Professional Documents

Culture Documents

4lex® 10F13100

4lex® 10F13100

Uploaded by

srinivasaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4lex® 10F13100

4lex® 10F13100

Uploaded by

srinivasaCopyright:

Available Formats

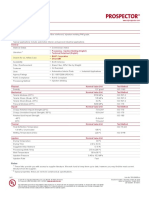

4LEX® 10F13100

Polycarbonate www.ulprospector.com

4Plas

Technical Data

Product Description

4LEX 10F13100 is a MFI 14 to 16 FR-V0 Polycarbonate

General

Material Status • Commercial: Active

Availability • Europe

Processing Method • Injection Molding

Physical Nominal Value Unit Test Method

Density 1.24 g/cm³ ISO 1183

Molding Shrinkage - Flow 0.50 %

Water Absorption 2 (Equilibrium, 23°C, 50% RH) 0.15 % ISO 62

Mechanical Nominal Value Unit Test Method

Tensile Modulus (23°C) 2500 MPa ISO 527-1/5

Tensile Stress (Break, 23°C) 66.0 MPa ISO 527-2/5

Tensile Strain (Break, 23°C) 93 % ISO 527-2/5

Impact Nominal Value Unit Test Method

Notched Izod Impact Strength ISO 180/1A

-30°C 15 kJ/m²

-20°C 15 kJ/m²

23°C 50 kJ/m²

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load

0.45 MPa, Unannealed 144 °C ISO 75-2/B

1.8 MPa, Unannealed 133 °C ISO 75-2/A

Vicat Softening Temperature 140 °C ISO 306/B

Ball Indentation Temperature 125 °C IEC 335

Electrical Nominal Value Unit Test Method

Comparative Tracking Index 225 V IEC 60112

Flammability Nominal Value Unit Test Method

Flame Rating (1.6 mm) V-0 UL 94

Glow Wire Flammability Index (2.0 mm) 960 °C IEC 60695-2-12

Glow Wire Ignition Temperature (2.0 mm) 875 °C IEC 60695-2-13

Injection Nominal Value Unit

Drying Temperature 120 °C

Drying Time 3.0 to 4.0 hr

Suggested Max Moisture 0.020 %

Processing (Melt) Temp 260 to 300 °C

Mold Temperature 80 to 100 °C

Injection Rate Moderate-Fast

Holding Pressure 60.0 to 120 MPa

Screw Speed < 200 rpm

Injection Notes

Feed Throat Temperature: 60 - 80 °C

Back Pressure: Low

Notes

1 Typical properties: these are not to be construed as specifications.

2 24 Hrs

1 of 2 Form No. TDS-114680-en

UL LLC ©2023. All rights reserved. Document Created: Wednesday, September 6, 2023

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2008

Last Updated: 2/11/2015

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

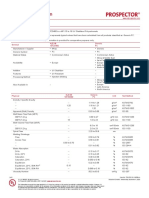

4LEX® 10F13100

Polycarbonate

4Plas www.ulprospector.com

Where to Buy

Supplier

4Plas

Hinckley, Hinckley United Kingdom

Telephone: +44-870-446-0424

Web: http://www.4plas.com/

Distributor

Please contact the supplier to find a distributor for 4LEX® 10F13100

2 of 2 Form No. TDS-114680-en

UL LLC ©2023. All rights reserved. Document Created: Wednesday, September 6, 2023

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2008

Last Updated: 2/11/2015

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

You might also like

- Decline Curve Analysis CourseDocument29 pagesDecline Curve Analysis CourseBella cedric75% (4)

- CYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetmustafaNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Sample Planning and Design LabDocument3 pagesSample Planning and Design LabQuerwty53% (15)

- CFD Tutorial 2 - Mesh Regions and Porous MediaDocument29 pagesCFD Tutorial 2 - Mesh Regions and Porous Mediamichal_lysyNo ratings yet

- 4lex® 10F13500Document2 pages4lex® 10F13500srinivasaNo ratings yet

- 4lex® 10F10000Document3 pages4lex® 10F10000srinivasaNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- Victrex TDS 450GDocument3 pagesVictrex TDS 450GPRAMOD KUMARNo ratings yet

- Panlite L-1250Y: TEIJIN LIMITED - PolycarbonateDocument2 pagesPanlite L-1250Y: TEIJIN LIMITED - PolycarbonateDamjan DespotovskiNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Amcel KP20: Celanese Corporation - Acetal (POM) CopolymerDocument1 pageAmcel KP20: Celanese Corporation - Acetal (POM) CopolymerSamuelNo ratings yet

- Nexeo Plastics Kingfa PBT RG151Document2 pagesNexeo Plastics Kingfa PBT RG151kls.thorodinsonNo ratings yet

- Kumho 750SWDocument1 pageKumho 750SWChu ChuNo ratings yet

- Technyl Star® A 205F Natural SDocument3 pagesTechnyl Star® A 205F Natural STiago GalloNo ratings yet

- Product PDF 301308Document2 pagesProduct PDF 301308Andrew JacksonNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Ultrason E 3010: Polyethersulfone (PESU)Document2 pagesUltrason E 3010: Polyethersulfone (PESU)AmirNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- Chang Chun Plastics CO., LTDDocument2 pagesChang Chun Plastics CO., LTDChunYenHuangNo ratings yet

- ULTRADUR B4300G6 (03p023)Document3 pagesULTRADUR B4300G6 (03p023)ayala castroNo ratings yet

- Polyflam Rabs 90000 Uv5 LS (E128762)Document3 pagesPolyflam Rabs 90000 Uv5 LS (E128762)simonNo ratings yet

- Terluran GP35Document5 pagesTerluran GP35cristinamss33No ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- UltrasonS6010 IsoDocument2 pagesUltrasonS6010 IsoKablayialijanNo ratings yet

- SE-316 Parts Data SheetDocument27 pagesSE-316 Parts Data SheetElnBEKKARYNo ratings yet

- Victrex TDS 450CA30Document3 pagesVictrex TDS 450CA30s1LLaNo ratings yet

- Styrolution TDS302200150418Document3 pagesStyrolution TDS302200150418erayNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- 76 StyrolutionPS454NDocument5 pages76 StyrolutionPS454N59074No ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- Luran S757 GDocument5 pagesLuran S757 GPeter EvansNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- ABS Terluran GP35Document2 pagesABS Terluran GP35Alan MoraisNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- LEXAN™ Resin - 121R - Europe - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 121R - Europe - Technical - Data - Sheetanggun dewiNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 pagesDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- TDS Pa6 MVM2750LDocument1 pageTDS Pa6 MVM2750Lkls.thorodinsonNo ratings yet

- Xydar® SRT-900 by Syensqo ADPDocument3 pagesXydar® SRT-900 by Syensqo ADPFAUSANo ratings yet

- TerluranGP 22Document5 pagesTerluranGP 22Chu ChuNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Vendor Performance Evaluation FormDocument4 pagesVendor Performance Evaluation FormsrinivasaNo ratings yet

- 4LEX® 10F20400 - Generic PCDocument6 pages4LEX® 10F20400 - Generic PCsrinivasaNo ratings yet

- 4POM® 10I30000 - Generic Acetal (POM) HomopolymerDocument5 pages4POM® 10I30000 - Generic Acetal (POM) HomopolymersrinivasaNo ratings yet

- 3DXMAX® ESD-Safe PC 3D Filament - Generic PCDocument6 pages3DXMAX® ESD-Safe PC 3D Filament - Generic PCsrinivasaNo ratings yet

- Moldmasters Hot RunnerDocument42 pagesMoldmasters Hot RunnersrinivasaNo ratings yet

- LKM Steel Rainbow Chart 2014 UpmoldDocument1 pageLKM Steel Rainbow Chart 2014 UpmoldsrinivasaNo ratings yet

- EnCounter 3GF20Document1 pageEnCounter 3GF20srinivasaNo ratings yet

- Ultradur® B 4300 G6Document4 pagesUltradur® B 4300 G6srinivasaNo ratings yet

- Bulletin SI 2020Document24 pagesBulletin SI 2020srinivasaNo ratings yet

- Hasco PlateDocument217 pagesHasco PlatesrinivasaNo ratings yet

- Surface FinishDocument24 pagesSurface Finishsrinivasa100% (2)

- Process Validation EngineerDocument2 pagesProcess Validation EngineersrinivasaNo ratings yet

- Zytel® 70G30HSLR BK099Document4 pagesZytel® 70G30HSLR BK099srinivasaNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- 1 2743-DatasheetDocument2 pages1 2743-DatasheetsrinivasaNo ratings yet

- Tier 3 Practice TestDocument5 pagesTier 3 Practice TestMarcos RengifoNo ratings yet

- HVAC System PDFDocument79 pagesHVAC System PDFBülent KabadayiNo ratings yet

- Elcometer 345 Coating Thickness Gauge - Datasheet PDFDocument1 pageElcometer 345 Coating Thickness Gauge - Datasheet PDFVallik TadNo ratings yet

- Suitability of Conventional Data For Blast DesignDocument18 pagesSuitability of Conventional Data For Blast DesignOkta ChristalNo ratings yet

- Comparison of HPLC Method and FT-NIR For Quantification Glucose, Fructose, SucroseDocument6 pagesComparison of HPLC Method and FT-NIR For Quantification Glucose, Fructose, Sucrosedoga1759No ratings yet

- OTE Outotec Flotation Technologies Eng WebDocument12 pagesOTE Outotec Flotation Technologies Eng Webpmanquera89No ratings yet

- Energy and Exergy Based Analysis of Hybrid Solar DryerDocument12 pagesEnergy and Exergy Based Analysis of Hybrid Solar DryerDeepika ChauhanNo ratings yet

- RBSE Class 8 Science Notes Chapter 14 Refraction of Light - RBSE GuideDocument4 pagesRBSE Class 8 Science Notes Chapter 14 Refraction of Light - RBSE GuideAlpine AcademiaNo ratings yet

- Physics 1a8 Questions Part 1Document9 pagesPhysics 1a8 Questions Part 1ymrh4svj9gNo ratings yet

- Nafems Code AsterDocument8 pagesNafems Code AsterSofiene InNo ratings yet

- Pioneer Anomaly PDFDocument13 pagesPioneer Anomaly PDFdfrtfNo ratings yet

- Beam DeflectionDocument14 pagesBeam DeflectionPrudvi Krishna MaladiNo ratings yet

- Unit Ii Vector Calculus Part-A: Problem 1 SolutionDocument22 pagesUnit Ii Vector Calculus Part-A: Problem 1 Solutionkenny kannaNo ratings yet

- 1.3 and 1.4 Review Set Stage 2 Physics Solutions 2021Document14 pages1.3 and 1.4 Review Set Stage 2 Physics Solutions 2021Maan PatelNo ratings yet

- Pds Tial m80Document2 pagesPds Tial m80Yan FerizalNo ratings yet

- Sonic InstructionsDocument2 pagesSonic InstructionsE CNo ratings yet

- Technical Guidance Note (Monitoring)Document72 pagesTechnical Guidance Note (Monitoring)Arindam BhowmickNo ratings yet

- 13 - Co-Ordinate Geometry BBADocument6 pages13 - Co-Ordinate Geometry BBAVeerannaSHiremathNo ratings yet

- Dynamics HW2Document12 pagesDynamics HW2Ddsaasdh Dhaka100% (1)

- Plastic Solar Cell, ArticleDocument2 pagesPlastic Solar Cell, ArticleAbhishek ModiNo ratings yet

- SCHIZAS Qualitative GradingDocument6 pagesSCHIZAS Qualitative GradingDitaAnggaraKusumaNo ratings yet

- Lab Report 2Document19 pagesLab Report 2Kim DimaanoNo ratings yet

- Relene J1005FY20Document1 pageRelene J1005FY20Anuj Kumar SinghNo ratings yet

- 5 - Pulleys and Systems PracticeDocument3 pages5 - Pulleys and Systems PracticeCalebNo ratings yet

- ArtisanDocument19 pagesArtisanKevin CossuttaNo ratings yet

- Sot26 SC74RDocument6 pagesSot26 SC74RchetanNo ratings yet

- Iluminacion Natural CircadianaDocument17 pagesIluminacion Natural CircadianaJorge DávilaNo ratings yet