Professional Documents

Culture Documents

Ixef 1032 1

Ixef 1032 1

Uploaded by

Renan Lucena da CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ixef 1032 1

Ixef 1032 1

Uploaded by

Renan Lucena da CruzCopyright:

Available Formats

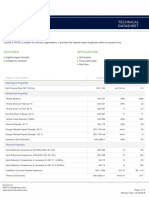

IXEF

Product Data polyarylamide

1032

IXEF1032 is a 60% glass-fiber reinforced, general pur- stress levels, high flow, low and slow moisture pickup,

pose polyarylamide compound which exhibits very high excellent dimensional stability, and excellent surface qual-

strength and rigidity, outstanding surface gloss, and excel- ity and gloss. They can be easily processed on conven-

lent creep resistance. tional injection molding equipment.

The IXEF family of materials consists of polyarylamide

resins compounded with glass fibers, minerals, and other

additives. The compounds in this family are characterized

by high strength and stiffness, creep resistance at high

Typical Properties of IXEF 1032

Typical Values (1)

Test SI Units U.S. Customary Units

Property Method DAM(2) 50% RH Units DAM(2) 50% RH Units

Mechanical

Tensile Strength ISO 527 280 250 MPa 40.6 36.3 kpsi

Tensile Elongation ISO 527 1.8 2.0 % 1.8 2.0 %

Tensile Modulus ISO 527 24 23 GPa 3.48 3.34 Mpsi

Flexural Strength ISO 178 400 MPa 58.0 kpsi

Flexural Modulus ISO 178 23.5 GPa 3.41 Mpsi

Izod Impact, Notched ASTM D 256 120 J/m 2.3 ft-lb/in

Izod Impact, Unnotched ASTM D 256 900 J/m 17 ft-lb/in

Thermal

Heat Deflection Temperature ISO 75A 230 °C 446 °F

Flammability(3) UL 94 HB HB

-6 -1 -6

Coefficient of Thermal Expansion ISO 11359 14 10 K 8 10 in/in°F

Limiting Oxygen Index ISO 4589 25 % 25 %

Electrical

Dielectric Strength IEC 243 24 kV/mm 602 V/mil

Volume Resistivity IEC 93/167 1013 ohm-cm 1013 ohm-cm

Comparative Tracking Index (CTI) IEC 112 600 V 600 V

Dielectric Constant at 100 Hz IEC 250 4.5 4.5

Dielectric Loss Angle at 100 Hz IEC 250 0.009 0.009

General

Specific Gravity ISO 1183 1.77 1.77

Reinforcement Content 60 % 60 %

Moisture Absorption, 24 hr. ISO 62 0.13 % 0.13 %

Moisture Absorption (Equil) 65% RH Solvay 1.3 % 1.3 %

(4)

Mold Shrinkage in Flow Direction Solvay 0.1-0.3 % 0.1-0.3 %

(1) Actual properties of individual batches will vary within specification limits. Properties are typical of uncolored resin. Colorants or other additives will alter values.

(2) Dry as molded.

(3) These flammability ratings are not intended to reflect hazards presented by these or any other materials under actual fire conditions.

(4) Solvay Internal procedure, Pressure 750 bars (10.9 kpsi); specimen 40 mm x 20 mm x 2-4 mm. (1.6 in. x 0.8 in. x 0.08-0.16 in.)

Solvay Advanced Polymers has offices in the

Americas, Europe, and Asia. To locate the

office nearest to you, visit our website at

www.solvayadvancedpolymers.com.

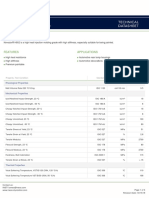

IXEF 1032

Drying Individual packages will be plainly marked with the prod-

uct number, the color, the lot number, and the net weight.

The material as supplied is ready for molding without dry-

ing. However, If the bags have been open for longer than Product Safety and Emergency Service

24 hours, the material needs to be dried.

For product safety information or a Material Safety Data

When using a desiccant air dryer with dew point of -28°C Sheet on a product of Solvay Advanced Polymers

(-18°F) or lower, these guidelines can be followed: 0.5–1.5

hour at 120°C (248°F), 1–3 hours at 100°C (212°F), or 1 (800) 621-4557

1–7 hours at 80°C (176°F). 1 (770) 772-8880 outside of U.S.

For information or help in an emergency such as a spill,

Injection Molding leak, fire or explosion, call day or night:

IXEF 1032 compound can be readily injection molded in

most screw injection molding machines. A general pur- Emergency Health Information

pose screw is recommended, with minimum back 1 (800) 621-4590 or

pressure. 1 (770) 772-5177 outside of U.S.

The measured melt temperature should be about 280°C Emergency Spill Information

(536°F), and the barrel temperatures should be around

250 to 260°C (482 to 500°F) in the rear zone, gradually CHEMTREC 1 (800) 424-9300

increasing to 260 to 290°C (500 to 554°F) in the front 1 (703) 527-3887 outside of U.S.

zone. If hot runners are used, they should be set to 250 to collect calls accepted

260°C (482 to 500°F). For Additional Information

To maximize crystallinity, the temperature of the mold cav- Europe

ity surface must be held between 120 and 140°C (248 and

284°F). Molding at lower temperatures will produce arti- +49 211 513 590 00 (Germany)

cles that may warp, have poor surface appearance, and USA and rest of world

have a greater tendency to creep.

Technical Service

Set injection pressure to give rapid injection. Adjust hold- 1 (800) 621-4557 or

ing pressure and hold time to maximize part weight. 1 (770) 772-8760 outside of U.S.

Transfer from injection to hold pressure at the screw posi-

tion just before the part is completely filled (95-99%). Customer Service

1 (800) 848-9744 or

Standard Packaging and Labeling 1 (770) 772-8762 outside of U.S.

IXEF 1032 compound is packaged in foil lined, multiwall

paper bags containing 25 kg (55.115 pounds) of material.

Special packaging can be supplied upon request.

IXEF is a registered trademark of Solvay Advanced Polymers, L.L.C.

To our actual knowledge, the information contained herein is accurate as of the date of this document. However, neither Solvay Advanced Polymers, L.L.C. nor any of its affiliates makes any warranty, express or

implied, or accepts any liability in connection with this information or its use. This information is for use by technically skilled persons at their own discretion and risk and does not relate to the use of this product in

combination with any other substance or any other process. This is not a license under any patent or other proprietary right. The user alone must finally determine suitability of any information or material for any

contemplated use, the manner of use and whether any patents are infringed. This information gives typical properties only and is not to be used for specification purposes. Solvay Advanced Polymers, L.L.C. re-

serves the right to make additions, deletions, or modifications to the information at any time without prior notification.

XF-50344 Copyright 2005, Solvay Advanced Polymers, L.L.C. All rights reserved. R 02/09

You might also like

- Hollymatic Super: Operators Manual Parts ListDocument45 pagesHollymatic Super: Operators Manual Parts ListCarlosERodriguezA100% (1)

- Electronic Prescriptions For Controlled SubstancesDocument335 pagesElectronic Prescriptions For Controlled SubstancesJames Lindon100% (1)

- 06 237046 001 - BDDocument1 page06 237046 001 - BDcarlos yepezNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Bayer Makrolon 2407Document3 pagesBayer Makrolon 2407DiegoTierradentro100% (1)

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Luran S757 GDocument5 pagesLuran S757 GPeter EvansNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Bakelite PF6507Document4 pagesBakelite PF6507dioguitomsolhaNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- TECHNYL® A 216 Y10: DescriptionDocument2 pagesTECHNYL® A 216 Y10: DescriptionpaquienNo ratings yet

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 pagesEmerge™ Pc/Abs 7740: Technical InformationbobNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- TerluranGP 22Document5 pagesTerluranGP 22Chu ChuNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- Santoprene 201 64 - MDS - ENDocument3 pagesSantoprene 201 64 - MDS - ENLITCoupie RAKVANNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- Techtron PPSDocument5 pagesTechtron PPSSenthil Kumar GanesanNo ratings yet

- ASA Styrolution: Luran® S 778 TDocument2 pagesASA Styrolution: Luran® S 778 TayyappanNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocument3 pagesNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmNo ratings yet

- 76 StyrolutionPS454NDocument5 pages76 StyrolutionPS454N59074No ratings yet

- Radipol A45 TDSDocument1 pageRadipol A45 TDSxy2zjgNo ratings yet

- Lamitex G-5 Tube Technical Data: Plastics & Non-Metallics For Industry Since 1921Document1 pageLamitex G-5 Tube Technical Data: Plastics & Non-Metallics For Industry Since 1921abdulloh_99No ratings yet

- Sarlink 3939D - Data Sheet PDFDocument1 pageSarlink 3939D - Data Sheet PDFRafi deenNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- Ultramid A3 KDocument8 pagesUltramid A3 Kmani01kandanNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Perspex Cell Cast Acrylic: Technical Data SheetDocument1 pagePerspex Cell Cast Acrylic: Technical Data Sheetarun manchekarNo ratings yet

- Allbro Material-Properties-Smc-DmcDocument1 pageAllbro Material-Properties-Smc-Dmcfajar agungNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 pagesDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- SABIC® PPcompound - H1030 - Global - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - H1030 - Global - Technical - Data - SheetRobertoNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Total 1540Document1 pageTotal 1540sercanworkNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- Terluran GP35Document5 pagesTerluran GP35cristinamss33No ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Uenr8357uenr8357 SisDocument8 pagesUenr8357uenr8357 Sisjhonas del marNo ratings yet

- Cô Mai Phương - Đề chuẩn 08 - File word có lời giải chi tiếtDocument20 pagesCô Mai Phương - Đề chuẩn 08 - File word có lời giải chi tiếtMinh Đức NguyễnNo ratings yet

- Republic of The Philippines Municipality of DiffunDocument3 pagesRepublic of The Philippines Municipality of DiffunKrisna Criselda SimbreNo ratings yet

- Design For Multiple ReactionsDocument43 pagesDesign For Multiple Reactionsmuhammad shahadat awanNo ratings yet

- De Ce of Eterm Emen F The Mina NT by e Solu Ation y Pho Ubiliz Nofa Otom Zed P Alum Metric Prod Inum C Titr Uct Min Ratio NDocument2 pagesDe Ce of Eterm Emen F The Mina NT by e Solu Ation y Pho Ubiliz Nofa Otom Zed P Alum Metric Prod Inum C Titr Uct Min Ratio NRomy Iván Cruz VillarroelNo ratings yet

- Final Seat Position For Addendum For Tentative Seat Position For AIIMS PG January 2019 SessionDocument4 pagesFinal Seat Position For Addendum For Tentative Seat Position For AIIMS PG January 2019 SessionShivam DuttaNo ratings yet

- How Much Floor Space Needs A Broiler Chicken?: July 2011Document4 pagesHow Much Floor Space Needs A Broiler Chicken?: July 2011zohaib hafeezNo ratings yet

- Access - Catalog - DP&Casing Tools-15-18Document4 pagesAccess - Catalog - DP&Casing Tools-15-18RICHARDNo ratings yet

- Magnum Ms - Pae DatasheetDocument1 pageMagnum Ms - Pae DatasheetGissell Del CastilloNo ratings yet

- 27 3310 01 Ecosmooth Rice Husk Cosmetic PowderDocument2 pages27 3310 01 Ecosmooth Rice Husk Cosmetic PowderJdNo ratings yet

- Drone UnfinishedDocument10 pagesDrone UnfinishedLance Kelly ManlangitNo ratings yet

- Ats Acb 3 Pole Diagram Shuntz BigDocument1 pageAts Acb 3 Pole Diagram Shuntz BigRyan Dalay100% (1)

- London Food Strategy Implementation 07Document24 pagesLondon Food Strategy Implementation 07Martyn ClarkNo ratings yet

- Compressor PresentationDocument24 pagesCompressor PresentationPrashant Kumar mishraNo ratings yet

- Lesson Plan Cont OhDocument7 pagesLesson Plan Cont OhAnonymous viipLHxyNo ratings yet

- Operation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20Document64 pagesOperation Manual: SUT06D40L16-20 SUT10D40L16-20 SUT06D60L21-20 SUT10D60L21-20hungstampNo ratings yet

- Stoichiometric CalculationsDocument13 pagesStoichiometric Calculationsandrew surajNo ratings yet

- Cerebrovascular AccidentDocument42 pagesCerebrovascular AccidentGideon HaburaNo ratings yet

- Total Parenteral NutritionDocument59 pagesTotal Parenteral NutritionMARIAH ALEXIE GASALNo ratings yet

- 17-Stream Water Quality Analysis - F11Document12 pages17-Stream Water Quality Analysis - F11Michelle de Jesus100% (1)

- Batch 3 UnescoDocument27 pagesBatch 3 UnescoHeaven Diaz100% (1)

- ISV SM Ch36Document44 pagesISV SM Ch36손은결No ratings yet

- Bomb Calorimeter TheoryDocument2 pagesBomb Calorimeter TheoryTub Pitthayuth33% (3)

- Masterpact NT12 H1 User ManualDocument56 pagesMasterpact NT12 H1 User ManualSlaxNo ratings yet

- LPM (Care and Management of Calf, Heifer, Milch Animal, Dry and Prignant Animal, Bull and Bullock)Document20 pagesLPM (Care and Management of Calf, Heifer, Milch Animal, Dry and Prignant Animal, Bull and Bullock)Atharv KingeNo ratings yet

- As A Man Thinketh: by James AllenDocument24 pagesAs A Man Thinketh: by James AllenAce OfbaseNo ratings yet

- Vulvovaginitis: Find The Cause To Treat It: ReviewDocument10 pagesVulvovaginitis: Find The Cause To Treat It: ReviewMinati Yohana SiagianNo ratings yet