Professional Documents

Culture Documents

Acciaierie Valbruna: EN 10204 (2004), 3.1 / ISO 10474 (2013), 3.1

Acciaierie Valbruna: EN 10204 (2004), 3.1 / ISO 10474 (2013), 3.1

Uploaded by

AgoritsaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acciaierie Valbruna: EN 10204 (2004), 3.1 / ISO 10474 (2013), 3.1

Acciaierie Valbruna: EN 10204 (2004), 3.1 / ISO 10474 (2013), 3.1

Uploaded by

AgoritsaCopyright:

Available Formats

Acciaierie Valbruna

36100 VICENZA (Italia) - Viale della scienza, 25 z.i.

Telefono 0444.968211 - Fax 0444.963836

S.p.A. Stab.: 39100 BOLZANO (Italia) - Via A. Volta, 4/37

Telefono 0471.924111 - Fax 0471.924497

CERTIFICATO DI COLLAUDO - ABNAHMEPRUEFZEUGNIS - INSPECTION CERTIFICATE - CERTIFICAT DE RECEPTION

In conformità a : EN 10204 (2004) , 3.1 / ISO 10474 (2013) , 3.1 Certificato nr. MEST450570 / 2019 /

Nach/According to/Selon Prüfung/Test/Essai

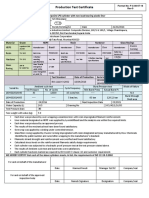

Cliente / Besteller/Purchaser/Client Stato di fornitura : Hot rolled Descaled Annealed Hot Produttore :

TECHNOMETAL S.A. Lieferzustand rolled Hersteller/Item/Usine productrice

Delivery state

20 DRAGATSANIOU Etat de livraison

18545 - PIRAEUS GREECE - GR ACCIAIERIE VALBRUNA S.P.A.

Tipo di Elaborazione: E+AOD Marchi di Fabbrica:

Erschmelzungsart Zeichen des Liefernwerkes

Ordine nr: PO#GE.029 Melting process Trade marks

Bestell Mode d'elaboration Sigles de l'usine productrice

Your order

Commande

Qualità: 1.4301/1.4307/304/304L Punzone del Collaudatore:

Stempel des Werkssachverständigen

Conferma ordine nr: EI19004346 Werkstoff/Grade/Nuance

Inspector`s stamp/Poinçon de l`assayeur

Werks/Our Order/Ref nr.

Avviso di Spedizione: D-VI19022720 Marca: Punzonatura: 1.4301/7/304/L

AISL Kennzeichnung

Lieferanzeige/Packing list/B.L. Markenbezeichnung Marking

Brand / Nuance Marquage

SPECIFICHE : Note:

Anforderungen / Requirements / Exigences Aufzeichnungen / Notes / Notes

VAL STOCK 2010 1.4307/304L A

AISI 304

AISI 304L

ASME SA182 2017 S30400 A (0) (0)Section II Part A 2017 EDITION For products machined directly from bar refer to ASME SA479.

ASME SA182 2017 S30403 A (1) (1)Section II Part A 2017 EDITION For products machined directly from bar refer to ASME SA479.

ASME SA193 2017 B8 CLASS 1 (2) (2)Section II Part A 2017 EDITION

ASME SA276 2017 S30400 A (3) (3)Section II Part A 2017 EDITION

ASME SA276 2017 S30403 A (4) (4)Section II Part A 2017 EDITION

ASME SA320 2017 B8 CLASS1 (5) (5)Section II Part A 2017 EDITION

ASME SA479 2017 S30400 A (6) (6)Section II Part A 2017 EDITION

ASME SA479 2017 S30403 A (7) (7)Section II Part A 2017 EDITION

ASTM A182 2019 S30400 A (8) (8)For products machined directly from bar refer also to ASTM A479.

ASTM A182 2019 S30403 A (9) (9)For products machined directly from bar refer also to ASTM A479.

ASTM A193 2017 B8 CLASS 1

ASTM A262 2015 PRACTICE E

ASTM A276 2017 S30400 A

ASTM A276 2017 S30403 A

ASTM A320 2017A B8 CLASS1

ASTM A479 2018 S30400 A

ASTM A479 2018 S30403 A

DIN 17440 96 1.4301 A

EN 10088-3 2014 1.4301 A

EN 10088-3 2014 1.4307 A

EN 10272 2007 1.4301 A

EN 10272 2007 1.4307 A

NACE MR0103 2015 S30400 A (A) (A)ANSI/NACE MR0103/ISO 17945 November 23, 2015

NACE MR0103 2015 S30403 A (B) (B)ANSI/NACE MR0103/ISO 17945 November 23, 2015

NACE MR0175 2015 S30400 A (C) (C)ANSI/NACE MR0175/ISO 15156-3, third edition November 23,2015

NACE MR0175 2015 S30403 A (D) (D)ANSI/NACE MR0175/ISO 15156-3, third edition November 23,2015

Tolleranza: Tol. DIN 1017

Tolleranza/Allowance/Tolerance

Pos. nr. Oggetto Dimensioni - mm Lunghezza - mm Colata Pezzi Peso - KG Lotto nr.

Pos. nr. Gegenstand Abmessungen Lange Schmelze Stückzahi Gewicht Losnr.

Item nr. Product description Dimension Length Heat Pieces Weight Lot nr.

Nr. de poste Descrip. du produit Dimension Longueur Coulée Pieces Poids Lot nr.

0020 Flat 50,000 x 25,000 6000/ 6190 277565 306,0 817205511

QUALITY MANAGEMENT SYSTEM CERTIFIED BY LLOYD'S REGISTER ACCORDING TO ISO 9001 : 2015, IATF 16949 : 2016, AS 9100D

Direzione Qualità Direzione Prodotto

Vicenza, 28/08/19 Qualitätsmanagement/Quality Management/Gestion Qualité Produktmanagement/Product Management/Direction Produit Pagina

VCQ008 - MEST450570 1 di 3

R.BERTELLI P.MESSORI

Acciaierie Valbruna

36100 VICENZA (Italia) - Viale della scienza, 25 z.i.

Telefono 0444.968211 - Fax 0444.963836

S.p.A. Stab.: 39100 BOLZANO (Italia) - Via A. Volta, 4/37

Telefono 0471.924111 - Fax 0471.924497

CERTIFICATO DI COLLAUDO - ABNAHMEPRUEFZEUGNIS - INSPECTION CERTIFICATE - CERTIFICAT DE RECEPTION

In conformità a : EN 10204 (2004) , 3.1 / ISO 10474 (2013) , 3.1 Certificato nr. MEST450570 / 2019 /

Nach/According to/Selon Prüfung/Test/Essai

Cliente / Besteller/Purchaser/Client Stato di fornitura : Hot rolled Descaled Annealed Hot Produttore :

TECHNOMETAL S.A. Lieferzustand rolled Hersteller/Item/Usine productrice

Delivery state

20 DRAGATSANIOU Etat de livraison

18545 - PIRAEUS GREECE - GR ACCIAIERIE VALBRUNA S.P.A.

Tipo di Elaborazione: E+AOD Marchi di Fabbrica:

Erschmelzungsart Zeichen des Liefernwerkes

Ordine nr: PO#GE.029 Melting process Trade marks

Bestell Mode d'elaboration Sigles de l'usine productrice

Your order

Commande

Qualità: 1.4301/1.4307/304/304L Punzone del Collaudatore:

Stempel des Werkssachverständigen

Conferma ordine nr: EI19004346 Werkstoff/Grade/Nuance

Inspector`s stamp/Poinçon de l`assayeur

Werks/Our Order/Ref nr.

Avviso di Spedizione: D-VI19022720 Marca: Punzonatura: 1.4301/7/304/L

AISL Kennzeichnung

Lieferanzeige/Packing list/B.L. Markenbezeichnung Marking

Brand / Nuance Marquage

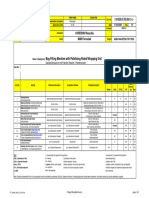

TEST ALLO STATO DI FORNITURA

Test on delivery condition Prüefung auf lieferbereitem produkt test a l'etat de fourniture Prueba sobre el material así come entregado

1) L=longitudinale/längs, T=trasversale/quer, Q=Tangenziale/tangential

Provetta/ Probestab Posiz. Snervamento Snervamento Resistenza Allungamento Strizione Resilienza Durezza

Specimen/Eprouvette Saggio Streckgrenze Streckgrenze Zugfestigkeit Bruchdehnung Einschnürung Kerbschlagarbelt Haerte

Larg.diam Spess. Yield Stress Yield Stress Tensile strength Elongation Reduction of area Impact Value Hardness

TEST Breite Diam. Dicke

Width Diam. Thickness

°C Probentage

Location

Emplacement

Limite elastique Limite elastique Resistance á traction Allongement Striction Resilience Durete

Larg. diam. epais

Rp 0,2% Rp 1% Rm A5 E 4d Z RA KV HB

1)

mm N/mm2 N/mm2 N/mm2 % % % % J

Valori richiesti min 205 230 515 45 40 - 50 100 -

Anfonderungen/Required values

Valeurs démandées max 680 215

A 10 20 L 282 328 592 55 57 68 68 242 240 243 170

TEST ALLO STATO DI FORNITURA

Test on delivery condition / Prüefung auf lieferbereitem produkt / Test a l'etat de fourniture / Prueba sobre el material así come entregado

TEST min max

A Grain size for ASTM E112 6

Analisi chimica

Chemische Zusammensetzung/Chemical Analysis/Analyse chimique

Colata /Heat min - - - 18,00 8,00 - - - - - - - - - -

Schmelze/Coulée max 0,030 1,00 2,00 19,50 10,00 0,045 0,030 0,100 - - - - - - -

C% Si % Mn % Cr % Ni % P% S% N%

277565 0,016 0,37 1,85 18,25 8,14 0,025 0,025 0,100

Corrosion test in 16% sulfuric acid and copper sulfate solutions

Test standard: ASTM A262-Practice E

Result of visual inspection

Heat treatment Length of Test temp Ø spindle

Test Bend Angle (°) at 20 x magnification after Result

before test Period (h) (°C) (mm)

bend test

Intergranular

Sensitization 15 boil 180 5 Absence of cracks SATISFACTORY

corrosion

Corrosion test in 16% sulfuric acid and copper sulfate solutions

Test standard: UNI EN ISO 3651-2 Method A

Result of visual inspection

Heat treatment Length of Test temp Ø spindle

Test Bend Angle (°) at 20 x magnification after Result

before test Period (h) (°C) (mm)

bend test

Intergranular

Sensitized T1 20 boil 90 5 Absence of cracks SATISFACTORY

corrosion

Reduction ratio = 25,9 : 1

Solution annealing by process annealing 1040°C min /

/ cooling water

QUALITY MANAGEMENT SYSTEM CERTIFIED BY LLOYD'S REGISTER ACCORDING TO ISO 9001 : 2015, IATF 16949 : 2016, AS 9100D

Direzione Qualità Direzione Prodotto

Vicenza, 28/08/19 Qualitätsmanagement/Quality Management/Gestion Qualité Produktmanagement/Product Management/Direction Produit Pagina

VCQ008 - MEST450570 2 di 3

R.BERTELLI P.MESSORI

Acciaierie Valbruna

36100 VICENZA (Italia) - Viale della scienza, 25 z.i.

Telefono 0444.968211 - Fax 0444.963836

S.p.A. Stab.: 39100 BOLZANO (Italia) - Via A. Volta, 4/37

Telefono 0471.924111 - Fax 0471.924497

CERTIFICATO DI COLLAUDO - ABNAHMEPRUEFZEUGNIS - INSPECTION CERTIFICATE - CERTIFICAT DE RECEPTION

In conformità a : EN 10204 (2004) , 3.1 / ISO 10474 (2013) , 3.1 Certificato nr. MEST450570 / 2019 /

Nach/According to/Selon Prüfung/Test/Essai

Cliente / Besteller/Purchaser/Client Stato di fornitura : Hot rolled Descaled Annealed Hot Produttore :

TECHNOMETAL S.A. Lieferzustand rolled Hersteller/Item/Usine productrice

Delivery state

20 DRAGATSANIOU Etat de livraison

18545 - PIRAEUS GREECE - GR ACCIAIERIE VALBRUNA S.P.A.

Tipo di Elaborazione: E+AOD Marchi di Fabbrica:

Erschmelzungsart Zeichen des Liefernwerkes

Ordine nr: PO#GE.029 Melting process Trade marks

Bestell Mode d'elaboration Sigles de l'usine productrice

Your order

Commande

Qualità: 1.4301/1.4307/304/304L Punzone del Collaudatore:

Stempel des Werkssachverständigen

Conferma ordine nr: EI19004346 Werkstoff/Grade/Nuance

Inspector`s stamp/Poinçon de l`assayeur

Werks/Our Order/Ref nr.

Avviso di Spedizione: D-VI19022720 Marca: Punzonatura: 1.4301/7/304/L

AISL Kennzeichnung

Lieferanzeige/Packing list/B.L. Markenbezeichnung Marking

Brand / Nuance Marquage

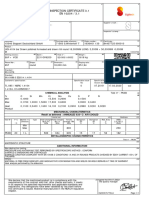

Sono state soddisfatte tutte le condizioni richieste Controllo antimescolanza: OK Controllo visivo e dimensionale: soddisfa le esigenze

Die gestellen Anforderungen sind it. Anlage erfüllt Verwechslungprüfung: spectralanalytisch durchgeführt Besichtiguñg und Ausmessung: ohne Beanstandung

The material has been furnished in accordance with the requirements Antimixing testing performed: OK Visual inspection and dimensional checks:satisfactory

Le materiel â eté trouvé conforme aux exigences Contrôle antimelange falt: r.a.s. Contrôle visuel et dimensions: satisfaisant

Melted and manufactured in Italy No welding or weld repair Material free from Mercury contamination

We declare that the finished product is checked for radioactive contamination through Portal System when it leaves the production plant.

The Quality Management System is also Certified according Pressure Equipment Directive 2014/68/EU Annex 1,chapt.4.3 by TÜV and LLOYD`S

Any act of tampering, modification, alteration, counterfeiting and/or falsification and/or any other action which modifies the contents of this test certificate shall constitute a violation

of applicable civil and criminal laws. Acciaierie Valbruna shall protect its rights and interests before any competent court, authority and jurisdiction.

Maxival and/or Valplus grades/products are manufactured with ladle techniques to control composition, distribution, size and shape of non-metallic inclusions for improved

machinability.

The supplied product conforms to requirements expressly requested by the purchaser and conforms to requirements specified by certified norms and standards. Should the

product be used for more severe, critical and/ or in any case different applications than those the material is generally intended for, any different and/or supplementary

requirements shall be specifically demanded, at least, upon order of the Product by the Purchaser. Acciaierie Valbruna SpA shall not be responsible for any improper use of the

Products. WSPE63E3BEB4E234FB08FA3A48BDA33C1FB

QUALITY MANAGEMENT SYSTEM CERTIFIED BY LLOYD'S REGISTER ACCORDING TO ISO 9001 : 2015, IATF 16949 : 2016, AS 9100D

Direzione Qualità Direzione Prodotto

Vicenza, 28/08/19 Qualitätsmanagement/Quality Management/Gestion Qualité Produktmanagement/Product Management/Direction Produit Pagina

VCQ008 - MEST450570 3 di 3

R.BERTELLI P.MESSORI

You might also like

- Asmt E2533Document47 pagesAsmt E2533krperz100% (1)

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- LTOM Updated BOOK 1Document55 pagesLTOM Updated BOOK 1Angelynne N. Nievera88% (8)

- Production Test CertificateDocument2 pagesProduction Test CertificateSolomon MacwanNo ratings yet

- hot rolled Φ60 AISI 304L (14.230)Document3 pageshot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- Ss 316l 3.0 MTC NewDocument2 pagesSs 316l 3.0 MTC NewSahil Hashmi100% (1)

- (WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11543 IDHHDocument4 pages(WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11543 IDHHDhanush NairNo ratings yet

- PL 07 165 10003 Rev02 Control Switch RH - Acaa - 13-09-2023Document3 pagesPL 07 165 10003 Rev02 Control Switch RH - Acaa - 13-09-2023Naveendesai DesaiNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Data SheetDocument5 pagesData SheetamirNo ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- E/Aod: According To en 10204Document1 pageE/Aod: According To en 10204agungNo ratings yet

- Test On Linear Motorl ML40 Annex 1 2Document38 pagesTest On Linear Motorl ML40 Annex 1 2claudio cadizNo ratings yet

- Marking Guidelines - PM-PU-6.022Document14 pagesMarking Guidelines - PM-PU-6.022PINNACLE ENGINEERINGNo ratings yet

- SPM/FERBAUER/C2-3/C2.3/G1 Pag. 1/1Document1 pageSPM/FERBAUER/C2-3/C2.3/G1 Pag. 1/1Manea GeorgeNo ratings yet

- WS 059Document4 pagesWS 059san2inNo ratings yet

- Arcelormittal Nippon Steel India Limited: Heat Analysis (%) of 24400486Document1 pageArcelormittal Nippon Steel India Limited: Heat Analysis (%) of 24400486pranav kariaNo ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- KTH-225 PPAP (INNER TUBE - TM-741A-2 - BS-15C-20x14.5 - 190530)Document21 pagesKTH-225 PPAP (INNER TUBE - TM-741A-2 - BS-15C-20x14.5 - 190530)pitchapon janprasertNo ratings yet

- Critic-Special 109-0443-01-103Document1 pageCritic-Special 109-0443-01-103Manea GeorgeNo ratings yet

- DLC3010Document2 pagesDLC3010Abid Hossain RupamNo ratings yet

- Critic-Special 109-0443-01-103: SCPS/CTCTT/C1-4-2/C1-3-1/G9 Pag. 1/1Document1 pageCritic-Special 109-0443-01-103: SCPS/CTCTT/C1-4-2/C1-3-1/G9 Pag. 1/1Manea GeorgeNo ratings yet

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocument1 page9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- Bohler E 8010 4,0mm 2142568 PDFDocument1 pageBohler E 8010 4,0mm 2142568 PDFJack KomboyNo ratings yet

- 16111-16 Componenta CertificateDocument8 pages16111-16 Componenta CertificateMahen PereraNo ratings yet

- Bohler E7018 Ø4.00mm LT-8105848Document1 pageBohler E7018 Ø4.00mm LT-8105848Ivonne Yana EnriquezNo ratings yet

- Hollow Bar 304L Φ80ΧΦ50Document6 pagesHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- Snervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMDocument1 pageSnervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMMygame 1402No ratings yet

- MIR - TankDocument10 pagesMIR - TankanandNo ratings yet

- Itp - 1101620.0.705.5612.4.01Document1 pageItp - 1101620.0.705.5612.4.01zakattsh4345No ratings yet

- Certification: Bill of MaterialDocument7 pagesCertification: Bill of MaterialNinaNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- 19 Test CertificatesDocument10 pages19 Test CertificatesBernice AkotoNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- Sablare Uscata /dry Blasting - Sablare Uscata Conform STA100-83-43/Dry Blasting Acc. To STA100-83-43 10.sablare Uscata/dry Blasting 20.Curatire/CleaningDocument1 pageSablare Uscata /dry Blasting - Sablare Uscata Conform STA100-83-43/Dry Blasting Acc. To STA100-83-43 10.sablare Uscata/dry Blasting 20.Curatire/CleaningManea GeorgeNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- Material Test & Inspection CertificateDocument1 pageMaterial Test & Inspection CertificateKato Megumi ChanNo ratings yet

- Operation Description: Op. Class Op. Rev. / Date Nr. / No. Sequence Variant PN Designation Part NumberDocument2 pagesOperation Description: Op. Class Op. Rev. / Date Nr. / No. Sequence Variant PN Designation Part NumberManea GeorgeNo ratings yet

- Inspection Recod LCDocument1 pageInspection Recod LChendry gunawanNo ratings yet

- Certification: Bill of MaterialDocument6 pagesCertification: Bill of MaterialBrett ThomasNo ratings yet

- Certificate Material Tubing 3.1-Voorbeeld-CertificaatDocument3 pagesCertificate Material Tubing 3.1-Voorbeeld-Certificaatcahyo wibowoNo ratings yet

- Sulzer-Moret 121 NFDDocument89 pagesSulzer-Moret 121 NFDCardoso MalacaoNo ratings yet

- MTC'sDocument5 pagesMTC'sWalid DamiNo ratings yet

- IVR 010101105622 - 488 1 Rev.0Document6 pagesIVR 010101105622 - 488 1 Rev.0maheshpanditNo ratings yet

- Work Order: VN 23980529 6 - MiscellaneousDocument2 pagesWork Order: VN 23980529 6 - MiscellaneousJohn SmithNo ratings yet

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- 01-HDPE Pipe & Fitting (Chuangrong)Document22 pages01-HDPE Pipe & Fitting (Chuangrong)Thy YuNo ratings yet

- 380 1 PDFDocument7 pages380 1 PDFJimyTeránAgudeloNo ratings yet

- 8100 IpgDocument1 page8100 IpgmraoNo ratings yet

- Operation Description: Pos. Code Edition DescriptionDocument1 pageOperation Description: Pos. Code Edition DescriptionManea GeorgeNo ratings yet

- Itp - 1101620.0.705.5611.4.01 - 30.04.08Document1 pageItp - 1101620.0.705.5611.4.01 - 30.04.08zakattsh4345No ratings yet

- PL Inox 9 MMDocument1 pagePL Inox 9 MMHugo BeltranNo ratings yet

- 2004 B Rev03Document31 pages2004 B Rev03qaqcrohiniNo ratings yet

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Document3 pagesFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsNo ratings yet

- 26 Portable Dry Powder Fire Extinguisher MS1539Document1 page26 Portable Dry Powder Fire Extinguisher MS1539eafarmihar2554No ratings yet

- Operation Description: TurningDocument1 pageOperation Description: TurningManea GeorgeNo ratings yet

- 851 Inorganic Zinc Primer TDS enDocument2 pages851 Inorganic Zinc Primer TDS enAgoritsaNo ratings yet

- PL 3x1500 Coil 1.4307 2BDocument6 pagesPL 3x1500 Coil 1.4307 2BAgoritsaNo ratings yet

- Round Φ18 1.4104Document1 pageRound Φ18 1.4104AgoritsaNo ratings yet

- Hollow Bar 304L Φ80ΧΦ50Document6 pagesHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- Intel Core I5 Mobile Compare ChartDocument2 pagesIntel Core I5 Mobile Compare ChartLJUBISA RADONJICNo ratings yet

- A B C - S of Hoodoo - Tina HarrisDocument152 pagesA B C - S of Hoodoo - Tina HarrisDarío Ol100% (11)

- Film Appreciation (Notes)Document29 pagesFilm Appreciation (Notes)Deb BonNo ratings yet

- Quick and Economic Setups JitDocument2 pagesQuick and Economic Setups JitDharshan KofiNo ratings yet

- AP - LiabilitiesDocument4 pagesAP - LiabilitiesEarl Donne Cruz100% (4)

- Grade 12 Mathematics Composite SBA Documents 2020 22 OctDocument26 pagesGrade 12 Mathematics Composite SBA Documents 2020 22 OctWonder Bee Nzama0% (1)

- Andreas: Focused Assessment With Sonography in TraumaDocument13 pagesAndreas: Focused Assessment With Sonography in Traumarina paramitaNo ratings yet

- Flow Visualization, Edited by Tsuyoshi AsanumaDocument2 pagesFlow Visualization, Edited by Tsuyoshi AsanumaAnonymous A415sJ9No ratings yet

- Lesson 1 Social Science and Applied Social ScienceDocument51 pagesLesson 1 Social Science and Applied Social ScienceGERALDINE ROBLESNo ratings yet

- Study ThisDocument83 pagesStudy Thispavithiran subramaniNo ratings yet

- The Weeknd Essay 1Document4 pagesThe Weeknd Essay 1api-549614851No ratings yet

- Angle MergesDocument1 pageAngle Mergesdesky nguyenNo ratings yet

- How LPG Industry Operates Its Marketing OperationsDocument7 pagesHow LPG Industry Operates Its Marketing OperationsShakir AhmadNo ratings yet

- Original PDF Automotive Technology A Systems Approach 3rd Edition PDFDocument41 pagesOriginal PDF Automotive Technology A Systems Approach 3rd Edition PDFryan.whitson353100% (43)

- Brunner Normal Intracranial Pressure 10-20 MMHGDocument16 pagesBrunner Normal Intracranial Pressure 10-20 MMHGlovely99_dyahNo ratings yet

- NYC DOE Fact Sheet On Closure of Monroe Academy of Business/Law in The BronxDocument4 pagesNYC DOE Fact Sheet On Closure of Monroe Academy of Business/Law in The BronxCity Limits (New York)No ratings yet

- CDS4004 AnntDocument5 pagesCDS4004 AnntJiaxing ShenNo ratings yet

- Year 6 Mco Lesson PlanDocument25 pagesYear 6 Mco Lesson PlanVanitha ThiagarajNo ratings yet

- Midwifery: Kelly Ackerson, PHD, RN, WHNP-BC, Ruth Zielinski, PHD, CNM, FacnmDocument26 pagesMidwifery: Kelly Ackerson, PHD, RN, WHNP-BC, Ruth Zielinski, PHD, CNM, FacnmMILANo ratings yet

- Operating System Unit 3 Part 1Document20 pagesOperating System Unit 3 Part 1kuldeep kumarNo ratings yet

- Schedule Waste HandlingDocument3 pagesSchedule Waste Handlingosha911No ratings yet

- 9 Chapter Teaching Family Gods Greatest GiftDocument4 pages9 Chapter Teaching Family Gods Greatest GiftSTEVE JHONSON LepasanaNo ratings yet

- Modelling Nutrient Utilization in Farm AnimalsDocument432 pagesModelling Nutrient Utilization in Farm AnimalsHéctor W Moreno QNo ratings yet

- Issues Surrounding Reliability and Validity-1Document38 pagesIssues Surrounding Reliability and Validity-1kylieverNo ratings yet

- City PumpsDocument2 pagesCity PumpsJohan ConradieNo ratings yet

- Skills Needed For Discussion of Research PaperDocument21 pagesSkills Needed For Discussion of Research PaperPacha Khan Khogyani100% (1)

- MotivationDocument39 pagesMotivationnavin_tiwari_king100% (1)

- MS2A - Ch7 - Practice and Answers With MC Ans Update-1Document56 pagesMS2A - Ch7 - Practice and Answers With MC Ans Update-1s200522No ratings yet