Professional Documents

Culture Documents

Rapid Fit

Rapid Fit

Uploaded by

Doanh NguyenCopyright:

Available Formats

You might also like

- Met Accounting and ReconciliationDocument14 pagesMet Accounting and ReconciliationHelbert Lino100% (1)

- CATIA - Composites Design For Manufacturing (CPM)Document4 pagesCATIA - Composites Design For Manufacturing (CPM)rakeshpa_2078662100% (2)

- Specification PedestalsDocument19 pagesSpecification PedestalsmikecomninosNo ratings yet

- Optimizing Innovation in Machine Design White Paper WP VH 00110Document4 pagesOptimizing Innovation in Machine Design White Paper WP VH 00110Jorge Raul AcostaNo ratings yet

- UAV & Other RTM Applications: Design Through Production - We're The RTM Experts!Document2 pagesUAV & Other RTM Applications: Design Through Production - We're The RTM Experts!Angel LagrañaNo ratings yet

- 0 PRO Gamma 450 ENDocument12 pages0 PRO Gamma 450 ENjuan lopezNo ratings yet

- MF White Paper CFR ApplicationsDocument11 pagesMF White Paper CFR ApplicationsrawsteelNo ratings yet

- Automatica NouDocument12 pagesAutomatica NouMadalin SerbanNo ratings yet

- Bearings For Steel IndustryDocument18 pagesBearings For Steel IndustryCarlos BarriosNo ratings yet

- Mate410 First Report Berk Cansel Seli̇n Group2Document10 pagesMate410 First Report Berk Cansel Seli̇n Group2temir.berkNo ratings yet

- MetalForming-Magazine 2021 06Document1 pageMetalForming-Magazine 2021 06waqar mansoorNo ratings yet

- Spectrumprinting16 e Kolbus GMBHDocument2 pagesSpectrumprinting16 e Kolbus GMBHвикторNo ratings yet

- Bosch - Lean Cell Layout, Modular WorkcellDocument6 pagesBosch - Lean Cell Layout, Modular Workcellmạnh nguyễnNo ratings yet

- Jose Antonio Moreno - Danobat ScoopDocument6 pagesJose Antonio Moreno - Danobat ScoopÂrbaoui MedNo ratings yet

- CATIA - Composite Engineering (CPE)Document4 pagesCATIA - Composite Engineering (CPE)saqibcatiaNo ratings yet

- Simufact Sheet Metal Forming 2015Document8 pagesSimufact Sheet Metal Forming 2015MrLanternNo ratings yet

- WhatsNew CimatronE 9.0 Version HighlightsDocument3 pagesWhatsNew CimatronE 9.0 Version HighlightsfaizNo ratings yet

- Ecotrim: Sustainable Robotic Cutting SolutionsDocument4 pagesEcotrim: Sustainable Robotic Cutting SolutionsAquilesNo ratings yet

- Arkitech Catalogue EnglishDocument16 pagesArkitech Catalogue Englishangel_deeaNo ratings yet

- Simufact - Forming The Simulation Solution For Bulk Sheet Metal FormingDocument15 pagesSimufact - Forming The Simulation Solution For Bulk Sheet Metal FormingShashin VyasNo ratings yet

- Die Casting AutomationDocument7 pagesDie Casting AutomationAditya samalNo ratings yet

- Visit Indo SchottleDocument18 pagesVisit Indo Schottleshubham bandalNo ratings yet

- Abb - Catalogo ACS355 PDFDocument56 pagesAbb - Catalogo ACS355 PDFRodrigo Jacy Monteiro MartinsNo ratings yet

- ACS850 Drive Modules Technical CatalogueDocument20 pagesACS850 Drive Modules Technical CatalogueANOOP KRISHNANNo ratings yet

- ToolingU Additive ManufacturingDocument18 pagesToolingU Additive Manufacturingblake basanskyNo ratings yet

- Oem Ap149 - en PDocument4 pagesOem Ap149 - en PdangkhuyenmaiNo ratings yet

- Design World Robotics Handbook 11 2023Document60 pagesDesign World Robotics Handbook 11 2023ql yuanNo ratings yet

- ACS350 Technical CatalogueDocument20 pagesACS350 Technical CatalogueJNo ratings yet

- KUKADocument4 pagesKUKAUmesh SNo ratings yet

- Additive Fact SheetDocument2 pagesAdditive Fact SheetMustafaNo ratings yet

- 5 - PowerMill 2019 BrochureDocument4 pages5 - PowerMill 2019 BrochureAhmedBrahamNo ratings yet

- Hemming 2Document6 pagesHemming 2erbilodevNo ratings yet

- Nouveau Document Microsoft WordDocument11 pagesNouveau Document Microsoft Wordsoukehal wail mohamed redhaNo ratings yet

- Coinco Savings DesignfaxDocument2 pagesCoinco Savings Designfaxmax molenaar100% (2)

- Pipe Cutting Machine 1-4Document16 pagesPipe Cutting Machine 1-4Jackson MtongaNo ratings yet

- Reconfigurable Tooling For Airframe AssemblyDocument21 pagesReconfigurable Tooling For Airframe AssemblyDennis Padec BwochengoNo ratings yet

- 1 s2.0 S2212827119303142 MainDocument6 pages1 s2.0 S2212827119303142 Maindigvijaybhingare1243No ratings yet

- Unit 2Document51 pagesUnit 2Avanish BajpaiNo ratings yet

- Robotic Systems: Flexible Parts Management - Fully IntegratedDocument20 pagesRobotic Systems: Flexible Parts Management - Fully IntegratedEduardo SilvaNo ratings yet

- Hexagon MI Romax Flyer EnduroDocument2 pagesHexagon MI Romax Flyer EnduroSanjay ShelarNo ratings yet

- CATIA V5R20 FactsheetDocument11 pagesCATIA V5R20 FactsheetlijinnuaaNo ratings yet

- Chapter 01 Vacuum Chambers Special Components PDFDocument14 pagesChapter 01 Vacuum Chambers Special Components PDFmindrumihaiNo ratings yet

- 3rd party LCI DRIVE with SINAMICS CU320-2_flyerDocument2 pages3rd party LCI DRIVE with SINAMICS CU320-2_flyereltripperNo ratings yet

- Computer On Module (COM) For Military Applications: Author: Advantech E-MailDocument7 pagesComputer On Module (COM) For Military Applications: Author: Advantech E-MailThongLeNo ratings yet

- Beckwood Guide To Press AutomationDocument16 pagesBeckwood Guide To Press AutomationOARIASCONo ratings yet

- Desain Otomatis KonveyorDocument8 pagesDesain Otomatis KonveyoragungNo ratings yet

- 3 DPDocument44 pages3 DPPooja AngolkarNo ratings yet

- ABB ACS850 Latest CatalogueDocument24 pagesABB ACS850 Latest CatalogueRajeev M PuthiyedathNo ratings yet

- Modulo SDocument164 pagesModulo SItzel AparicioNo ratings yet

- Abb Machinery Drives Catalog Acs850Document24 pagesAbb Machinery Drives Catalog Acs850Neeraj RaushanNo ratings yet

- Aberlink Zenith TooDocument8 pagesAberlink Zenith Toodanielbo2220No ratings yet

- Lexium 32i: Integrated Servo DriveDocument21 pagesLexium 32i: Integrated Servo DrivejesusortegavNo ratings yet

- Automation Doc 1Document13 pagesAutomation Doc 1Shah Sajjan KumarNo ratings yet

- SAS Catalog 2013 PartsDocument136 pagesSAS Catalog 2013 PartsAri Ercilio Farias FereirraNo ratings yet

- Guide To 3D PrintingDocument6 pagesGuide To 3D PrintingKomsa Csongor És AndreaNo ratings yet

- Accuracy Enhancement of Industrial Robots by On-Line Pose CorrectionDocument7 pagesAccuracy Enhancement of Industrial Robots by On-Line Pose CorrectionDavid Rogelio Alvarez ReyesNo ratings yet

- STAR-CCM+ v11 Brochure 2016Document12 pagesSTAR-CCM+ v11 Brochure 2016Anonymous scnl9rHNo ratings yet

- Case Study Raising The Bar On Rotary Table AccuracyDocument3 pagesCase Study Raising The Bar On Rotary Table AccuracynidhinNo ratings yet

- Sae Technical Paper Series: Khawar M. Zuberi, Padmanabhan Pillai and Kang G. ShinDocument9 pagesSae Technical Paper Series: Khawar M. Zuberi, Padmanabhan Pillai and Kang G. ShinmuradbashirNo ratings yet

- Mastering Siemens S7: A Comprehensive Guide to PLC ProgrammingFrom EverandMastering Siemens S7: A Comprehensive Guide to PLC ProgrammingNo ratings yet

- Xslicer-SMX 160 KVDocument16 pagesXslicer-SMX 160 KVDoanh NguyenNo ratings yet

- Brochuresmx 1000 SMX 1000 LC 251 e 023 ADocument18 pagesBrochuresmx 1000 SMX 1000 LC 251 e 023 ADoanh NguyenNo ratings yet

- Powertrain REVO RetrofitDocument4 pagesPowertrain REVO RetrofitDoanh NguyenNo ratings yet

- PSS-40 Solution Rev 2Document20 pagesPSS-40 Solution Rev 2Doanh NguyenNo ratings yet

- 2ce Iwhh 10Document7 pages2ce Iwhh 10Doanh NguyenNo ratings yet

- CMM Coordinate Measuring MachinesDocument16 pagesCMM Coordinate Measuring MachinesDoanh NguyenNo ratings yet

- Industrial X-Ray and CTDocument7 pagesIndustrial X-Ray and CTDoanh NguyenNo ratings yet

- TA7000series ProductGuide Eng Mar2016 SDocument44 pagesTA7000series ProductGuide Eng Mar2016 SDoanh NguyenNo ratings yet

- Nexiv VMZ H en - NewDocument3 pagesNexiv VMZ H en - NewDoanh NguyenNo ratings yet

- Nikon Solutions enDocument21 pagesNikon Solutions enDoanh NguyenNo ratings yet

- Altera - ENDocument8 pagesAltera - ENDoanh NguyenNo ratings yet

- L300L200 FinalDocument5 pagesL300L200 FinalDoanh NguyenNo ratings yet

- ByprovinceDocument128 pagesByprovinceLun Do100% (1)

- General Description: Plug Fan ER..C With Standard MotorDocument7 pagesGeneral Description: Plug Fan ER..C With Standard MotorwildanNo ratings yet

- wph16 01 Pef 20230302Document17 pageswph16 01 Pef 20230302the dsNo ratings yet

- Introduction To Work HoldingDocument29 pagesIntroduction To Work HoldingAndres Fitria FarrelNo ratings yet

- Mintmade FashionDocument15 pagesMintmade FashionJack ZNo ratings yet

- Hse PlanDocument44 pagesHse PlanSheldon Van RooyenNo ratings yet

- Anterior and Lateral Views of The SkullDocument18 pagesAnterior and Lateral Views of The SkullArshad hussainNo ratings yet

- Class 6 NSTSE PQP 10-Papers 2019-20 2-In-A4 PDFDocument85 pagesClass 6 NSTSE PQP 10-Papers 2019-20 2-In-A4 PDFSanjib Mandal100% (3)

- Sacred Places of The World A Religious Journey Across The GlobeDocument209 pagesSacred Places of The World A Religious Journey Across The GlobeDenis-Elena Cotea100% (1)

- BDSsteelhandbookDocument80 pagesBDSsteelhandbookVeeraiah AnbuNo ratings yet

- Anatomy of An EMC VNXDocument3 pagesAnatomy of An EMC VNXRajNo ratings yet

- Peta CalculusDocument2 pagesPeta CalculusAbby NavarroNo ratings yet

- SM 25Document144 pagesSM 25Jan Svein HammerNo ratings yet

- MS 1050 - Physics of Solids: - Ranjith RamaduraiDocument25 pagesMS 1050 - Physics of Solids: - Ranjith RamaduraiproNo ratings yet

- Factors Affecting ProductivityDocument16 pagesFactors Affecting ProductivityArslan MunawarNo ratings yet

- Business English ModuleDocument70 pagesBusiness English ModuleSatria Candra CandraNo ratings yet

- Deborah Ohiani - MKT 2100 (Milestone 2)Document27 pagesDeborah Ohiani - MKT 2100 (Milestone 2)d2ohianiNo ratings yet

- Phytosome: Presented byDocument14 pagesPhytosome: Presented bySari RamadhaniNo ratings yet

- Methane MSDSDocument2 pagesMethane MSDSa0% (1)

- Indusrial Ethernet: Powerlink Ou EtherCAT?Document36 pagesIndusrial Ethernet: Powerlink Ou EtherCAT?Marco Antonio100% (1)

- AHU Datasheet Sample Detailed Page 1 of 6 1635440149Document1 pageAHU Datasheet Sample Detailed Page 1 of 6 1635440149alim khanNo ratings yet

- CB Unit 2Document67 pagesCB Unit 2Hardik KhandharNo ratings yet

- 07.R03Final MS For Erection of Diaphragm Wall PDFDocument52 pages07.R03Final MS For Erection of Diaphragm Wall PDFDEBASIS BARMAN100% (1)

- Project 0TH Review Batch 1 Ece CDocument10 pagesProject 0TH Review Batch 1 Ece CTeju TejaswiniNo ratings yet

- Lista de Medicamentos Esenciales para Emergencias Radiológicas y NuclearesDocument66 pagesLista de Medicamentos Esenciales para Emergencias Radiológicas y NuclearesMartin GonzalezNo ratings yet

- Lab 1a - ME3000 Practical Op-Amp Circuits - v1.32Document7 pagesLab 1a - ME3000 Practical Op-Amp Circuits - v1.32MrmouzinhoNo ratings yet

- DBMS Unit VDocument60 pagesDBMS Unit VYuvaraj V, Assistant Professor, BCANo ratings yet

- PR 6423/.. Series: Eddy Current Displacement SensorDocument4 pagesPR 6423/.. Series: Eddy Current Displacement SensorMohamad YusufNo ratings yet

- Full Download Test Bank For Management 14th Edition John R Schermerhorn JR Daniel G Bachrach PDF Full ChapterDocument36 pagesFull Download Test Bank For Management 14th Edition John R Schermerhorn JR Daniel G Bachrach PDF Full Chaptercrincumose.at2d100% (26)

- Issues in Urban Planning in India Explained PointwiseDocument6 pagesIssues in Urban Planning in India Explained PointwiseAnchal kumariNo ratings yet

Rapid Fit

Rapid Fit

Uploaded by

Doanh NguyenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid Fit

Rapid Fit

Uploaded by

Doanh NguyenCopyright:

Available Formats

CASE STUDY

LK horizontal-arm CMM

inspects next-generation

automotive fixtures

RapidFit modular gauging and holding fixtures with 3D printed

locators provide major benefits in vehicle manufacture

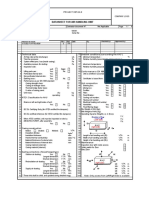

Quality control of the fixtures is crucial. There was a need at the Leuven facility for higher accuracy

when checking fixture calibration and to achieve this, an LK HC90 40.16.16 premium performance,

horizontal arm CMM was purchased, together with the manufacturer’s CAMIO 8 multi-sensor

programming and analysis software.

RapidFit • LK HC90 40.16.16 CMM • CAMIO 8 software

The accuracy and repeatability of the LK

CMM is very high for its large size. It can measure

two of our fixtures at a time, resulting in high

productivity in the inspection department.

Stefan Roeding, Marketing Manager, RapidFit

Materialise Group spin-off RapidFit has deployed to standard fixture components. The technology

a horizontal-arm co-ordinate measuring machine enables vehicle production to be streamlined,

(CMM) manufactured by LK Metrology in as innovative fixtures can be constructed with

Derbyshire, UK to check the accuracy of bespoke enhanced functionality and better repeatability.

gauging and holding fixtures produced for the

automotive industry. Often, this is achieved by incorporating complex

clamping elements with freeform contours

Based in Leuven, Belgium, RapidFit has reduced that are traditionally produced by conventional

costs and lead-times by making use of additive machining, which is expensive, time consuming

manufacturing (AM), also known as 3D printing, and creates a lot of waste material. Integration of

to produce workpiece locators that are added intelligent, quick-release mechanisms that do not

damage the component being retained is another

possibility. Even moving elements like hinges can

be printed, as well as features such as clips, pins

and holes.

High-wear plastics are used to manufacture the

components, sometimes with steel inserts or

bushings. Alternatively, parts can be produced

from aluminium-filled nylon powder, allowing

robust elements to be printed that may be

subsequently milled and drilled to an accuracy of

± 0.05 mm.

Users of the fixtures are mainly manufacturers

of plastic and composite components for

vehicles, from relatively simple, lightweight

housings or small sheet metal parts to full body

panels, dashboards and bumpers for sports cars.

Customers include automotive OEMs such as

Audi, Bentley, Lamborghini and Volvo as well as

A fixture with additively manufactured locators

leading players in their supply chains, for example

being inspected on the LK HC90 40.16.16 CMM

Mecaplast and Valeo.

2 RapidFit • LK HC90 40.16.16 CMM • CAMIO 8 software

Users are given more time and flexibility to

fine-tune their product designs and still meet

deadlines. An added advantage is that the

locators and contours are typically half the weight

of their conventionally machined equivalents and

therefore the fixture is lighter and less tiring for

operators to use.

A high degree of modularity is provided using

standard holding elements, such as the Aluquick

range from German firm, Horst Witte, to support

the bespoke 3D printed locators. The system

Inspection programs are generated offline using LK’s

allows easy modification by simply replacing them,

CAMIO 8 software to maximise the use of the CMM

so fixtures can be reconfigured inexpensively to

accommodate design changes.

Shorter lead-time from receipt of order to

delivery of the fixture, especially when complex The patented, customised products supplied

geometries are involved, is a result of not having by RapidFit are of two types. Gauge fixtures are

to program a milling machine to remove typically for inspecting automotive components after

90 per cent of material from an aluminium billet, manufacture to verify their accuracy, while

or expending time and expense having a casting holding fixtures support components as they are

made and then machining it. built into a vehicle and measured using CMMs or

Close-up of modular fixture inspection in progress on the LK CMM

RapidFit • LK HC90 40.16.16 CMM • CAMIO 8 software 3

other metrology equipment. Both types provide A Renishaw PH10-MQ motorised indexing head

comprehensive management of dimensional with in-quill head mount and autojoint probe

accuracy, which is vital to the overall quality of mount together with a TP200 touch trigger

the final vehicle. probe and various extension bars formed part

of the package. The HC90 is housed in a climate

Accuracy is critical for RapidFit controlled metrology room and is currently

operated over a single shift.

customers

Stefan Roeding, Marketing Manager at RapidFit,

This in turn means that quality control of

commented, “Customers will only accept

the fixtures is crucial. There was a need at

measurement results if they trust the equipment

the Leuven facility for higher accuracy when

that generates them.

checking fixture calibration and to achieve this,

an LK HC90 40.16.16 premium performance,

horizontal arm CMM was purchased, together “The accuracy and repeatability of the LK CMM is

with the manufacturer’s CAMIO 8 multi-sensor very high for its large size. It can measure two of

programming and analysis software. The machine our fixtures at a time, resulting in high productivity

provides almost unrestricted access to its 4m x in the inspection department.

1.6 m x 1.6 m measuring envelope and features

ceramic guideways and air bearings for stability at “Installation of the machine has been a big step

high velocity and acceleration. forward in assuring the quality of our products

A RapidFit fixture secures a bumper as it is being assembled onto a car, providing major benefits for the vehicle manufacturer

4 RapidFit • LK HC90 40.16.16 CMM • CAMIO 8 software

before delivery and avoiding costly reworking. It

is fulfilling all of our customers’ requirements.”

Filip Dehing, RapidFit’s CEO, added “With a

worldwide sales and support network, our

company is in an ideal position to grow by

becoming a preferred partner for large automotive

companies on a global scale and by fully exploiting

new opportunities.

“Underpinning all of this is our commitment to

high quality. Our inspection department with the

LK Metrology CMM breathes accuracy, making it

A Nikon Metrology laser scanning head deployed

an important marketing tool when customers and on the LK HC90 40.16.16 CMM at RapidFit

prospects visit us.”

Offline programming fixture can take up to six weeks. The customer

is invited to the RapidFit measurement room for

maximises use of the CMM acceptance and sign-off.

A typical project at RapidFit starts with the More recently, for checking contours faster, the

customer sending a CAD drawing of the manufacturer has added laser scanning capability

component to be fixtured and instructions on how to the CMM by purchasing an LC15Dx from Nikon

it should be clamped for the required application. Metrology. It is interchangeable with the touch

The fixture is virtually constructed in CATIA by probes and both are supported by LK’s CAMIO 8

one of RapidFit’s nine design engineers and the software.

3D locator elements are output as STL files so that

they can be produced in one of the company’s The technology offers twice the resolution of

powder laser-sintering AM machines. camera-based optical systems, so is suitable for

quality control of RapidFit’s automotive fixtures.

After 3D printing, the locators are assembled It is therefore replacing relatively slow touch

with standard holding elements and a measuring probing routines in parts of the cycle that involve

program is created in CAMIO 8, in this case collection of freeform data.

offline in RapidFit’s Kiev subsidiary, which allows

maximum use to be made of the CMM for

inspection. As each fixture is different, ease of

programming based on the original CAD file is a

critical advantage.

The program is transferred to the LK HC90

and the inspection cycle is run to verify that all

fixture dimensions are in tolerance. If changes are

needed, engineers modify the fixture and run the

cycle again. Measuring program changes can be

made quickly in teach mode if necessary.

Turn-around for a fixture of average complexity

is three to four weeks, although a very complex

RapidFit • LK HC90 40.16.16 CMM • CAMIO 8 software 5

About LK Metrology

LK Metrology is renowned for innovative CMM hardware and software solutions. The company’s metrology

products are used worldwide to control and improve the quality of manufactured components. Its precision

technology underpins the process chain from design, development, production and assembly through to

quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical

and contract inspection.

Established in England in 1963, LK Metrology has an impressive heritage in metrology dating back to the birth

of CMM technology. Founded by CMM pioneer Norman Key and his father-in-law Jim Lowther, LK Metrology

is credited with many of the CMM industry’s firsts including the first bridge-type design, first OEM to integrate

computers, first to use a touch trigger probe, first to develop inspection software, first to use all air bearings

and granite guideways, first to use carbon fibre composite spindles, first to use microprocessor-controlled

drive systems, first to produce a truly thermally stable CMM and first to produce a high-accuracy horizontal-

spindle CMM.

In 2018, LK Metrology was relaunched as an independent CMM manufacturer after several years as a division

of Nikon Metrology. Headquartered in the UK, LK’s CMM development and production are at the company’s

facility in Castle Donington. Sales and support offices are located in the UK, North America, Belgium, France,

Germany, Italy and China, supplemented by a worldwide distributor network.

Copyright © 2019. LK Metrology. All right reserved.

www.LKmetrology.com 6

You might also like

- Met Accounting and ReconciliationDocument14 pagesMet Accounting and ReconciliationHelbert Lino100% (1)

- CATIA - Composites Design For Manufacturing (CPM)Document4 pagesCATIA - Composites Design For Manufacturing (CPM)rakeshpa_2078662100% (2)

- Specification PedestalsDocument19 pagesSpecification PedestalsmikecomninosNo ratings yet

- Optimizing Innovation in Machine Design White Paper WP VH 00110Document4 pagesOptimizing Innovation in Machine Design White Paper WP VH 00110Jorge Raul AcostaNo ratings yet

- UAV & Other RTM Applications: Design Through Production - We're The RTM Experts!Document2 pagesUAV & Other RTM Applications: Design Through Production - We're The RTM Experts!Angel LagrañaNo ratings yet

- 0 PRO Gamma 450 ENDocument12 pages0 PRO Gamma 450 ENjuan lopezNo ratings yet

- MF White Paper CFR ApplicationsDocument11 pagesMF White Paper CFR ApplicationsrawsteelNo ratings yet

- Automatica NouDocument12 pagesAutomatica NouMadalin SerbanNo ratings yet

- Bearings For Steel IndustryDocument18 pagesBearings For Steel IndustryCarlos BarriosNo ratings yet

- Mate410 First Report Berk Cansel Seli̇n Group2Document10 pagesMate410 First Report Berk Cansel Seli̇n Group2temir.berkNo ratings yet

- MetalForming-Magazine 2021 06Document1 pageMetalForming-Magazine 2021 06waqar mansoorNo ratings yet

- Spectrumprinting16 e Kolbus GMBHDocument2 pagesSpectrumprinting16 e Kolbus GMBHвикторNo ratings yet

- Bosch - Lean Cell Layout, Modular WorkcellDocument6 pagesBosch - Lean Cell Layout, Modular Workcellmạnh nguyễnNo ratings yet

- Jose Antonio Moreno - Danobat ScoopDocument6 pagesJose Antonio Moreno - Danobat ScoopÂrbaoui MedNo ratings yet

- CATIA - Composite Engineering (CPE)Document4 pagesCATIA - Composite Engineering (CPE)saqibcatiaNo ratings yet

- Simufact Sheet Metal Forming 2015Document8 pagesSimufact Sheet Metal Forming 2015MrLanternNo ratings yet

- WhatsNew CimatronE 9.0 Version HighlightsDocument3 pagesWhatsNew CimatronE 9.0 Version HighlightsfaizNo ratings yet

- Ecotrim: Sustainable Robotic Cutting SolutionsDocument4 pagesEcotrim: Sustainable Robotic Cutting SolutionsAquilesNo ratings yet

- Arkitech Catalogue EnglishDocument16 pagesArkitech Catalogue Englishangel_deeaNo ratings yet

- Simufact - Forming The Simulation Solution For Bulk Sheet Metal FormingDocument15 pagesSimufact - Forming The Simulation Solution For Bulk Sheet Metal FormingShashin VyasNo ratings yet

- Die Casting AutomationDocument7 pagesDie Casting AutomationAditya samalNo ratings yet

- Visit Indo SchottleDocument18 pagesVisit Indo Schottleshubham bandalNo ratings yet

- Abb - Catalogo ACS355 PDFDocument56 pagesAbb - Catalogo ACS355 PDFRodrigo Jacy Monteiro MartinsNo ratings yet

- ACS850 Drive Modules Technical CatalogueDocument20 pagesACS850 Drive Modules Technical CatalogueANOOP KRISHNANNo ratings yet

- ToolingU Additive ManufacturingDocument18 pagesToolingU Additive Manufacturingblake basanskyNo ratings yet

- Oem Ap149 - en PDocument4 pagesOem Ap149 - en PdangkhuyenmaiNo ratings yet

- Design World Robotics Handbook 11 2023Document60 pagesDesign World Robotics Handbook 11 2023ql yuanNo ratings yet

- ACS350 Technical CatalogueDocument20 pagesACS350 Technical CatalogueJNo ratings yet

- KUKADocument4 pagesKUKAUmesh SNo ratings yet

- Additive Fact SheetDocument2 pagesAdditive Fact SheetMustafaNo ratings yet

- 5 - PowerMill 2019 BrochureDocument4 pages5 - PowerMill 2019 BrochureAhmedBrahamNo ratings yet

- Hemming 2Document6 pagesHemming 2erbilodevNo ratings yet

- Nouveau Document Microsoft WordDocument11 pagesNouveau Document Microsoft Wordsoukehal wail mohamed redhaNo ratings yet

- Coinco Savings DesignfaxDocument2 pagesCoinco Savings Designfaxmax molenaar100% (2)

- Pipe Cutting Machine 1-4Document16 pagesPipe Cutting Machine 1-4Jackson MtongaNo ratings yet

- Reconfigurable Tooling For Airframe AssemblyDocument21 pagesReconfigurable Tooling For Airframe AssemblyDennis Padec BwochengoNo ratings yet

- 1 s2.0 S2212827119303142 MainDocument6 pages1 s2.0 S2212827119303142 Maindigvijaybhingare1243No ratings yet

- Unit 2Document51 pagesUnit 2Avanish BajpaiNo ratings yet

- Robotic Systems: Flexible Parts Management - Fully IntegratedDocument20 pagesRobotic Systems: Flexible Parts Management - Fully IntegratedEduardo SilvaNo ratings yet

- Hexagon MI Romax Flyer EnduroDocument2 pagesHexagon MI Romax Flyer EnduroSanjay ShelarNo ratings yet

- CATIA V5R20 FactsheetDocument11 pagesCATIA V5R20 FactsheetlijinnuaaNo ratings yet

- Chapter 01 Vacuum Chambers Special Components PDFDocument14 pagesChapter 01 Vacuum Chambers Special Components PDFmindrumihaiNo ratings yet

- 3rd party LCI DRIVE with SINAMICS CU320-2_flyerDocument2 pages3rd party LCI DRIVE with SINAMICS CU320-2_flyereltripperNo ratings yet

- Computer On Module (COM) For Military Applications: Author: Advantech E-MailDocument7 pagesComputer On Module (COM) For Military Applications: Author: Advantech E-MailThongLeNo ratings yet

- Beckwood Guide To Press AutomationDocument16 pagesBeckwood Guide To Press AutomationOARIASCONo ratings yet

- Desain Otomatis KonveyorDocument8 pagesDesain Otomatis KonveyoragungNo ratings yet

- 3 DPDocument44 pages3 DPPooja AngolkarNo ratings yet

- ABB ACS850 Latest CatalogueDocument24 pagesABB ACS850 Latest CatalogueRajeev M PuthiyedathNo ratings yet

- Modulo SDocument164 pagesModulo SItzel AparicioNo ratings yet

- Abb Machinery Drives Catalog Acs850Document24 pagesAbb Machinery Drives Catalog Acs850Neeraj RaushanNo ratings yet

- Aberlink Zenith TooDocument8 pagesAberlink Zenith Toodanielbo2220No ratings yet

- Lexium 32i: Integrated Servo DriveDocument21 pagesLexium 32i: Integrated Servo DrivejesusortegavNo ratings yet

- Automation Doc 1Document13 pagesAutomation Doc 1Shah Sajjan KumarNo ratings yet

- SAS Catalog 2013 PartsDocument136 pagesSAS Catalog 2013 PartsAri Ercilio Farias FereirraNo ratings yet

- Guide To 3D PrintingDocument6 pagesGuide To 3D PrintingKomsa Csongor És AndreaNo ratings yet

- Accuracy Enhancement of Industrial Robots by On-Line Pose CorrectionDocument7 pagesAccuracy Enhancement of Industrial Robots by On-Line Pose CorrectionDavid Rogelio Alvarez ReyesNo ratings yet

- STAR-CCM+ v11 Brochure 2016Document12 pagesSTAR-CCM+ v11 Brochure 2016Anonymous scnl9rHNo ratings yet

- Case Study Raising The Bar On Rotary Table AccuracyDocument3 pagesCase Study Raising The Bar On Rotary Table AccuracynidhinNo ratings yet

- Sae Technical Paper Series: Khawar M. Zuberi, Padmanabhan Pillai and Kang G. ShinDocument9 pagesSae Technical Paper Series: Khawar M. Zuberi, Padmanabhan Pillai and Kang G. ShinmuradbashirNo ratings yet

- Mastering Siemens S7: A Comprehensive Guide to PLC ProgrammingFrom EverandMastering Siemens S7: A Comprehensive Guide to PLC ProgrammingNo ratings yet

- Xslicer-SMX 160 KVDocument16 pagesXslicer-SMX 160 KVDoanh NguyenNo ratings yet

- Brochuresmx 1000 SMX 1000 LC 251 e 023 ADocument18 pagesBrochuresmx 1000 SMX 1000 LC 251 e 023 ADoanh NguyenNo ratings yet

- Powertrain REVO RetrofitDocument4 pagesPowertrain REVO RetrofitDoanh NguyenNo ratings yet

- PSS-40 Solution Rev 2Document20 pagesPSS-40 Solution Rev 2Doanh NguyenNo ratings yet

- 2ce Iwhh 10Document7 pages2ce Iwhh 10Doanh NguyenNo ratings yet

- CMM Coordinate Measuring MachinesDocument16 pagesCMM Coordinate Measuring MachinesDoanh NguyenNo ratings yet

- Industrial X-Ray and CTDocument7 pagesIndustrial X-Ray and CTDoanh NguyenNo ratings yet

- TA7000series ProductGuide Eng Mar2016 SDocument44 pagesTA7000series ProductGuide Eng Mar2016 SDoanh NguyenNo ratings yet

- Nexiv VMZ H en - NewDocument3 pagesNexiv VMZ H en - NewDoanh NguyenNo ratings yet

- Nikon Solutions enDocument21 pagesNikon Solutions enDoanh NguyenNo ratings yet

- Altera - ENDocument8 pagesAltera - ENDoanh NguyenNo ratings yet

- L300L200 FinalDocument5 pagesL300L200 FinalDoanh NguyenNo ratings yet

- ByprovinceDocument128 pagesByprovinceLun Do100% (1)

- General Description: Plug Fan ER..C With Standard MotorDocument7 pagesGeneral Description: Plug Fan ER..C With Standard MotorwildanNo ratings yet

- wph16 01 Pef 20230302Document17 pageswph16 01 Pef 20230302the dsNo ratings yet

- Introduction To Work HoldingDocument29 pagesIntroduction To Work HoldingAndres Fitria FarrelNo ratings yet

- Mintmade FashionDocument15 pagesMintmade FashionJack ZNo ratings yet

- Hse PlanDocument44 pagesHse PlanSheldon Van RooyenNo ratings yet

- Anterior and Lateral Views of The SkullDocument18 pagesAnterior and Lateral Views of The SkullArshad hussainNo ratings yet

- Class 6 NSTSE PQP 10-Papers 2019-20 2-In-A4 PDFDocument85 pagesClass 6 NSTSE PQP 10-Papers 2019-20 2-In-A4 PDFSanjib Mandal100% (3)

- Sacred Places of The World A Religious Journey Across The GlobeDocument209 pagesSacred Places of The World A Religious Journey Across The GlobeDenis-Elena Cotea100% (1)

- BDSsteelhandbookDocument80 pagesBDSsteelhandbookVeeraiah AnbuNo ratings yet

- Anatomy of An EMC VNXDocument3 pagesAnatomy of An EMC VNXRajNo ratings yet

- Peta CalculusDocument2 pagesPeta CalculusAbby NavarroNo ratings yet

- SM 25Document144 pagesSM 25Jan Svein HammerNo ratings yet

- MS 1050 - Physics of Solids: - Ranjith RamaduraiDocument25 pagesMS 1050 - Physics of Solids: - Ranjith RamaduraiproNo ratings yet

- Factors Affecting ProductivityDocument16 pagesFactors Affecting ProductivityArslan MunawarNo ratings yet

- Business English ModuleDocument70 pagesBusiness English ModuleSatria Candra CandraNo ratings yet

- Deborah Ohiani - MKT 2100 (Milestone 2)Document27 pagesDeborah Ohiani - MKT 2100 (Milestone 2)d2ohianiNo ratings yet

- Phytosome: Presented byDocument14 pagesPhytosome: Presented bySari RamadhaniNo ratings yet

- Methane MSDSDocument2 pagesMethane MSDSa0% (1)

- Indusrial Ethernet: Powerlink Ou EtherCAT?Document36 pagesIndusrial Ethernet: Powerlink Ou EtherCAT?Marco Antonio100% (1)

- AHU Datasheet Sample Detailed Page 1 of 6 1635440149Document1 pageAHU Datasheet Sample Detailed Page 1 of 6 1635440149alim khanNo ratings yet

- CB Unit 2Document67 pagesCB Unit 2Hardik KhandharNo ratings yet

- 07.R03Final MS For Erection of Diaphragm Wall PDFDocument52 pages07.R03Final MS For Erection of Diaphragm Wall PDFDEBASIS BARMAN100% (1)

- Project 0TH Review Batch 1 Ece CDocument10 pagesProject 0TH Review Batch 1 Ece CTeju TejaswiniNo ratings yet

- Lista de Medicamentos Esenciales para Emergencias Radiológicas y NuclearesDocument66 pagesLista de Medicamentos Esenciales para Emergencias Radiológicas y NuclearesMartin GonzalezNo ratings yet

- Lab 1a - ME3000 Practical Op-Amp Circuits - v1.32Document7 pagesLab 1a - ME3000 Practical Op-Amp Circuits - v1.32MrmouzinhoNo ratings yet

- DBMS Unit VDocument60 pagesDBMS Unit VYuvaraj V, Assistant Professor, BCANo ratings yet

- PR 6423/.. Series: Eddy Current Displacement SensorDocument4 pagesPR 6423/.. Series: Eddy Current Displacement SensorMohamad YusufNo ratings yet

- Full Download Test Bank For Management 14th Edition John R Schermerhorn JR Daniel G Bachrach PDF Full ChapterDocument36 pagesFull Download Test Bank For Management 14th Edition John R Schermerhorn JR Daniel G Bachrach PDF Full Chaptercrincumose.at2d100% (26)

- Issues in Urban Planning in India Explained PointwiseDocument6 pagesIssues in Urban Planning in India Explained PointwiseAnchal kumariNo ratings yet