Professional Documents

Culture Documents

JSA Template

JSA Template

Uploaded by

Rassie ErasmusOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Template

JSA Template

Uploaded by

Rassie ErasmusCopyright:

Available Formats

Rev. No.

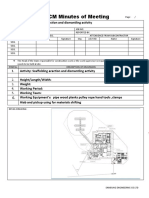

JOB SAFETY ANALYSIS : To be filled out by FM/Supervisor and Superintendent

Area : To be complete by ARCC Job Description : To be complete by ARCC JSA Group Exercise: Punch holes in Electrical Cabinet that cannot be isolated System/ID : To be complete by ARCC

JSA Ref. No.

To be complete by ARCC To be sign by ARCC

Name/Signature/Date

0

Prepared by:

(FM/Supervisor)

Reviewed by :

(HSSE Dept.)

To be sign by ARCC

Name/Signature/Date

Approved by :

(Const./ Project Manager)

To be sign by ARCC

Name/Signature/Date

Job Step 1. Verify pre-planned access to top of panel has been completed

Potential Hazard 1a Injury from fall resulting in cut or fractures. 1b Damage to adjacent equipment in the event of a fall or dropping tools. 2a None 3a Electrical shock by touching exposed wiring on connections.

H/M/L Risk M

Mitigating Steps 1a and b Work will not start until pre-planned access is in place.

Remaining* Risk H/M/L L

2. 3.

Open the front cover of the panel Verify that there are no cables in the work area and that no live electrical connections are in the work area.

M M

2a None 3a Visual check only do not place hands inside compartment

L L

Hold point if exposed wiring or connectors are evident in the work area stop and develop appropriate hazard and mitigation steps. If none found (compartment is as expected) then proceed to next step. 4. Worker performing drill / punch position himself and tools to execute work. 4a Fallen tools damage adjacent equipment. M 4a Take tools to work face one at a time and ensure they are appropriately secured with straps to L

5.

Worker performing drill / punch position himself and tools to execute work.

4b Fallen tools injure, cut or bruise, co-worker in the area. 5a Worker struck in head or other body part from falling tools dropped by worker on upper level of cabinet drilling holes. 6a Hot shavings burn lower worker on face or arms or lodge in his eye. 6b Flying metal particle lodges in eye of the upper worker. 7a Punch bit falls and damages internals of equipment. 8a Upper worker activities hydraulic punch before lower worker hand is clear and pinches finger between punch bit and cabinet causing laceration.

prevent fall to lower level. 4b Co-workers remain outside of the area until tools are secured and work is ready to start. 5b Lower worker does not go to cabinet until upper work area and tools are secure.

L L

6.

Drill pilot holes in top of cabinet

6a Lower work ensures that there is no exposed skin when his arms are extended holding debris container and wears full wrap around eyewear. 6b Upper workers wears full wrap around eyewear.

7.

Lower worker attaches screwed punch bit on inserted punch anvil.

7a Worker screws bit to anvil while holding a container with the other hand.

8.

Punch hole in panel

8a Upper worker does not activate hydraulics until visual clearance that lower worker is out of the cabinet.

9.

Punch second hole repeat steps 5, 6, 7 and 8.

You might also like

- Pathfinder Character Sheet (Fillable)Document4 pagesPathfinder Character Sheet (Fillable)djroth724100% (4)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Unit 2 AOS2 Englishes in Contact - Course NotesDocument8 pagesUnit 2 AOS2 Englishes in Contact - Course Notes9993huwegNo ratings yet

- Activity Hazard AnalysisDocument43 pagesActivity Hazard AnalysisShawn James100% (4)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- 6S (5S+1) Audit Check Sheet AdaptiveBMSDocument5 pages6S (5S+1) Audit Check Sheet AdaptiveBMSSara SunriseNo ratings yet

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- Operating The Man LiftDocument1 pageOperating The Man LiftEllecer anthony Permejo67% (3)

- SUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDocument17 pagesSUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDavid O'BrienNo ratings yet

- Tbam: Dikkowita Fisheries HarbourDocument8 pagesTbam: Dikkowita Fisheries HarbourkskahatadeniyaNo ratings yet

- JHA Valve Leak Test and RepairDocument16 pagesJHA Valve Leak Test and Repairrosevelvet100% (1)

- Powered Mobile Equipment (Including Fork Lift) For MateDocument15 pagesPowered Mobile Equipment (Including Fork Lift) For MateImtiyaz AkhtarNo ratings yet

- Job Safety Analysis Construction, EtcDocument3 pagesJob Safety Analysis Construction, EtcCamilo Salvadora MasbateNo ratings yet

- Safety Orientation - Warehouse OperationsDocument66 pagesSafety Orientation - Warehouse OperationsRalph Castillo0% (1)

- 2 - Hot Work and Modification 5-12-2012Document19 pages2 - Hot Work and Modification 5-12-2012Perwez21100% (1)

- Visitors Site Safety Induction Bris1Document2 pagesVisitors Site Safety Induction Bris1Than ZawNo ratings yet

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- JSA - Clearing Brush Chain SawDocument2 pagesJSA - Clearing Brush Chain SawRetselisitsoe100% (1)

- Jha For Storage TanksDocument4 pagesJha For Storage TanksIziyon Harrison Osaloboh50% (2)

- Hazardous Material Handling ProcedureDocument7 pagesHazardous Material Handling ProcedureSinghaNo ratings yet

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- Hot Work ProceduresDocument4 pagesHot Work ProceduresMuhammad Sajid Shams100% (1)

- Manual HandlingDocument15 pagesManual HandlingNithun Deenadayalan100% (3)

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- Oilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDocument6 pagesOilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDheeraj MenonNo ratings yet

- 37 HSE Lesson Learnt 29 - Eye InjuryDocument1 page37 HSE Lesson Learnt 29 - Eye InjuryKyaw MinNo ratings yet

- Angle Grinder Sop 2 PDFDocument1 pageAngle Grinder Sop 2 PDFMALLADI PRADEEPNo ratings yet

- Jsa PDFDocument5 pagesJsa PDFVAMSINo ratings yet

- First Aid Procedure (Revised) 0-dDocument19 pagesFirst Aid Procedure (Revised) 0-dFarizan BolkafliNo ratings yet

- Job Safety Analysis Risk Assess Restricted Spaces v1 290311Document9 pagesJob Safety Analysis Risk Assess Restricted Spaces v1 290311Anto MaryadiNo ratings yet

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 pagesJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNo ratings yet

- Appen E - Work in Progress Audit Checklist ExampDocument9 pagesAppen E - Work in Progress Audit Checklist ExampGovind Shriram ChhawsariaNo ratings yet

- PPE PolicyDocument4 pagesPPE PolicyalbertNo ratings yet

- Site Safety InspectionDocument2 pagesSite Safety InspectionDarius DsouzaNo ratings yet

- HSE PresentationDocument46 pagesHSE Presentationshan123455555555No ratings yet

- Job Safety Analysis Installation (JSA)Document4 pagesJob Safety Analysis Installation (JSA)Aser Batoy Jr.No ratings yet

- Hand Tools Inspection ChecklistDocument2 pagesHand Tools Inspection ChecklistSaravana KumarNo ratings yet

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)

- SOP 06 - Portable Tools and EquipmentDocument3 pagesSOP 06 - Portable Tools and EquipmentEdwins Gabrelle Hendrawan DalfadoNo ratings yet

- JHA Air Compressor and Air ToolsDocument1 pageJHA Air Compressor and Air ToolshaziqawangNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Confined Space Management PlanDocument27 pagesConfined Space Management PlanYusuf KhanNo ratings yet

- Monthly Inspection Report For Cranes and HoistsDocument2 pagesMonthly Inspection Report For Cranes and HoistsGrace PassiniNo ratings yet

- Safety and Health ProgramsDocument21 pagesSafety and Health ProgramsJason SunnyNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument4 pagesJsa Grinding Welding Gas CuttingMark Roger Huberit IINo ratings yet

- Jsa Manual ExcavationDocument1 pageJsa Manual ExcavationIan MardiansyahNo ratings yet

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- JSA For Fab Erec of STRL Steel StackDocument5 pagesJSA For Fab Erec of STRL Steel StackkrishnakumarNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- JHA Lifting-Moving Heavy ObjectsDocument6 pagesJHA Lifting-Moving Heavy ObjectsMiguel AugustoNo ratings yet

- Microsoft Word - Checklist For Cafeteria Inspection - LatestDocument1 pageMicrosoft Word - Checklist For Cafeteria Inspection - LatestAyong EntilyNo ratings yet

- JSA Working in Live AreasDocument1 pageJSA Working in Live Areasyc safetyNo ratings yet

- Basic Hse TrainingDocument33 pagesBasic Hse Trainingnsankar71100% (3)

- 3.ceiling Installation JSA ADocument2 pages3.ceiling Installation JSA APijah AhmadNo ratings yet

- Table of Contents: Cold Weather ExposureDocument11 pagesTable of Contents: Cold Weather Exposureotak04No ratings yet

- Monthly Camp Inspection FormDocument22 pagesMonthly Camp Inspection FormvijithNo ratings yet

- Fatigue Management Procedure Sew39Document13 pagesFatigue Management Procedure Sew39Viem Abdul HalimNo ratings yet

- Job Hazard and Risk AssessmentDocument5 pagesJob Hazard and Risk Assessmentasponce2003No ratings yet

- B. Walk Ways To BeDocument4 pagesB. Walk Ways To BeikeagharanyaNo ratings yet

- Safe Operating Procedures: Medium To High RiskDocument6 pagesSafe Operating Procedures: Medium To High Riskmuhammad imtiazNo ratings yet

- Hazard Analysis For UtilityDocument4 pagesHazard Analysis For UtilityBoiler ScrubberNo ratings yet

- S-PCM Flare AreaDocument7 pagesS-PCM Flare Areasudeesh kumarNo ratings yet

- MMB Application FormDocument4 pagesMMB Application FormDhiangga JauharyNo ratings yet

- CSC Resolution Qualification Standard LLB Degree ConsideredDocument2 pagesCSC Resolution Qualification Standard LLB Degree ConsideredNadine GabaoNo ratings yet

- Rule 1960 - Occupational Health ServicesDocument31 pagesRule 1960 - Occupational Health ServicesSofiaJabadanEspulgar100% (1)

- Power Plant Maintenance Mechanic 536Document2 pagesPower Plant Maintenance Mechanic 536SubburajMechNo ratings yet

- A Profession Is An Occupation That Involves Specialized Training and Formal QualificationDocument2 pagesA Profession Is An Occupation That Involves Specialized Training and Formal QualificationJeffrey LabartiniNo ratings yet

- Employment - Form NetsolDocument8 pagesEmployment - Form Netsol9874567No ratings yet

- Online - Uwin.ac - Id: Bachelor in Economics (S.E) : ManajemenDocument17 pagesOnline - Uwin.ac - Id: Bachelor in Economics (S.E) : ManajemenelearninglsprNo ratings yet

- High Voltage Electrical Safety ProgramDocument12 pagesHigh Voltage Electrical Safety Programsathesh0% (2)

- Impact of Job Stress On Job Performance Among The Employees of JordanDocument9 pagesImpact of Job Stress On Job Performance Among The Employees of Jordanfst3040501No ratings yet

- The Dog: by Banjo Paterson (/author/banjo Paterson/bio Books Stories)Document3 pagesThe Dog: by Banjo Paterson (/author/banjo Paterson/bio Books Stories)Wellington LinsNo ratings yet

- Application Form: Orchid CentreDocument4 pagesApplication Form: Orchid CentreAnkur DesaiNo ratings yet

- Know Your Profession Via AstrologyDocument3 pagesKnow Your Profession Via AstrologyDr. Shanker AdawalNo ratings yet

- Open Mind Beginner SB Unit 5Document12 pagesOpen Mind Beginner SB Unit 5Lucimar Santos da CruzNo ratings yet

- This House Does Not Believe That Brain Drain Is Caused by A Lack of Opportunities. I. ArgumentDocument1 pageThis House Does Not Believe That Brain Drain Is Caused by A Lack of Opportunities. I. ArgumentJilliana TumanganNo ratings yet

- Evidencia Familia Ingles SenaDocument5 pagesEvidencia Familia Ingles SenaJeison FerneyNo ratings yet

- 4 - Social StratificationDocument8 pages4 - Social StratificationJeters VillaruelNo ratings yet

- Alat Pelindung DiriDocument345 pagesAlat Pelindung Diritemter100% (1)

- CESO Checklist A-02 Accident Prevention PlanDocument4 pagesCESO Checklist A-02 Accident Prevention PlanRomoex R RockNo ratings yet

- Career Planning HRMDocument23 pagesCareer Planning HRMKritika Singh100% (1)

- Construction Interview QuestionsDocument3 pagesConstruction Interview Questionstafzeman891No ratings yet

- The Bermuda Job Market: Employment BriefsDocument12 pagesThe Bermuda Job Market: Employment Briefspatburchall6278No ratings yet

- Unemployment and Underemploymentin Rural IndiaDocument9 pagesUnemployment and Underemploymentin Rural IndiaPranavVohraNo ratings yet

- Nominee Programs CanadaDocument8 pagesNominee Programs CanadashilpaNo ratings yet

- List of OccupationsDocument2 pagesList of OccupationsRodrigo ZuñigaNo ratings yet

- Resource Sheet For #NewtoCanada #NewcomersDocument5 pagesResource Sheet For #NewtoCanada #NewcomersKhatija QureshiNo ratings yet

- Templates and Resources For: Joint Health and Safety CommitteesDocument23 pagesTemplates and Resources For: Joint Health and Safety CommitteesEngr AliyanNo ratings yet

- JerichoDocument4 pagesJerichoWissam AoudiNo ratings yet