Professional Documents

Culture Documents

HiS SYSTEM - METAL Welding Machine

HiS SYSTEM - METAL Welding Machine

Uploaded by

Sharmishta AngreCopyright:

Available Formats

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Hot Desking Policy TemplateDocument3 pagesHot Desking Policy Templatesfdfsdf100% (1)

- INCOME TAX Ready Reckoner - by CA HARSHIL SHETHDocument38 pagesINCOME TAX Ready Reckoner - by CA HARSHIL SHETHCA Harshil ShethNo ratings yet

- Howard's Gift Uncommon Wisdom To Inspire Your Life's WorkDocument13 pagesHoward's Gift Uncommon Wisdom To Inspire Your Life's WorkMacmillan Publishers83% (6)

- Anti Avoidance RulesDocument15 pagesAnti Avoidance RulesAanchal KashyapNo ratings yet

- Electronic CircuitsDocument91 pagesElectronic Circuitsvinay Shastry100% (6)

- HiQ Modular Systems - VarioDocument3 pagesHiQ Modular Systems - VarioSharmishta AngreNo ratings yet

- Smart Panel Litemax Sld1968-Enb-G11Document3 pagesSmart Panel Litemax Sld1968-Enb-G11romuald konhawoNo ratings yet

- FPM-3191G DS20110812110554Document2 pagesFPM-3191G DS20110812110554Khang DoanTanNo ratings yet

- Ds Hd13t21std XXX FXXXDocument2 pagesDs Hd13t21std XXX FXXXbbbru1No ratings yet

- Motoman HP 20Document2 pagesMotoman HP 20Esteban Quezada NeriNo ratings yet

- StratosH 2300 Scanner BrochureDocument2 pagesStratosH 2300 Scanner BrochureJohnny BarcodeNo ratings yet

- HattelandDocument2 pagesHattelandbbbru1No ratings yet

- 3D Solutions BrochureDocument4 pages3D Solutions BrochureJesús SánchezNo ratings yet

- MH5S MH5LS DXM100Document2 pagesMH5S MH5LS DXM100Myagmarbayar NerguiNo ratings yet

- Proyector de PerfilesDocument22 pagesProyector de PerfilesAlexis Guzmán MéndezNo ratings yet

- Sharp Lq065t5ar01 Lcdpanel DatasheetDocument33 pagesSharp Lq065t5ar01 Lcdpanel Datasheetkarol1301No ratings yet

- EWTR910Document7 pagesEWTR910Codreanu FanelNo ratings yet

- PH A14 WebsiteDocument6 pagesPH A14 WebsiteAlfredo Geovanni Magaña De La FuenteNo ratings yet

- DisplayDocument2 pagesDisplaybbbru1No ratings yet

- DLD 5500 LNWDocument4 pagesDLD 5500 LNWManu MathewNo ratings yet

- DL1100Document2 pagesDL1100Wong Wong WLNo ratings yet

- Qsi Treq-M4x Data SheetDocument2 pagesQsi Treq-M4x Data Sheettrivinho24No ratings yet

- No Wi P6 6: Krautkramer USM 32XDocument2 pagesNo Wi P6 6: Krautkramer USM 32XAsif HameedNo ratings yet

- TH-37PHD8UK: High-Definition Plasma DisplayDocument2 pagesTH-37PHD8UK: High-Definition Plasma DisplayngayitNo ratings yet

- 2013 OWON Product Catalogue v4.0.1Document12 pages2013 OWON Product Catalogue v4.0.1JJGNo ratings yet

- SMT-3231 DatasheetDocument2 pagesSMT-3231 DatasheetJosephNo ratings yet

- Dus 6000Document4 pagesDus 6000Tung DaoNo ratings yet

- Ds Jh15t17mmd XXX AxxxDocument2 pagesDs Jh15t17mmd XXX Axxxbbbru1No ratings yet

- Ds Hd26t21mmd XXX FXXXDocument2 pagesDs Hd26t21mmd XXX FXXXbbbru1No ratings yet

- Ea7 Cmore HmiDocument16 pagesEa7 Cmore HmiJesus GarciaNo ratings yet

- AGP3000 eDocument25 pagesAGP3000 eElena MaxmiucNo ratings yet

- BrakesDocument34 pagesBrakesMilan GrujićNo ratings yet

- Hi-Scan 5030C: Compact, Durable and Transportable X-Ray ScannerDocument2 pagesHi-Scan 5030C: Compact, Durable and Transportable X-Ray Scannernazariehsan128No ratings yet

- Ctf700-Hm - Vga 7 TFT - Touchscreen Usb - Open-FrameDocument3 pagesCtf700-Hm - Vga 7 TFT - Touchscreen Usb - Open-FrameOriol AragonesNo ratings yet

- 928TEII Turning Machine CNC SystemDocument0 pages928TEII Turning Machine CNC SystemCNCmakersNo ratings yet

- Venture Depliants Macchines For Industry - EngDocument9 pagesVenture Depliants Macchines For Industry - EngTanvon MalikNo ratings yet

- Ds Hd12t21mmc XXX XXXXDocument2 pagesDs Hd12t21mmc XXX XXXXbbbru1No ratings yet

- Mobile XDocument14 pagesMobile XCahyadi KsmNo ratings yet

- Tatung Guide 6-15-2010 Rev 1 PDFDocument13 pagesTatung Guide 6-15-2010 Rev 1 PDFKatie VaughnNo ratings yet

- LTY400HM01Document28 pagesLTY400HM01plasma plasmaNo ratings yet

- Documentare ElectroeroziuneDocument7 pagesDocumentare Electroeroziuneprofanu1No ratings yet

- Ds Hd12t21mmd XXX FXXXDocument2 pagesDs Hd12t21mmd XXX FXXXbbbru1No ratings yet

- Hi-Scan 6030d: Heimann X-Ray TechnologyDocument2 pagesHi-Scan 6030d: Heimann X-Ray TechnologyLinssen KongNo ratings yet

- XRC 75 55 ENG Rev30012016Document2 pagesXRC 75 55 ENG Rev30012016lechehebghanouNo ratings yet

- AgieCharmile SP1UDocument20 pagesAgieCharmile SP1URezza KudoNo ratings yet

- Tiger: CCD 4 MPDocument2 pagesTiger: CCD 4 MPmahmoud khairyNo ratings yet

- LSUBL6432ADocument4 pagesLSUBL6432ATotoxaHCNo ratings yet

- TX18D11VM1CAA HitachiDocument1 pageTX18D11VM1CAA HitachiDan LapugeanuNo ratings yet

- XRC 100 100DV ENG Rev15102018Document2 pagesXRC 100 100DV ENG Rev15102018Antonio QuispeNo ratings yet

- SimpleDocument24 pagesSimpleWonbae ChoiNo ratings yet

- TH-50PH11UK: High Definition Plasma DisplayDocument3 pagesTH-50PH11UK: High Definition Plasma DisplaymasternikeNo ratings yet

- Info-Hmi Mt6056iDocument2 pagesInfo-Hmi Mt6056iwaleed alqatabNo ratings yet

- Ds Hd08t21mmc XXX XXXXDocument2 pagesDs Hd08t21mmc XXX XXXXbbbru1No ratings yet

- SSI 8000 SpecificationsDocument20 pagesSSI 8000 SpecificationsMindaugas DaugelaNo ratings yet

- Xd3500u BrochuresDocument2 pagesXd3500u BrochuresBilly Ţhe KidsNo ratings yet

- Heidenhain MANUALplus620Document48 pagesHeidenhain MANUALplus620Muhammed ShahidNo ratings yet

- 5006 Controller - 1Document2 pages5006 Controller - 1pawanmandeep2012No ratings yet

- Payload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotDocument2 pagesPayload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotRuben AlvaradoNo ratings yet

- 1964 - SJ 201 301Document16 pages1964 - SJ 201 301Jose Ignacio CastilloNo ratings yet

- Ehb-300g++ & 3000G++Document1 pageEhb-300g++ & 3000G++Eong Huat Corporation Sdn BhdNo ratings yet

- TouchscreenDocument2 pagesTouchscreenRanadurjoy GhoshNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- SJP - Laser - Presentation - New 14 VersionDocument20 pagesSJP - Laser - Presentation - New 14 VersionSharmishta AngreNo ratings yet

- VWPage 2Document2 pagesVWPage 2Sharmishta AngreNo ratings yet

- SJP Plastic Laser Welding PresentationDocument12 pagesSJP Plastic Laser Welding PresentationSharmishta AngreNo ratings yet

- Hiq-Logic SeriesDocument7 pagesHiq-Logic SeriesSharmishta AngreNo ratings yet

- 35kHz 900W Hand Welding Machine Data SheetDocument3 pages35kHz 900W Hand Welding Machine Data SheetSharmishta AngreNo ratings yet

- 35kHz K745 AdvancedDocument1 page35kHz K745 AdvancedSharmishta AngreNo ratings yet

- SJP Make 15kHz 2600W Ultrasonic Welding Machine DatasheetDocument2 pagesSJP Make 15kHz 2600W Ultrasonic Welding Machine DatasheetSharmishta AngreNo ratings yet

- 20k 3000watt Ultrasonic Plastic Welding Machine-Digital - SE-DS300 - 1Document4 pages20k 3000watt Ultrasonic Plastic Welding Machine-Digital - SE-DS300 - 1Sharmishta AngreNo ratings yet

- 16 L745 Standard Machine Data SheetDocument1 page16 L745 Standard Machine Data SheetSharmishta AngreNo ratings yet

- SJP Catalogue Speed and GrowthDocument12 pagesSJP Catalogue Speed and GrowthSharmishta AngreNo ratings yet

- Skylab 3 PAO Mission Commentary 3 of 6Document851 pagesSkylab 3 PAO Mission Commentary 3 of 6Bob AndrepontNo ratings yet

- Inspyrus - White PaperDocument8 pagesInspyrus - White PaperBayCreativeNo ratings yet

- GRIT221 Fundamentals of Business Analytics: I. ObjectivesDocument3 pagesGRIT221 Fundamentals of Business Analytics: I. ObjectivesnaspuloyNo ratings yet

- Obo Commissioning 9Document75 pagesObo Commissioning 998257002No ratings yet

- Instrument PanelDocument7 pagesInstrument Panelindrajith.meNo ratings yet

- 57e4d64a5ae56 1317890 SampleDocument32 pages57e4d64a5ae56 1317890 Samplemanaswini sharma B.G.100% (2)

- Consolidated Terminals Inc. v. Artex - G.R. No. L-25748Document1 pageConsolidated Terminals Inc. v. Artex - G.R. No. L-25748eiram23No ratings yet

- Wget - Curl Large File From Google Drive - Stack OverflowDocument29 pagesWget - Curl Large File From Google Drive - Stack OverflowManoj KamisettiNo ratings yet

- CHAPTER 10 One and Two Bar Price PatternDocument21 pagesCHAPTER 10 One and Two Bar Price Patternnurul zulaikaNo ratings yet

- Tutorial Letter 203/2/2017: General Chemistry 1BDocument18 pagesTutorial Letter 203/2/2017: General Chemistry 1BLeigh MakanNo ratings yet

- 37 Nyquist Criterion For Zero ISIDocument3 pages37 Nyquist Criterion For Zero ISIJGS MAGICALNo ratings yet

- Sulphate Attack in Concrete and Its PreventionDocument21 pagesSulphate Attack in Concrete and Its PreventionvempadareddyNo ratings yet

- .. Thesis Title .Document31 pages.. Thesis Title .Tanut VongsoontornNo ratings yet

- At The End of The Lesson, The Students Will Be Able To Apply The Indefinite Articles in The Given SentencesDocument11 pagesAt The End of The Lesson, The Students Will Be Able To Apply The Indefinite Articles in The Given SentencesRhielle Dimaculangan CabañezNo ratings yet

- Level 1 Workbook (Complete Ielts Bands 4-5)Document66 pagesLevel 1 Workbook (Complete Ielts Bands 4-5)Hồng ThưNo ratings yet

- CANBUSDocument18 pagesCANBUSSamuel SimbolonNo ratings yet

- PreTest Electronics 2022Document2 pagesPreTest Electronics 2022Joan VillarcaNo ratings yet

- CASE REPORT Vertigo PutriDocument20 pagesCASE REPORT Vertigo PutriRizqina PutriNo ratings yet

- Anatomy and Histology of The Cardiovascular SystemDocument16 pagesAnatomy and Histology of The Cardiovascular SystemTasmiah HossainNo ratings yet

- Protocol Germ CellDocument82 pagesProtocol Germ CellTanh NguyenNo ratings yet

- Ireland Climate Action Plan 2024Document7 pagesIreland Climate Action Plan 2024Fursey WhyteNo ratings yet

- Magaso v. COA - Jan 2023 - Full TextDocument7 pagesMagaso v. COA - Jan 2023 - Full TextSam LeynesNo ratings yet

- PO-04 Drug-Free Workplace Policy 4.15.2019Document16 pagesPO-04 Drug-Free Workplace Policy 4.15.2019Matt ThomasNo ratings yet

- Technical SpecificationDocument14 pagesTechnical SpecificationbinodeNo ratings yet

- Brunswick Manual Preinstalacion GSXDocument33 pagesBrunswick Manual Preinstalacion GSXroberto dominguezNo ratings yet

- Confidence Siswa Sma Dalam Materi Peluang: Analisis Kemampuan Kemampuan Penalaran Dan SelfDocument8 pagesConfidence Siswa Sma Dalam Materi Peluang: Analisis Kemampuan Kemampuan Penalaran Dan SelfAfifah R. AminiNo ratings yet

HiS SYSTEM - METAL Welding Machine

HiS SYSTEM - METAL Welding Machine

Uploaded by

Sharmishta AngreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HiS SYSTEM - METAL Welding Machine

HiS SYSTEM - METAL Welding Machine

Uploaded by

Sharmishta AngreCopyright:

Available Formats

HiS B 20 kHz system HiS B 35 kHz system HiS T system

SPOTWELDER FOR BATTERY, CABLE, AND TERMINAL APPLICATIONS

SJP Ultrasonics pvt. Ltd.

Leading in process stability and precision. Whether you are using a manual work station or require

integration into production lines, SJP has the solution for extremely strong and conductive metal

connections. Fast setup and fewer suspect parts save considerable costs.

Cost savings through higher production quality

Long term proven ultrasonic components

Digital Ultrasonic Generator

Ensuring and monitoring quality is the main focus in metal welding. Setup of the process in a stable

and reproducible manner and always keeping an eye on it via the graphic visualization - these tasks

are met by the HiS product line by means of the VARIO Control controller. In addition, it ensures fast

tool change for both the weld tool and the equipment of the application, as well as a space-saving

design for easy integration. The well thought-out design guarantees cleanliness when working,

accessibility, and maximum safety for the operator.

SJP Ultrasonics pvt. Ltd.

Precise alignment

Easy and fast tool change

Modularity and flexibility for automation

engineers

SJP Ultrasonics pvt. Ltd.

SJP Ultrasonics pvt. Ltd.

SJP Ultrasonics pvt. Ltd.

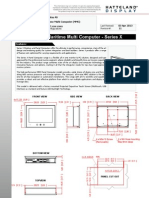

HiS SYSTEM VARIO B (left and right version) 20 kHz

Generator power [W] 2400 / 4800 / 6200

Weld force max [N] at 6 bar 3500

Stroke [mm] 15 / 30 / 60

Outside dimensions (W x H x D) [mm] 191 x 415 x 345

Control Panel 12" touch screen, color

Operating modes 5

Technical data

Application memories 32

Number of stored welds (graphics & data) 100

Control of auxiliary functions (optional) 4

SJP Ultrasonics pvt. Ltd.

SJP Ultrasonics pvt. Ltd.

SJP Ultrasonics pvt. Ltd.

Generator power [W] 2400 / 4800 / 6200

Weld force max [N] at 6 bar 3500

Stroke [mm] 15 / 30 / 60

Outside dimensions (W x H x D) [mm] 191 x 415 x 345

Control Panel 12" touch screen, color

Operating modes 5

Application memories 32

SJP Ultrasonics pvt. Ltd.

Number of stored welds (graphics & data) 100

Control of auxiliary functions (optional) 4

SJP Ultrasonics pvt. Ltd.

SJP Ultrasonics pvt. Ltd.

Modularity and flexibility for

Automation engineers

SJP Ultrasonics pvt. Ltd.

35 kHz

HiS SYSTEM VARIO B

Generator power [W] 1200

Weld force max. [N] at 6 bar 115 / 260

Stroke [mm] 10, 30, 50

Outside dimensions (W x H x D) [mm] 69x315x406

Control panel touch screen color 8,4"

Operating modes 5

Application memories 32

Number of saved welds (graphs & data) 100

SJP Ultrasonics pvt. Ltd.

SJP Ultrasonics pvt. Ltd.

Quick and easy application change

Innovative equipment concept for a widerange

of parts and applications

Equipment indexed and changeable with

plug-in type connections

Rapidly exchangeable format sets

HiS VARIO T 20 kHz

Generator power [W] 2400 / 4800 / 6200

Weld force max [N] at 6 bar 6000

Stroke / Revision stroke [mm] 50 / 100

Outside dimensionse (W x H x D) [mm] 530 x 768 x 600

Control panel (weld process control) 12“ / 9“ Touchscreen

Operating modes 5

Application memories 32

Number of saved welds (graphics & data) 100

Number of controllable auxiliary functions (optional) 4

SJP Ultrasonics pvt. Ltd.

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Hot Desking Policy TemplateDocument3 pagesHot Desking Policy Templatesfdfsdf100% (1)

- INCOME TAX Ready Reckoner - by CA HARSHIL SHETHDocument38 pagesINCOME TAX Ready Reckoner - by CA HARSHIL SHETHCA Harshil ShethNo ratings yet

- Howard's Gift Uncommon Wisdom To Inspire Your Life's WorkDocument13 pagesHoward's Gift Uncommon Wisdom To Inspire Your Life's WorkMacmillan Publishers83% (6)

- Anti Avoidance RulesDocument15 pagesAnti Avoidance RulesAanchal KashyapNo ratings yet

- Electronic CircuitsDocument91 pagesElectronic Circuitsvinay Shastry100% (6)

- HiQ Modular Systems - VarioDocument3 pagesHiQ Modular Systems - VarioSharmishta AngreNo ratings yet

- Smart Panel Litemax Sld1968-Enb-G11Document3 pagesSmart Panel Litemax Sld1968-Enb-G11romuald konhawoNo ratings yet

- FPM-3191G DS20110812110554Document2 pagesFPM-3191G DS20110812110554Khang DoanTanNo ratings yet

- Ds Hd13t21std XXX FXXXDocument2 pagesDs Hd13t21std XXX FXXXbbbru1No ratings yet

- Motoman HP 20Document2 pagesMotoman HP 20Esteban Quezada NeriNo ratings yet

- StratosH 2300 Scanner BrochureDocument2 pagesStratosH 2300 Scanner BrochureJohnny BarcodeNo ratings yet

- HattelandDocument2 pagesHattelandbbbru1No ratings yet

- 3D Solutions BrochureDocument4 pages3D Solutions BrochureJesús SánchezNo ratings yet

- MH5S MH5LS DXM100Document2 pagesMH5S MH5LS DXM100Myagmarbayar NerguiNo ratings yet

- Proyector de PerfilesDocument22 pagesProyector de PerfilesAlexis Guzmán MéndezNo ratings yet

- Sharp Lq065t5ar01 Lcdpanel DatasheetDocument33 pagesSharp Lq065t5ar01 Lcdpanel Datasheetkarol1301No ratings yet

- EWTR910Document7 pagesEWTR910Codreanu FanelNo ratings yet

- PH A14 WebsiteDocument6 pagesPH A14 WebsiteAlfredo Geovanni Magaña De La FuenteNo ratings yet

- DisplayDocument2 pagesDisplaybbbru1No ratings yet

- DLD 5500 LNWDocument4 pagesDLD 5500 LNWManu MathewNo ratings yet

- DL1100Document2 pagesDL1100Wong Wong WLNo ratings yet

- Qsi Treq-M4x Data SheetDocument2 pagesQsi Treq-M4x Data Sheettrivinho24No ratings yet

- No Wi P6 6: Krautkramer USM 32XDocument2 pagesNo Wi P6 6: Krautkramer USM 32XAsif HameedNo ratings yet

- TH-37PHD8UK: High-Definition Plasma DisplayDocument2 pagesTH-37PHD8UK: High-Definition Plasma DisplayngayitNo ratings yet

- 2013 OWON Product Catalogue v4.0.1Document12 pages2013 OWON Product Catalogue v4.0.1JJGNo ratings yet

- SMT-3231 DatasheetDocument2 pagesSMT-3231 DatasheetJosephNo ratings yet

- Dus 6000Document4 pagesDus 6000Tung DaoNo ratings yet

- Ds Jh15t17mmd XXX AxxxDocument2 pagesDs Jh15t17mmd XXX Axxxbbbru1No ratings yet

- Ds Hd26t21mmd XXX FXXXDocument2 pagesDs Hd26t21mmd XXX FXXXbbbru1No ratings yet

- Ea7 Cmore HmiDocument16 pagesEa7 Cmore HmiJesus GarciaNo ratings yet

- AGP3000 eDocument25 pagesAGP3000 eElena MaxmiucNo ratings yet

- BrakesDocument34 pagesBrakesMilan GrujićNo ratings yet

- Hi-Scan 5030C: Compact, Durable and Transportable X-Ray ScannerDocument2 pagesHi-Scan 5030C: Compact, Durable and Transportable X-Ray Scannernazariehsan128No ratings yet

- Ctf700-Hm - Vga 7 TFT - Touchscreen Usb - Open-FrameDocument3 pagesCtf700-Hm - Vga 7 TFT - Touchscreen Usb - Open-FrameOriol AragonesNo ratings yet

- 928TEII Turning Machine CNC SystemDocument0 pages928TEII Turning Machine CNC SystemCNCmakersNo ratings yet

- Venture Depliants Macchines For Industry - EngDocument9 pagesVenture Depliants Macchines For Industry - EngTanvon MalikNo ratings yet

- Ds Hd12t21mmc XXX XXXXDocument2 pagesDs Hd12t21mmc XXX XXXXbbbru1No ratings yet

- Mobile XDocument14 pagesMobile XCahyadi KsmNo ratings yet

- Tatung Guide 6-15-2010 Rev 1 PDFDocument13 pagesTatung Guide 6-15-2010 Rev 1 PDFKatie VaughnNo ratings yet

- LTY400HM01Document28 pagesLTY400HM01plasma plasmaNo ratings yet

- Documentare ElectroeroziuneDocument7 pagesDocumentare Electroeroziuneprofanu1No ratings yet

- Ds Hd12t21mmd XXX FXXXDocument2 pagesDs Hd12t21mmd XXX FXXXbbbru1No ratings yet

- Hi-Scan 6030d: Heimann X-Ray TechnologyDocument2 pagesHi-Scan 6030d: Heimann X-Ray TechnologyLinssen KongNo ratings yet

- XRC 75 55 ENG Rev30012016Document2 pagesXRC 75 55 ENG Rev30012016lechehebghanouNo ratings yet

- AgieCharmile SP1UDocument20 pagesAgieCharmile SP1URezza KudoNo ratings yet

- Tiger: CCD 4 MPDocument2 pagesTiger: CCD 4 MPmahmoud khairyNo ratings yet

- LSUBL6432ADocument4 pagesLSUBL6432ATotoxaHCNo ratings yet

- TX18D11VM1CAA HitachiDocument1 pageTX18D11VM1CAA HitachiDan LapugeanuNo ratings yet

- XRC 100 100DV ENG Rev15102018Document2 pagesXRC 100 100DV ENG Rev15102018Antonio QuispeNo ratings yet

- SimpleDocument24 pagesSimpleWonbae ChoiNo ratings yet

- TH-50PH11UK: High Definition Plasma DisplayDocument3 pagesTH-50PH11UK: High Definition Plasma DisplaymasternikeNo ratings yet

- Info-Hmi Mt6056iDocument2 pagesInfo-Hmi Mt6056iwaleed alqatabNo ratings yet

- Ds Hd08t21mmc XXX XXXXDocument2 pagesDs Hd08t21mmc XXX XXXXbbbru1No ratings yet

- SSI 8000 SpecificationsDocument20 pagesSSI 8000 SpecificationsMindaugas DaugelaNo ratings yet

- Xd3500u BrochuresDocument2 pagesXd3500u BrochuresBilly Ţhe KidsNo ratings yet

- Heidenhain MANUALplus620Document48 pagesHeidenhain MANUALplus620Muhammed ShahidNo ratings yet

- 5006 Controller - 1Document2 pages5006 Controller - 1pawanmandeep2012No ratings yet

- Payload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotDocument2 pagesPayload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotRuben AlvaradoNo ratings yet

- 1964 - SJ 201 301Document16 pages1964 - SJ 201 301Jose Ignacio CastilloNo ratings yet

- Ehb-300g++ & 3000G++Document1 pageEhb-300g++ & 3000G++Eong Huat Corporation Sdn BhdNo ratings yet

- TouchscreenDocument2 pagesTouchscreenRanadurjoy GhoshNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- SJP - Laser - Presentation - New 14 VersionDocument20 pagesSJP - Laser - Presentation - New 14 VersionSharmishta AngreNo ratings yet

- VWPage 2Document2 pagesVWPage 2Sharmishta AngreNo ratings yet

- SJP Plastic Laser Welding PresentationDocument12 pagesSJP Plastic Laser Welding PresentationSharmishta AngreNo ratings yet

- Hiq-Logic SeriesDocument7 pagesHiq-Logic SeriesSharmishta AngreNo ratings yet

- 35kHz 900W Hand Welding Machine Data SheetDocument3 pages35kHz 900W Hand Welding Machine Data SheetSharmishta AngreNo ratings yet

- 35kHz K745 AdvancedDocument1 page35kHz K745 AdvancedSharmishta AngreNo ratings yet

- SJP Make 15kHz 2600W Ultrasonic Welding Machine DatasheetDocument2 pagesSJP Make 15kHz 2600W Ultrasonic Welding Machine DatasheetSharmishta AngreNo ratings yet

- 20k 3000watt Ultrasonic Plastic Welding Machine-Digital - SE-DS300 - 1Document4 pages20k 3000watt Ultrasonic Plastic Welding Machine-Digital - SE-DS300 - 1Sharmishta AngreNo ratings yet

- 16 L745 Standard Machine Data SheetDocument1 page16 L745 Standard Machine Data SheetSharmishta AngreNo ratings yet

- SJP Catalogue Speed and GrowthDocument12 pagesSJP Catalogue Speed and GrowthSharmishta AngreNo ratings yet

- Skylab 3 PAO Mission Commentary 3 of 6Document851 pagesSkylab 3 PAO Mission Commentary 3 of 6Bob AndrepontNo ratings yet

- Inspyrus - White PaperDocument8 pagesInspyrus - White PaperBayCreativeNo ratings yet

- GRIT221 Fundamentals of Business Analytics: I. ObjectivesDocument3 pagesGRIT221 Fundamentals of Business Analytics: I. ObjectivesnaspuloyNo ratings yet

- Obo Commissioning 9Document75 pagesObo Commissioning 998257002No ratings yet

- Instrument PanelDocument7 pagesInstrument Panelindrajith.meNo ratings yet

- 57e4d64a5ae56 1317890 SampleDocument32 pages57e4d64a5ae56 1317890 Samplemanaswini sharma B.G.100% (2)

- Consolidated Terminals Inc. v. Artex - G.R. No. L-25748Document1 pageConsolidated Terminals Inc. v. Artex - G.R. No. L-25748eiram23No ratings yet

- Wget - Curl Large File From Google Drive - Stack OverflowDocument29 pagesWget - Curl Large File From Google Drive - Stack OverflowManoj KamisettiNo ratings yet

- CHAPTER 10 One and Two Bar Price PatternDocument21 pagesCHAPTER 10 One and Two Bar Price Patternnurul zulaikaNo ratings yet

- Tutorial Letter 203/2/2017: General Chemistry 1BDocument18 pagesTutorial Letter 203/2/2017: General Chemistry 1BLeigh MakanNo ratings yet

- 37 Nyquist Criterion For Zero ISIDocument3 pages37 Nyquist Criterion For Zero ISIJGS MAGICALNo ratings yet

- Sulphate Attack in Concrete and Its PreventionDocument21 pagesSulphate Attack in Concrete and Its PreventionvempadareddyNo ratings yet

- .. Thesis Title .Document31 pages.. Thesis Title .Tanut VongsoontornNo ratings yet

- At The End of The Lesson, The Students Will Be Able To Apply The Indefinite Articles in The Given SentencesDocument11 pagesAt The End of The Lesson, The Students Will Be Able To Apply The Indefinite Articles in The Given SentencesRhielle Dimaculangan CabañezNo ratings yet

- Level 1 Workbook (Complete Ielts Bands 4-5)Document66 pagesLevel 1 Workbook (Complete Ielts Bands 4-5)Hồng ThưNo ratings yet

- CANBUSDocument18 pagesCANBUSSamuel SimbolonNo ratings yet

- PreTest Electronics 2022Document2 pagesPreTest Electronics 2022Joan VillarcaNo ratings yet

- CASE REPORT Vertigo PutriDocument20 pagesCASE REPORT Vertigo PutriRizqina PutriNo ratings yet

- Anatomy and Histology of The Cardiovascular SystemDocument16 pagesAnatomy and Histology of The Cardiovascular SystemTasmiah HossainNo ratings yet

- Protocol Germ CellDocument82 pagesProtocol Germ CellTanh NguyenNo ratings yet

- Ireland Climate Action Plan 2024Document7 pagesIreland Climate Action Plan 2024Fursey WhyteNo ratings yet

- Magaso v. COA - Jan 2023 - Full TextDocument7 pagesMagaso v. COA - Jan 2023 - Full TextSam LeynesNo ratings yet

- PO-04 Drug-Free Workplace Policy 4.15.2019Document16 pagesPO-04 Drug-Free Workplace Policy 4.15.2019Matt ThomasNo ratings yet

- Technical SpecificationDocument14 pagesTechnical SpecificationbinodeNo ratings yet

- Brunswick Manual Preinstalacion GSXDocument33 pagesBrunswick Manual Preinstalacion GSXroberto dominguezNo ratings yet

- Confidence Siswa Sma Dalam Materi Peluang: Analisis Kemampuan Kemampuan Penalaran Dan SelfDocument8 pagesConfidence Siswa Sma Dalam Materi Peluang: Analisis Kemampuan Kemampuan Penalaran Dan SelfAfifah R. AminiNo ratings yet