Professional Documents

Culture Documents

SSRN Id4446360

SSRN Id4446360

Uploaded by

Almas XamiCopyright:

Available Formats

You might also like

- Renos Puffy InglésDocument33 pagesRenos Puffy InglésLinthalaa RivendelNo ratings yet

- Specification For Bare Stainless Steel Welding Electrodes andDocument33 pagesSpecification For Bare Stainless Steel Welding Electrodes andpurnawanNo ratings yet

- Capillary Column EquivalentsDocument9 pagesCapillary Column EquivalentsNatalia CruzNo ratings yet

- Biocompatibility of Aluminium Alloys and Anodic Al2O3Document6 pagesBiocompatibility of Aluminium Alloys and Anodic Al2O3Nícolas LaraNo ratings yet

- A Beginner's Guide To Eco Printing Fabric: Bonnie BowmanDocument4 pagesA Beginner's Guide To Eco Printing Fabric: Bonnie BowmanBagio Ranthe100% (2)

- Accelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesDocument9 pagesAccelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesAlmas XamiNo ratings yet

- SSRN Id4447455Document8 pagesSSRN Id4447455Almas XamiNo ratings yet

- Corrosion Propagation of Steel Rebar Embedded in MarineDocument8 pagesCorrosion Propagation of Steel Rebar Embedded in MarineAlmas XamiNo ratings yet

- SSRN Id4447482Document7 pagesSSRN Id4447482Almas XamiNo ratings yet

- SSRN Id4447479Document7 pagesSSRN Id4447479Almas XamiNo ratings yet

- Shridevi 2020 IOP Conf. Ser. Mater. Sci. Eng. 989 012024Document11 pagesShridevi 2020 IOP Conf. Ser. Mater. Sci. Eng. 989 012024ron_danyNo ratings yet

- Corrosion of Steel Rebar Embedded in Ternary Blended Concrete Exposed To High Humidity EnvironmentDocument7 pagesCorrosion of Steel Rebar Embedded in Ternary Blended Concrete Exposed To High Humidity EnvironmentAlmas XamiNo ratings yet

- Research ArticleDocument11 pagesResearch Articlezaman ahmadNo ratings yet

- OTIENO 2016 - Corrosion Rate Prediction Models PART IDocument13 pagesOTIENO 2016 - Corrosion Rate Prediction Models PART IVinícius RamosNo ratings yet

- Corrosion Behavior of Reinforcing Steel Embedded in Fly Ash ConcreteDocument7 pagesCorrosion Behavior of Reinforcing Steel Embedded in Fly Ash ConcreteAlmas XamiNo ratings yet

- 1 s2.0 S0143974X24001111 MainDocument21 pages1 s2.0 S0143974X24001111 MainAashima sharmaNo ratings yet

- Remaining Fatigue Life of Corroded SteelDocument10 pagesRemaining Fatigue Life of Corroded SteelRaees MazharNo ratings yet

- Detailed Modeling of Corrosion Macrocells On Steel Reinforcing in ConcreteDocument18 pagesDetailed Modeling of Corrosion Macrocells On Steel Reinforcing in ConcreteDaniel RochaNo ratings yet

- 2 PDFDocument11 pages2 PDFbaneNo ratings yet

- 03 - 15842 - IJCEA - PP 21-32 New1Document12 pages03 - 15842 - IJCEA - PP 21-32 New1sanjeev kumar vermaNo ratings yet

- Investigation of Steel Corrosion in Cracked Concrete Evaluation of Macrocell and Microcell Rates Using Tafel Polarization Response 2010Document11 pagesInvestigation of Steel Corrosion in Cracked Concrete Evaluation of Macrocell and Microcell Rates Using Tafel Polarization Response 2010sryh2012No ratings yet

- Accelerated CorrosionDocument8 pagesAccelerated Corrosionjuli_rad100% (2)

- Corrosion Science: Chong Cao, Moe M.S. Cheung, Ben Y.B. ChanDocument13 pagesCorrosion Science: Chong Cao, Moe M.S. Cheung, Ben Y.B. ChanEjazulhaq RahimiNo ratings yet

- Artigo Sobre CorrosãoDocument13 pagesArtigo Sobre CorrosãoSandro MendesNo ratings yet

- Numerical Analysis of Localized Steel Corrosion in Concrete: MaterialsDocument8 pagesNumerical Analysis of Localized Steel Corrosion in Concrete: MaterialsEjazulhaq RahimiNo ratings yet

- materials-15-00497Document22 pagesmaterials-15-00497VINH VÕ ĐỨC THÀNHNo ratings yet

- Study On The Influence of Compound Rust Inhibitor On Corrosion of Steel Bars in Chloride Concrete by Electrical ParametersDocument14 pagesStudy On The Influence of Compound Rust Inhibitor On Corrosion of Steel Bars in Chloride Concrete by Electrical ParametersRAGHUNo ratings yet

- Influence of Rust Inhibitor On The Corrosion ResisDocument10 pagesInfluence of Rust Inhibitor On The Corrosion Resisaldrinramirez20No ratings yet

- Cement and Concrete CompositesDocument10 pagesCement and Concrete CompositesAman KumarNo ratings yet

- 1.1 General: (BertoliniDocument3 pages1.1 General: (BertoliniEka SupriantoNo ratings yet

- Corrosion Inhibitors PDFDocument9 pagesCorrosion Inhibitors PDFmanil_5100% (1)

- Ann 2006Document6 pagesAnn 2006sumanthNo ratings yet

- Effect of Chloride Concentration On The Corrosion Rate in Carbon SteelDocument7 pagesEffect of Chloride Concentration On The Corrosion Rate in Carbon SteelAziz SaputraNo ratings yet

- Coorosion 3Document9 pagesCoorosion 3Ramin ShojaNo ratings yet

- Jiang Et Al, 2017Document11 pagesJiang Et Al, 2017ANA LAURA BRAGA NASCIMENTONo ratings yet

- 1 s2.0 S0010938X08003296 Main PDFDocument16 pages1 s2.0 S0010938X08003296 Main PDFSaRah Yasmin TajuldinNo ratings yet

- Electrical Resistivity and Microstructural Properties of Concrete Materials in Conditions of Current FlowDocument14 pagesElectrical Resistivity and Microstructural Properties of Concrete Materials in Conditions of Current FlowRetana González Manuel AbrahamNo ratings yet

- Rehabilitation and Maintenance of Rusted Reinforcement Bar in RCC BeamDocument3 pagesRehabilitation and Maintenance of Rusted Reinforcement Bar in RCC BeamkelmazodroNo ratings yet

- Lect-4 Corrosion of Steel in ConcreteDocument25 pagesLect-4 Corrosion of Steel in ConcreteYoukhanna ZayiaNo ratings yet

- Case Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeDocument7 pagesCase Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeGina BerríoNo ratings yet

- Garba 01Document7 pagesGarba 01Ameera IzmieNo ratings yet

- Corrosion Science: SciencedirectDocument19 pagesCorrosion Science: SciencedirectArturo CervantesNo ratings yet

- Mci BavarianDocument13 pagesMci BavarianmuqeetNo ratings yet

- Coatings 11 00517Document16 pagesCoatings 11 00517Domingo FernándezNo ratings yet

- Construction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiDocument11 pagesConstruction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiIsrael WakumaNo ratings yet

- Corrosion in ConcreteDocument8 pagesCorrosion in ConcreteOpany JuliusNo ratings yet

- Crack Shape and Rust Distribution in Corrosion-Induced Cracking ConcreteDocument9 pagesCrack Shape and Rust Distribution in Corrosion-Induced Cracking ConcretenagarajuNo ratings yet

- Michel Et Al. (2016)Document12 pagesMichel Et Al. (2016)Vinícius RamosNo ratings yet

- Prevention of Corrosion of SteelDocument8 pagesPrevention of Corrosion of SteelZainal AbidhynNo ratings yet

- Using Cathodic Protection To Control Corrosion of Coastal Reinforced Concrete Infrastructures PDFDocument7 pagesUsing Cathodic Protection To Control Corrosion of Coastal Reinforced Concrete Infrastructures PDFBoussaid SouheilNo ratings yet

- Corrosion Evolution of Scaled Rebar in Concrete Under Dry/Wet Cyclic Condition in 3.5% Nacl SolutionDocument15 pagesCorrosion Evolution of Scaled Rebar in Concrete Under Dry/Wet Cyclic Condition in 3.5% Nacl Solutionjack21abNo ratings yet

- Reference 2Document28 pagesReference 2daniadaniellaaaaaNo ratings yet

- Corrosion of Reinforcing Bars in Concrete PaperDocument33 pagesCorrosion of Reinforcing Bars in Concrete PaperMamta BaxlaNo ratings yet

- Electrochemical-Mechanistic Model For Concrete Cover Cracking DueDocument41 pagesElectrochemical-Mechanistic Model For Concrete Cover Cracking DueNora al-anssariNo ratings yet

- Macrocell and Microcell Corrosion of Steel in Ordinary Portland Cement and High Performance ConcretesDocument5 pagesMacrocell and Microcell Corrosion of Steel in Ordinary Portland Cement and High Performance ConcretesEjazulhaq RahimiNo ratings yet

- Effects of DC Stray Current On Concrete Structure: BstractDocument4 pagesEffects of DC Stray Current On Concrete Structure: BstractAldrin SantosNo ratings yet

- Bicharaetal 2019Document17 pagesBicharaetal 2019asaad biqaiNo ratings yet

- Longterm Seismic Performance of Reinforced Concrete Bridges Under Steel Reinforcement Corrosion Due To Chloride Attack PDFDocument15 pagesLongterm Seismic Performance of Reinforced Concrete Bridges Under Steel Reinforcement Corrosion Due To Chloride Attack PDFnagarajuNo ratings yet

- Study On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeDocument8 pagesStudy On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeNew NSskinNo ratings yet

- CP Criteria 01Document15 pagesCP Criteria 01Sheik DawoodNo ratings yet

- Experimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagDocument6 pagesExperimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagIJRASETPublicationsNo ratings yet

- Corrosion CinéticaDocument9 pagesCorrosion CinéticaOscar David Madera OzunaNo ratings yet

- Failure Analysis of Structural Steel Subjected To Long Term ExposureDocument13 pagesFailure Analysis of Structural Steel Subjected To Long Term ExposureDeepak wadgeNo ratings yet

- Corrosion of Steel in High Strength SelfDocument12 pagesCorrosion of Steel in High Strength SelfAtta Ur RehmanNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Ion Exchange SofteningDocument16 pagesIon Exchange SofteningMohamed ElbehlilNo ratings yet

- Corrosion Damage (Forms of Corrosion)Document105 pagesCorrosion Damage (Forms of Corrosion)Andiappan Pillai100% (5)

- Hydrogen and SAF For Aviation 1696853988Document17 pagesHydrogen and SAF For Aviation 1696853988Gurvinder SinghNo ratings yet

- Nyfgby: Twin Cores, Armoured Cable Low Voltage Armoured CableDocument6 pagesNyfgby: Twin Cores, Armoured Cable Low Voltage Armoured CableOffice ccNo ratings yet

- Materials Advances: PaperDocument10 pagesMaterials Advances: PapercathyyNo ratings yet

- Crealco ApplicationsDocument1 pageCrealco ApplicationswittypeeNo ratings yet

- Doe Method of Mix DesignDocument25 pagesDoe Method of Mix DesignAbarahamNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- Failure and CarbonsDocument19 pagesFailure and CarbonsSherif AdelNo ratings yet

- Petersenplgpckrcats PDFDocument112 pagesPetersenplgpckrcats PDFEdixon ZambranoNo ratings yet

- Sandvik - Technical Guide - Materials ISODocument41 pagesSandvik - Technical Guide - Materials ISOznovak77100% (1)

- Column Design ExcelDocument4 pagesColumn Design Excelvimal patelNo ratings yet

- Stoody 130Document1 pageStoody 130Cheker HaddedNo ratings yet

- Benefits of STT PDFDocument8 pagesBenefits of STT PDFElias KapaNo ratings yet

- Rules of CreditDocument14 pagesRules of Creditwes01010No ratings yet

- Cemtop 200Document4 pagesCemtop 200milanbrasinaNo ratings yet

- ANOVA-Ballistic Behavior of Epoxy Matrix Composites ReinDocument8 pagesANOVA-Ballistic Behavior of Epoxy Matrix Composites ReinNhanNo ratings yet

- Caustic SodaDocument24 pagesCaustic SodaSiddesh PatilNo ratings yet

- Binary Phase DiagramsDocument60 pagesBinary Phase DiagramsmaryzeenNo ratings yet

- Metal Injection MoldingDocument211 pagesMetal Injection MoldingYudhaPrawiraNo ratings yet

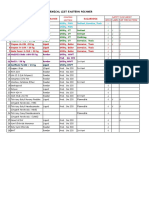

- Chemical List Eastern PolymerDocument1 pageChemical List Eastern PolymerIan MardiansyahNo ratings yet

- G. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityDocument7 pagesG. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityMadhusudhan ModemNo ratings yet

- Nyungu T R197826R MG103 Assignment1 PDFDocument8 pagesNyungu T R197826R MG103 Assignment1 PDFTamiranashe Tammie NyunguNo ratings yet

SSRN Id4446360

SSRN Id4446360

Uploaded by

Almas XamiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSRN Id4446360

SSRN Id4446360

Uploaded by

Almas XamiCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/370822601

Accelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of

Reservoir Length and Concrete Mixes

Article in SSRN Electronic Journal · January 2023

DOI: 10.2139/ssrn.4446360

CITATIONS READS

0 8

2 authors, including:

Kazi Naimul Hoque

Bangladesh University of Engineering and Technology

19 PUBLICATIONS 34 CITATIONS

SEE PROFILE

All content following this page was uploaded by Kazi Naimul Hoque on 30 May 2023.

The user has requested enhancement of the downloaded file.

Hosted on SSRN.com

Proceedings of MARTEC 2022

The International Conference on Marine Technology

21-22 December 2022, BUET, Dhaka, Bangladesh

ACCELERATED CORROSION OF STEEL REBAR IN CONCRETE BY

ELECTROMIGRATION: EFFECT OF RESERVOIR LENGTH AND CONCRETE

MIXES

Kazi Naimul Hoque1 and Francisco Presuel-Moreno2

1 2

Department of Naval Architecture and Marine Engineering, Department of Ocean and Mechanical Engineering, Florida

Bangladesh University of Engineering and Technology (BUET), Atlantic University (FAU), Dania Beach, Florida, USA

Dhaka-1000, Bangladesh E-mail: fpresuel@fau.edu

E-mail: kazinaim@name.buet.ac.bd

ABSTRACT

Two separate binary blended concrete mixes were prepared, one of which contains cement replacement of 50% slag

(referred to as SL) and the other of which contains cement replacement of 20% fly ash (termed as FA). Concrete

specimens were made using a water to cementitious ratio of 0.41. Different size reservoir lengths ranging from 2.5

cm to 17.5 cm were installed on the top surface of each specimen, and these reservoirs were ponded with 10 percent

NaCl solution. Chloride transport was accelerated by electromigration, using an applied potential of 9V initially, and

then reduced to 3V after around a week. Steel corrosion parameters were monitored using rebar potential

measurements and galvanostatic pulse measurements, over a period of approximately 400 days. Corrosion current

values obtained from experimental measurements were then converted to mass loss. Based on the results of

experimental findings, the corrosion current values as well as the mass loss values were found to be significantly

influenced by the length of the solution reservoirs. This study provides a guideline for subsequent research on

accelerated steel corrosion in concrete.

Keywords: Accelerated corrosion, Electromigration, Fly ash, Slag, Corrosion current, Mass loss.

1. INTRODUCTION

Accelerated corrosion of steel (in concrete) typically stainless steel), or using admixed chlorides, or using

refers to a steel corrosion process that takes place at a cyclic wetting and drying with a chloride-solution, or a

faster rate than the corresponding natural process. In suitable combination of these can accelerate chloride-

contrast to natural corrosion, accelerated corrosion's induced corrosion. When impressed current (IC) is used,

consequences, such as depassivation and/or corrosion- the steel is artificially polarized [1] and an electric field

induced damage, can be observed rather shortly. One is applied to the steel surface to accelerate the corrosion

similarity between natural and accelerated corrosion is [8, 9]. When impressed current or voltage is utilized, the

that anodic and cathodic reactions occur in both cases [1]. penetration of chloride ions (Cl-) in concrete is

Accelerated corrosion techniques have previously been migration-dominated as opposed to natural chloride

used to examine the time to corrosion initiation, ingress into concrete through diffusion. The whole

corrosion-induced damage, and the impact on parameters exposed surface area of the steel is anodic during the

like deformation behavior, ductility, bond strength, and application of anodic IC, causing general corrosion as

mechanism of failure in RC structures [2–5]. However, opposed to the pitting-type corrosion that occurs

due to the current needs to quantify and account for the naturally with discrete anodes and cathodes (high

corrosion propagation phase in the service life of cathode-to-anode area ratio). Furthermore, the concrete

corrosion-affected RC structures [6, 7], it is necessary to pore solution around the steel changes in local chemistry

research and develop techniques that can eliminate the due to the applied anodic IC by altering its ionic

initiation phase while, to the greatest degree possible, distribution. This technique is preferred when studying

simulating natural corrosion propagation and causing the degree of steel corrosion in concrete and its related

very little corrosion-induced damage. effects such as flexural strength, ductility, and so on

because it has the advantage of being able to control the

A variety of techniques, such as applying an anodic degree of corrosion. The degree of corrosion is one of the

impressed current (galvanostatic) or potential key parameters to predict the useful service life of

(potentiostatic) between the steel reinforcement (anode) corroding RC structures [2].

and a separate (internal or external) cathode (e.g.,

58-1

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

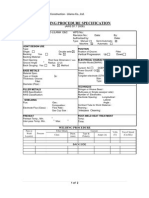

To avoid the corrosion initiation phase, admixed technique was accomplished. Figure 1 shows some single

chlorides, which typically range from 1 to 5% by mass of rebar molds with reinforcement prior to casting. All

cement, are primarily used in accelerated corrosion specimens had stainless steel (or titanium mix metal

investigations [2, 10, 11]. The process prevents the steel oxide 'TiMMO') mesh inserted on the top side at the time

from forming a passive protective film before the of casting. This surface served as the bottom surface

chloride threshold is reached. Additionally, it prevents during the experiment. Chloride transportation was

the chloride binding-effects that naturally occur under accelerated using the mesh. Meshes were

certain circumstances and is extremely likely to change approximately 3 cm wide, positioned along the center of

the alkalinity of the concrete pore solution. Cyclic the rebar and varied in length from 2.5 cm to 17.5 cm.

wetting and drying technique accelerate steel corrosion After a day, the molds were taken out and brought to the

in concrete by allowing chlorides to quickly penetrate the fog room for curing.

concrete by capillary suction in addition to diffusion [3–

5] and by allowing dissolved oxygen to be replenished at

the steel surface during the drying cycle to support the

cathodic reaction process.

Two different binary blended concrete mixtures were

produced for this study. Chloride transport was

accelerated by electromigration. The method was

developed from the results of earlier studies [12].

Corrosion of rebar typically starts after a few weeks or

months. Galvanostatic pulse measurements and rebar

potential measurements were carried out to assess the

progression of corrosion.

2. EXPERIMENTAL

Figure 1. Some single rebar molds with reinforcement

2.1 Materials prior to casting

Concrete specimens of dimensions 30.5 cm x 12.7 cm

x 7.6 cm (12 in X 5 in X 3 in) were made using a w/cm 2.3 Exposure environment

ratio of 0.41 and two different binder types (80/20

PC/FA, 50/50 PC/SL) where PC: Portland cement, FA: Following casting, the samples were transported to the

fly ash, and SL: slag. The mix proportions are Marine Materials & Corrosion Laboratory at the FAU

summarized in Table 1. Appendix 2 from reference [13] SeaTech campus for the experiment's next stage, and

contains details on each concrete mixes. A 0.94 cm these samples were kept there until the solution reservoir

diameter high yield steel reinforcing rebar was embedded was set up in a high humidity chamber. The solution

in each specimen at a cover of 0.75 cm. For both SL and reservoir for ponding was then fitted, and the samples

FA concrete mixes, eleven single rebar specimens were were then moved to the laboratory setting (65% RH and

prepared per mix, totaling 22 specimens. 21°C).

2.2 Casting and curing of specimens 2.4 Preparation of the specimen setup for

electromigration

Each rebar was drilled on one end and a stainless-steel

screw was inserted prior to casting the concrete. To make At least 40 days following casting, the solution

an electrical contact for monitoring corrosion, this reservoir was positioned on the top surface of the

Accelerated corrosion of steel rebar in concrete by electromigration… 58-2

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

specimen. The reservoir was filled with NaCl solution end dates of electromigration and the calculated Ampere-

(10% by weight). The samples were stored in high hour applied.

humidity for 3 to 7 days prior to the process. On the top

surface of the solution reservoir, electrodes (made of When the system was turned off, the rebar potential

stainless-steel wire mesh or TiMMO mesh) with was assessed. Despite not being connected, an ionic

dimensions comparable to those embedded were current produced by the applied electric field polarized

positioned. the rebars. The applied potential was restarted if the most

recent rebar potential measurement showed that

The samples were stored in clear plastic jars. About one corrosion had not occurred after monitoring the rebar

cm of each concrete specimen was immersed in a potential for a while (typically up to two hours) with the

saturated calcium hydroxide solution. A white plastic system disconnected. The electromigration procedure

mesh was placed on top of each sample. This process was was carried out until the sample displayed an off-rebar

used to minimize concrete's ability to leach potential (a value of -150 mVsce or more negative),

contaminants. which may suggest the initiation of corrosion in that

embedded rebar. Corrosion initiates at a potential

value of -150 mVsce (-220 mV vs. CSE), according to

3. ELECTROMIGRATION AND INITIATION

earlier studies [12].

OF CORROSION

A power source was employed to develop a

potential hold between the top and bottom meshes. The

chlorides in the solution above each rebar were then

driven into the concrete and in the direction of the

embedded rebar via an electric field. The electrode in the

NaCl solution was wired to the power source's negative

end. The positive end of the power supply was connected

to the embedded mesh in each specimen. The

experimental setup for the electromigration process is

depicted in Figure 2.

Figure 2. Experimental setup used for electromigration

On each specimen, electromigration was performed.

The first applied potential was 9 V. A potential greater

than +2V was noticed when the rebar potential was

measured in relation to a saturated calomel reference 4. CORROSION MONITORING

electrode while the electric field was still present. After 7

days, the potential was reduced to 3 V. The amount of During the stage of corrosion propagation, the potential

current applied when a particular voltage was given for of the rebar was continuously observed using a saturated

several days at a time was calculated using the delta calomel reference electrode. The same kind of electrode

potential across a 100-ohm resistor. Table 2 and Table 3 used to detect the rebar potential during the

shows the sample name/ID, reservoir length, the start and electromigration stage was utilized to measure it in the

Accelerated corrosion of steel rebar in concrete by electromigration… 58-3

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

samples selected for modest anodic polarization. The mostly more positive than -150 mVsce, which might

solution resistance (Rs) and polarization resistance (Rc) suggest that corrosion initiated, but with time the rebar

were measured at least two days after the system was tended to repassivate.

disconnected (turned off).

Figure 4 illustrates the evolution of corrosion current

The galvanostatic pulse (GP) tests provided an and potential over time for FA single rebar samples under

alternative approach of determining Rs and Rc values. A the solution reservoir of 7.5 cm. While observing the first

galvanostatic pulse of 10 microamperes was used. The plot (Icorr plot) in Figure 4, it was noticed that the

GP testing was conducted for 200 seconds. The GP test corrosion current values followed an oscillating trend for

measures the open circuit potential for a few seconds all the samples. For FA-4 sample, corrosion current

first. The rebar potential is then measured as a function

values increased monotonically until day 240, followed

of time after the pulse is applied. Using the rebar potential

by a significant drop on day 330, and then increased.

prior to the GP and the first potential reading with the

current pulse (i.e., the initial on-potential), the Rs (GP) Corrosion current values for FA-5 sample tended to

was determined. The difference between the initial on- decrease monotonically from day 80 to day 272,

potential and the rebar potential value obtained at 200 following a cyclic trend thereafter. Icorr values ranged

seconds was used to determine the Rc (GP). Rc values from 11.7-39.5 μA for these samples (7.5 cm solution

obtained from GP readings were converted to corrosion reservoir). Figure 3's second plot (potential plot) was

current (Icorr) where the corroding area is unknown. The examined, and it was observed that the potential values

corrosion current values were finally converted to mass were more negative than -350 mVsce until day 150 for

loss using Faradaic calculation. The Icorr was determined all these samples and the values tended to become more

using the Stern-Geary equation i.e., Icorr = B/Rp where positive as the day progresses. This phenomenon might

Rp is the polarization resistance (defined previously as occur if corrosion advanced more slowly. The rebar

Rc) and B is the Stern-Geary coefficient that ranged from might have repassivated in some instances, or over time,

13 to 52 mV depending on the steel's corrosion condition

the non-corroding rebar might have polarized the

(i.e., passive, or active) [14, 15]. Therefore, a value of 26

corroding sites to a more positive value. Reference [13,

mV was used for this study.

16, 17, 18] contains the plots for the other SL and FA

5. RESULTS AND DISCUSSION specimens.

Table 4 depicts the Icorr average and STD values

The section that follows shows the evolution of obtained from GP readings for SL single rebar

corrosion current (Icorr) over time for samples specimens. The measurements taken between May 2017

prepared with various concrete mixes and cast with a and May 2018 were included to calculate these averages.

single rebar as determined by GP measurements. The It was observed that for a reservoir length of 17.5 cm,

Icorr plots and potential plots for the SL and FA single Icorr average & STD values for SL-1, SL-2, and SL-3

rebar samples were developed using the GP samples were 20.5 μA, 25.9 μA, and 19.1 μA & 3.2 μA,

readings collected between April 2017 and May 2018. 2.5 μA, and 3.7 μA respectively. While comparing the

Icorr average measured on rebars for 10 cm reservoir

Figure 3 shows the evolution of corrosion current and length samples, it was found that Icorr average & STD

potential over time for SL single rebar samples under the values for SL-9, SL-10, and SL-11 were 11.7 μA, 14.9

solution reservoir of 5 cm. While observing the first plot μA, and 14.3 μA & 2.4 μA, 3.4 μA, and 3.9 μA

(Icorr plot) in Figure 3, it was noted that most of the respectively. It was noted that for 5 cm reservoir length

samples showed an oscillating trend in terms of corrosion samples, the Icorr average & STD values for SL-6, SL-7,

current, except for SL-6 sample which gives a plateau and SL-8 were 8.0 μA, 12.1 μA, and 17.9 μA & 1.1 μA,

trend for the most period. For SL-6 sample, all Icorr 4.1 μA, and 4.9 μA respectively. It was noticed that for

values were less than 10 μA. SL-7 and SL-8 samples had 2.5 cm reservoir length samples, the Icorr average & STD

several cyclic periods (i.e., increase followed by a values for SL-4, and SL-5 were 6.9 μA, and 7.4 μA & 1.5

decrease). Icorr values were found to be larger for SL-8 μA, and 4.8 μA respectively. It was interesting to note

samples than in comparison with other SL samples that the rebar with the largest average Icorr was the rebar

having the 5 cm reservoir size. Icorr values ranged from embedded in sample SL-2, which has the longer solution

5.0-28.7 μA for these samples (5 cm solution reservoir). reservoir of 17.5 cm. The rebar with the lowest average

While looking at the second plot (potential plot) in Figure Icorr was for SL-4 sample, that has the smaller solution

3, it was found that the potential values were more reservoir of 2.5 cm.

negative than -150 mVsce for most of the readings for

SL-7 and SL-8 samples, thus suggests ongoing corrosion

propagation. But for SL-6 sample, potential values were

Accelerated corrosion of steel rebar in concrete by electromigration… 58-4

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

Table 5 highlights the Icorr average and STD values solution reservoir for SL and FA concrete mixes cast with

obtained from GP measurements for FA single rebar a single rebar.

specimens. These averages were calculated using data

obtained from May 2017 to May 2018. It was observed

that for a reservoir length of 17.5 cm, Icorr average &

STD values for FA-7, FA-8, and FA-9 samples were 16.7

μA, 8.1 μA, and 15.5 μA & 2.2 μA, 0.8 μA, and 3.2 μA

respectively. While comparing the Icorr average

measured on rebars for 7.5 cm reservoir length samples,

it was found that Icorr average & STD values for FA-4,

FA-5, and FA-6 were 24.3 μA, 16.6 μA, and 23.8 μA &

4.6 μA, 2.4 μA, and 7.8 μA respectively. It was noted that

for 5 cm reservoir length samples, the Icorr average &

STD values for FA-1, FA-2, and FA-3 were 5.4 μA, 6.0

μA, and 19.6 μA & 0.7 μA, 2.5 μA, and 8.9 μA

respectively. It was noticed that for 2.5 cm reservoir

length samples, the Icorr average & STD values for FA-

10, and FA-11 were 7.4 μA, and 3.3 μA & 3.0 μA, and

1.2 μA respectively. It was interesting to note that the

rebar with the largest average Icorr was the rebar

embedded in sample FA-4, which has a solution reservoir

of 7.5 cm. The rebar with the lowest average Icorr was

for FA-11 sample, that has the smaller solution reservoir

of 2.5 cm. Figure 5 summarizes the correlation between

the average corrosion current and the length of the

Accelerated corrosion of steel rebar in concrete by electromigration… 58-5

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

composition samples and from 0.048 to 0.178 grams for

FA samples. Finally, for rebars with a 2.5 cm solution

reservoir size, the mass loss for SL mix samples ranged

from 0.062 to 0.070 grams, while it ranged from 0.030 to

0.066 grams for rebars in FA samples. Figure 6

summarizes the relationship between the maximum mass

loss values and the length of the solution reservoir for SL

and FA concrete mixes cast with a single rebar.

Figure 5. Summary of average corrosion current with

length of solution reservoir and concrete mixes cast with

single rebar

Table 6 and Table 7 shows the estimated mass loss in

grams for SL and FA single rebar samples obtained from

the GP method according to the length of solution

reservoir installed. Measurements taken between May

2017 to May 2018 were included to calculate these

values. The mass loss values for rebars in SL samples

with 17.5 cm solution reservoir size ranged from 0.142 to

0.170 grams, whereas the values for rebars in FA samples

with the same reservoir length ranged from 0.056 to

0.149 grams. The mass loss for rebars in SL samples with

a solution reservoir size of 10 cm ranged from 0.106 to

0.131 grams, whereas it ranged from 0.150 to 0.220

grams for FA samples with a ponding length of 7.5 cm.

For rebars with a solution reservoir size of 5 cm, the mass

loss ranged from 0.072 to 0.155 grams for SL

Accelerated corrosion of steel rebar in concrete by electromigration… 58-6

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

simulate corrosion of steel reinforcement in

concrete,” ASCE J. Mater. Civ. Eng., 15(1), pp. 41–

47 (2003).

[3] Polder, R.B., and Peelen, H.A., “Characterization of

chloride transport and reinforcement corrosion in

concrete under cyclic wetting and drying by electrical

resistivity,” Cem. Concr. Compos., vol. 24, pp. 427–

435 (2002).

[4] Wu, J., Li, H., Wang, Z., and Liu, J., “Transport

model of chloride ions in concrete under loads and

drying-wetting cycles,” Constr. Build. Mater., vol.

112, pp. 733–738 (2016).

[5] Ye, H., Jin, X., Fu, C., Jin, N., Xu, Y., and Huang, T.,

“Chloride penetration in concrete exposed to cyclic

drying-wetting and carbonation,” Constr. Build.

Mater., vol. 112, pp. 457–463 (2016).

[6] Jung, W.Y., Yoon, Y.S., and Sohn, Y.M., “Predicting

Figure 6. Summary of maximum mass loss (GP) with

the remaining service life of land concrete by steel

length of solution reservoir and concrete mixes cast with

corrosion.” Cem. Concr. Res., 33(5), pp. 663–677

single rebar

(2003).

[7] Otieno, M.B., Beushausen, H.D., and Alexander,

6. CONCLUSIONS M.G., “Chloride-induced corrosion of steel in

cracked concrete-part II: corrosion rate prediction

The chlorine transport was successfully accelerated by models,” Cem. Concr. Res., vol. 79, pp. 386–394

the electromigration approach, causing corrosion to (2016).

initiate on every single rebar specimen. [8] Care, S., and Raharinaivo, A., “Influence of

impressed current on the initiation of damage in

The corrosion current values obtained from reinforced mortar due to corrosion of embedded

electrochemical experiments were significantly steel,” Cem. Concr. Res., 37(12), pp. 1598–1612

influenced by the length of the solution reservoirs. The (2007).

corrosion current value was found to increase with the [9] Rahman, M.M., Biswas, M.A.S., and Hoque, K.N.,

length of the solution reservoir, except for samples with “Recent development on micro-texturing of

reservoir sizes of 10 cm (SL) and 17.5 cm (FA). UHMWPE surfaces for orthopedic bearings: A

Corrosion current values were comparable for 2.5 cm and review,” Biotribology, vol. 31, pp. 1-10 (2022).

5 cm reservoir size for both SL and FA concrete mixes. [10] Badawi, M., and Soudki, K., “Control of corrosion-

But for 17.5 cm reservoir size, corrosion current values induced damage in reinforced concrete beams using

were found to be larger for SL mix than in comparison carbon fiber-reinforced polymer laminates,” J.

with FA mix. For FA concrete mix, the larger corrosion Compos. Constr., 9(2), pp. 195–201 (2005).

current values were observed for 7.5 cm reservoir size [11] Hoque, K. N., “Analysis of structural discontinuities

samples. in ship hull using finite element method,” M.Sc.

Thesis, Department of Naval Architecture and

Except for samples with reservoir sizes of 10 cm (SL) Marine Engineering, Bangladesh University of

and 17.5 cm (FA), it was found that the calculated mass Engineering and Technology (BUET), Dhaka,

loss value increased with the length of the solution Bangladesh (2016).

reservoir. For SL concrete mix and FA concrete mix, [12] Presuel-Moreno, F., Balasubramanian, H., and Wu,

samples with reservoir sizes of 17.5 cm and 7.5 cm, Y.-Y., “Corrosion of reinforced concrete pipes: an

respectively, showed maximum mass loss values. accelerated approach,” Corrosion 2013, paper no.

C2013-0002551, Houston, TX: NACE (2013).

REFERENCES [13] Presuel-Moreno, F., Nazim, M. Tang, F., Hoque, K.,

and Bencosme, R., “Corrosion Propagation of

[1] Austin, S.A., Lyons, R., and Ing, M.J., Carbon Steel Rebars in High Performance Concrete,”

“Electrochemical behavior of steel-reinforced BDV27-977-08 Final Report for FDOT (2018).

concrete during accelerated corrosion testing,” [14] Feliu, V., Gonzalez, J.A., and Feliu, S., “Corrosion

Corrosion, 60(2), pp. 203–212 (2004). estimates from transient response to a potential step,”

[2[ El Maaddawy, T.A., and Soudki, K.A., Corrosion Science, 49(8), pp. 3241-3255 (2007).

“Effectiveness of impressed current technique to

Accelerated corrosion of steel rebar in concrete by electromigration… 58-7

Electronic copy available at: https://ssrn.com/abstract=4446360

Proceedings of MARTEC 2022 hosted on SSRN.com

[15] Gonzalez, J.A., Miranda, J.M., and Feliu, S., [17] Presuel-Moreno, F., and Hoque, K., “Corrosion

“Consideration on the reproducibility of potential and propagation of carbon steel rebar embedded in

corrosion rate measurements in reinforced concrete,” concrete,” Corrosion 2019, Nashville, Tennessee,

Corrosion Science, 46(10), pp. 2467-2485 (2004). USA (2019).

[16] Hoque, K., “Corrosion propagation of reinforcing [18] Presuel-Moreno, F., Hoque, K., and Rosa-Pagan, A.,

steel embedded in binary and ternary concrete,” “Corrosion propagation monitoring using

Ph.D. Dissertation, Department of Ocean and galvanostatic pulse on reinforced concrete legacy

Mechanical Engineering, Florida Atlantic University samples,” 2020-FAU-02 Final Report for National

(FAU), Boca Raton, Florida, USA (2020). University Transportation Center TriDurLE (2022).

Accelerated corrosion of steel rebar in concrete by electromigration… 58-8

Electronic copy available at: https://ssrn.com/abstract=4446360

View publication stats

You might also like

- Renos Puffy InglésDocument33 pagesRenos Puffy InglésLinthalaa RivendelNo ratings yet

- Specification For Bare Stainless Steel Welding Electrodes andDocument33 pagesSpecification For Bare Stainless Steel Welding Electrodes andpurnawanNo ratings yet

- Capillary Column EquivalentsDocument9 pagesCapillary Column EquivalentsNatalia CruzNo ratings yet

- Biocompatibility of Aluminium Alloys and Anodic Al2O3Document6 pagesBiocompatibility of Aluminium Alloys and Anodic Al2O3Nícolas LaraNo ratings yet

- A Beginner's Guide To Eco Printing Fabric: Bonnie BowmanDocument4 pagesA Beginner's Guide To Eco Printing Fabric: Bonnie BowmanBagio Ranthe100% (2)

- Accelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesDocument9 pagesAccelerated Corrosion of Steel Rebar in Concrete by Electromigration: Effect of Reservoir Length and Concrete MixesAlmas XamiNo ratings yet

- SSRN Id4447455Document8 pagesSSRN Id4447455Almas XamiNo ratings yet

- Corrosion Propagation of Steel Rebar Embedded in MarineDocument8 pagesCorrosion Propagation of Steel Rebar Embedded in MarineAlmas XamiNo ratings yet

- SSRN Id4447482Document7 pagesSSRN Id4447482Almas XamiNo ratings yet

- SSRN Id4447479Document7 pagesSSRN Id4447479Almas XamiNo ratings yet

- Shridevi 2020 IOP Conf. Ser. Mater. Sci. Eng. 989 012024Document11 pagesShridevi 2020 IOP Conf. Ser. Mater. Sci. Eng. 989 012024ron_danyNo ratings yet

- Corrosion of Steel Rebar Embedded in Ternary Blended Concrete Exposed To High Humidity EnvironmentDocument7 pagesCorrosion of Steel Rebar Embedded in Ternary Blended Concrete Exposed To High Humidity EnvironmentAlmas XamiNo ratings yet

- Research ArticleDocument11 pagesResearch Articlezaman ahmadNo ratings yet

- OTIENO 2016 - Corrosion Rate Prediction Models PART IDocument13 pagesOTIENO 2016 - Corrosion Rate Prediction Models PART IVinícius RamosNo ratings yet

- Corrosion Behavior of Reinforcing Steel Embedded in Fly Ash ConcreteDocument7 pagesCorrosion Behavior of Reinforcing Steel Embedded in Fly Ash ConcreteAlmas XamiNo ratings yet

- 1 s2.0 S0143974X24001111 MainDocument21 pages1 s2.0 S0143974X24001111 MainAashima sharmaNo ratings yet

- Remaining Fatigue Life of Corroded SteelDocument10 pagesRemaining Fatigue Life of Corroded SteelRaees MazharNo ratings yet

- Detailed Modeling of Corrosion Macrocells On Steel Reinforcing in ConcreteDocument18 pagesDetailed Modeling of Corrosion Macrocells On Steel Reinforcing in ConcreteDaniel RochaNo ratings yet

- 2 PDFDocument11 pages2 PDFbaneNo ratings yet

- 03 - 15842 - IJCEA - PP 21-32 New1Document12 pages03 - 15842 - IJCEA - PP 21-32 New1sanjeev kumar vermaNo ratings yet

- Investigation of Steel Corrosion in Cracked Concrete Evaluation of Macrocell and Microcell Rates Using Tafel Polarization Response 2010Document11 pagesInvestigation of Steel Corrosion in Cracked Concrete Evaluation of Macrocell and Microcell Rates Using Tafel Polarization Response 2010sryh2012No ratings yet

- Accelerated CorrosionDocument8 pagesAccelerated Corrosionjuli_rad100% (2)

- Corrosion Science: Chong Cao, Moe M.S. Cheung, Ben Y.B. ChanDocument13 pagesCorrosion Science: Chong Cao, Moe M.S. Cheung, Ben Y.B. ChanEjazulhaq RahimiNo ratings yet

- Artigo Sobre CorrosãoDocument13 pagesArtigo Sobre CorrosãoSandro MendesNo ratings yet

- Numerical Analysis of Localized Steel Corrosion in Concrete: MaterialsDocument8 pagesNumerical Analysis of Localized Steel Corrosion in Concrete: MaterialsEjazulhaq RahimiNo ratings yet

- materials-15-00497Document22 pagesmaterials-15-00497VINH VÕ ĐỨC THÀNHNo ratings yet

- Study On The Influence of Compound Rust Inhibitor On Corrosion of Steel Bars in Chloride Concrete by Electrical ParametersDocument14 pagesStudy On The Influence of Compound Rust Inhibitor On Corrosion of Steel Bars in Chloride Concrete by Electrical ParametersRAGHUNo ratings yet

- Influence of Rust Inhibitor On The Corrosion ResisDocument10 pagesInfluence of Rust Inhibitor On The Corrosion Resisaldrinramirez20No ratings yet

- Cement and Concrete CompositesDocument10 pagesCement and Concrete CompositesAman KumarNo ratings yet

- 1.1 General: (BertoliniDocument3 pages1.1 General: (BertoliniEka SupriantoNo ratings yet

- Corrosion Inhibitors PDFDocument9 pagesCorrosion Inhibitors PDFmanil_5100% (1)

- Ann 2006Document6 pagesAnn 2006sumanthNo ratings yet

- Effect of Chloride Concentration On The Corrosion Rate in Carbon SteelDocument7 pagesEffect of Chloride Concentration On The Corrosion Rate in Carbon SteelAziz SaputraNo ratings yet

- Coorosion 3Document9 pagesCoorosion 3Ramin ShojaNo ratings yet

- Jiang Et Al, 2017Document11 pagesJiang Et Al, 2017ANA LAURA BRAGA NASCIMENTONo ratings yet

- 1 s2.0 S0010938X08003296 Main PDFDocument16 pages1 s2.0 S0010938X08003296 Main PDFSaRah Yasmin TajuldinNo ratings yet

- Electrical Resistivity and Microstructural Properties of Concrete Materials in Conditions of Current FlowDocument14 pagesElectrical Resistivity and Microstructural Properties of Concrete Materials in Conditions of Current FlowRetana González Manuel AbrahamNo ratings yet

- Rehabilitation and Maintenance of Rusted Reinforcement Bar in RCC BeamDocument3 pagesRehabilitation and Maintenance of Rusted Reinforcement Bar in RCC BeamkelmazodroNo ratings yet

- Lect-4 Corrosion of Steel in ConcreteDocument25 pagesLect-4 Corrosion of Steel in ConcreteYoukhanna ZayiaNo ratings yet

- Case Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeDocument7 pagesCase Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeGina BerríoNo ratings yet

- Garba 01Document7 pagesGarba 01Ameera IzmieNo ratings yet

- Corrosion Science: SciencedirectDocument19 pagesCorrosion Science: SciencedirectArturo CervantesNo ratings yet

- Mci BavarianDocument13 pagesMci BavarianmuqeetNo ratings yet

- Coatings 11 00517Document16 pagesCoatings 11 00517Domingo FernándezNo ratings yet

- Construction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiDocument11 pagesConstruction and Building Materials: L. Abosrra, A.F. Ashour, M. YouseffiIsrael WakumaNo ratings yet

- Corrosion in ConcreteDocument8 pagesCorrosion in ConcreteOpany JuliusNo ratings yet

- Crack Shape and Rust Distribution in Corrosion-Induced Cracking ConcreteDocument9 pagesCrack Shape and Rust Distribution in Corrosion-Induced Cracking ConcretenagarajuNo ratings yet

- Michel Et Al. (2016)Document12 pagesMichel Et Al. (2016)Vinícius RamosNo ratings yet

- Prevention of Corrosion of SteelDocument8 pagesPrevention of Corrosion of SteelZainal AbidhynNo ratings yet

- Using Cathodic Protection To Control Corrosion of Coastal Reinforced Concrete Infrastructures PDFDocument7 pagesUsing Cathodic Protection To Control Corrosion of Coastal Reinforced Concrete Infrastructures PDFBoussaid SouheilNo ratings yet

- Corrosion Evolution of Scaled Rebar in Concrete Under Dry/Wet Cyclic Condition in 3.5% Nacl SolutionDocument15 pagesCorrosion Evolution of Scaled Rebar in Concrete Under Dry/Wet Cyclic Condition in 3.5% Nacl Solutionjack21abNo ratings yet

- Reference 2Document28 pagesReference 2daniadaniellaaaaaNo ratings yet

- Corrosion of Reinforcing Bars in Concrete PaperDocument33 pagesCorrosion of Reinforcing Bars in Concrete PaperMamta BaxlaNo ratings yet

- Electrochemical-Mechanistic Model For Concrete Cover Cracking DueDocument41 pagesElectrochemical-Mechanistic Model For Concrete Cover Cracking DueNora al-anssariNo ratings yet

- Macrocell and Microcell Corrosion of Steel in Ordinary Portland Cement and High Performance ConcretesDocument5 pagesMacrocell and Microcell Corrosion of Steel in Ordinary Portland Cement and High Performance ConcretesEjazulhaq RahimiNo ratings yet

- Effects of DC Stray Current On Concrete Structure: BstractDocument4 pagesEffects of DC Stray Current On Concrete Structure: BstractAldrin SantosNo ratings yet

- Bicharaetal 2019Document17 pagesBicharaetal 2019asaad biqaiNo ratings yet

- Longterm Seismic Performance of Reinforced Concrete Bridges Under Steel Reinforcement Corrosion Due To Chloride Attack PDFDocument15 pagesLongterm Seismic Performance of Reinforced Concrete Bridges Under Steel Reinforcement Corrosion Due To Chloride Attack PDFnagarajuNo ratings yet

- Study On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeDocument8 pagesStudy On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeNew NSskinNo ratings yet

- CP Criteria 01Document15 pagesCP Criteria 01Sheik DawoodNo ratings yet

- Experimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagDocument6 pagesExperimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagIJRASETPublicationsNo ratings yet

- Corrosion CinéticaDocument9 pagesCorrosion CinéticaOscar David Madera OzunaNo ratings yet

- Failure Analysis of Structural Steel Subjected To Long Term ExposureDocument13 pagesFailure Analysis of Structural Steel Subjected To Long Term ExposureDeepak wadgeNo ratings yet

- Corrosion of Steel in High Strength SelfDocument12 pagesCorrosion of Steel in High Strength SelfAtta Ur RehmanNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Ion Exchange SofteningDocument16 pagesIon Exchange SofteningMohamed ElbehlilNo ratings yet

- Corrosion Damage (Forms of Corrosion)Document105 pagesCorrosion Damage (Forms of Corrosion)Andiappan Pillai100% (5)

- Hydrogen and SAF For Aviation 1696853988Document17 pagesHydrogen and SAF For Aviation 1696853988Gurvinder SinghNo ratings yet

- Nyfgby: Twin Cores, Armoured Cable Low Voltage Armoured CableDocument6 pagesNyfgby: Twin Cores, Armoured Cable Low Voltage Armoured CableOffice ccNo ratings yet

- Materials Advances: PaperDocument10 pagesMaterials Advances: PapercathyyNo ratings yet

- Crealco ApplicationsDocument1 pageCrealco ApplicationswittypeeNo ratings yet

- Doe Method of Mix DesignDocument25 pagesDoe Method of Mix DesignAbarahamNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- Failure and CarbonsDocument19 pagesFailure and CarbonsSherif AdelNo ratings yet

- Petersenplgpckrcats PDFDocument112 pagesPetersenplgpckrcats PDFEdixon ZambranoNo ratings yet

- Sandvik - Technical Guide - Materials ISODocument41 pagesSandvik - Technical Guide - Materials ISOznovak77100% (1)

- Column Design ExcelDocument4 pagesColumn Design Excelvimal patelNo ratings yet

- Stoody 130Document1 pageStoody 130Cheker HaddedNo ratings yet

- Benefits of STT PDFDocument8 pagesBenefits of STT PDFElias KapaNo ratings yet

- Rules of CreditDocument14 pagesRules of Creditwes01010No ratings yet

- Cemtop 200Document4 pagesCemtop 200milanbrasinaNo ratings yet

- ANOVA-Ballistic Behavior of Epoxy Matrix Composites ReinDocument8 pagesANOVA-Ballistic Behavior of Epoxy Matrix Composites ReinNhanNo ratings yet

- Caustic SodaDocument24 pagesCaustic SodaSiddesh PatilNo ratings yet

- Binary Phase DiagramsDocument60 pagesBinary Phase DiagramsmaryzeenNo ratings yet

- Metal Injection MoldingDocument211 pagesMetal Injection MoldingYudhaPrawiraNo ratings yet

- Chemical List Eastern PolymerDocument1 pageChemical List Eastern PolymerIan MardiansyahNo ratings yet

- G. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityDocument7 pagesG. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityMadhusudhan ModemNo ratings yet

- Nyungu T R197826R MG103 Assignment1 PDFDocument8 pagesNyungu T R197826R MG103 Assignment1 PDFTamiranashe Tammie NyunguNo ratings yet