Professional Documents

Culture Documents

PRDBOEN Full en Us Letter

PRDBOEN Full en Us Letter

Uploaded by

Partagon PowOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRDBOEN Full en Us Letter

PRDBOEN Full en Us Letter

Uploaded by

Partagon PowCopyright:

Available Formats

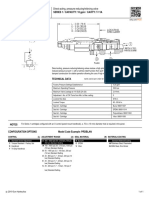

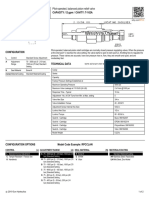

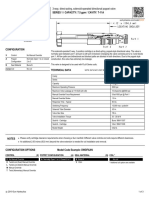

MODEL Direct-acting, pressure reducing/relieving valve

PRDB SERIES 1 / CAPACITY: 10 gpm / CAVITY: T-11A

sunhydraulics.com/model/PRDB

Direct-acting, pressure reducing/relieving valves reduce a high primary pressure at the inlet (port 2) to a constant

reduced pressure at port 1, with a full-flow relief function from port 1 to tank (port 3). These valves incorporate a

CONFIGURATION damped construction for stable operation allowing the use of high reduced pressure.

O Control Handknob with Panel Mount

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

E Adjustment 25 - 400 psi (1,7 - 28 bar), 200

Range psi (14 bar) Standard Setting Cavity T-11A

N Seal Material Buna-N Series 1

(none) Material/Coating Standard Material/Coating Capacity 10 gpm

Factory Pressure Settings Established at 0.25 gpm

Maximum Operating Pressure 5000 psi

Maximum Valve Leakage at 110 SUS (24 cSt) 2 in³/min.

Adjustment - No. of CW Turns from Min. to Max. setting 5

Valve Hex Size 7/8 in.

Valve Installation Torque 30 - 35 lbf ft

Adjustment Screw Internal Hex Size 5/32 in.

Locknut Hex Size 9/16 in.

Locknut Torque 80 - 90 lbf in.

Seal kit - Cartridge Buna: 990011007

Seal kit - Cartridge EPDM: 990011014

Seal kit - Cartridge Polyurethane: 990011002

Seal kit - Cartridge Viton: 990011006

Model Weight 0.51 lb.

NOTES For Series 1 cartridges configured with an O control (panel mount handknob), a .75 in. (19 mm) diameter hole is required in the panel.

CONFIGURATION OPTIONS Model Code Example: PRDBOEN

CONTROL (O) ADJUSTMENT RANGE (E) SEAL MATERIAL (N) MATERIAL/COATING

O Handknob with Panel Mount E 25 - 400 psi (1,7 - 28 bar), 200 psi (14 N Buna-N Standard Material/Coating

L Standard Screw Adjustment bar) Standard Setting E EPDM /AP Stainless Steel, Passivated

C Tamper Resistant - Factory Set A 500 - 3000 psi (35 - 210 bar), 700 psi V Viton /LH Mild Steel, Zinc-Nickel

K Handknob (50 bar) Standard Setting

Y Tri-Grip Handknob W 750 - 4500 psi (50 - 315 bar), 1000 psi

(70 bar) Standard Setting

B 50 - 1500 psi (3,5 - 105 bar), 200 psi

(14 bar) Standard Setting

D 25 - 800 psi (1,7 - 55 bar), 200 psi (14

bar) Standard Setting

S 25 - 200 psi (1,7 - 14 bar), 100 psi (7

bar) Standard Setting

c 2019 Sun Hydraulics

1 of 3

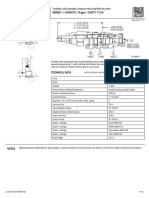

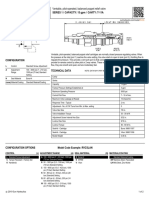

TECHNICAL FEATURES

All three-port pressure reducing and reducing/relieving cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size). When

considering mounting configurations, it is sometimes recommended that a full capacity return line (port 3) be used with reducing/relieving cartridges.

Full reverse flow from reduced pressure (port 1) to inlet (port 2) may cause the main spool to close. If reverse free flow is required in the circuit, consider adding a

separate check valve to the circuit.

All spring ranges are tested for correct operation with 5000 psi (350 bar) inlet pressure.

Suitable for accumulator circuits since the absence of pilot control flow results in reduced secondary circuit leakage.

Direct acting concept provides highly reliable operation in contaminated systems, especially at dead headed conditions.

Unlike pilot operated versions, direct acting valves exhibit a transitional step between reducing and relieving modes. This step equals 5% of the high end of the

adjustment range, independent of the valve setting. Therefore, these valves may not be suitable for counterbalancing applications.

Direct operated version offers superior dynamic response compared to equivalent pilot operated models.

Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 5000 psi (350 bar).

Leakage specified in Technical Data is out of port 3 with a supply pressure of 2000 psi (140 bar) and the valve set at mid range. This leakage is directly proportional

to pressure differential and inversely proportional to viscosity expressed in centistokes.

W and Y controls (where applicable) can be specified with or without a special setting. When no special setting is specified, the valve is adjustable throughout its full

range using the W or Y control. When a special setting is specified, this setting represents the maximum setting of the valve.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

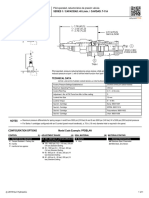

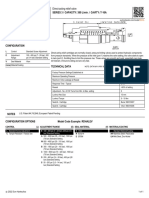

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 3

c 2019 Sun Hydraulics

3 of 3

You might also like

- Canopy CostingDocument1 pageCanopy Costingtyn de guzmanNo ratings yet

- Unit-12 Wall Frame TestDocument3 pagesUnit-12 Wall Frame TestYeng LugtuNo ratings yet

- Macalloy Bars For Use in Post Tensioning ApplicationDocument21 pagesMacalloy Bars For Use in Post Tensioning Applicationsanusi69No ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- PPDB en Us A4Document1 pagePPDB en Us A4Felipe DiazNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4Document1 pageModel Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4mhasansharifiNo ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- Relife Valve Rpeclnn - Pilot OperatedDocument2 pagesRelife Valve Rpeclnn - Pilot OperatedHassan KhattabNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument1 pageModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoNo ratings yet

- PPDBLAN Es Metric LetterDocument1 pagePPDBLAN Es Metric Lettersebastian.vegaNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- Valvula Reguladora Continental PBFB-LAVDocument1 pageValvula Reguladora Continental PBFB-LAVsalesparts.norvateNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- Modelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Document1 pageModelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Erasmo LimaNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- Modelo Acción-Directa Alivio Válvula: Series 1 / Capacidad: 25 GPM / Cavidad: T-10ADocument1 pageModelo Acción-Directa Alivio Válvula: Series 1 / Capacidad: 25 GPM / Cavidad: T-10AErasmo LimaNo ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- Model Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162ADocument1 pageModel Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162AmhasansharifiNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNo ratings yet

- RPECOAN Full Es Metric LetterDocument2 pagesRPECOAN Full Es Metric Letteralfredo lopez regaladoNo ratings yet

- RDDALAN Es Metric LetterDocument1 pageRDDALAN Es Metric Lettersebastian.vegaNo ratings yet

- RDBALAN Full en Metric A4Document2 pagesRDBALAN Full en Metric A4David AltarribaNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- RPEI en Us A4Document1 pageRPEI en Us A4Rafael GoulartNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- RSBC Full en Us A4Document2 pagesRSBC Full en Us A4Mykola TitovNo ratings yet

- CODA Full en Us LetterDocument2 pagesCODA Full en Us Lettercesar5984No ratings yet

- RDBALAN Full Es Metric A4Document2 pagesRDBALAN Full Es Metric A4Willam Hugo Luna PonteNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Sun Hydraulics FDBA-LANDocument2 pagesSun Hydraulics FDBA-LANJustinNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Model Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3ADocument2 pagesModel Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3AJustinNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveRobertoNo ratings yet

- CBGGLJN Es Metric LetterDocument1 pageCBGGLJN Es Metric LetterjesusNo ratings yet

- RDDA Es Metric A4Document1 pageRDDA Es Metric A4Daniel GómezNo ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- 004 Steel Tube PipeDocument48 pages004 Steel Tube PipePartagon PowNo ratings yet

- 007 Red MetalsDocument32 pages007 Red MetalsPartagon PowNo ratings yet

- 012 Additional AlroDocument18 pages012 Additional AlroPartagon PowNo ratings yet

- 006 AluminumDocument102 pages006 AluminumPartagon PowNo ratings yet

- Nutrition Facts Label Download Label1Document1 pageNutrition Facts Label Download Label1Partagon PowNo ratings yet

- 009 Other ProductsDocument58 pages009 Other ProductsPartagon PowNo ratings yet

- Stainless Steel Shapes Stainless Steel Shapes: Tel: +81-3-6867-4111 Tel: +81-3-6867-4111Document6 pagesStainless Steel Shapes Stainless Steel Shapes: Tel: +81-3-6867-4111 Tel: +81-3-6867-4111Partagon PowNo ratings yet

- 011 ReferenceDocument34 pages011 ReferencePartagon PowNo ratings yet

- Nutrition Facts Label Download Label4Document1 pageNutrition Facts Label Download Label4Partagon PowNo ratings yet

- 005 Stainless SteelDocument32 pages005 Stainless SteelPartagon PowNo ratings yet

- DWDFXAN Full en Us LetterDocument3 pagesDWDFXAN Full en Us LetterPartagon PowNo ratings yet

- 010 Met ProcessingDocument8 pages010 Met ProcessingPartagon PowNo ratings yet

- D03 Valves Eng Data WFDG4V3SDocument11 pagesD03 Valves Eng Data WFDG4V3SPartagon PowNo ratings yet

- Hydrostatic Motor (S - N 512716001 & Above, 508630001 & Above, 513911001 & Above, 511476001 & Above) - 753Document3 pagesHydrostatic Motor (S - N 512716001 & Above, 508630001 & Above, 513911001 & Above, 511476001 & Above) - 753Partagon PowNo ratings yet

- Eaton Hydrokraft Transmission Closed Loop TVW Series Piston Pump Technical Catalog V Pupi tm002 e en UsDocument56 pagesEaton Hydrokraft Transmission Closed Loop TVW Series Piston Pump Technical Catalog V Pupi tm002 e en UsPartagon PowNo ratings yet

- TCT - Owners - Operators - Manual1.pdf WINCHDocument29 pagesTCT - Owners - Operators - Manual1.pdf WINCHPartagon PowNo ratings yet

- Product ComparisonDocument1 pageProduct ComparisonPartagon PowNo ratings yet

- Tompkins Catalog UsaDocument332 pagesTompkins Catalog UsaPartagon PowNo ratings yet

- Series 18 Axial Piston Pumps and Motors Parts ManualDocument1 pageSeries 18 Axial Piston Pumps and Motors Parts ManualPartagon PowNo ratings yet

- Denison HydraulicsDocument48 pagesDenison HydraulicsPartagon Pow100% (1)

- Icc Control: Finn-PowerDocument36 pagesIcc Control: Finn-PowerPartagon PowNo ratings yet

- BICS Control Valve (S - N 514450007, 514541083, 514641203 & Above) - 863Document2 pagesBICS Control Valve (S - N 514450007, 514541083, 514641203 & Above) - 863Partagon PowNo ratings yet

- Gear Pump (Aluminum) - (S - N 514449259, 514541068 & Below) - 863Document2 pagesGear Pump (Aluminum) - (S - N 514449259, 514541068 & Below) - 863Partagon PowNo ratings yet

- Serial Production and Cutting MachinesDocument12 pagesSerial Production and Cutting MachinesPartagon PowNo ratings yet

- 0491 AbDocument8 pages0491 AbPartagon PowNo ratings yet

- Planer (Motor) (R921805375) (18 - ) (24 - ) - (S - N 341000655 & Above, 231611101 & Above, 721700342 & Above, 231711101 & Above) - PlanerDocument3 pagesPlaner (Motor) (R921805375) (18 - ) (24 - ) - (S - N 341000655 & Above, 231611101 & Above, 721700342 & Above, 231711101 & Above) - PlanerPartagon PowNo ratings yet

- Heavy-Duty ProductionDocument12 pagesHeavy-Duty ProductionPartagon PowNo ratings yet

- Planer (Motor) (18 - ) (24 - ) - (S - N 341000329 - 341000654, 721700161 - 721700341) - PlanerDocument3 pagesPlaner (Motor) (18 - ) (24 - ) - (S - N 341000329 - 341000654, 721700161 - 721700341) - PlanerPartagon PowNo ratings yet

- Side Feed, Nut & Cable MachinesDocument16 pagesSide Feed, Nut & Cable MachinesPartagon PowNo ratings yet

- Options: Numerous Ways To Make Your Production MoreDocument4 pagesOptions: Numerous Ways To Make Your Production MorePartagon PowNo ratings yet

- CHPT 5 ST Excel Heat Exch - Edit - 2Document5 pagesCHPT 5 ST Excel Heat Exch - Edit - 2Claimir GuinzelliNo ratings yet

- ASTM C1609 - Standard Test Method For Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)Document9 pagesASTM C1609 - Standard Test Method For Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)carlos salinasNo ratings yet

- BS 1881-Part 207-92Document17 pagesBS 1881-Part 207-92Hussein El BeqaiNo ratings yet

- 1 Draft Revision IRC 37 Guidelines For The Design of Flexible Pavements (H-2) PDFDocument104 pages1 Draft Revision IRC 37 Guidelines For The Design of Flexible Pavements (H-2) PDFaejazNo ratings yet

- New 10 Fluid MechanicsDocument22 pagesNew 10 Fluid Mechanicsyusuf efendiNo ratings yet

- Calculating Drainage Works ProductivityDocument2 pagesCalculating Drainage Works ProductivityMukhlish AkhatarNo ratings yet

- Adidas Case StudyDocument6 pagesAdidas Case StudyAndrea ToscoNo ratings yet

- IJEE Thapa PaperDocument11 pagesIJEE Thapa PaperakanshuNo ratings yet

- Other Pumps Sumps For Solids-Bearing Waters: 12-6. Summary of Trench-Type Wet Well CharacteristicsDocument29 pagesOther Pumps Sumps For Solids-Bearing Waters: 12-6. Summary of Trench-Type Wet Well Characteristicsshady mohamedNo ratings yet

- Rate AnalysisDocument21 pagesRate AnalysisMugahed Abdo Al-gahdari100% (1)

- May2012 - Renovating and Revamping Your Home PDFDocument45 pagesMay2012 - Renovating and Revamping Your Home PDFKapil RampalNo ratings yet

- Data Tanah ToyoningDocument55 pagesData Tanah Toyoningmuhammad faisalNo ratings yet

- JU Floor System...Document34 pagesJU Floor System...kaafiNo ratings yet

- Technische Beschreibung SanitaerDocument39 pagesTechnische Beschreibung SanitaerBegüm ÖzgünNo ratings yet

- MEQ-Truss - Steel Purlins DesignDocument3 pagesMEQ-Truss - Steel Purlins DesignJohn Rom CabadonggaNo ratings yet

- 3.1 Project Description ACSDocument12 pages3.1 Project Description ACSgilang mrNo ratings yet

- Cross-Section Properties: GeometryDocument2 pagesCross-Section Properties: GeometryFilip StojkovskiNo ratings yet

- Procedure Road ConstructionDocument11 pagesProcedure Road Constructioncharlessimo100% (1)

- Water Supply Products: No. Products Standard Number Standard TitleDocument12 pagesWater Supply Products: No. Products Standard Number Standard TitleMohd Naim Bin KaramaNo ratings yet

- Steel Vicwest HB30V-Z275 Steel Deck PDFDocument2 pagesSteel Vicwest HB30V-Z275 Steel Deck PDFMike SmithNo ratings yet

- P3/12 Review of Theoretical Models For Soil NailingDocument11 pagesP3/12 Review of Theoretical Models For Soil NailingLaura SilviNo ratings yet

- Atlanta Pipes and FittingsDocument2 pagesAtlanta Pipes and Fittingsotadoyreychie31No ratings yet

- 1999-Performance Comparison of Bored and Excavated Piles in The Layered Soils of Bangkok PDFDocument10 pages1999-Performance Comparison of Bored and Excavated Piles in The Layered Soils of Bangkok PDFDavid Aponte RojasNo ratings yet

- Richmond-Steveston Dike Master Plan PDFDocument25 pagesRichmond-Steveston Dike Master Plan PDFMartinvdHNo ratings yet

- Daily Concrete LogDocument28 pagesDaily Concrete Logbkrishna.g1896No ratings yet

- 7.rock PropertiesDocument58 pages7.rock PropertiesBoos yousufNo ratings yet

- Design of AbutmentDocument5 pagesDesign of AbutmentPAWANNo ratings yet