Professional Documents

Culture Documents

tm1tEMPLATES MTF

tm1tEMPLATES MTF

Uploaded by

Analeen NolascoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

tm1tEMPLATES MTF

tm1tEMPLATES MTF

Uploaded by

Analeen NolascoCopyright:

Available Formats

Maintain

Training

Facilities

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

DIFFERENT FORMS USED IN MAINTAINING TRAINING

FACILITIES

Forms No. Title

1…………………………………HOUSEKEEPING SCHEDULE

2…………………………………EQUIPMENT MAINTENANCE SCHEDULE

3…………………………………HOUSEKEEPING INSPECTION CHECKLIST

4…………………………………EQUIPMENT MAINTENANCE INSPECTION

CHECKLIST

5…………………………………WASTE DISPOSAL PLAN

6…………………………………EQUIPMENT RECORD W/ CODE AND

DRAWING

7…………………………………TAG-OUT INDEX CARD

8…………………………………BREAK DOWN REPAIR REPORT

9…………………………………INSPECTION REPORT

10……………………………….WORK REQUEST

11……………………………….PURCHASE REQUEST

12……………………………….SALVAGE REPORT

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

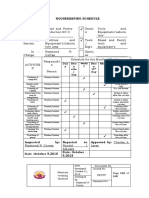

Form No.1

HOUSEKEEPING SCHEDULE

Qualification Dressmaking NC-II

Area/section Practical Work Area

In-Charge Analeen S. Nolasco

Schedule for the Month of July 2020

ACTIVITIES Responsibl Daily Every Weekly Every Monthly Remarks

other 15th

e Person day Day

Cleaning of the Trainer/ every

after

floor and Trainee

session

windows

Checking of the Trainer/ before

session

working place Trainee

ventilation

Cleaning, Trainer/

inspecting of Trainee

ceiling, windows

pane and walls

Cleaning of Trainer/ before

and

cutting table Trainee

after

session

Checking of the Trainer/

cutting tools, Trainee before

shaping tools, and

and measuring after

tools pinning session

tools

Organizing the Trainer/ every

cutting tools, Trainee after

shaping tools, session

pinning tools and

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

measuring tools

Checking of the Trainer/ Daily/

before

sewing machines Trainee

and

if well-

after

functioning

session

Cleaning the Trainer/ Daily/

before

sewing machines Trainee

and

free from dust

after

and dirt

session

Preparing the Trainer/ Daily/

before

sewing machines Trainee session

for training

Cleaning and Trainer/ Weekly

lubricate the Every

Trainee

inside of the Friday

sewing machines

Checking light Trainer/ Daily/

before

source if it is Trainee session

function well

Arranging Trainer/ Daily/

before

and cleaning Trainee

and

the tables

after

and chairs

session

Sanitizing Trainer/ Daily/

every

the comfort Trainee

after

Room

session

Waste Trainer/ Daily/

every

disposal Trainee

after

(segregation)

session

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Checking the Trainer/ Daily/

before

function of Trainee session

the water

dispenser

and the cord

and the male

plug

Checking the Trainer/ Daily/

before

function of the Trainee session

LCD

projector/wide

screen

Checking the Trainer/ Daily/

before

computer set. Trainee session

wiring, CPU,

keyboard and

AVR

To be included:

Training equipment

Audio visual

Computer set

Air conditioning

Support equipment

Fax machine

Photo copier

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

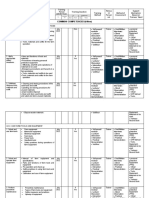

Form No. 2

EQUIPMENT MAINTENANCE SCHEDULE

EQUIPMENT TYPE Single Needle/Edging/Four Threads/Button

Holler/ Cutting Machine

EQUIPMENT CODE 2023-SN01 – SN04/2023-OL05 – 06/ 2023-FT07

– 08 / 2023- BH09/ 2023- CM-010

LOCATION Practical Work Area

Schedule for the Month of July 2023

Daily Every Weekly Every Monthly Remarks

ACTIVITIES MANPOWER other 15th

day Day

Wipe out dust Trainer/ Daily/

from the Trainee before

external parts of session

the sewing

machine

Check the Trainer/ before

sewing machine Trainee session

if it is in good

condition

Check and Trainer/

inspect the Trainee

power switch of

the sewing

machine

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Check and Trainer/

Clean the inside Trainee

of the sewing

machine

Checking the oil Trainer/

level of the Trainee

sewing machine

Cleaning the Trainer/ Daily/

Cutting Trainee before

Machine’s blade session

Checking of the Trainer/ Daily/

sewing Trainee before

machine’s motor session

sound/smell

Checking of the Trainer/ Daily/

sewing Trainee before

machines parts session

(rewinder, pump

belt, electrical

cords, male plug

Special Instruction: For safety of trainee’s this scheduled

maintenance must be done before daily activities started.

Trainer:

Arthuro G. Ramos

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Form No.3

HOUSEKEEPING INSPECTION CHECKLIST

EQUIPMENT TYPE Single Needle/Edging/Four Threads/Button

Holler/ Cutting Machine

EQUIPMENT CODE 2023-SN01 – SN04/2023-OL05 – 06/ 2023-FT07

– 08 / 2023- BH09/ 2023- CM-010

LOCATION Practical Work Area

YES NO

1. Are the sewing machines cleaned after daily

use?

2. Are the sewing s accessories complete and

segregated?

3. Are the sewing tools and cutting are checked

for any damage??

4. Are the sewing tools are properly arranged in

their designated box?

5. Are the sewing machines checked after every

session?

6. Are all the machine and equipment’s in the

room are unplug from the socket?

7. Are the designated area cleaned every after

session?

8. Are the waste materials are disposed

properly?

9. Are the windows are properly close?

10. Are the other supporting equipment in the

area are properly arrange?

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Remarks: The practical work area is properly maintain, and

ready for the next session.

Inspected by: Analeen S. Nolasco

Date: August 5, 2023

Form No. 4

EQUIPMENT MAINTENANCE INSPECTION CHECKLIST

Equipment Type Single Needle/Edging/Four Threads/Button

Holler/ Cutting Machine

Property Code/Number 2023-SN01 – SN04/2023-OL05 – 06/ 2023-

FT07 – 08 / 2023- BH09/ 2023- CM-010

Location Practical Work Area

Trainer In –Charge Analeen S. Nolasco

YES NO INSPECTION ITEMS

Is the power switch is check or inspect for stability?

Is the sewing machine’s parts are properly checked

/inspect. (lights/belt/winder/electrical cord)

Is the sewing machine’s motor are properly working?

Free from unwanted sounds and smell?

Is the sewing machine in good sewing condition?

Are the external parts of the sewing machine are wipe

out from dust?

Is the internal part of the sewing machines are

I cleaned?

Is the sewing machine cleaned from the inside?

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Is the oil level of the sewing machine checked?

Remarks: In good working condition

Inspected by: Danny Werble

Date: August 05, 2023

Form No. 5

WASTE DISPOSAL PLAN

Qualification NCII Dressmaking

Area/Section Practical Work area

In-Charge Analeen S. Nolasco

GENERAL ACCUMULATED WASTE SEGREGATION METHOD

WASTES

Recycle Compose Dispose

Cloth fragment

Broken needle/ pins

Plastic Cones

Threads fragments

Broken ripper

Paper fragments

Broken tailors chalk

Broken tape measure

Dull Scissors

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Dull Blades

Schedule of Disposal (Daily,

Weekly Weekly Weekly

Weekly, Monthly)

Mode of Disposal (Selling, Selling/

Donation, or thru Waste Donation Donation

Disposal Plant

Form No. 6

EQUIPMENT RECORD W/CODE AND DRAWING

No Loca Equip Quanti Title Description PO. No. Drawi

. tion ment ty ng

No. Ref.

1. PWA Sewing Single Needle 181921 pi. 0.1

SN01 4

01 Machine

2. = Sewing Edging/ 181921 Pi.

PWA OL002 2 Machine Three 0.02

01 Threads

3. PWA Sewing Button Holler 181921 Pi. 003

BH003 1

01 Machine

4. PWA Cutting For Cutting 181921 Pi. 004

CM004 1

01 Machine

5. PWA Sewing Four Threads 181921 Pi. 005

FT004 2

01 machine

6.

7.

8.

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

9

10

NOTES: SN ( Single Needle) FT (four thread)

OL ( Over Lock/Edging)

BH ( Button Holler)

CM ( Cutting Machine)

Form No. 7

TAG-OUT INDEX CARD

LOG DATE TYPE DESCRIPTION

SERIAL ISSUED

(Danger/Caution) (System Components,

Test Reference, etc.

2023- July 13, caution Broken rotating

SN01 2023

2023- July 13, caution Broken Looper

OL05 2023

2023- July 14 Danger Broken Fuse

SN03

2023- July 13 Caution Dull Blade

CM010

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Form No. 8

BREAKDOWN /REPAIR REPORT

Property ID Number: 2023- SN01

Property Name: Single Needle

Location: PWA01

Findings:

Broken Rotating

Inspected by: Reported to:

Analeen S. Nolasco Arthuro G. Ramos

Date: Date:

August 06, 2023 August 06, 2023

Subsequent Action Taken: Recommendation:

Immediate repair/replacement Repair/ Replacement rotating

By Technician: Reported to:

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Danny Werble Arthuro G. Ramos

Date: Date:

August 06, 2023 August 06, 2023

Form No. 8

BREAKDOWN /REPAIR REPORT

Property ID Number: 2023-SN03

Property Name: Single Needle

Location: PWA

Findings:

Broken Fuse

Inspected by: Reported to:

Analeen S. Nolasco Arthuro G. Ramos

Date: Date:

August 06, 2023 August 06 2023

Subsequent Action Taken: Recommendation:

Immediate repair/replacement Repair/ Replacement fuse

By Technician: Reported to:

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Danny Werble Arthuro G. Ramos

Date: Date:

August 06, 2023 August 06, 2023

Form No. 8

BREAKDOWN /REPAIR REPORT

Property ID Number: 2023-OL05

Property Name: Over lock/ Edging/Three Threads

Location:PWA01

Findings:

Broken Looper

Inspected by: Reported to:

Analeen S. Nolasco Arthuro G. Ramos

Date: Date:

August 07, 2023 August 07, 2023

Subsequent Action Taken: Recommendation:

Immediate repair/replacement Repair/ Replacement looper

By Technician: Reported to:

Danny Werble Arthuro G. Ramos

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Date: Date:

August 07, 2023 August 07, 2023

Form No. 8

BREAKDOWN /REPAIR REPORT

Property ID Number: 2023-CM010

Property Name: Cutting Machine

Location:PWA01

Findings:

Dull Blade

Inspected by: Reported to:

Analeen S. Nolasco Arthuro G. Ramos

Date: Date:

August 07, 2023 August 07, 2023

Subsequent Action Taken: Recommendation:

Immediate repair/replacement Repair/ Replacement Blade

By Technician: Reported to:

Danny Werble Arthuro G. Ramos

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Date: Date:

August 07, 2023 August 07, 2023

Form No. 9

INSPECTION REPORT

Property ID Number 2023-SN02 – 04 /2023-OL06/

2023-FT07 – 08 / 2023- BH09/

2023- CM-010

Property Name Single Needle/Edging/Four

Threads/Button Holler/ Cutting

Machine

Location Practical Work Area

Findings: Recommendation:

In Good working condition All machines are safe and in good

working condition and ready for use

in the training.

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Inspected by: Reported to:

Danny Werble Arthuro G. Ramos

Date: Date:

August 13, 2023 August 13, 2023

Form No. 10

WORK REQUEST

Unit Description

Sewing Machine Single needle

Observation/s Date Reported:

Jump Stitch/ bubbles August 13, 2023

stitch

Reported by:

Analeen Nolasco

Activity: Date completed:

Repair the rotating August 14, 2023

Signature:

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Spare parts used:

Rotating

Form No. 10

WORK REQUEST

Unit Description

Sewing Machine Single needle

Observation/s Date Reported:

Smoke coming from August 13, 2023

the sewing motor/ foul

Smell Reported by:

Analeen Nolasco

Activity: Date completed:

Replace Fuse August 14, 2023

Signature:

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Spare parts used:

Fuse

Form No. 10

WORK REQUEST

Unit Description

Sewing Machine Over lock/ Edging

Observation/s Date Reported:

Looper accidentally August 13, 2023

broke, due to stack

fabrics on the sewing Reported by:

machines

Analeen Nolasco

Activity: Date completed:

Replace Looper August 14, 2023

Signature:

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Spare parts used:

Looper

Form No. 10

WORK REQUEST

Unit Description

Cutting Machine Round knife

Observation/s Date Reported:

Fabrics stuck to its August 13, 2023

blade/ grinder doesn’t

workig Reported by:

Analeen Nolasco

Activity: Date completed:

Repair grinder August 14, 2023

Signature:

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Spare parts used:

grinder

Form No. 11

PURCHASE REQUEST

TECHNICAL EDUCATION AND SKILLS DEVELOPMENT

AUTHORITY

Gate 1 TESDA Complex, East Service Road, South Luzon Expressway,

Taguig City

Office/Div./Section: PR No.:_______Date:

Qty. Unit of Issue Item Estimated Estimated

Description Unit Cost Total Cost

10 packs needle 70 700

2 Box Tailors 240 480

chalk

1 Box Tape 310 310

measures

3 box Push pins 220 660

5 Pcs scissors 220 1100

10 pcs Clutch 75 750

lining

TOTAL Php.3,000

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

Purpose NCII – Dressmaking

Requested by: Approved by:

Signature:

Printed Analeen S. Nolasco

Name:

Trainor PTC- Director

Designation

NOTE: 1. Unit Cost are optional unless the requisitioning office is aware of

the estimated market cost.

2. All information required must duly provide.

Form No. 12

SALVAGE REPORT

AREA / SECTION Practical Work Area

IN-CHARGE Danny Werble

FACILITY TYPE PART ID RECOMMENDATION

Sewing motor SN-181921-23 Forwarded to the stock

room for future use

Belt SN-101212-23 Forwarded to the stock

room for future use

Rotating SN-828311-23 Forwarded to sewing

mechanics for repair

Needle plate OL-401139-23 Forwarded to the stock

room for future use

Cutting Blade CM-121983-23 Forwarded to sewing

mechanics for grinding

Sewing Pedal SN-102183-23 Forwarded to the stock

room for future use

Used Oil All machine Forwarded to the stock

room for future use

Date Developed: Document No.

Issued by:

JULY 13, 2023

DRESSMAKING Page 1 to 23

NC-II Developed by: PTC Basilan

ANALEEN S. NOLASCO Revision # 01

You might also like

- Maintain Training Facilities: Driving NC 11 Document No. Issued By: Page 1 of 13Document12 pagesMaintain Training Facilities: Driving NC 11 Document No. Issued By: Page 1 of 13Cherry Mae Claire Villanueva-Gomez80% (5)

- Induction & On The Job TraningDocument6 pagesInduction & On The Job TraningDhananjay Patil100% (1)

- Pfaff 1183 Service ManualDocument46 pagesPfaff 1183 Service Manualmedellin100No ratings yet

- Maintain Training FacilitiesDocument10 pagesMaintain Training Facilitiessandy c lasaNo ratings yet

- 1 Housekeeping Schedule (DONE)Document3 pages1 Housekeeping Schedule (DONE)Vine Kasim-DitanNo ratings yet

- MTF CLabadanDocument14 pagesMTF CLabadanDanica HerealwaysNo ratings yet

- Housekeeping ScheduleDocument3 pagesHousekeeping ScheduleByron AbelitaNo ratings yet

- MTF Jasrah AbdulaDocument18 pagesMTF Jasrah AbdulaJasrah Weesam100% (1)

- Don Bosco TVET Center-Calauan IncDocument3 pagesDon Bosco TVET Center-Calauan IncJuliet N. Coronado100% (1)

- MTF Template TM1Document13 pagesMTF Template TM1Gina LimNo ratings yet

- TC - Admin - Sales Audit Clerk PDFDocument2 pagesTC - Admin - Sales Audit Clerk PDFW055 ADMNo ratings yet

- 3 MTF Equipment Maintenance ScheduleDocument1 page3 MTF Equipment Maintenance ScheduleJhenalyn MagsipocNo ratings yet

- Facilitate Learning SessionDocument7 pagesFacilitate Learning Sessionroselyn ayensaNo ratings yet

- 1 Housekeeping Schedule FinalDocument1 page1 Housekeeping Schedule FinalGuada LupeNo ratings yet

- Maintain Training Facilities: Housekeeping ScheduleDocument15 pagesMaintain Training Facilities: Housekeeping ScheduleMichelle CamineroNo ratings yet

- Workbased Learning - TemplateDocument12 pagesWorkbased Learning - TemplateJezon CasqueteNo ratings yet

- MTF 9 Form Sample For FBSDocument6 pagesMTF 9 Form Sample For FBSJellane SeletariaNo ratings yet

- Workbased Learning - TemplateDocument11 pagesWorkbased Learning - Templatekurapota100% (1)

- Northlink: Technological CollegeDocument2 pagesNorthlink: Technological CollegeRienard BravoNo ratings yet

- Trainee'S Record Book: Technical Education and Skills Development Authority (Your Institution)Document17 pagesTrainee'S Record Book: Technical Education and Skills Development Authority (Your Institution)Ronald Dequilla PacolNo ratings yet

- 02 Equipment Maintenance Schedule - OkDocument1 page02 Equipment Maintenance Schedule - OkJovemer AgudoNo ratings yet

- MTF (Cuajotor) RevisedDocument14 pagesMTF (Cuajotor) RevisedvirginiacuajotorNo ratings yet

- Alexander Lucero MTF NewDocument13 pagesAlexander Lucero MTF NewKemerutNo ratings yet

- Form Training Record 2Document6 pagesForm Training Record 2Dewi Hijriani Sekar NingtyasNo ratings yet

- 04 SWL TemplateDocument25 pages04 SWL TemplateJojo AnocheNo ratings yet

- House Keeping ScheduleDocument3 pagesHouse Keeping ScheduleRoldan EstibaNo ratings yet

- Equipment Maintenance ScheduleDocument1 pageEquipment Maintenance ScheduleJandee BarrientosNo ratings yet

- 2 Equipment Maintenance ScheduleDocument1 page2 Equipment Maintenance Schedulejobelynlego07No ratings yet

- Housekeeping Schedule (For Check)Document4 pagesHousekeeping Schedule (For Check)mohammadnorhamilNo ratings yet

- Laboratory/Equipment Maintenance ScheduleDocument3 pagesLaboratory/Equipment Maintenance ScheduleChristian Dela CruzNo ratings yet

- Maintain Training Facilities: Template #1Document22 pagesMaintain Training Facilities: Template #1DALISAY GINGCO100% (1)

- Maintain Training FacilitiesDocument23 pagesMaintain Training FacilitiesNorman BalatayNo ratings yet

- OAP Training Activity MatrixDocument24 pagesOAP Training Activity MatrixEugenio Jr. Mates67% (3)

- Reflective Template Wae Patosa Montano2Document3 pagesReflective Template Wae Patosa Montano2Karl Angelo MontanoNo ratings yet

- Housekeeping Schedule: of Trainee's)Document7 pagesHousekeeping Schedule: of Trainee's)unknownNo ratings yet

- P Disk GrinderDocument17 pagesP Disk GrinderLoila Arañas ParagosoNo ratings yet

- Knapsack Sprayer KS-16 Practical Work Area: Prepared byDocument13 pagesKnapsack Sprayer KS-16 Practical Work Area: Prepared byaaronjulesNo ratings yet

- 02 Housekeeping ScheduleDocument2 pages02 Housekeeping ScheduleGlenn TotzNo ratings yet

- HOUSEKEEPING SCHEDULE-finalDocument4 pagesHOUSEKEEPING SCHEDULE-finalReynon ReyesNo ratings yet

- Training Activity MatrixDocument1 pageTraining Activity Matrixdumasig22liliaNo ratings yet

- Housekeeping ScheduleDocument3 pagesHousekeeping ScheduleTESDA Regional Training Center- TaclobanNo ratings yet

- 2 Equipment Maintainance SkedDocument2 pages2 Equipment Maintainance SkedKhael Angelo Zheus JaclaNo ratings yet

- 05 - Equipment Maintenance ScheduleDocument2 pages05 - Equipment Maintenance ScheduleEddie Fernando CatapangNo ratings yet

- Timeline Work Ethic TrainingDocument4 pagesTimeline Work Ethic Trainingike hrNo ratings yet

- 2019 4 Supervised Workbased Training Templates 091518Document18 pages2019 4 Supervised Workbased Training Templates 091518karla villafloresNo ratings yet

- Developed By: Your Full Name Supervised Work Based Training Page 1 Esm/2021Document19 pagesDeveloped By: Your Full Name Supervised Work Based Training Page 1 Esm/2021bob guintoNo ratings yet

- Equipment Maintenance ScheduleDocument1 pageEquipment Maintenance ScheduleMhalleen Cabigon Testa100% (1)

- MTF Op-PrDocument11 pagesMTF Op-PrPayjay BlynNo ratings yet

- TinaCloud TeachersGuide2020Document39 pagesTinaCloud TeachersGuide2020alejoNo ratings yet

- Training Activity Matrix CarpentryDocument67 pagesTraining Activity Matrix CarpentryEugenio Jr. MatesNo ratings yet

- House Keeping ScheduleDocument3 pagesHouse Keeping ScheduleJheen CruzNo ratings yet

- Supervised Workbased Training TemplatesDocument16 pagesSupervised Workbased Training TemplatesPher G. Delos SantosNo ratings yet

- 4.training Activity MatrixDocument2 pages4.training Activity MatrixRinalyn G. CanetesNo ratings yet

- Housekeeping Schedule: Qualification Station/Bldg Area/Section In-Charge Schedule For The 2nd Semester, 2019Document3 pagesHousekeeping Schedule: Qualification Station/Bldg Area/Section In-Charge Schedule For The 2nd Semester, 2019Eddie Fernando CatapangNo ratings yet

- Daily Log For Trainees and InsrructorsDocument5 pagesDaily Log For Trainees and InsrructorsMfon Udo ObotNo ratings yet

- CNC Programmer 670c en Ts4Document19 pagesCNC Programmer 670c en Ts4kirat16singh11No ratings yet

- Oap TP CommonDocument4 pagesOap TP CommonBautista PalalayNo ratings yet

- RVFS - Equipment Maintenance ScheduleDocument1 pageRVFS - Equipment Maintenance ScheduleRoy SumugatNo ratings yet

- Non Destructive Testing: NDT Technicians and Engineers Jobs GuideFrom EverandNon Destructive Testing: NDT Technicians and Engineers Jobs GuideNo ratings yet

- Pegasus ETS Technical Manual.....Document16 pagesPegasus ETS Technical Manual.....centraliso2023No ratings yet

- Equipment Details (AMH SSC)Document50 pagesEquipment Details (AMH SSC)zeeshan_220No ratings yet

- SD03 Assessment Tool Package Sewing Machine OperationDocument78 pagesSD03 Assessment Tool Package Sewing Machine OperationSadikul IslamNo ratings yet

- Types of Sewing MachinesDocument8 pagesTypes of Sewing Machinestintin plataNo ratings yet

- Singer 107W13Document49 pagesSinger 107W13Andrew OrmeNo ratings yet

- Service Manual Elna 745Document61 pagesService Manual Elna 745alexa bNo ratings yet

- Husqvarna/Viking Tribute 150C Sewing Machine Instruction ManualDocument52 pagesHusqvarna/Viking Tribute 150C Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Juki MH-38Document20 pagesJuki MH-38SilasNo ratings yet

- Pfaff Sewing Machine ManualDocument52 pagesPfaff Sewing Machine ManualaokoyeNo ratings yet

- 0022500-00001-02 Sunrise Cushion Punch Needle Sara MooreDocument6 pages0022500-00001-02 Sunrise Cushion Punch Needle Sara MooreÁngela Burbano100% (2)

- BSC - Costume DesignFashionDocument64 pagesBSC - Costume DesignFashionrdannyNo ratings yet

- Module 1 Tools and Materials Needed in SewingDocument8 pagesModule 1 Tools and Materials Needed in SewingMayeth Silva Gonzales100% (1)

- Sewing Tools and EquipmentDocument2 pagesSewing Tools and EquipmentLeonilyn GeronimoNo ratings yet

- 5-Footwear Pattern MakingDocument16 pages5-Footwear Pattern MakingTungleNo ratings yet

- Complete Sewing Instructions 1917Document100 pagesComplete Sewing Instructions 1917shedzaNo ratings yet

- SOP For Sewing Operator Recruitment and TrainingDocument10 pagesSOP For Sewing Operator Recruitment and TrainingChodathKulangareth BhagavathiTemple100% (2)

- Singer 61W66, W156, W157Document77 pagesSinger 61W66, W156, W157Andrew OrmeNo ratings yet

- Mesin Dokumen Dan Tanpa DokumenDocument33 pagesMesin Dokumen Dan Tanpa DokumenparajuserNo ratings yet

- Resource004455 Rep6349 PDFDocument29 pagesResource004455 Rep6349 PDFRhea PardiñasNo ratings yet

- Manual Servico Recubridora Janome 2000CPXDocument39 pagesManual Servico Recubridora Janome 2000CPXmiquelsintesNo ratings yet

- Kamal Mandlawi Resume 2021 2Document3 pagesKamal Mandlawi Resume 2021 2kamalmandlawiNo ratings yet

- Value Stream MappingDocument34 pagesValue Stream MappingMushfiqur Rahman AshiqueNo ratings yet

- Sewing Machine Tension Adjustment EbookDocument19 pagesSewing Machine Tension Adjustment Ebookfoin clarisseNo ratings yet

- Business Plan Abm A3 Group 2Document25 pagesBusiness Plan Abm A3 Group 2Jm JuanillasNo ratings yet

- New Catalog of Filter Bag Making MachineDocument20 pagesNew Catalog of Filter Bag Making MachineJuan OrtegaNo ratings yet

- Manual de Instrucciones SINGER 8280 PDFDocument84 pagesManual de Instrucciones SINGER 8280 PDFBETEL VARIEDADESNo ratings yet

- Other SuppliersDocument4 pagesOther SuppliersPrab KrisNo ratings yet

- Singer Sewing Motors SpecificationDocument4 pagesSinger Sewing Motors SpecificationScott LawlessNo ratings yet

- TLE 8 Module 7Document2 pagesTLE 8 Module 7Jowel Mercado RespicioNo ratings yet