Professional Documents

Culture Documents

Diy Lego Led Bricks

Diy Lego Led Bricks

Uploaded by

CarolCopyright:

Available Formats

You might also like

- Get Fit Stay Well Chapter 4Document31 pagesGet Fit Stay Well Chapter 4Paden TranNo ratings yet

- EN Facelift LED Heckleuchten - VW Passat B8 - PreviewDocument3 pagesEN Facelift LED Heckleuchten - VW Passat B8 - PreviewLaurentiu Nancu0% (1)

- Republic of Zambia Form of Certificate of Medical ExaminationDocument2 pagesRepublic of Zambia Form of Certificate of Medical ExaminationKas Mus90% (10)

- Designmate 3024/3036 Top AssemblyDocument11 pagesDesignmate 3024/3036 Top AssemblySerge MaciaNo ratings yet

- English: Quarter 4 - Module 18: Matching Picture With Its Sight WordsDocument16 pagesEnglish: Quarter 4 - Module 18: Matching Picture With Its Sight WordsMark Edson Aboy100% (1)

- Ielts (Sample Answers Writing)Document101 pagesIelts (Sample Answers Writing)Dang Thuy Lieu100% (6)

- Thermal Camera With Display PDFDocument30 pagesThermal Camera With Display PDFImam Fakhrurrozi HidayatNo ratings yet

- Adafruit Data Logger ShieldDocument68 pagesAdafruit Data Logger ShieldArieffin NatawidjajaNo ratings yet

- Ruota Panoramica SMDDocument18 pagesRuota Panoramica SMDfattizzituaNo ratings yet

- Adafruit Feather m0 Express Designed For Circuit Python CircuitpythonDocument62 pagesAdafruit Feather m0 Express Designed For Circuit Python CircuitpythonConejoSinPompon gomaNo ratings yet

- AdaFruit Introducing Circuit PlaygroundDocument35 pagesAdaFruit Introducing Circuit Playgroundgardener10No ratings yet

- 12mm Led Pixels - 1539265432184Document16 pages12mm Led Pixels - 1539265432184Ritesh KatalkarNo ratings yet

- 10kw Hybrid SystemDocument6 pages10kw Hybrid SystemUmar HamidNo ratings yet

- Breadboards For Beginners: Created by Lady AdaDocument37 pagesBreadboards For Beginners: Created by Lady AdaTukser Dalibor SmetiškoNo ratings yet

- Practical Electronics - December 2022 PDFDocument76 pagesPractical Electronics - December 2022 PDFsameins100% (2)

- Create An Arduino 3X3 LED Cube in 30 Minutes - Arduino Hacks - Arduino HacksDocument11 pagesCreate An Arduino 3X3 LED Cube in 30 Minutes - Arduino Hacks - Arduino HacksGustavo Seben ColleNo ratings yet

- Raspberry Pi Pipboy 3000Document64 pagesRaspberry Pi Pipboy 3000AurélienMoulietsNo ratings yet

- LED DiceDocument6 pagesLED DicesuchigautamNo ratings yet

- 14 Segment Alpha Numeric Led Featherwing PDFDocument36 pages14 Segment Alpha Numeric Led Featherwing PDFDeepak S SNo ratings yet

- FD Series Position Switches: Selection DiagramDocument10 pagesFD Series Position Switches: Selection DiagramKoray AğsakalNo ratings yet

- Live Line WorkingDocument36 pagesLive Line WorkingNirina TsivazaNo ratings yet

- Docs 07 5356 18 0zse Zigbee Smart Energy Profile SpecificationDocument356 pagesDocs 07 5356 18 0zse Zigbee Smart Energy Profile SpecificationSang tae KimNo ratings yet

- Mine CraftDocument34 pagesMine Craftevidal881107No ratings yet

- Adafruit Capacitive Touch Sensor BreakoutsDocument32 pagesAdafruit Capacitive Touch Sensor BreakoutsCharlie HerbertNo ratings yet

- Doodle Bot Instruction ManualDocument12 pagesDoodle Bot Instruction ManualPepe DoserNo ratings yet

- Equinox II11 ADocument5 pagesEquinox II11 AMaulana AdiNo ratings yet

- JolliCube LEDDocument18 pagesJolliCube LEDBobbyNo ratings yet

- Adafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis PlayerDocument33 pagesAdafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis PlayerYudi 135791No ratings yet

- Metallized Polypropylene Film Capacitors (MKP) in Plastic Case B 32 652 B 32 656Document12 pagesMetallized Polypropylene Film Capacitors (MKP) in Plastic Case B 32 652 B 32 656Taoufik TaouhouNo ratings yet

- Lazy 7 MiniDocument36 pagesLazy 7 MinidiegargyNo ratings yet

- TANITA kd200Document10 pagesTANITA kd200King MaxNo ratings yet

- Pizzato FP Posswitch BrochureDocument10 pagesPizzato FP Posswitch BrochureBubu ChachaNo ratings yet

- DIY LED ProjectorDocument5 pagesDIY LED Projector余醫師No ratings yet

- All About LedsDocument29 pagesAll About LedsLatifa BoukhrisNo ratings yet

- Live Line WorkingDocument34 pagesLive Line WorkingMario HerediaNo ratings yet

- NOA Build ManualDocument42 pagesNOA Build ManualJelly PinNo ratings yet

- LED DiceDocument16 pagesLED DiceRenzo RomeroNo ratings yet

- Dancing LedsDocument2 pagesDancing LedsHarsha100% (1)

- Schematic - Matrex LEDDocument1 pageSchematic - Matrex LEDvinNo ratings yet

- Arduino LED Matrix DisplayDocument16 pagesArduino LED Matrix DisplayJulio MontesNo ratings yet

- Digital IC Projects RayerDocument51 pagesDigital IC Projects RayerYuri SeifaneNo ratings yet

- Datasheet 558Document16 pagesDatasheet 558Carlos GomezNo ratings yet

- 044-053 LeoDocument10 pages044-053 LeoAjmeerNo ratings yet

- Coils Strips Sheets MCS ENG - Rev-02-2023Document21 pagesCoils Strips Sheets MCS ENG - Rev-02-2023Arnoldas MockusNo ratings yet

- Clipping Indicator: For Compact DiscDocument5 pagesClipping Indicator: For Compact DiscSanedrac AcNo ratings yet

- Lampro Distribution Product Brochure 2023-11-15Document14 pagesLampro Distribution Product Brochure 2023-11-15nghidn269No ratings yet

- EN Spurwechselassistent - Audi A4 8K A5 8T Q5 8R - PreviewDocument4 pagesEN Spurwechselassistent - Audi A4 8K A5 8T Q5 8R - Previewsandyboy2000No ratings yet

- Led LampDocument6 pagesLed LampYonas GereNo ratings yet

- TZXCassette Mod v0.2Document25 pagesTZXCassette Mod v0.2Alfonso Dou OblancaNo ratings yet

- Adafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis PlayerDocument38 pagesAdafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis Playeranonymous2018 decemberNo ratings yet

- Matrix LED Candle Light: InstructablesDocument23 pagesMatrix LED Candle Light: InstructablesjlpicardNo ratings yet

- No. Jenis Barang Nama Barang Qty Toko Mitraabadi: Led Strip SMD 5050 BiruDocument10 pagesNo. Jenis Barang Nama Barang Qty Toko Mitraabadi: Led Strip SMD 5050 BiruChu Khil'sNo ratings yet

- Lauterbach Tricore App OcdsDocument52 pagesLauterbach Tricore App OcdsssssdaNo ratings yet

- LEDLamp PDFDocument6 pagesLEDLamp PDFLuly PerezkNo ratings yet

- Kontron JIDA32 Library API: Technical Manual Rev. 1.8Document61 pagesKontron JIDA32 Library API: Technical Manual Rev. 1.8kostalexisNo ratings yet

- List of Materials - SUGDocument9 pagesList of Materials - SUGVioktavian ErlanggaNo ratings yet

- Partcomp 3D HelpDocument45 pagesPartcomp 3D HelpEric LavrijsenNo ratings yet

- Top PlugDocument2 pagesTop Plugwar10ckjupiNo ratings yet

- Brosur LED POINT 3CM With CoverDocument1 pageBrosur LED POINT 3CM With Coverleo adelan sihombingNo ratings yet

- Mosaic Bulkhead LightsDocument2 pagesMosaic Bulkhead LightsManuel MunozNo ratings yet

- LampBook Final Lowres PDFDocument40 pagesLampBook Final Lowres PDFFabricio Merida GonzalesNo ratings yet

- SPE IM120424014 EONE 12864 Graphic LCDDocument16 pagesSPE IM120424014 EONE 12864 Graphic LCDИванNo ratings yet

- Concrete Scanning With GPR BookDocument33 pagesConcrete Scanning With GPR BookfaisaltmNo ratings yet

- High Power LED Torch From JunkDocument22 pagesHigh Power LED Torch From JunkPierre LevertNo ratings yet

- Salmonella Enterica Salmonella EntericaDocument10 pagesSalmonella Enterica Salmonella EntericaBrasco KaramNo ratings yet

- ALS 204 LH (Top Labelling)Document2 pagesALS 204 LH (Top Labelling)Yashvanth ShettyNo ratings yet

- Upstream Innovation (English)Document101 pagesUpstream Innovation (English)Yanxi EvaristoNo ratings yet

- Number of Research PapersDocument18 pagesNumber of Research PapersVM SARAVANANo ratings yet

- Seismic Data ProcessingDocument45 pagesSeismic Data ProcessingFayyaz AbbasiNo ratings yet

- Marxism by Thozhar ThiyaguDocument4 pagesMarxism by Thozhar ThiyaguMathursathyaNo ratings yet

- Timing Calibration Harness AssemblyDocument5 pagesTiming Calibration Harness Assemblyflordeliz jimenez rodriguezNo ratings yet

- Cifra Club - Debbie Gibson - Lost in Your EyesDocument3 pagesCifra Club - Debbie Gibson - Lost in Your Eyesnivaldo de oliveira OliveiraNo ratings yet

- Avionics BasicsDocument7 pagesAvionics BasicsFiroz AhmedNo ratings yet

- Acg01 IntroDocument34 pagesAcg01 IntroGiang T.C. TranNo ratings yet

- DMGT501 1Document2 pagesDMGT501 1Hemanth KumarNo ratings yet

- 3 Most Dangerous Pressure PointsDocument4 pages3 Most Dangerous Pressure PointsNano ZetaNo ratings yet

- Comparative Study Based On Thermal Efficiency of Solar Air HeatersDocument6 pagesComparative Study Based On Thermal Efficiency of Solar Air Heatershicham El FeroualiNo ratings yet

- Verbs List SoundDocument16 pagesVerbs List SoundEliana Zapata RuedaNo ratings yet

- Product News: Cat C12 ACERT™ Marine Propulsion EngineDocument6 pagesProduct News: Cat C12 ACERT™ Marine Propulsion EnginericardoNo ratings yet

- Moxa Embedded Solution On IEC 61850Document25 pagesMoxa Embedded Solution On IEC 61850vovick_vovickNo ratings yet

- Assignment 2Document15 pagesAssignment 2NOOR HALIZA BINTI ALI (HMELAKA)No ratings yet

- ImmunoAssay ProtocolDocument31 pagesImmunoAssay ProtocolSanta Kumar75% (4)

- Cambridge International General Certificate of Secondary EducationDocument4 pagesCambridge International General Certificate of Secondary EducationlolNo ratings yet

- Wolverton Chapter 25 Photodynamic TherapyDocument9 pagesWolverton Chapter 25 Photodynamic TherapyNahas NazarNo ratings yet

- Anti-Inflammatory and Analgesic Activities of Flavonoid and Saponin Fractions From Zizyphus Lotus (L.) LamDocument5 pagesAnti-Inflammatory and Analgesic Activities of Flavonoid and Saponin Fractions From Zizyphus Lotus (L.) LamDaris UntoroNo ratings yet

- Investigation and Analysis Efficiency of A Sinusoidaly and Non-Sinusoidaly Supplied Transformer Under Linear and Non-Linear LoadingDocument5 pagesInvestigation and Analysis Efficiency of A Sinusoidaly and Non-Sinusoidaly Supplied Transformer Under Linear and Non-Linear LoadingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mathilde III.: MaterialsDocument10 pagesMathilde III.: MaterialsMaria Jose Lopez Needham100% (1)

- 4th Quarter ExamDocument2 pages4th Quarter ExamMa. Cynthia San JuanNo ratings yet

- ASTM C 566 Kadar AirDocument2 pagesASTM C 566 Kadar AirBengkulu BetonNo ratings yet

Diy Lego Led Bricks

Diy Lego Led Bricks

Uploaded by

CarolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diy Lego Led Bricks

Diy Lego Led Bricks

Uploaded by

CarolCopyright:

Available Formats

DIY Lego LED Bricks

Created by Ruiz Brothers

Last updated on 2018-08-22 03:59:05 PM UTC

Guide Contents

Guide Contents 2

Overview 3

DIY Lego LED Bricks 3

The Research Institute 3

More Glowy! 4

LED Sequins 6

Prerequisite Guides 6

Parts 7

Tools & Supplies 7

Adafruit LED Sequins - Multicolor Pack of 5 8

Tactile Switch Buttons (6mm slim) x 20 pack 8

Copper Foil Tape with Conductive Adhesive - 6mm x 15 meter roll 8

PLA Filament for 3D Printers - 1.75mm Natural Translucent - 1KG 8

Circuit Diagram 10

Wired Connections 10

Battery Power 10

3D Printing 11

Download and 3D Print 11

Edit Design 11

3D Printing Lego Bricks 11

Diffusing LEDs 12

Slice Settings 12

Supports, Brims & Walls 12

Brims 12

Wall Strength 12

Support Removal 14

Assembly 15

Prep LED Sequins 15

Measure and Tin Wires 16

Copper Tape 18

Button 18

LED wires 20

Copper Tape contacts 20

Mounting LEDs 22

Mount Buttton 23

Wedge Wires 24

Insert Batteries 25

Attach bottom 25

Completed Bricks 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 2 of 27

Overview

DIY Lego LED Bricks

In this guide, you'll learn how to build our own DIY Lego Light Bricks! Inside these bricks are 3D printed and house a

tiny LED with batteries. They’re pretty cool for adding lighting effects to your scenes and you can easily connect to

them to just about any lego compatible brick. You can make them in several colors and turn them on with a tiny button

on the side.

The Research Institute

The set used in this project is LEGO Cuusoo Research

Institute 21110 . This set was voted by LEGO idea

members and was sucessfully supported and

manufactured as a limited edition. Originally titled,

"Female Minifigure Set (https://adafru.it/uvA)", this set

was designed to encourage women to get into science

and technology professions. The goal was to help

overcome gender stereotyping in construction play toys.

The set features female paleontologist, astronomer and

chemist. The set has VERY limited availabilty on

amazon (https://adafru.it/uvB).

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 3 of 27

More Glowy!

Compared to official light bricks, these diffuse the whole brick instead of just being a spotlight. They’re both the same

size but offer different types lighting. The lego light bricks are great for pointing light, while the 3D printed brick glows

brighter and can fit in tighter spaces. But you can connect them together to make interesting combinations that

illuminate your projects.

This looks great because the LED is small enough to

diffuse the whole brick by angling the light.

Our printed version uses a tiny push button to turn the

lights on and off. Of course the two parts can fit

together, so you can combine them to any existing light

bricks!

These bricks can fit on even the smallest build plates, so

it should print on all 3D printers. It’s also a pretty fast

print, taking about 8 minutes to finish!

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 4 of 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 5 of 27

LED Sequins

These are the kid-sister to our popular Flora NeoPixel,

they only show a single color and they don't have digital

control, but that makes them smaller easier to use for

many projects!

We noticed the green LEDs seem to light bricks the

brightest!

Prerequisite Guides

We recommend walking through the following tutorial to get familiar with the components used in this project.

Collin's Lab: Soldering (https://adafru.it/rBf)

Collin's Lab: Multimeters (https://adafru.it/tIf)

All about LEDs (https://adafru.it/uuC)

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 6 of 27

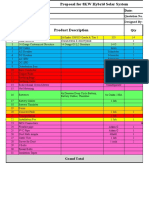

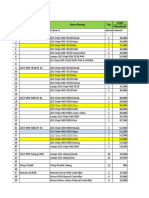

Parts

You'll need the following parts to build this project.

LED Sequins (http://adafru.it/3377)

6mm Push Button (http://adafru.it/1489)

2X LR41 Coin Cell Batteries (https://adafru.it/uuD)

M2x.4x9mm (https://adafru.it/pek) or #2-56x3/8 screw

Tactile Switch Buttons (6mm slim) (http://adafru.it/1489)

Copper Tape (http://adafru.it/1128)

Translucent PLA (http://adafru.it/2451)

Tools & Supplies

You'll also need the following tools and supplise to complete this project.

Soldering Iron & Solder (https://adafru.it/drI)

Tweezers (http://adafru.it/3096)

Wire Strippers (http://adafru.it/527)

Diagonal Flush Snips (https://adafru.it/dxQ)

Helping Third Hands (http://adafru.it/291)

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 7 of 27

Adafruit LED Sequins - Multicolor Pack of 5

$3.95

IN STOCK

ADD TO CART

Tactile Switch Buttons (6mm slim) x 20 pack

$4.95

IN STOCK

ADD TO CART

Copper Foil Tape with Conductive Adhesive - 6mm x 15

meter roll

$5.95

IN STOCK

ADD TO CART

PLA Filament for 3D Printers - 1.75mm Natural Translucent -

1KG

$39.95

IN STOCK

ADD TO CART

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 8 of 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 9 of 27

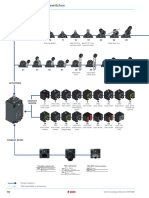

Circuit Diagram

Wired Connections

The circuit diagram above shows how the components will be wired together inside the brick. This won't be

100% exact in the actual circuit but it's a very close approximation.

A push button will open and close the connection between the batteries to turn the LED on and off. When the button is

held down, the LED stays on, and when it’s released the LED turns off.

Button to the + and - sides of the batteries

- on the battery to - on the LED sequin

+ on the battery to + on the LED squin

Battery Power

The circuit will be powered by two small LR 41 coin cell batteries. The batteries are arranged in series to increase the

voltage required to power the LED.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 10 of 27

3D Printing

Download and 3D Print

You can 3D print the bricks using opaque filament on almost any desktop 3D printer. The 3D printed parts can be

downloaded with the link below. If you don’t have a 3D printer, the files are free to download so can send them to a 3D

printing service.

Edit Design

You can easily update the size or add features by editing the Fusion360 designs. The sketches are all listed in the

timeline, so it's easy to adjust the size to each component.

https://adafru.it/uva

https://adafru.it/uva

https://adafru.it/uvb

https://adafru.it/uvb

https://adafru.it/svF

https://adafru.it/svF

https://adafru.it/svF

https://adafru.it/svF

3D Printing Lego Bricks

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 11 of 27

The LED brick was designed in Autodesk Fusion 360 and designed to print in PLA filament. The parts were 3D printed

using the BCN3D Sigma and Micro M3D. If you don’t have access to a 3D printer, you could use a service like 3D

Hubs (https://adafru.it/jNb) to make it for you.

Diffusing LEDs

We found Natural White PLA/PHA (http://adafru.it/3059) filament diffuses the LEDs the best. The soft diffusion

illuminates the whole brick. You can also use Translucent filament (http://adafru.it/2451) for a brighter light.

Slice Settings

Depending on your 3D printer, you may need to adjust the slice settings. We tested the enclosure on a BCN3D Sigma.

The legoBody.stl part will require support materials. The parts are oriented to print "as is".

Nozzle: 0.31mm

Extrusion Multiplier: 1.0

Extrusion Width: 0.39mm

Layer Height: 0.2mm

Nozzle Temperature: 225c

Print Speed: 60mm/s

Brim: 6mm

Supports, Brims & Walls

The legoBody.stl will require supports to support the

LED, battery and screw mounts .

Make sure to disable "dense supports" and vertical

upper and lower separation layers to make the supports

easier to remove.

We added pillars with a resolution of 2mm to the middle

under the walls that hold the parts in place. Add the

pillars so they can support the corners no the walls.

Brims

If you encounter lifting on the corners, we'll need to add

a brim to hold down the part. We used no heat and blue

painter tape and a 4 brim outlines around the part.

Wall Strength

We'll want the walls of the brick to be really strong by

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 12 of 27

making sure gaps between them are solid (no zig zags

inside the gaps). We had to adjust the nozzle diameter

and extrusion width to make sure no "zig zag" paths

are inside the wall gaps. Always preview tools paths

before printing to insure no strange paths are created.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 13 of 27

Support Removal

The 3D printed part will need supports to hold up the

mounting walls, so we can use flat pliers to help remove

them.

Position the pliers under the supports and lift up the pry

off as one piece. Use a hobby knife to clean up the gaps

between the walls.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 14 of 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 15 of 27

Assembly

Prep LED Sequins

LED sequins come in a pack of five. Use flush diagonal

cutters to them break away from the panel.

Cut close to the pads to avoid having to remove any

perforations on the edges.

We'll need to connect wires to the LED sequin from the

bottom of the PCB. You can tell which pad is positive

and negative by looking at Tthe adafruit logo – It's right

next to the postive+ pad.

Use third helping hands to secure the LED sequin.

Then, tin the positive and negative pads with a bit of

solder.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 16 of 27

Measure and Tin Wires

Now we can measure the wires for the LED and the

push button. For the push buttons we’ll measure from

the battery walls in the center, to the opening on the

side of the brick. The LED will connect from the center

cut away to the top of the two middle walls.

Match up the wire lengths for the opposite side and cut

them to size. Tin all of the wires so they won’t fray while

soldering together. It’s also a good idea use silicone

coated wires since we’ll need to flex the wires to fit

inside the brick. Here we’re using 30 gauge silicone

coated wire to fit between the wall gaps.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 17 of 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 18 of 27

Copper Tape

Now we can create the contacts for the coin cell by

using pieces of copper foil tape. The tape has a sticky

backing and we can solder wire directly to the tape.

Hold the pieces of copper foil tape with tweezers.

Secure the tweezers to third helping hands to keep it

sturdy while soldering. Tin one side of the piece of

copper foil tape with a bit of solder. Then, solder the

longer wires to the copper tape. Repeat this process for

the second wire.

Button

The longer wires will connect to the push button. To fit

our button inside the brick, we’ll first need to trim the

two pins from the button short. Cut both pins using a

pair of flush snips, just below where the they bend.

Secure the button to third helping hands. Then, tin the

two short pins with a bit of solder.

Next, we’ll connect the wires to the pins on the button.

These should be positioned on the inner side of the pins

at an up right angle. This way we can fit the button

through the opening on the brick.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 19 of 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 20 of 27

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 21 of 27

LED wires

Now we can solder the two shorter wires to the pads on

the LED sequin. Secure the LED sequin to third helping

hands. To diffuse the brick, we’ll need to position the

LED face down. Then, solder the wires on the bottom of

the PCB.

Copper Tape contacts

We’ll need two more pieces of copper foil tape for

connecting the batteries to the LED sequin. Use scissors

to cut thin slices of copper foil tape. Then, remove the

backing and stick them to the inside of the brick.

You can use tweezers to stick the copper foil tape to the

inner lining of the brick. Use the flat end of the tweezers

to evenly stick them to the walls. Follow the photo to

reference the correct position.

Next, tin the two pieces of copper foil tape with a bit of

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 22 of 27

solder.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 23 of 27

Mounting LEDs

Now we can insert the LED into the brick, face down. It

should press fit into place with the wire facing upright.

Next, position the wires toward the two pieces of

copper foil tape.

Hold the wire in place and carefully apply heat to solder

each wire to the copper foil tape. Make sure your iron is

clean so you can quickly solder the wires without

melting the brick.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 24 of 27

Mount Buttton

Now we can insert the push button into the brick with

the wiring going through the opening first. Press the

button in until it snaps into place.

The pins should be short enough to push up against the

wall. If the button stick out too much, you’ll need to trim

the pins until it fits.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 25 of 27

Wedge Wires

Now we can wedge both wires between the gaps in the

walls. Use the flat end of the tweezers to help tuck the

wires inside.

Remove the backing from the copper tape and stick it

the inner side of the walls.

© Adafruit Industries https://learn.adafruit.com/diy-lego-led-bricks Page 26 of 27

Insert Batteries

Next, insert the batteries in the brick. Line up the

positive and negative contacts with the copper foil tape

so they have matching polarities.

If the batteries are loose, you can add an additional

piece of copper tape to help keep the batteries from

moving around. Press the push button to check if the

LED powers on.

If it doesn’t power on, make sure the copper tape is

making contact with the batteries.

Attach bottom

Now we can secure the bottom cover to the brick. Use

an M2 (or a #2-56) machine screw to mount the two

parts together.

Fasten the screw through the bottom cover to create

threads in the mounting hole. Try to keep the machine

screw straight while fastening. Then, position it over the

brick and fasten the screw until both parts are tightly

mounted together.

© Adafruit Industries Last Updated: 2018-08-22 03:58:59 PM UTC Page 27 of 27

Completed Bricks

And now we have a super bright DIY lego light brick!! Add these to light light up props in scenes or even add it to

characters to give them a cool looking glow. You can of course combine these with original light bricks to create

different light combinations.

You might also like

- Get Fit Stay Well Chapter 4Document31 pagesGet Fit Stay Well Chapter 4Paden TranNo ratings yet

- EN Facelift LED Heckleuchten - VW Passat B8 - PreviewDocument3 pagesEN Facelift LED Heckleuchten - VW Passat B8 - PreviewLaurentiu Nancu0% (1)

- Republic of Zambia Form of Certificate of Medical ExaminationDocument2 pagesRepublic of Zambia Form of Certificate of Medical ExaminationKas Mus90% (10)

- Designmate 3024/3036 Top AssemblyDocument11 pagesDesignmate 3024/3036 Top AssemblySerge MaciaNo ratings yet

- English: Quarter 4 - Module 18: Matching Picture With Its Sight WordsDocument16 pagesEnglish: Quarter 4 - Module 18: Matching Picture With Its Sight WordsMark Edson Aboy100% (1)

- Ielts (Sample Answers Writing)Document101 pagesIelts (Sample Answers Writing)Dang Thuy Lieu100% (6)

- Thermal Camera With Display PDFDocument30 pagesThermal Camera With Display PDFImam Fakhrurrozi HidayatNo ratings yet

- Adafruit Data Logger ShieldDocument68 pagesAdafruit Data Logger ShieldArieffin NatawidjajaNo ratings yet

- Ruota Panoramica SMDDocument18 pagesRuota Panoramica SMDfattizzituaNo ratings yet

- Adafruit Feather m0 Express Designed For Circuit Python CircuitpythonDocument62 pagesAdafruit Feather m0 Express Designed For Circuit Python CircuitpythonConejoSinPompon gomaNo ratings yet

- AdaFruit Introducing Circuit PlaygroundDocument35 pagesAdaFruit Introducing Circuit Playgroundgardener10No ratings yet

- 12mm Led Pixels - 1539265432184Document16 pages12mm Led Pixels - 1539265432184Ritesh KatalkarNo ratings yet

- 10kw Hybrid SystemDocument6 pages10kw Hybrid SystemUmar HamidNo ratings yet

- Breadboards For Beginners: Created by Lady AdaDocument37 pagesBreadboards For Beginners: Created by Lady AdaTukser Dalibor SmetiškoNo ratings yet

- Practical Electronics - December 2022 PDFDocument76 pagesPractical Electronics - December 2022 PDFsameins100% (2)

- Create An Arduino 3X3 LED Cube in 30 Minutes - Arduino Hacks - Arduino HacksDocument11 pagesCreate An Arduino 3X3 LED Cube in 30 Minutes - Arduino Hacks - Arduino HacksGustavo Seben ColleNo ratings yet

- Raspberry Pi Pipboy 3000Document64 pagesRaspberry Pi Pipboy 3000AurélienMoulietsNo ratings yet

- LED DiceDocument6 pagesLED DicesuchigautamNo ratings yet

- 14 Segment Alpha Numeric Led Featherwing PDFDocument36 pages14 Segment Alpha Numeric Led Featherwing PDFDeepak S SNo ratings yet

- FD Series Position Switches: Selection DiagramDocument10 pagesFD Series Position Switches: Selection DiagramKoray AğsakalNo ratings yet

- Live Line WorkingDocument36 pagesLive Line WorkingNirina TsivazaNo ratings yet

- Docs 07 5356 18 0zse Zigbee Smart Energy Profile SpecificationDocument356 pagesDocs 07 5356 18 0zse Zigbee Smart Energy Profile SpecificationSang tae KimNo ratings yet

- Mine CraftDocument34 pagesMine Craftevidal881107No ratings yet

- Adafruit Capacitive Touch Sensor BreakoutsDocument32 pagesAdafruit Capacitive Touch Sensor BreakoutsCharlie HerbertNo ratings yet

- Doodle Bot Instruction ManualDocument12 pagesDoodle Bot Instruction ManualPepe DoserNo ratings yet

- Equinox II11 ADocument5 pagesEquinox II11 AMaulana AdiNo ratings yet

- JolliCube LEDDocument18 pagesJolliCube LEDBobbyNo ratings yet

- Adafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis PlayerDocument33 pagesAdafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis PlayerYudi 135791No ratings yet

- Metallized Polypropylene Film Capacitors (MKP) in Plastic Case B 32 652 B 32 656Document12 pagesMetallized Polypropylene Film Capacitors (MKP) in Plastic Case B 32 652 B 32 656Taoufik TaouhouNo ratings yet

- Lazy 7 MiniDocument36 pagesLazy 7 MinidiegargyNo ratings yet

- TANITA kd200Document10 pagesTANITA kd200King MaxNo ratings yet

- Pizzato FP Posswitch BrochureDocument10 pagesPizzato FP Posswitch BrochureBubu ChachaNo ratings yet

- DIY LED ProjectorDocument5 pagesDIY LED Projector余醫師No ratings yet

- All About LedsDocument29 pagesAll About LedsLatifa BoukhrisNo ratings yet

- Live Line WorkingDocument34 pagesLive Line WorkingMario HerediaNo ratings yet

- NOA Build ManualDocument42 pagesNOA Build ManualJelly PinNo ratings yet

- LED DiceDocument16 pagesLED DiceRenzo RomeroNo ratings yet

- Dancing LedsDocument2 pagesDancing LedsHarsha100% (1)

- Schematic - Matrex LEDDocument1 pageSchematic - Matrex LEDvinNo ratings yet

- Arduino LED Matrix DisplayDocument16 pagesArduino LED Matrix DisplayJulio MontesNo ratings yet

- Digital IC Projects RayerDocument51 pagesDigital IC Projects RayerYuri SeifaneNo ratings yet

- Datasheet 558Document16 pagesDatasheet 558Carlos GomezNo ratings yet

- 044-053 LeoDocument10 pages044-053 LeoAjmeerNo ratings yet

- Coils Strips Sheets MCS ENG - Rev-02-2023Document21 pagesCoils Strips Sheets MCS ENG - Rev-02-2023Arnoldas MockusNo ratings yet

- Clipping Indicator: For Compact DiscDocument5 pagesClipping Indicator: For Compact DiscSanedrac AcNo ratings yet

- Lampro Distribution Product Brochure 2023-11-15Document14 pagesLampro Distribution Product Brochure 2023-11-15nghidn269No ratings yet

- EN Spurwechselassistent - Audi A4 8K A5 8T Q5 8R - PreviewDocument4 pagesEN Spurwechselassistent - Audi A4 8K A5 8T Q5 8R - Previewsandyboy2000No ratings yet

- Led LampDocument6 pagesLed LampYonas GereNo ratings yet

- TZXCassette Mod v0.2Document25 pagesTZXCassette Mod v0.2Alfonso Dou OblancaNo ratings yet

- Adafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis PlayerDocument38 pagesAdafruit Music Maker Shield vs1053 mp3 Wav Wave Ogg Vorbis Playeranonymous2018 decemberNo ratings yet

- Matrix LED Candle Light: InstructablesDocument23 pagesMatrix LED Candle Light: InstructablesjlpicardNo ratings yet

- No. Jenis Barang Nama Barang Qty Toko Mitraabadi: Led Strip SMD 5050 BiruDocument10 pagesNo. Jenis Barang Nama Barang Qty Toko Mitraabadi: Led Strip SMD 5050 BiruChu Khil'sNo ratings yet

- Lauterbach Tricore App OcdsDocument52 pagesLauterbach Tricore App OcdsssssdaNo ratings yet

- LEDLamp PDFDocument6 pagesLEDLamp PDFLuly PerezkNo ratings yet

- Kontron JIDA32 Library API: Technical Manual Rev. 1.8Document61 pagesKontron JIDA32 Library API: Technical Manual Rev. 1.8kostalexisNo ratings yet

- List of Materials - SUGDocument9 pagesList of Materials - SUGVioktavian ErlanggaNo ratings yet

- Partcomp 3D HelpDocument45 pagesPartcomp 3D HelpEric LavrijsenNo ratings yet

- Top PlugDocument2 pagesTop Plugwar10ckjupiNo ratings yet

- Brosur LED POINT 3CM With CoverDocument1 pageBrosur LED POINT 3CM With Coverleo adelan sihombingNo ratings yet

- Mosaic Bulkhead LightsDocument2 pagesMosaic Bulkhead LightsManuel MunozNo ratings yet

- LampBook Final Lowres PDFDocument40 pagesLampBook Final Lowres PDFFabricio Merida GonzalesNo ratings yet

- SPE IM120424014 EONE 12864 Graphic LCDDocument16 pagesSPE IM120424014 EONE 12864 Graphic LCDИванNo ratings yet

- Concrete Scanning With GPR BookDocument33 pagesConcrete Scanning With GPR BookfaisaltmNo ratings yet

- High Power LED Torch From JunkDocument22 pagesHigh Power LED Torch From JunkPierre LevertNo ratings yet

- Salmonella Enterica Salmonella EntericaDocument10 pagesSalmonella Enterica Salmonella EntericaBrasco KaramNo ratings yet

- ALS 204 LH (Top Labelling)Document2 pagesALS 204 LH (Top Labelling)Yashvanth ShettyNo ratings yet

- Upstream Innovation (English)Document101 pagesUpstream Innovation (English)Yanxi EvaristoNo ratings yet

- Number of Research PapersDocument18 pagesNumber of Research PapersVM SARAVANANo ratings yet

- Seismic Data ProcessingDocument45 pagesSeismic Data ProcessingFayyaz AbbasiNo ratings yet

- Marxism by Thozhar ThiyaguDocument4 pagesMarxism by Thozhar ThiyaguMathursathyaNo ratings yet

- Timing Calibration Harness AssemblyDocument5 pagesTiming Calibration Harness Assemblyflordeliz jimenez rodriguezNo ratings yet

- Cifra Club - Debbie Gibson - Lost in Your EyesDocument3 pagesCifra Club - Debbie Gibson - Lost in Your Eyesnivaldo de oliveira OliveiraNo ratings yet

- Avionics BasicsDocument7 pagesAvionics BasicsFiroz AhmedNo ratings yet

- Acg01 IntroDocument34 pagesAcg01 IntroGiang T.C. TranNo ratings yet

- DMGT501 1Document2 pagesDMGT501 1Hemanth KumarNo ratings yet

- 3 Most Dangerous Pressure PointsDocument4 pages3 Most Dangerous Pressure PointsNano ZetaNo ratings yet

- Comparative Study Based On Thermal Efficiency of Solar Air HeatersDocument6 pagesComparative Study Based On Thermal Efficiency of Solar Air Heatershicham El FeroualiNo ratings yet

- Verbs List SoundDocument16 pagesVerbs List SoundEliana Zapata RuedaNo ratings yet

- Product News: Cat C12 ACERT™ Marine Propulsion EngineDocument6 pagesProduct News: Cat C12 ACERT™ Marine Propulsion EnginericardoNo ratings yet

- Moxa Embedded Solution On IEC 61850Document25 pagesMoxa Embedded Solution On IEC 61850vovick_vovickNo ratings yet

- Assignment 2Document15 pagesAssignment 2NOOR HALIZA BINTI ALI (HMELAKA)No ratings yet

- ImmunoAssay ProtocolDocument31 pagesImmunoAssay ProtocolSanta Kumar75% (4)

- Cambridge International General Certificate of Secondary EducationDocument4 pagesCambridge International General Certificate of Secondary EducationlolNo ratings yet

- Wolverton Chapter 25 Photodynamic TherapyDocument9 pagesWolverton Chapter 25 Photodynamic TherapyNahas NazarNo ratings yet

- Anti-Inflammatory and Analgesic Activities of Flavonoid and Saponin Fractions From Zizyphus Lotus (L.) LamDocument5 pagesAnti-Inflammatory and Analgesic Activities of Flavonoid and Saponin Fractions From Zizyphus Lotus (L.) LamDaris UntoroNo ratings yet

- Investigation and Analysis Efficiency of A Sinusoidaly and Non-Sinusoidaly Supplied Transformer Under Linear and Non-Linear LoadingDocument5 pagesInvestigation and Analysis Efficiency of A Sinusoidaly and Non-Sinusoidaly Supplied Transformer Under Linear and Non-Linear LoadingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mathilde III.: MaterialsDocument10 pagesMathilde III.: MaterialsMaria Jose Lopez Needham100% (1)

- 4th Quarter ExamDocument2 pages4th Quarter ExamMa. Cynthia San JuanNo ratings yet

- ASTM C 566 Kadar AirDocument2 pagesASTM C 566 Kadar AirBengkulu BetonNo ratings yet