Professional Documents

Culture Documents

Positions

Positions

Uploaded by

thomasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Positions

Positions

Uploaded by

thomasCopyright:

Available Formats

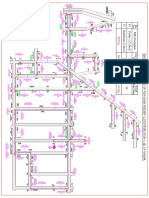

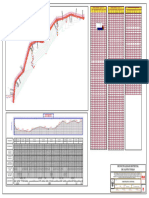

WELDING POSITIONS

ACCORDING TO DIN EN ISO 6947: 2011-08

pipe rotating

plate flat position

flat position (1FR*)

(1F*)

plate

pipe fixed

horizontal vertical position

vertical down position

(2F*)

(5F downhill*)

pipe fixed

horizontal vertical position

(2F*)

pipe fixed

vertical up position

(5F uphill*)

plate

flat position pipe rotating

(1G*) pipe rotating horizontal vertical position

flat position (2FR*)

(1G*)

pipe fixed

vertical down

position

(5G downhill*)

pipe fixed

vertical up

position

J-L045 (5G uphill*)

pipe fixed

inclined position

welding downwards plate

(6G downhill*) horizontal position

plate

horizontal position

(2G*)

H-L045 pipe fixed

pipe fixed horizontal position

inclined position (2G*)

welding upwards

(6G uphill*)

plate

vertical down

position

(3G downhill*)

plate

vertical up

position

(3G uphill*)

ds

el

plate

tt w

overhead position

(4G*) bu

plate

horizontal overhead position

(4F*)

plate

vertical down position

(3F downhill*)

pipe fixed

horizontal overhead position

el ds (4F*)

plate

vertical up position fillet w

(3F uphill*)

plate

overhead position

* Welding position according to AWS A3.0 and ASME Section IX

© DVS Media GmbH, Düsseldorf

ww w. bin zel -a b i cor . com www.lorch-cobot-welding.com/en

BOeHL-W19009_Boehler_UTP-Logos-115x55-DVS.indd 1 04.04.19 14:45

Issue

020419

Issue

05

2019

1919

2019

Perfecthancing

Chargin

g

technology!”

r Ene

“En

rgy /

/ Sola

ding

ect Wel

M

D 15 M

/ Perf

TT WEL Schweisstec

-V BU DING

Visit us at

er 2019

5-8 Novemb

SINGLE PASS WELN R ATE

t/Germany

in Stuttgar

7413

Hall 7, booth

LE O

Get your free issue!

SING DEPOSITI OUR. Pioneers

WITH KG PER H

of Welding

.

Technology

OF 20

.

For 100 years

– that‘s

technology

Enhancing

at CLOOS have

The job market for the branch.

what the people They

for 100 years.

been doing

g work every

achieve pioneerin

s your

innovative

day when creating d

e?

flexibly configure

What‘ g challeng

solutions for

sources and

welding power

e, automated

highly integrativ

weldin

systems.

nted welding

track-mou

www.tuev-nord.de

. story with

a future.

nnected

CLOOS – a

t co 100.cloos.de

www.welding-and-cutting.info

Let‘s ge

www.home-of-welding.com/jobportal

ius. ns

erfectio

Cutting 5/2019

of Fron

system d imp current

Push e of wel h and

TWIN

15:27:20

TPS/i Influenc ue strengt elines 25.09.2019

guid

ut the on fatig t design

9

viability

g 4/201

e abo economic

Welding and

in

out mor m/pw/tw ding

and

for relevan Raising the ire

Find

onius.co wet wel trodes arc single-w

ater of submerged

Cuttin

ww w.fr

1 ater k elec dimens t 1 ional underw

Underw with stic Large

s_EN.indd

r_TitelW+C_

Messehinwei

s - Par for repair and processes

lication arc stud welds

ng and

J_210x185+3

100Jahre_AC

with liquid

cutt ing drawn

cturing e app es

Additive gy in use

manufa

offshor maintenance

measur

Weldi

technololarg ls est

beam materia ld's

Electron in the wor

R

at ITE project

research

BOeHL-W19009_Boehler_UTP-Logos-115x55-DVS.indd 2 04.04.19 14:45

Anzeige.indd 1 28.07.11 14:18

You might also like

- Bản Sao Của DOWNYDocument50 pagesBản Sao Của DOWNYDuy AnhNo ratings yet

- ABC Risk ClassificationDocument1 pageABC Risk ClassificationdocsenNo ratings yet

- Cziffra-Verdi Il TrovatoreDocument24 pagesCziffra-Verdi Il Trovatore김민규100% (3)

- Sousa-Horowitz - Stars and Stripes ForeverDocument14 pagesSousa-Horowitz - Stars and Stripes ForeverEdward Lee100% (2)

- A1 - Detalii de Armare Radier R1Document1 pageA1 - Detalii de Armare Radier R1Andrei Kovacs100% (1)

- BPR For Oil and Gas ConstructionDocument6 pagesBPR For Oil and Gas ConstructionMOORTHY.KENo ratings yet

- TrommelDocument2 pagesTrommelÁlvaro BarbosaNo ratings yet

- Anand Kasaudhan Assignment 1Document1 pageAnand Kasaudhan Assignment 1Anand KasaudhanNo ratings yet

- Bathroom Elevation Alma PDFDocument1 pageBathroom Elevation Alma PDFRoopakNo ratings yet

- The Bee Full Score F. SchubertDocument3 pagesThe Bee Full Score F. SchubertMaria Figa VaelloNo ratings yet

- Shop Drawings For Door Detail, Door Type-FHC FHC Door (Mezz. Floor) Non Fire Rated Door Tower-02-BDocument2 pagesShop Drawings For Door Detail, Door Type-FHC FHC Door (Mezz. Floor) Non Fire Rated Door Tower-02-BSilajit Rony DasguptaNo ratings yet

- Table - : WidthDocument1 pageTable - : WidthTABIBI11No ratings yet

- Construction Drawing: Boundary Line Boundary Line Boundary LineDocument1 pageConstruction Drawing: Boundary Line Boundary Line Boundary LinerajavelNo ratings yet

- Section A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesDocument1 pageSection A-A Section B-B Section A-A Section B-B: E-Glass/Carbon NotesProfessor PuppiesNo ratings yet

- SF 42 FP FP SF P: Hungarian Dance No. 21Document1 pageSF 42 FP FP SF P: Hungarian Dance No. 21ArjunJethwaNo ratings yet

- Typical One Way Slab Details: Chair BarDocument1 pageTypical One Way Slab Details: Chair BarJaybert DumaranNo ratings yet

- Giant Map TM 2023Document1 pageGiant Map TM 2023evih646No ratings yet

- L2 (磚架)Document1 pageL2 (磚架)Suntech Testing Limited STLNo ratings yet

- 2021 Cyberthum GroundDocument1 page2021 Cyberthum GroundPKCL027 Rishabh JainNo ratings yet

- Wingspan Transition Section Charts V2.0Document2 pagesWingspan Transition Section Charts V2.0constantinescuana200No ratings yet

- GF Joineries - Scope of WorksDocument3 pagesGF Joineries - Scope of Workscoybit.functionsmithNo ratings yet

- As BUILT 0131888 LM Colegio Inmaculada A02Document1 pageAs BUILT 0131888 LM Colegio Inmaculada A02nioc19No ratings yet

- Mz-04-00001-00-05-Ar-Aed-Dg-011209 (03) - Mzfw-Elevations Part 5 - 1Document1 pageMz-04-00001-00-05-Ar-Aed-Dg-011209 (03) - Mzfw-Elevations Part 5 - 1AMR ABDALHNo ratings yet

- Planos de VeredaDocument1 pagePlanos de VeredaRonar RodriguezNo ratings yet

- Workshop 2Document1 pageWorkshop 2Thamarai kannan SrinivasanNo ratings yet

- Midship Section: General ArrangementDocument1 pageMidship Section: General Arrangementmaritim2k16No ratings yet

- Electrical Schematic (1/6) : Pub. No. 99719 - 6M110Document6 pagesElectrical Schematic (1/6) : Pub. No. 99719 - 6M110sales Redforklifts75% (4)

- Telecom Map CentralDocument1 pageTelecom Map Centralloc khaNo ratings yet

- Am Een A Cli Nic Viy Eng Ar Bak Ery: Va Ca NT La ND Ol DP Ap Er ST or eDocument1 pageAm Een A Cli Nic Viy Eng Ar Bak Ery: Va Ca NT La ND Ol DP Ap Er ST or eNagamani ManiNo ratings yet

- Dog Wash - Roof Plan Dog Wash - First Floor Plan: Golf CartDocument1 pageDog Wash - Roof Plan Dog Wash - First Floor Plan: Golf CartJhamir Bravo LandaNo ratings yet

- Utilaje Depozite Frigorifice Compresor Tip 1 Compresor Tip 2Document1 pageUtilaje Depozite Frigorifice Compresor Tip 1 Compresor Tip 2Anda Angheluș PetrescuNo ratings yet

- 15341-1 TopDocument1 page15341-1 TopBruno VastayaNo ratings yet

- Chincholi FootingDocument1 pageChincholi FootingAmey MorankarNo ratings yet

- AUDITORIUM - zone02-GA MARKUPS& REINF-2 - 101Document1 pageAUDITORIUM - zone02-GA MARKUPS& REINF-2 - 101Omer HayatNo ratings yet

- Site Office PlansDocument9 pagesSite Office Plansfrancisco riveraNo ratings yet

- Logistic Warehouse - Drainage Schematic ServiceDocument1 pageLogistic Warehouse - Drainage Schematic ServiceWuillNo ratings yet

- PS106042 - Ground Floor Slab Detail PDFDocument1 pagePS106042 - Ground Floor Slab Detail PDFTasi ZafirNo ratings yet

- SVT3 Pro - CopieDocument63 pagesSVT3 Pro - CopieBernard Joseph CalteauNo ratings yet

- 5m100 mh99719 5m100schemDocument6 pages5m100 mh99719 5m100schemMagoraNo ratings yet

- prancha-PRANCHA 4 - DET - BLOCOS E BALDRAMEDocument1 pageprancha-PRANCHA 4 - DET - BLOCOS E BALDRAMEPhelipe AlmeidaNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Roof Level Ga PlanDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Roof Level Ga PlanhemanthsridharaNo ratings yet

- Loader 3Document1 pageLoader 3anabasim919No ratings yet

- Formulaire GMRT 1Document1 pageFormulaire GMRT 1martaNo ratings yet

- Zamboanga Pet Line 110419Document1 pageZamboanga Pet Line 110419PAul JoHn MeNdozaNo ratings yet

- Schematics Xt1965 LaDocument66 pagesSchematics Xt1965 LasetrabporciunculaNo ratings yet

- Schedule of Columns NTS: Scale:: Beam Reinforcements and Schedules Beam Reinforcements and SchedulesDocument1 pageSchedule of Columns NTS: Scale:: Beam Reinforcements and Schedules Beam Reinforcements and Schedulesdomin domNo ratings yet

- Legend: (OTS) (OTS) (OTS) (OTS)Document1 pageLegend: (OTS) (OTS) (OTS) (OTS)Cristo BglezNo ratings yet

- Progetti - S05 - 10022020-A10 - 2 (E)Document1 pageProgetti - S05 - 10022020-A10 - 2 (E)Nevena IlicNo ratings yet

- 5 Styles For Piano (2006) - 230113 - 094805Document10 pages5 Styles For Piano (2006) - 230113 - 094805Sarah SNo ratings yet

- COMPONENT LOCATION - XT1965 - Top PDFDocument1 pageCOMPONENT LOCATION - XT1965 - Top PDFNando ParraNo ratings yet

- NCC PSB Db03 Ch2a DWG Ar 1301 r0c Opt1Document1 pageNCC PSB Db03 Ch2a DWG Ar 1301 r0c Opt1Pradeep GoudaNo ratings yet

- Pmi 635Document3 pagesPmi 635api-3703813No ratings yet

- 10393565Document2 pages10393565Jackson3006No ratings yet

- Vista en Planta Detalles de Instalacion: Plant View Installation DetailsDocument1 pageVista en Planta Detalles de Instalacion: Plant View Installation DetailsDulce victoria MorenoNo ratings yet

- Esr 18 Mahulpali 520kl 23m - RCDocument4 pagesEsr 18 Mahulpali 520kl 23m - RCGopal SinghNo ratings yet

- A3 Floor Plans - WhatsappDocument9 pagesA3 Floor Plans - WhatsappOm WalunjNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Ga PlanDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Ga PlanhemanthsridharaNo ratings yet

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkNo ratings yet

- Solo JR - Victor Raul-Iso A1 FullDocument1 pageSolo JR - Victor Raul-Iso A1 FullEmerson Aldair Monsalve DíazNo ratings yet

- McDonald's PlansDocument25 pagesMcDonald's PlansDennis CarmodyNo ratings yet

- STrategic Management AssignmentDocument7 pagesSTrategic Management AssignmentYvhl NarasimharaoNo ratings yet

- Introduction To Operations and Supply Chain Management 5th Edition Bozarth Test BankDocument33 pagesIntroduction To Operations and Supply Chain Management 5th Edition Bozarth Test Bankchihungqo9td5100% (35)

- Embracing The Power of Social Media For Broadcast Business InsightDocument6 pagesEmbracing The Power of Social Media For Broadcast Business InsightCognizantNo ratings yet

- Lowe'S - Brand Strategy AnalysisDocument10 pagesLowe'S - Brand Strategy AnalysisLouis JacquotNo ratings yet

- RMK Group A4 PPT MT-I (UNIT-I)Document82 pagesRMK Group A4 PPT MT-I (UNIT-I)Rajmchz100% (1)

- Ict Implementation in Governance PDFDocument11 pagesIct Implementation in Governance PDFkomallotulkarNo ratings yet

- F2.1-Management Accounting (Answ) August 2023Document19 pagesF2.1-Management Accounting (Answ) August 2023jbah saimon baptisteNo ratings yet

- Advertising and Sales Promotion: Dharmendra Pandey Amity University NoidaDocument52 pagesAdvertising and Sales Promotion: Dharmendra Pandey Amity University Noidadpandey82No ratings yet

- Mec205 Manufacturing TechnologyDocument6 pagesMec205 Manufacturing TechnologyDeedar SinghNo ratings yet

- Compatibility of PaintsDocument1 pageCompatibility of Paintslonglong3003100% (1)

- Retail Store Format Quiz ..Document2 pagesRetail Store Format Quiz ..Christian DuatNo ratings yet

- E-Crm of Bajaj AutoDocument20 pagesE-Crm of Bajaj AutoHiralal Mistry0% (1)

- A536-84 R14 Ductile Iron CastingsDocument6 pagesA536-84 R14 Ductile Iron CastingsLalit Bom MallaNo ratings yet

- Case Study 3 Railroad - AnswersDocument7 pagesCase Study 3 Railroad - AnswersMahesh GunasenaNo ratings yet

- DSQ Dossier.Document62 pagesDSQ Dossier.suria qaqcNo ratings yet

- Sunguard GlassDocument8 pagesSunguard GlassfasfasasNo ratings yet

- Objectives of The StudyDocument3 pagesObjectives of The StudyShruthika RNo ratings yet

- Tool and MoldDocument4 pagesTool and MoldWilmar MattesNo ratings yet

- Graham Process MappingDocument5 pagesGraham Process MappinggacvdoconNo ratings yet

- Apqp Workflow - EXAMPLEDocument1 pageApqp Workflow - EXAMPLEMiguel NetoNo ratings yet

- Full Annealing Full Annealing Is The Process of Slowly Raising The Temperature About 50Document10 pagesFull Annealing Full Annealing Is The Process of Slowly Raising The Temperature About 50scorpionarnoldNo ratings yet

- Essentials of Services Marketing 4 The Dition SamplerDocument138 pagesEssentials of Services Marketing 4 The Dition SamplerSyeda MahvishNo ratings yet

- Material ControllerDocument5 pagesMaterial ControllermctmcNo ratings yet

- Supply Chain Management Assignment Domino's Pizza: Section IM B: GROUP 9Document17 pagesSupply Chain Management Assignment Domino's Pizza: Section IM B: GROUP 9shailesh khotNo ratings yet

- Lean Implementati ON: Dr. Muhammad JunaidDocument17 pagesLean Implementati ON: Dr. Muhammad Junaidjunaid aliNo ratings yet

- Marking SchemeDocument8 pagesMarking Schememohamed sajithNo ratings yet