DC withstand voltage

The joints shall withstand following test voltage without breakdown or flashover for the

time specified in Table 4 of this specification.

Table 4 – DC withstand voltage and duration

Rated voltage of joint DC test voltage

Duration

(kV) (kV, dry)

8.7/15 35 15 min

18/30 72 15 min

36/66 144 15 min

5.4.3 Partial discharge voltage

Minimum partial discharge voltage of the joints shall greater than following Table 5 of

this specification. The joints shall be tested at 5K to 10K above maximum cable conductor

temperature in normal operation and at ambient temperature.

Table 5 - Minimum partial discharge voltage

Rated voltage of joint Test voltage level Partial discharge limit

(kV) (kV rms) (pC)

8.7/15 15 10

18/30 30 10

36/66 54 5

5.4.4 Impulse voltage withstand

The joints shall withstand 10 positive and 10 negative full wave impulses with a

magnitude equal to the value specified in Table 6 of this specification under 5K to 10K

above maximum cable conductor temperature in normal operation and ambient

temperature.

10/17 Amended on Jan. 2013

Table 6 - Impulse voltage withstand level

Rated voltage of joint Impulse withstand voltage level

(kV) (kV peak)

8.7/15 95

18/30 170

36/66 325

5.4.5 Thermal cycling characteristics

The joints shall withstand AC test voltage specified in Table 7 of this specification

without breakdown or flashover during 30 times (8.7/15kV and 18/30kV joint) or 20 times

(36/66kV joint) of heating and cooling cycles in the air and in the water. Thermal cycle is

specified in Clause 9 of IEC 61442 and Clause 12.3.6 of IEC 60840.

Table 7 - AC withstand voltage

Rated voltage of joint AC test voltage

(kV) (kV rms, dry)

8.7/15 23

18/30 45

36/66 72

5.4.6 Thermal short circuit current withstand of screen connector

The screen connector of joints shall withstand short time, short circuit currents. The

magnitude and duration shall comply with Table 8 of this specification. The joints shall be

tested at 5K to 10K above maximum cable conductor temperature in normal operation and

ambient temperature. The short-circuit test shall not cause any deterioration of the joints

ability.

Table 8 – Short circuit current and duration

Cross sectional area of Short circuit current

Duration

conductor (mm2) (kA)

150 21.5 1 sec.

185 26.5 1 sec.

240 34.3 1 sec.

400 57.2 1 sec.

500 71.5 1 sec.

630 90.0 1 sec.

11/17 Amended on Jan. 2013

5.4.7 Thermal short circuit current withstand of conductor connector

The conductor connector of joints shall withstand short time, short circuit currents. Test

method is specified in Clause 11 of IEC 61442. The short-circuit test shall not cause any

deterioration of the joints ability.

5.4.8 Dynamic short circuit current withstand

The joints shall withstand dynamic short circuit currents. Test method is specified in

Clause 12 of IEC 61442. The short-circuit test shall not cause any deterioration of the

joints ability.

6 Tests

6.1 Type tests

Tenderer shall include with their offers type test certificates including test carried out in

accordance with the IEC 60502-4, IEC 60840 and IEC 61442, which are issued by an

approved internationally acknowledged reputable independent testing laboratory.

(a) AC withstand voltage test (IEC 61442 Clause 4, IEC 60840 Clause 12.3.7)

(b) DC withstand voltage test (IEC 61442 Clause 5)

(c) Impulse withstand voltage test (IEC 61442 Clause 6, IEC 60840 Clause 12.3.7)

(d) Partial discharge voltage level test (IEC 61442 Clause 7, IEC 60840 Clause 12.3.4)

(e) Thermal cycling test (IEC 61442 Clause 9, IEC 60840 Clause 12.3.6)

(f) Thermal short circuit test (IEC 61442 Clause 10, 11)

(g) Dynamic short circuit test (IEC 61442 Clause 12)

6.2 Routine tests

Following routine tests shall be applied 100% of production.

(a) Partial discharge voltage level test (IEC 61442 Clause 7, IEC 60840 Clause 12.3.4)

(b) AC withstand voltage test (IEC 61442 Clause 4, , IEC 60840 Clause 12.3.7)

6.3 Acceptance tests

Cable joint kits are to be checked for compliance with this specification and with the

ordering quantity. GECOL reserves the rights to ask for several kinds of type tests to

confirm the quality of the joints in the presence of GECOL representatives.

7 Marking

The joints shall be permanently and legibly identified with the following information

items.

(a) Manufacturer’s identification

(b) Model identification

(c) Part identification

12/17 Amended on Jan. 2013

(d) Date of manufacture (month and year)

(e) “Use before” (if applicable)

(f) Maximum phase-to-phase voltage ratings

(g) Applicable cable type, cross sectional area of conductor and insulation diameter range

8 Packing and Delivery

Each joint kit shall be in a separate corrugated cardboard box and every 100 kits shall be

contained in a wood box. Each joint kit shall have a list of materials indicating quantities

and instruction sheet.

The supplier shall provide packing of the joints as is required to prevent their damage or

deterioration during transit to their final destination and long period of storage, as indicated

in the contract. The packing shall be sufficient to withstand, without limitation, rough

handling during transit and exposure to extreme temperatures, salt and precipitation during

transit and storage.

(a) The supplier shall prepare the kit and its components for shipment to protect it from

damage during shipment and subsequent storage.

(b) All joints and their components shall be shipped from the factory to the specified site.

(c) Each shipment shall include a detailed packing list identifying all items by part

number, including hardware.

(d) All material shall be carefully loaded for protection during shipment.

(e) All materials shall be arranged to allow safe unloading at the site.

(f) There shall be handling instruction to minimize damage.

The outer packing must be clearly marked on at least four (4) sides as follows;

(a) Name of the procuring department

(b) Name of the supplier

(c) Contract description and number

(d) Final destination

(e) Gross weight

(f) Any special lifting instructions

(g) Any special handling instructions

(h) Any relevant pollution or environment classifications

9 Document and Certificate

The joints and all associated materials quoted by the supplier shall be approved by

GECOL. The quantity of documents and certificates submitted shall be not less than three

copies. The joints shall conform to the latest edition of IEC 60502-4, IEC 60840 and

relevant international standards including Clause 2 of this specification. The design and

construction of joint shall be subjected to the approval of GECOL.

13/17 Amended on Jan. 2013

9.1 Information to be provided with the BID

Technical descriptions, data sheets, catalogues and other information shall be submitted

with the BID and those which are submitted shall be sufficient to enable GECOL to

evaluate thoroughly the proposal as to its compliance with the requirements of this

specification.

The minimum requirement is as follows:

(a) Detailed summary of difference with this specification

(b) Technical Data Sheet duly filled in and signed (Annex A)

(c) Material safety data certificates of all chemical materials used for manufacturing

(d) Detailed drawing including outer figures of all components with dimension and inner

structure in A3 or A4 size

(e) Detailed handling, installation and maintenance manual & schedule for good operation

(f) Component list and numbers

(g) Electrical field diagram and calculations

(h) Brochures and catalogues containing outline dimensions, main electrical and

mechanical data, etc.

(i) Applicable design specification and standards in English language

(j) Test certificates approved by international institute in accordance with Table 5 of IEC

60502-4 and/or Annex C of IEC 60840

(k) Quality control system and relevant certificate

9.2 Documents to be approved by GECOL

The supplier shall furnish all relevant technical information, drawings etc. to GECOL

for approval prior to the start of manufacture. Offers without Technical Data Sheet

completely filled in will be rejected.

(a) Vendor(s) details/ Reference list

(b) Technical Data Sheet

(c) Tests schedule and procedures

(d) Transportation schedule and storage conditions

(e) Drawings of materials (All drawings shall be in A3 or A4 size with title block

approved by GECOL)

9.3 Documentation

All documents supplied under this specification shall be documented to the extent that

the end user can easily understand its theory of operation, performance, installation and

maintenance for the product. All documents shall be submitted being filed in order to

approve of GECOL and reorder later.

Language in all documents and drawings shall be written in English and dimensions

shall be used in metric SI-units.

14/17 Amended on Jan. 2013

10 Warranty

The supplier shall provide a full three-year limited warranty on all equipment supplied.

The warranty shall cover all parts and all costs, which are directly attributable to the

supplier. Warranty coverage shall begin on the date that the equipment is received.

15/17 Amended on Jan. 2013

Appendix A

Technical Data Sheet

No. Description Particulars

1 Manufacturer’s name

2 Applicable standards

3 Identification No. (Model No.)

4 Applicable cable type

5 Applicable cross sectional area of conductor (mm2)

6 Applicable diameter of insulation (mm)

7 Applicable diameter of oversheath (mm)

8 Rating current (A)

9 No. of core(s)

10 Type of joint

11 Voltage rating phase to ground (kV rms)

12 Voltage rating phase to phase (kV rms)

13 Normal operation temperature (°C)

14 Emergency operation temperature (°C)

15 Dimension

a) Diameter (mm)

b) Length (mm)

16 AC withstand voltage test

a) Minute(s)

b) Voltage level (kV rms)

17 DC withstand voltage test

a) Minute(s)

b) Voltage level (kV avg)

18 Minimum partial discharge voltage level (kV rms, pC)

a) at above normal operation temperature

b) at ambient temperature

19 Impulse withstand voltage test (kV peak)

Signature :

16/17 Amended on Jan. 2013

Technical Data Sheet

No. Description Particulars

20 Thermal cycle test (kV rms)

a) In air

b) In water

21 Thermal short circuit test of screen

a) Short circuit current (kA)

b) Short circuit duration (Sec.)

22 Thermal short circuit test of conductor

a) Short circuit current (kA)

b) Short circuit temperature (Sec.)

23 Dynamic short circuit test

a) Short circuit current (kA)

b) Short circuit duration (Sec.)

24 Packing method

25 Joint kit components

26 Special tools and equipment for jointing work

Signature :

Designation :

Name of Tenderer :

Date :

17/17 Amended on Jan. 2013

You might also like

- Koehler - Installation Manual 7-28EFOZDDocument76 pagesKoehler - Installation Manual 7-28EFOZDDouglas DiasNo ratings yet

- SL3000 - 113-General SpecificationDocument37 pagesSL3000 - 113-General SpecificationRadu IonutNo ratings yet

- Memo For Hand Receipt HoldersDocument10 pagesMemo For Hand Receipt HoldersTerrence StaplesNo ratings yet

- SAP PP PI Process ManagementDocument12 pagesSAP PP PI Process Managementravi_bandi1275100% (6)

- Low Voltage ABC FittingsDocument22 pagesLow Voltage ABC FittingsKhaled SalemNo ratings yet

- PV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlDocument96 pagesPV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlIonut Robert BalasoiuNo ratings yet

- Technical Specification of GECOL: Low Voltage Switchgear and Controlgear Assembly For Distribution StationsDocument22 pagesTechnical Specification of GECOL: Low Voltage Switchgear and Controlgear Assembly For Distribution StationsAYAZ MEHARNo ratings yet

- User's Manual: EJX110A, EJX120A, EJX130A, EJX310A, EJX430A and EJX440A Differential Pressure and Pressure TransmittersDocument76 pagesUser's Manual: EJX110A, EJX120A, EJX130A, EJX310A, EJX430A and EJX440A Differential Pressure and Pressure TransmittersotavioNo ratings yet

- Aluminum-Clad Steel Stranded Conductor For Earth WireDocument14 pagesAluminum-Clad Steel Stranded Conductor For Earth WireMohamed AhmiedNo ratings yet

- Installing and Maintaining Switchboards: Standard ForDocument34 pagesInstalling and Maintaining Switchboards: Standard ForOmar CruzNo ratings yet

- AMRMeterDocument23 pagesAMRMeterKhaled SalemNo ratings yet

- Elbow Connectors For XLPE Insulated Copper Cable (11kV PDFDocument21 pagesElbow Connectors For XLPE Insulated Copper Cable (11kV PDFIbrahim JamalNo ratings yet

- 3C - 11.30kV - CU - XLPE - MDPEDocument25 pages3C - 11.30kV - CU - XLPE - MDPEKhaled SalemNo ratings yet

- Model EJA115 Low Flow Transmitter (Style: S3)Document90 pagesModel EJA115 Low Flow Transmitter (Style: S3)Guru KathirNo ratings yet

- NEKTS606-202x DRAFT V2-HoringsdokumentDocument39 pagesNEKTS606-202x DRAFT V2-HoringsdokumentJulia SartorioNo ratings yet

- User's Manual: Differential Pressure and Pressure Transmitters EJ 110, EJ 120, EJ 130, EJ 310, EJ 430, and EJ 440Document65 pagesUser's Manual: Differential Pressure and Pressure Transmitters EJ 110, EJ 120, EJ 130, EJ 310, EJ 430, and EJ 440fragercitoNo ratings yet

- Im01c20c01-01en (9) - Ej210, Ej220Document73 pagesIm01c20c01-01en (9) - Ej210, Ej220Nguyen ThuongNo ratings yet

- Electrical Equipment CodeDocument106 pagesElectrical Equipment CodeHminhKen100% (1)

- Im01c25c01-01en 012Document68 pagesIm01c25c01-01en 012muhammad.wajahat194No ratings yet

- Im01c20b01-01en (9) - Ej110, Ej120, Ej130Document92 pagesIm01c20b01-01en (9) - Ej110, Ej120, Ej130Nguyen ThuongNo ratings yet

- S Met Stem CT 3p 1c 00Document19 pagesS Met Stem CT 3p 1c 00HARINo ratings yet

- NECA 400 SwitchboardsDocument34 pagesNECA 400 SwitchboardsJosé Luis FalconNo ratings yet

- Cross Bonding Link BoxDocument12 pagesCross Bonding Link BoxKhaled SalemNo ratings yet

- WF2 PDFDocument188 pagesWF2 PDFsoporteavlNo ratings yet

- Cable Installation Manual For Power and Control CablesDocument102 pagesCable Installation Manual For Power and Control CablesWashington VásquezNo ratings yet

- IG-A05 Pressure Transmitter - EJX530ADocument52 pagesIG-A05 Pressure Transmitter - EJX530AAdhitya ReNo ratings yet

- User's Manual: EJX510A, EJX530A, EJX610A and EJX630A Absolute Pressure and Gauge Pressure TransmittersDocument51 pagesUser's Manual: EJX510A, EJX530A, EJX610A and EJX630A Absolute Pressure and Gauge Pressure TransmittersInstrumentation GCS GanaNo ratings yet

- Dpharp Vigilantplant Eja310aDocument76 pagesDpharp Vigilantplant Eja310aOscarNo ratings yet

- MFS 9130 Hardware DescriptionDocument112 pagesMFS 9130 Hardware DescriptionYasser AlqadhiNo ratings yet

- 66 - 230 - 400kV Guidelines 9.1Document240 pages66 - 230 - 400kV Guidelines 9.1Alan ZorkotNo ratings yet

- Standard For Insulation Co Ordination 3058912Document26 pagesStandard For Insulation Co Ordination 3058912wester_bisNo ratings yet

- Skra - 06 001 LowVoltDocument42 pagesSkra - 06 001 LowVoltTotoroNo ratings yet

- Tr05 11e Insulators Revision 3Document21 pagesTr05 11e Insulators Revision 3Classic LipuNo ratings yet

- Manual BookDocument89 pagesManual Bookm usersNo ratings yet

- Standard - LV - Motors - Manual - ML - 01 - 2009 Rev DDocument160 pagesStandard - LV - Motors - Manual - ML - 01 - 2009 Rev DraluntitledNo ratings yet

- 31041302-MA5100 Installation Manual (V2.50)Document169 pages31041302-MA5100 Installation Manual (V2.50)nttam791100% (1)

- Standard - LV - Motors - Manual - EN - 01 - 2009 Rev D PDFDocument26 pagesStandard - LV - Motors - Manual - EN - 01 - 2009 Rev D PDFasifdcetNo ratings yet

- DatasheetDocument36 pagesDatasheetAndres GuerreroNo ratings yet

- Im01c22d01-01en (17) - Eja310, Eja430Document83 pagesIm01c22d01-01en (17) - Eja310, Eja430Nguyen ThuongNo ratings yet

- 9130 BSC HW DescriptionDocument138 pages9130 BSC HW DescriptionrajaNo ratings yet

- LuminaireDocument14 pagesLuminaireKhaled SalemNo ratings yet

- Air Force Power Supply (AFJMAN 32-1080)Document122 pagesAir Force Power Supply (AFJMAN 32-1080)EngSrakNo ratings yet

- Products Active ListDocument50 pagesProducts Active Listnamita.sultania26No ratings yet

- Liebert Exm 10 40kva User Manual SL 25648Document92 pagesLiebert Exm 10 40kva User Manual SL 25648Fernando RomeroNo ratings yet

- SOW-subst R1Document40 pagesSOW-subst R1cherif yahyaouiNo ratings yet

- Spider - Tle7238Gs: 8 Channel High-Side and Low-Side Relay Switch With Limp Home ModeDocument37 pagesSpider - Tle7238Gs: 8 Channel High-Side and Low-Side Relay Switch With Limp Home ModeHelal ShamesNo ratings yet

- DCRP-Products Active ListDocument48 pagesDCRP-Products Active ListskanthsnNo ratings yet

- Products Active ListDocument48 pagesProducts Active ListrajeshNo ratings yet

- Capitolato Trimod HE Trifase 30kW enDocument14 pagesCapitolato Trimod HE Trifase 30kW enEduardo CTNo ratings yet

- Yokogawa PDT ManualDocument83 pagesYokogawa PDT Manualvikkoo7No ratings yet

- Mobile Diesel Generator UnitDocument25 pagesMobile Diesel Generator UnitKhaled SalemNo ratings yet

- 4.manual de Usuario EXM 10-40KVADocument88 pages4.manual de Usuario EXM 10-40KVALiliana BallestasNo ratings yet

- 133228-000 X-Ray Tube Assembly & Installation ManualDocument80 pages133228-000 X-Ray Tube Assembly & Installation ManualEmmanuel RamirezNo ratings yet

- Neca Bicsi 607-2011 PDFDocument34 pagesNeca Bicsi 607-2011 PDFJosé Manuel Gambino100% (1)

- Lighting ColumnDocument17 pagesLighting ColumnKhaled SalemNo ratings yet

- CL1 Tech PDFDocument74 pagesCL1 Tech PDFIqbal MakhdoomNo ratings yet

- ELRV 450 - 10 - 10 - 01eDocument51 pagesELRV 450 - 10 - 10 - 01eabaelwalid01No ratings yet

- SHB 9300 Servo Position Controller v2-0 EN PDFDocument462 pagesSHB 9300 Servo Position Controller v2-0 EN PDFGuillermo Osvaldo Rivera MelladoNo ratings yet

- Expl SW Chapter 05 STP Part IDocument65 pagesExpl SW Chapter 05 STP Part IMohamed AhmiedNo ratings yet

- Gawedar Okstate 0664D 14871.pdf JsessionidDocument87 pagesGawedar Okstate 0664D 14871.pdf JsessionidMohamed AhmiedNo ratings yet

- Vol2 ConstructionDocument14 pagesVol2 ConstructionMohamed AhmiedNo ratings yet

- Paper 20Document4 pagesPaper 20Mohamed AhmiedNo ratings yet

- B1CreationofIntegratedofIndustrialSecuritywiththeuseofModern - KMMS Aug 04 2015 0023Document7 pagesB1CreationofIntegratedofIndustrialSecuritywiththeuseofModern - KMMS Aug 04 2015 0023Mohamed AhmiedNo ratings yet

- 11.5KW Solar System With ACDocument2 pages11.5KW Solar System With ACMohamed AhmiedNo ratings yet

- 42111-42144 - 04 Heat Shrinkable Termination Kit For XLPE PVC Insulated CU Cable 0.4kv - 002Document15 pages42111-42144 - 04 Heat Shrinkable Termination Kit For XLPE PVC Insulated CU Cable 0.4kv - 002Mohamed AhmiedNo ratings yet

- IS IEC 61730 1 SolarDocument22 pagesIS IEC 61730 1 SolarMohamed AhmiedNo ratings yet

- Insulator Pin For Line Post Type InsulatorDocument10 pagesInsulator Pin For Line Post Type InsulatorMohamed AhmiedNo ratings yet

- Energies 15 06418Document20 pagesEnergies 15 06418Mohamed AhmiedNo ratings yet

- Refinerry Techincal ProjectDocument11 pagesRefinerry Techincal ProjectMohamed AhmiedNo ratings yet

- 42221-42422 - 66kv-30kv-11kv Heat Shrinkable Outdoor Termination Kit For XLPE Insulated CableDocument17 pages42221-42422 - 66kv-30kv-11kv Heat Shrinkable Outdoor Termination Kit For XLPE Insulated CableMohamed AhmiedNo ratings yet

- 1649753618cable Magnetic Field Evalution Cal Fact Sheet Web 1 pdf1649753618Document2 pages1649753618cable Magnetic Field Evalution Cal Fact Sheet Web 1 pdf1649753618Mohamed AhmiedNo ratings yet

- Electric Power Ratings Guide: Seventeenth EditionDocument56 pagesElectric Power Ratings Guide: Seventeenth EditionMohamed AhmiedNo ratings yet

- 200KW Solar System-Technician ParametersDocument10 pages200KW Solar System-Technician ParametersMohamed AhmiedNo ratings yet

- 2 ELVAC RTU in Cable Network I Ring Main Unit I Secondary SubstationDocument8 pages2 ELVAC RTU in Cable Network I Ring Main Unit I Secondary SubstationMohamed AhmiedNo ratings yet

- Iec 60027letter Symbols To Be Used in Electrical TechnologyDocument16 pagesIec 60027letter Symbols To Be Used in Electrical TechnologyMohamed AhmiedNo ratings yet

- Appendix C Minimum Equipment Efficiency Standards: Port of StocktonDocument6 pagesAppendix C Minimum Equipment Efficiency Standards: Port of StocktonMohamed AhmiedNo ratings yet

- Promat Energy - Solar Brochure - EnglishDocument2 pagesPromat Energy - Solar Brochure - EnglishMohamed AhmiedNo ratings yet

- Mazda MPV Facelift Training ManualDocument3 pagesMazda MPV Facelift Training Manuallaverne100% (51)

- Iglidur W300 - The Marathon RunnerDocument20 pagesIglidur W300 - The Marathon RunnerMarcus ChongNo ratings yet

- Gadus S2 V 220 0Document2 pagesGadus S2 V 220 0AMITNo ratings yet

- Trihal TRI0400245298IP210Document2 pagesTrihal TRI0400245298IP210Eka Hospital BekasiNo ratings yet

- Introduction of Validation and QualificationDocument24 pagesIntroduction of Validation and QualificationMuhamad Bima Muria50% (2)

- Consduit Bending TypesDocument69 pagesConsduit Bending TypesNedilco RomeroNo ratings yet

- PG GovernorsDocument4 pagesPG GovernorsPj EastonNo ratings yet

- Archimides' PrincipleDocument2 pagesArchimides' PrincipleAna Gabriel Lopez NevarezNo ratings yet

- Fuel Consumption Measurement - InstalationDocument32 pagesFuel Consumption Measurement - InstalationadNo ratings yet

- 5 Minutes To Install Hyperledger Fabric v1Document7 pages5 Minutes To Install Hyperledger Fabric v1bp_sriNo ratings yet

- Diagram Electrico 962h Ssa00244Document27 pagesDiagram Electrico 962h Ssa00244eleuterio100% (2)

- 2-Critical Speed of ShaftDocument5 pages2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- Thermodyancs Chapter 9 Solution ManuelDocument36 pagesThermodyancs Chapter 9 Solution ManuelFarhad MojaverNo ratings yet

- Oakland County Autonomous Vehicle Pilot Program RFPDocument27 pagesOakland County Autonomous Vehicle Pilot Program RFPAnonymous 5DZE7gzUnNo ratings yet

- ME2401 Mechatronics NotesDocument99 pagesME2401 Mechatronics NotesVijayasuthaJero0% (1)

- Power SystemDocument52 pagesPower Systemtebelayhabitamu12No ratings yet

- Boarding & Alighting Time in Ducth Rail Stations - WiggenraadDocument26 pagesBoarding & Alighting Time in Ducth Rail Stations - WiggenraadAsif RehanNo ratings yet

- General MT Procedure - Rekind OffshoreDocument5 pagesGeneral MT Procedure - Rekind OffshoreNicko Arya Dharma100% (1)

- Gaskets: Standard Definitions of Terms Relating ToDocument2 pagesGaskets: Standard Definitions of Terms Relating ToAhmad Zubair RasulyNo ratings yet

- Compresor 1 3HP R134a 110V 1190BTU H Baja Media Alta FFI12HBX EmbracoDocument5 pagesCompresor 1 3HP R134a 110V 1190BTU H Baja Media Alta FFI12HBX EmbracoAntonioNo ratings yet

- CCK/W33: Spherical Roller BearingsDocument4 pagesCCK/W33: Spherical Roller BearingshamdaNo ratings yet

- A01 557Document40 pagesA01 557jaimeNo ratings yet

- United States Department of The Interior: Evan LindenbachDocument57 pagesUnited States Department of The Interior: Evan LindenbachRhem Aldrin CordovaNo ratings yet

- Draft Tube and CavitationDocument8 pagesDraft Tube and Cavitationasn90100% (1)

- CSO Computer ProgrammingDocument73 pagesCSO Computer ProgrammingAjNo ratings yet

- PDFDocument359 pagesPDFeuqehtbNo ratings yet

- Adiabatic FBR DesignDocument10 pagesAdiabatic FBR DesignRana UzairNo ratings yet

- Qa-Qc InterviewDocument7 pagesQa-Qc InterviewEmil MemmedovNo ratings yet