Professional Documents

Culture Documents

Lab 2 - Group 1

Lab 2 - Group 1

Uploaded by

Pilar MCopyright:

Available Formats

You might also like

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFLavanyan SatchithananthanNo ratings yet

- Din en Iso 9013Document8 pagesDin en Iso 9013Cemal NergizNo ratings yet

- Tensile TestingDocument12 pagesTensile TestingAhmed ElqazazNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Pipe Extrusion Lines - Defects & Suggested RemediesDocument2 pagesPipe Extrusion Lines - Defects & Suggested Remedieshvadnala100% (5)

- Department of Mechanical EngineeringDocument4 pagesDepartment of Mechanical EngineeringKano MolapisiNo ratings yet

- Experiment: Sheet Resistance and the Calculation of Resistivity () or Thickness (t) and Thermal coefficient of Resistivity (α)Document4 pagesExperiment: Sheet Resistance and the Calculation of Resistivity () or Thickness (t) and Thermal coefficient of Resistivity (α)AdityaNo ratings yet

- Lab 2 W7 Lab ResultsDocument22 pagesLab 2 W7 Lab ResultsmiraclelovesgamesNo ratings yet

- Circular Pitchs For DP DeterminationDocument3 pagesCircular Pitchs For DP DeterminationJaikumar LukeNo ratings yet

- How To Measure The Pressure Angle of A Physical Spur Gear PDFDocument16 pagesHow To Measure The Pressure Angle of A Physical Spur Gear PDFAnil PrajapatiNo ratings yet

- Unconfined Compressive Strength Test: Experiment 1Document5 pagesUnconfined Compressive Strength Test: Experiment 1Refisa JiruNo ratings yet

- AlDocument5 pagesAlshamsi862620No ratings yet

- Creep LabDocument23 pagesCreep LabkeeonNo ratings yet

- Practical # 1 StatementDocument10 pagesPractical # 1 StatementtasleemaeroNo ratings yet

- Tensile TestDocument12 pagesTensile TestDulshan uddeepanaNo ratings yet

- Spec25051 - Teck CableDocument4 pagesSpec25051 - Teck Cablecrfg2003No ratings yet

- ET 310 Lab 4Document19 pagesET 310 Lab 4DylanNo ratings yet

- Bab Iii Perhitungan Dimensi StrukturDocument17 pagesBab Iii Perhitungan Dimensi StrukturBurhan El-SumiratNo ratings yet

- Npat 2Document2 pagesNpat 2aaaNo ratings yet

- BS SRR-3Document20 pagesBS SRR-3anveshvarma365No ratings yet

- Din en Iso 9013Document8 pagesDin en Iso 90137netmaffiaNo ratings yet

- No Ti Si Tixsi TixsiDocument3 pagesNo Ti Si Tixsi TixsiPyoJihoonNo ratings yet

- Summary:: P= ΔL×E×A LDocument8 pagesSummary:: P= ΔL×E×A LMohammad Hasan NassarNo ratings yet

- Wetico Water Tank 70m Shell Ultimate ChecksDocument2 pagesWetico Water Tank 70m Shell Ultimate ChecksChristian Paul SanguyoNo ratings yet

- Instalatii aDIDocument19 pagesInstalatii aDIAndrei Manole PGNo ratings yet

- Pure Bending Exp ReportDocument5 pagesPure Bending Exp Reportabo MakbasNo ratings yet

- Base Slab Bottom Mesh 6.1 Spacing 0.17 Cover 0.035 Thickness 0.35 I Di Hook No Bottom Bar Top BarDocument5 pagesBase Slab Bottom Mesh 6.1 Spacing 0.17 Cover 0.035 Thickness 0.35 I Di Hook No Bottom Bar Top BarARSENo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)rezetane mohamed amineNo ratings yet

- Lab 1 Civl 222Document6 pagesLab 1 Civl 222nelo makhatheNo ratings yet

- Woven Fibre Glass Tensile StrengthDocument11 pagesWoven Fibre Glass Tensile StrengthDonald MathabelaNo ratings yet

- Uk Sections Datasheets 100723Document20 pagesUk Sections Datasheets 100723pkdscdubaiNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsIdongesit BenNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFneutron_87No ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFAnonymous omQzt3KgzwNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsHusam AhmedNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetsarathNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsRahesh MNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsLynx101No ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsYaziq NabilNo ratings yet

- Steel Universal Beams Ub Datasheet PDFDocument6 pagesSteel Universal Beams Ub Datasheet PDFSend MailNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub Datasheetzulkhairi lopNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsMuhammad Wazim AkramNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSérgio BernardesNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsvysakh51No ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFcruz enrique rodrguez lunaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsAdnan NajemNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFNicolae FloreaNo ratings yet

- Steel Tables (British) PDFDocument18 pagesSteel Tables (British) PDFdarulrajNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetMarzuqi A. HalimNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetPratyadip DuttaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsSyamil DzulfidaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSherin ShajiNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFSyed Shoaib RazaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsInfinity GHNo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)D.M.Ravindra DhanapalaNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub Datasheetsiva kumar rambalaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSteven KuaNo ratings yet

- Basics of Dental Technology: A Step by Step ApproachFrom EverandBasics of Dental Technology: A Step by Step ApproachRating: 5 out of 5 stars5/5 (1)

- IslamicDocument12 pagesIslamicPilar MNo ratings yet

- Lab 3Document4 pagesLab 3Pilar MNo ratings yet

- Letter To The EditorDocument1 pageLetter To The EditorPilar MNo ratings yet

- Centennial Book ReflectionDocument1 pageCentennial Book ReflectionPilar MNo ratings yet

- Building Utilities 1 Lecture 1 PDFDocument3 pagesBuilding Utilities 1 Lecture 1 PDFSey Santmore57% (7)

- Cold FormingDocument25 pagesCold Formingpatel ketan100% (3)

- 2016 Meter and Service Guide 091416nbDocument50 pages2016 Meter and Service Guide 091416nbLemdy AnwunaNo ratings yet

- Code-C04 - BIM-01-REVIT-https Usl-Tuguegarao - Neolms.com Student Lesson Show 2741431 Lesson Id12418802Document2 pagesCode-C04 - BIM-01-REVIT-https Usl-Tuguegarao - Neolms.com Student Lesson Show 2741431 Lesson Id12418802jomarie apolinarioNo ratings yet

- Horizontal Sidewall SprinklerDocument6 pagesHorizontal Sidewall SprinklerAhrian BenaNo ratings yet

- References Data: Drawing: Rakkiyapalayam Pirivu, Kangeyam Main Road Tiruppur-06Document4 pagesReferences Data: Drawing: Rakkiyapalayam Pirivu, Kangeyam Main Road Tiruppur-06E.PrasathNo ratings yet

- RC Box Culvert & U-Ditch: DescriptionDocument1 pageRC Box Culvert & U-Ditch: DescriptionAgung Mahendra STNo ratings yet

- Building Tech Current TrendsDocument30 pagesBuilding Tech Current TrendsMariane CadizNo ratings yet

- Baker Hughes Caisson ESP (2010)Document2 pagesBaker Hughes Caisson ESP (2010)hermit44535No ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- Growbox Schematics InstructablesDocument10 pagesGrowbox Schematics InstructablesTanner WrateNo ratings yet

- Naukri Applav (6y 0m)Document2 pagesNaukri Applav (6y 0m)Rajkumar TomerNo ratings yet

- Architecture Follows Sun - Arvind Krishan PaperDocument6 pagesArchitecture Follows Sun - Arvind Krishan PaperVaibhav JainNo ratings yet

- Health and Safety Hazards in Tunnel ConstructionDocument2 pagesHealth and Safety Hazards in Tunnel ConstructionZainab FaisalNo ratings yet

- Company InformationDocument2 pagesCompany InformationHelder FradeNo ratings yet

- IBRDocument36 pagesIBRPetropipe Academy100% (2)

- How It Works?Document2 pagesHow It Works?saimunNo ratings yet

- Chapter 4-Effective Stress StudentDocument20 pagesChapter 4-Effective Stress StudentKalsoma CarlsNo ratings yet

- Pss 10 13.1 eDocument2 pagesPss 10 13.1 ecandratrikusumaNo ratings yet

- TBC Fender PDFDocument3 pagesTBC Fender PDFmuhammad amanyNo ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- EASA PART 66 GUIDE - EASA Part 66 - Material QuestionDocument86 pagesEASA PART 66 GUIDE - EASA Part 66 - Material Questionpakaya pakayaNo ratings yet

- Manual de Partes GEP-110-4Document329 pagesManual de Partes GEP-110-4Jean carlos Flores martinez75% (4)

- Kashmir VernacularDocument30 pagesKashmir Vernacularsuruthipriyan alagusenthilNo ratings yet

- Flow Product Brochure V3Document8 pagesFlow Product Brochure V3KOMATSU SHOVEL100% (1)

- Sengkang N2 C34 S73Document57 pagesSengkang N2 C34 S73PcEngNo ratings yet

- ResumeDocument2 pagesResumejoliel gabasaNo ratings yet

- A Guide To Working Near The Electric Power NetworkDocument33 pagesA Guide To Working Near The Electric Power NetworkMilos VajagicNo ratings yet

Lab 2 - Group 1

Lab 2 - Group 1

Uploaded by

Pilar MOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab 2 - Group 1

Lab 2 - Group 1

Uploaded by

Pilar MCopyright:

Available Formats

Pilar Manzano, Natalia Pira, Building Construction Materials Group 201

Laura Toro

Objective

- Analyze the mechanical properties of a metal, in our case, a steel sample.

Parameters related to steel

- The ultimate compressive strength of mild steel is 4750 – 25200 kg/cm2

- It's ultimate tensile strength is 5510 – kg/cm2

Mechanical properties

- σ, working (tensile/compressive) stress

- τ, working (shear) stress

- σp, limit of proportional elasticity (proportionality limit)

- σy, yield strength (limit of elasticity or elastic limit)

- UTS, ultimate tensile strength

- UCS, ultimate compressive strength

- USS, ultimate shear strength

- σf, failure strength (breaking strength)

- E, modulus of elasticity (Young’s modulus)

- G, modulus of rigidity (shear modulus)

- K, bulk modulus of elasticity

- υ, Poisson’s ratio

- γ, safety factor

- Wf, flexural modulus

- Wt, torsional modulus

Description of steel

- Steel is an alloy of iron and carbon, which is one of the most important elements in

construction.

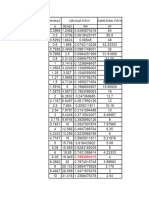

Findings obtained in the laboratory

Pressure Increment in

length (ΔL (10⁻²

mm)

1 0

1.4 3

1.6 4

1.8 4.5

2 5

2.4 5.5

2.8 6

3.4 8

4 10

5 11

5.6 13

6 14

6.4 15

6.8 15.5

7.4 16

8 17

8.4 20

9.2 21

10 24

10.2 27

10.6 38

Pilar Manzano, Natalia Pira, Building Construction Materials Group 201

Laura Toro

10.8 55

10.4 71

10 79

9.8 91

9.2 106

8.6 123

Procedure

1. From the pile of samples, choose either aluminum, brass or steel sample. We chose the

steel one.

2. Grab steel stick and place in Universal Testing Machine

a. Machine will be realizing a compression test

b. Begin by applying pressure to the sample

c. While one person applies pressure, the other person measures the pressure

applied, and a third person measures the change in length of the sample.

d. The machine will stop when the sample breaks.

3. Analyze the break of the sample.

a. Is it a ductile or brittle

b. Brittle will have unequal breaks, while ductile will have a concave and a convex

break.

c. Analyze if there is necking occurring

Equations for calculations

From pressure to force (KN)

16 kg/cm2 ≡7.5 kN

From KN to N

1 KN= 103N

Increment in length (mm)

From 10-2 mm to mm

Stress σ

Force/Area=Force/πR2

Strain ε

ε = Increment in length/Original length

Modulus of elasticity

Stress/strain

Final Table of Results

Force ΔL (10⁻² Modulus of

Pressure (kN) mm) Force (N) ΔL (mm) σ (MPa) Ε (%) Elasticity

σ/ ε (MPa)

1 0.46875 0 468.75 0 66.31459 0 -

Pilar Manzano, Natalia Pira, Building Construction Materials Group 201

Laura Toro

1.4 0.65625 3 656.25 0.03 92.84043 0.001579 5.88 x 10^4

1.6 0.75 4 750 0.04 106.1033 0.002105 5.04 x 10^4

1.8 0.84375 4.5 843.75 0.045 119.3663 0.002368 5.04 x 10^4

2 0.9375 5 937.5 0.05 132.6292 0.002632 5.04 x 10^4

2.4 1.125 5.5 1125 0.055 159.155 0.002895 5.50 x 10^4

2.8 1.3125 6 1312.5 0.06 185.6809 0.003158 5.88 x 10^4

3.4 1.59375 8 1593.75 0.08 225.4696 0.004211 5.35 x 10^4

4 1.875 10 1875 0.1 265.2584 0.005263 5.04 x 10^4

5 2.34375 11 2343.75 0.11 331.573 0.005789 5.73 x 10^4

5.6 2.625 13 2625 0.13 371.3617 0.006842 5.43 x 10^4

6 2.8125 14 2812.5 0.14 397.8876 0.007368 5.40 x 10^4

6.4 3 15 3000 0.15 424.4134 0.007895 5.38 x 10^4

6.8 3.1875 15.5 3187.5 0.155 450.9392 0.008158 5.53 x 10^4

7.4 3.46875 16 3468.75 0.16 490.728 0.008421 5.83 x 10^4

8 3.75 17 3750 0.17 530.5167 0.008947 5.93 x 10^4

8.4 3.9375 20 3937.5 0.2 557.0426 0.010526 5.29 x 10^4

9.2 4.3125 21 4312.5 0.21 610.0942 0.011053 5.52 x 10^4

10 4.6875 24 4687.5 0.24 663.1459 0.012632 5.25 x 10^4

10.2 4.78125 27 4781.25 0.27 676.4088 0.014211 4.76 x 10^4

10.6 4.96875 38 4968.75 0.38 702.9347 0.02 3.51 x 10^4

10.8 5.0625 55 5062.5 0.55 716.1976 0.028947 2.47 x 10^4

10.4 4.875 71 4875 0.71 689.6718 0.037368 1.85 x 10^4

10 4.6875 79 4687.5 0.79 663.1459 0.041579 1.59 x 10^4

9.8 4.59375 91 4593.75 0.91 649.883 0.047895 1.36 x 10^4

9.2 4.3125 106 4312.5 1.06 610.0942 0.055789 1.09 x 10^4

8.6 4.03125 123 4031.25 1.23 570.3055 0.064737 8.81 x 10^3

Pilar Manzano, Natalia Pira, Building Construction Materials Group 201

Laura Toro

Conclusions

As you apply pressure, the increment in length will go up (the material stretches), growing

almost exponentially in the elastic region. Once it enters the plastic region, the increment in

length will increase quite a bit without real changes in its tension. When it undergoes a maximum

plastic deformation it will decrease, until it fails and breaks.

The higher the pressure and increment in length, the higher the stress and strain.

You might also like

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFLavanyan SatchithananthanNo ratings yet

- Din en Iso 9013Document8 pagesDin en Iso 9013Cemal NergizNo ratings yet

- Tensile TestingDocument12 pagesTensile TestingAhmed ElqazazNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Pipe Extrusion Lines - Defects & Suggested RemediesDocument2 pagesPipe Extrusion Lines - Defects & Suggested Remedieshvadnala100% (5)

- Department of Mechanical EngineeringDocument4 pagesDepartment of Mechanical EngineeringKano MolapisiNo ratings yet

- Experiment: Sheet Resistance and the Calculation of Resistivity () or Thickness (t) and Thermal coefficient of Resistivity (α)Document4 pagesExperiment: Sheet Resistance and the Calculation of Resistivity () or Thickness (t) and Thermal coefficient of Resistivity (α)AdityaNo ratings yet

- Lab 2 W7 Lab ResultsDocument22 pagesLab 2 W7 Lab ResultsmiraclelovesgamesNo ratings yet

- Circular Pitchs For DP DeterminationDocument3 pagesCircular Pitchs For DP DeterminationJaikumar LukeNo ratings yet

- How To Measure The Pressure Angle of A Physical Spur Gear PDFDocument16 pagesHow To Measure The Pressure Angle of A Physical Spur Gear PDFAnil PrajapatiNo ratings yet

- Unconfined Compressive Strength Test: Experiment 1Document5 pagesUnconfined Compressive Strength Test: Experiment 1Refisa JiruNo ratings yet

- AlDocument5 pagesAlshamsi862620No ratings yet

- Creep LabDocument23 pagesCreep LabkeeonNo ratings yet

- Practical # 1 StatementDocument10 pagesPractical # 1 StatementtasleemaeroNo ratings yet

- Tensile TestDocument12 pagesTensile TestDulshan uddeepanaNo ratings yet

- Spec25051 - Teck CableDocument4 pagesSpec25051 - Teck Cablecrfg2003No ratings yet

- ET 310 Lab 4Document19 pagesET 310 Lab 4DylanNo ratings yet

- Bab Iii Perhitungan Dimensi StrukturDocument17 pagesBab Iii Perhitungan Dimensi StrukturBurhan El-SumiratNo ratings yet

- Npat 2Document2 pagesNpat 2aaaNo ratings yet

- BS SRR-3Document20 pagesBS SRR-3anveshvarma365No ratings yet

- Din en Iso 9013Document8 pagesDin en Iso 90137netmaffiaNo ratings yet

- No Ti Si Tixsi TixsiDocument3 pagesNo Ti Si Tixsi TixsiPyoJihoonNo ratings yet

- Summary:: P= ΔL×E×A LDocument8 pagesSummary:: P= ΔL×E×A LMohammad Hasan NassarNo ratings yet

- Wetico Water Tank 70m Shell Ultimate ChecksDocument2 pagesWetico Water Tank 70m Shell Ultimate ChecksChristian Paul SanguyoNo ratings yet

- Instalatii aDIDocument19 pagesInstalatii aDIAndrei Manole PGNo ratings yet

- Pure Bending Exp ReportDocument5 pagesPure Bending Exp Reportabo MakbasNo ratings yet

- Base Slab Bottom Mesh 6.1 Spacing 0.17 Cover 0.035 Thickness 0.35 I Di Hook No Bottom Bar Top BarDocument5 pagesBase Slab Bottom Mesh 6.1 Spacing 0.17 Cover 0.035 Thickness 0.35 I Di Hook No Bottom Bar Top BarARSENo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)rezetane mohamed amineNo ratings yet

- Lab 1 Civl 222Document6 pagesLab 1 Civl 222nelo makhatheNo ratings yet

- Woven Fibre Glass Tensile StrengthDocument11 pagesWoven Fibre Glass Tensile StrengthDonald MathabelaNo ratings yet

- Uk Sections Datasheets 100723Document20 pagesUk Sections Datasheets 100723pkdscdubaiNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsIdongesit BenNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFneutron_87No ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFAnonymous omQzt3KgzwNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsHusam AhmedNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetsarathNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsRahesh MNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsLynx101No ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsYaziq NabilNo ratings yet

- Steel Universal Beams Ub Datasheet PDFDocument6 pagesSteel Universal Beams Ub Datasheet PDFSend MailNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub Datasheetzulkhairi lopNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsMuhammad Wazim AkramNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSérgio BernardesNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsvysakh51No ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFcruz enrique rodrguez lunaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsAdnan NajemNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFNicolae FloreaNo ratings yet

- Steel Tables (British) PDFDocument18 pagesSteel Tables (British) PDFdarulrajNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetMarzuqi A. HalimNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetPratyadip DuttaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsSyamil DzulfidaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSherin ShajiNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFSyed Shoaib RazaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsInfinity GHNo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)D.M.Ravindra DhanapalaNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub Datasheetsiva kumar rambalaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSteven KuaNo ratings yet

- Basics of Dental Technology: A Step by Step ApproachFrom EverandBasics of Dental Technology: A Step by Step ApproachRating: 5 out of 5 stars5/5 (1)

- IslamicDocument12 pagesIslamicPilar MNo ratings yet

- Lab 3Document4 pagesLab 3Pilar MNo ratings yet

- Letter To The EditorDocument1 pageLetter To The EditorPilar MNo ratings yet

- Centennial Book ReflectionDocument1 pageCentennial Book ReflectionPilar MNo ratings yet

- Building Utilities 1 Lecture 1 PDFDocument3 pagesBuilding Utilities 1 Lecture 1 PDFSey Santmore57% (7)

- Cold FormingDocument25 pagesCold Formingpatel ketan100% (3)

- 2016 Meter and Service Guide 091416nbDocument50 pages2016 Meter and Service Guide 091416nbLemdy AnwunaNo ratings yet

- Code-C04 - BIM-01-REVIT-https Usl-Tuguegarao - Neolms.com Student Lesson Show 2741431 Lesson Id12418802Document2 pagesCode-C04 - BIM-01-REVIT-https Usl-Tuguegarao - Neolms.com Student Lesson Show 2741431 Lesson Id12418802jomarie apolinarioNo ratings yet

- Horizontal Sidewall SprinklerDocument6 pagesHorizontal Sidewall SprinklerAhrian BenaNo ratings yet

- References Data: Drawing: Rakkiyapalayam Pirivu, Kangeyam Main Road Tiruppur-06Document4 pagesReferences Data: Drawing: Rakkiyapalayam Pirivu, Kangeyam Main Road Tiruppur-06E.PrasathNo ratings yet

- RC Box Culvert & U-Ditch: DescriptionDocument1 pageRC Box Culvert & U-Ditch: DescriptionAgung Mahendra STNo ratings yet

- Building Tech Current TrendsDocument30 pagesBuilding Tech Current TrendsMariane CadizNo ratings yet

- Baker Hughes Caisson ESP (2010)Document2 pagesBaker Hughes Caisson ESP (2010)hermit44535No ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- Growbox Schematics InstructablesDocument10 pagesGrowbox Schematics InstructablesTanner WrateNo ratings yet

- Naukri Applav (6y 0m)Document2 pagesNaukri Applav (6y 0m)Rajkumar TomerNo ratings yet

- Architecture Follows Sun - Arvind Krishan PaperDocument6 pagesArchitecture Follows Sun - Arvind Krishan PaperVaibhav JainNo ratings yet

- Health and Safety Hazards in Tunnel ConstructionDocument2 pagesHealth and Safety Hazards in Tunnel ConstructionZainab FaisalNo ratings yet

- Company InformationDocument2 pagesCompany InformationHelder FradeNo ratings yet

- IBRDocument36 pagesIBRPetropipe Academy100% (2)

- How It Works?Document2 pagesHow It Works?saimunNo ratings yet

- Chapter 4-Effective Stress StudentDocument20 pagesChapter 4-Effective Stress StudentKalsoma CarlsNo ratings yet

- Pss 10 13.1 eDocument2 pagesPss 10 13.1 ecandratrikusumaNo ratings yet

- TBC Fender PDFDocument3 pagesTBC Fender PDFmuhammad amanyNo ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- EASA PART 66 GUIDE - EASA Part 66 - Material QuestionDocument86 pagesEASA PART 66 GUIDE - EASA Part 66 - Material Questionpakaya pakayaNo ratings yet

- Manual de Partes GEP-110-4Document329 pagesManual de Partes GEP-110-4Jean carlos Flores martinez75% (4)

- Kashmir VernacularDocument30 pagesKashmir Vernacularsuruthipriyan alagusenthilNo ratings yet

- Flow Product Brochure V3Document8 pagesFlow Product Brochure V3KOMATSU SHOVEL100% (1)

- Sengkang N2 C34 S73Document57 pagesSengkang N2 C34 S73PcEngNo ratings yet

- ResumeDocument2 pagesResumejoliel gabasaNo ratings yet

- A Guide To Working Near The Electric Power NetworkDocument33 pagesA Guide To Working Near The Electric Power NetworkMilos VajagicNo ratings yet