Professional Documents

Culture Documents

Datasheet 3

Datasheet 3

Uploaded by

mieftahul hudaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet 3

Datasheet 3

Uploaded by

mieftahul hudaCopyright:

Available Formats

PENGADAAN 1 (SATU) UNIT LP PRODUCTION SEPARATOR DI

GATHERING STATION 1 BUNYU FIELD

DOC.NO : TBA

REV. :

PAGE : OF

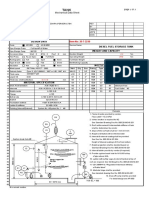

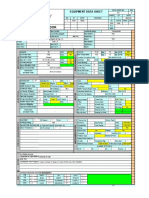

DATA SHEET FOR LP 2 (TWO) PHASE PRODUCTION SEPARATOR S-116 FIELD AREA : BUNYU

LOCATION : BUNYU

PLANT : GATHERING STATION 1

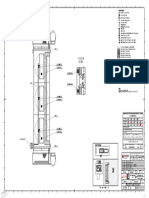

1 Item No. : S-116 Sheet Title : Sketch of Equipment

DRAWING NOT IN SCALE

3 NOTES

4 20). Mechanical and process performance guarantee are vendor's responsible.

5 21). Top Platform shall be provide full of vessel.

6 22). Complete set of Production Separator package unit shall be refers to Piping & Instrument Diagram doc. no.1922A624OO-11-PE-PID-004

7 23). Vessel Manufacturer and materials of construction shall be as per PT Pertamina EP Preferred Manufacturer List (PML)

8 24). Vendor to verify calculated weight

9 25). Maximum liquid carry over is 150 micron droplet size and 0.1 US Galoon/MMScf.

10 26). VENDOR shall provide all required internals include as a minimum inlet diverter (schoepentoeter) , vortex breaker, mist Extractor, and water jetting line.

11 27). Number of sand jetting nozzle, to be confirmed by Process Internal Vendor and Vendor to propose suitable sand jetting

12 28). Vessel Fabricator to verify or determine, and guarantee them for all service conditions.

13 29). With reinforcement plate SA 516 Gr. 70, subject to vendor calculation and verification. Seismic and transportation accelerations loads shall be considered

14 30). Vendor to ensure and guarantee that all internal part are satisfying and fulfill separation process by Vendor Process Guarantor.

15 31). The mist extractor and inlet momentum breaker shall be provided by Vendor with process performance guarantee

16 32). All gauge level glass, level transmiter, etc. having two connections are to be set with jig.

17 33). To be calculated for overall weight of the vessel with all internals installed. The minimum safety factor ti be used is 2.5. lifting lug shall be included in load test and

18 provided with certification.

19 34). Name plate to comply with local MIGAS regulation and ASME code complete with braket.

20 35). For each separator, Vendor shall provide Senior Orifice c/w Flow, Pressure & Temperature Recorder. Include Orifice Plate (2 pcs) & seal orifice plate (4 pcs)

21 36). Sizing for LCV, PCV & Senior Orifice, vendor to advice

22

23

24

25

26

You might also like

- Hirac - DoleDocument11 pagesHirac - DoleAngela Salumbides50% (2)

- Example Pump Selection: Equipment Data SheetDocument4 pagesExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiNo ratings yet

- 9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)Document7 pages9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)engr anharNo ratings yet

- Data Sheet 1Document1 pageData Sheet 1mieftahul hudaNo ratings yet

- Sheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdDocument4 pagesSheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdHafidz FirmansyahNo ratings yet

- Lampiran 5Document9 pagesLampiran 5Rifyan AlanaNo ratings yet

- Lampiran 4Document9 pagesLampiran 4Rifyan AlanaNo ratings yet

- Fru For Stenov Field Instructions: Revision History Rev # Date Author Modifications Owner Change Note NoDocument4 pagesFru For Stenov Field Instructions: Revision History Rev # Date Author Modifications Owner Change Note NoQasim SyedNo ratings yet

- Field Instrument List: Plant W1C / Compressor Unit Gb-2400 A/BDocument12 pagesField Instrument List: Plant W1C / Compressor Unit Gb-2400 A/BBou LemNo ratings yet

- STOD-GEN-AED-0000-PR-DAT-0009 - Anaguid Inlet Separator Data SheetDocument6 pagesSTOD-GEN-AED-0000-PR-DAT-0009 - Anaguid Inlet Separator Data SheetAHMED AMIRANo ratings yet

- Skh3-Ds-60-022-A4 Rev-4 11des2015Document15 pagesSkh3-Ds-60-022-A4 Rev-4 11des2015sugeng wahyudiNo ratings yet

- Sheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdDocument4 pagesSheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdHafidz FirmansyahNo ratings yet

- MY-SK410B-LLCPP-ME-DS-0036-00 Rev F0 - Fuel Gas TreatmentDocument48 pagesMY-SK410B-LLCPP-ME-DS-0036-00 Rev F0 - Fuel Gas TreatmentkelburnNo ratings yet

- 0591-8550-DS-03-0011 - F2-Data Sheet For Pressure Transmitters PDFDocument52 pages0591-8550-DS-03-0011 - F2-Data Sheet For Pressure Transmitters PDFSoumiyaNo ratings yet

- D01 CPO Tank 1 Sounding Report R1Document21 pagesD01 CPO Tank 1 Sounding Report R1Joko Sandi AsmoroNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- Field Instrument List: Plant S1A / Compressor Unit Gb-601Document8 pagesField Instrument List: Plant S1A / Compressor Unit Gb-601Bou LemNo ratings yet

- Mech - Data Sheet - Rev 0Document6 pagesMech - Data Sheet - Rev 0mieftahul hudaNo ratings yet

- Revision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsDocument2 pagesRevision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsAdilson MirandaNo ratings yet

- I de 3010.64.1200 223 PWR 034 - Sup. - 3 - Rev. - 0 PDFDocument8 pagesI de 3010.64.1200 223 PWR 034 - Sup. - 3 - Rev. - 0 PDFOrlando PWRNo ratings yet

- LPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetDocument4 pagesLPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetNyssaMaurillaNo ratings yet

- Indra: Gassi Touil Project (Job No.: 0-5353)Document83 pagesIndra: Gassi Touil Project (Job No.: 0-5353)Rachid MenserNo ratings yet

- Bsi LPTDocument37 pagesBsi LPT王马No ratings yet

- GJCDocument191 pagesGJCRachid MenserNo ratings yet

- PEMEX Exploración y Producción Paraiso - Tabasco Tg-2 Unit: Data SheetDocument11 pagesPEMEX Exploración y Producción Paraiso - Tabasco Tg-2 Unit: Data SheetdanieldayettddNo ratings yet

- 7c.5-Appendix III - Booster Compressor Package Process DatasheetDocument6 pages7c.5-Appendix III - Booster Compressor Package Process Datasheetshahrol effendy rodziNo ratings yet

- Alarm Trip SettingsDocument6 pagesAlarm Trip Settingsavenir334No ratings yet

- MWL-30-J3-DS-202-B (Level Indicator)Document4 pagesMWL-30-J3-DS-202-B (Level Indicator)Hafidz FirmansyahNo ratings yet

- PAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001Document44 pagesPAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001karthickeyanclass4No ratings yet

- 5 SS Data Sheet TurboDocument34 pages5 SS Data Sheet TurboYhony Gamarra VargasNo ratings yet

- Miniplant Water Level Cascade Control: Sheet 1 of 4Document6 pagesMiniplant Water Level Cascade Control: Sheet 1 of 4Hafidz FirmansyahNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- BCI11N03-070!04!0004-DS - Datasheet Compressed Air Line Accessories - 0Document7 pagesBCI11N03-070!04!0004-DS - Datasheet Compressed Air Line Accessories - 0Arifian NugrohoNo ratings yet

- Contract No. Contract No. Unit: UnitDocument3 pagesContract No. Contract No. Unit: Unitrameshkarthik810No ratings yet

- Air CompressorDocument139 pagesAir CompressorPraveen KumarNo ratings yet

- Keas - Itp - Rev B3-IlakkiyaDocument8 pagesKeas - Itp - Rev B3-IlakkiyaprojectNo ratings yet

- WHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchDocument18 pagesWHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchYasin ElaswadNo ratings yet

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Document6 pages1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNo ratings yet

- SPRID - 104.20 - List of Electric Equipment in Hazardous AreaDocument23 pagesSPRID - 104.20 - List of Electric Equipment in Hazardous AreaTrường Bửu TrầnNo ratings yet

- Mechanical Datasheet - Wellhead Compressor Package Rev BDocument12 pagesMechanical Datasheet - Wellhead Compressor Package Rev BRokan Pipeline100% (1)

- Molecular Sieve Inlet Gas HEATER (P-1233002) : Dp&T-SrgeDocument4 pagesMolecular Sieve Inlet Gas HEATER (P-1233002) : Dp&T-SrgeRobles DreschNo ratings yet

- VF003 - Level Gauge (ALL) PDFDocument21 pagesVF003 - Level Gauge (ALL) PDFPhạm Tấn PhướcNo ratings yet

- Area13-IO LIST-R3 (IFC)Document36 pagesArea13-IO LIST-R3 (IFC)Hân TiênNo ratings yet

- Mechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedDocument1 pageMechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedJovani G. BallonNo ratings yet

- B04425-RFLH 20201119Document1,010 pagesB04425-RFLH 20201119Gues001No ratings yet

- Example Pump Selection: Hoja de Datos de EquiposDocument2 pagesExample Pump Selection: Hoja de Datos de EquiposAlonso DIAZNo ratings yet

- Gas Compressor Package DatasheetDocument69 pagesGas Compressor Package Datasheetjohn100% (2)

- 20096-52110-4580091611-022-F Supplier Controler Communication ListDocument27 pages20096-52110-4580091611-022-F Supplier Controler Communication ListAlia RedhaNo ratings yet

- Ds-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Document2 pagesDs-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Panisa BanimaNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- BB4 Class 3 R01 ADocument1 pageBB4 Class 3 R01 AHendroNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDocument6 pagesPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNo ratings yet

- 3 - Pen Chart RecorderDocument1 page3 - Pen Chart RecorderHamza HashimNo ratings yet

- Recipiente: Equipment Data SheetDocument1 pageRecipiente: Equipment Data SheetAlonso DIAZNo ratings yet

- Vaporizador: Equipment Data SheetDocument1 pageVaporizador: Equipment Data SheetAlonso DIAZNo ratings yet

- Cpsf-El-Dat-01-Cp2017-014-00 A1Document3 pagesCpsf-El-Dat-01-Cp2017-014-00 A1Siro BabiroNo ratings yet

- Indra: - ROT/Sakumoto 21st-Dec-2018Document1 pageIndra: - ROT/Sakumoto 21st-Dec-2018Bou LemNo ratings yet

- CNOOC ITP Rev B5 - V2 - FIDocument11 pagesCNOOC ITP Rev B5 - V2 - FIprojectNo ratings yet

- Mathematics 6: Department of EducationDocument10 pagesMathematics 6: Department of EducationClarence De LeonNo ratings yet

- Solid Liquid Filtration and Separation Technology - 1996 - Rushton - Appendix A Particle Size Shape and SizeDocument15 pagesSolid Liquid Filtration and Separation Technology - 1996 - Rushton - Appendix A Particle Size Shape and SizeDevpriy sahuNo ratings yet

- 190102-DC10.5-Expansive and Stable Soils-Public ReviewDocument66 pages190102-DC10.5-Expansive and Stable Soils-Public Reviewvõ hoàng thái50% (2)

- Write A Report To Analyse The Key Factors Which Drive GlobalizationDocument7 pagesWrite A Report To Analyse The Key Factors Which Drive GlobalizationChúc Linh Đặng ThịNo ratings yet

- Product Catalog Fire Hydrant HoosekiDocument4 pagesProduct Catalog Fire Hydrant Hoosekiwika mepNo ratings yet

- A Study On Compensation Management in Chaitanya Chemicals PVTDocument44 pagesA Study On Compensation Management in Chaitanya Chemicals PVTShaik RubeenaNo ratings yet

- NS060 Light Sensor Specifications V1.1.2Document5 pagesNS060 Light Sensor Specifications V1.1.2DragutinSačarićNo ratings yet

- Engineering Physics Laboratory: Course ObjectivesDocument3 pagesEngineering Physics Laboratory: Course ObjectivesNaveenraj NNo ratings yet

- Adsorption Operation Lecture NotesDocument14 pagesAdsorption Operation Lecture NotesAnonymous FWlt8YNo ratings yet

- Catalogue 30XW-V Water Cooled Screw InverterDocument26 pagesCatalogue 30XW-V Water Cooled Screw Inverterekoindri.rkh2022No ratings yet

- Multiscale Designer - IntroductionDocument31 pagesMultiscale Designer - IntroductionaliNo ratings yet

- 1.0 - L - SP105 - Physical Quantities and MeasurementDocument35 pages1.0 - L - SP105 - Physical Quantities and MeasurementIsaac AndrewNo ratings yet

- Orgb 5th Edition Nelson Test BankDocument17 pagesOrgb 5th Edition Nelson Test Bankdominicxuyenpklf100% (32)

- English 8 Quarter 4 ReviewerDocument8 pagesEnglish 8 Quarter 4 ReviewerKAI BEATRIX GINGOYONNo ratings yet

- Raw NAV 102 Navigation ExamDocument9 pagesRaw NAV 102 Navigation ExamgadisaNo ratings yet

- Multihazard Mitigation Plan Bond County IllinoisDocument155 pagesMultihazard Mitigation Plan Bond County IllinoisJason RohrerNo ratings yet

- Original Paper LinkDocument3 pagesOriginal Paper LinkVinus yaduvanshiNo ratings yet

- Argumentative Writing: Sajjad Iqbal KhanDocument24 pagesArgumentative Writing: Sajjad Iqbal KhanM WaseemNo ratings yet

- Transactions of The Manchester Statistical Society (1854) (Mills On Credit Panics)Document132 pagesTransactions of The Manchester Statistical Society (1854) (Mills On Credit Panics)contulmmivNo ratings yet

- Ppce MCQDocument210 pagesPpce MCQjeevan ram vNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument2 pagesTuv India Private Limited: Inspection Visit Reportdavid dagarNo ratings yet

- Portuguese Maritime Exploration - WikipediaDocument14 pagesPortuguese Maritime Exploration - WikipediaRonaldbrzNo ratings yet

- Geological Hazard and Engineering Geological Map of DilaDocument140 pagesGeological Hazard and Engineering Geological Map of DilaMowlid MohammudNo ratings yet

- MENG 5-Yr Plan - Start Fall 20Document1 pageMENG 5-Yr Plan - Start Fall 20abdallah sabahNo ratings yet

- CFA Level II: Quantitative MethodsDocument169 pagesCFA Level II: Quantitative MethodsCrayonNo ratings yet

- Language and Communication - Nat Mock TestDocument7 pagesLanguage and Communication - Nat Mock TestKaren Jardeleza Quejano100% (3)

- Topics For Beauty Therapy ThesisDocument7 pagesTopics For Beauty Therapy Thesisqrikaiiig100% (2)

- Flow Stagnation PropertiesDocument8 pagesFlow Stagnation PropertiesHamza ShahidNo ratings yet

- 10 1021@acsfoodscitech 1c00098Document8 pages10 1021@acsfoodscitech 1c00098Huy Hoàng Lê ĐứcNo ratings yet