Professional Documents

Culture Documents

1206-1906 Qap

1206-1906 Qap

Uploaded by

Sambit NayakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1206-1906 Qap

1206-1906 Qap

Uploaded by

Sambit NayakCopyright:

Available Formats

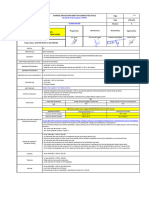

BBR INDIA PVT LTD,BANGALORE.

Inspection Test Plan for Post Tension Anchorage systems

Sl. Characteristics to be Quantum of Check / Verification / Inspection

Activity / Process Ref. Doc. / Code Acceptance criteria

No. cheked Frequency Records

Batch Test on raw material

a) Tensile strength IS:210-2009 Min 260 N/mm2 Each Heat No / Lot Manufacturers Test Certificate

As per IS 210 Chemical

Composition of Cast Iron shall

Bearing Plate

be left to the discretion of

castings b) Chemical Properties IS:210-2009 Each Heat No / Lot Manufacturers Test Certificate

manufacturer (to achieve the

1206/1906

1 mechanical properties-Tensile

Anchorage]

strength Min 260 N/mm2 )

Raw material FG260

Batch tests (on finished products)

a) Surface hardness IS:210-2009 180-230 BHN Each Heat No / Lot Manufacturers Test Certificate

b) Physical dimensions BBR dwg BBR Strandards 1% Batch Qty Dimensional Report

a) Tensile strength IS:1865-1991 Min 500 N/mm2 Each Heat No / Lot Manufacturers Test Certificate

As per IS 1865 Chemical

Composition of Cast Iron shall

Bearing Plate be left to the discretion of

castings b) Chemical Properties IS:1865-1991 Each Heat No / Lot Manufacturers Test Certificate

manufacturer (to achieve the

2 2206 Anchorage] mechanical properties-Tensile

Raw material SG500 strength Min 500 N/mm2 )

Batch tests (on finished products)

a) Surface hardness IS:1865-1991 160-240 BHN Each Heat No / Lot Manufacturers Test Certificate

b) Physical dimensions BBR dwg BBR Strandards 1% Batch Qty Dimensional Report

1206/1906/2206

3 Batch tests (on finished products)

Trumpet

a) Physical dimensions BBR dwg BBR Strandards 1% Batch Qty Dimensional Report

Inspection Test Plan for Post Tension Anchorage systems

Sl. Characteristics to be Quantum of Check / Verification / Inspection

Activity / Process Ref. Doc. / Code Acceptance criteria

No. cheked Frequency Records

Batch Test on raw material

a. Carbon.- 0.42-0.50

b. Manganese-0.50- 0.80

C45 as per DIN EN c. Silicon – 0.40Max

a) Chemical properties 1 sample per 10MT Manufacturers Test Certificate

10083-2 d. Sulphur- 0.045Max

e. Phosphorous -0.045Max

Anchor Heads

{1906 1206 & 2206 b) Tensile strength C45 as per DIN EN

Min 560 N/mm2 1 sample per 10MT Manufacturers Test Certificate

4 Anchorage] Raw 10083-2

material C45 C45 as per DIN EN

c) Elongation Min 16 % 1 sample per 10MT Manufacturers Test Certificate

10083-2

C45 as per DIN EN

d) Yeild stress Min 275 N/mm2 1 sample per 10MT Manufacturers Test Certificate

10083-2

Batch tests (on finished products)

C45 as per DIN EN

a) Surface Hardness 163-217 BHN 1 sample per 10MT Manufacturers Test Certificate

10083-2/DIN 17200

b) Physical dimensions BBR dwg BBR Strandards 1% Batch Qty Dimensional Report

Batch Test on raw material

a. Carbon. 0.07-0.15

b. Manganese-0.80- 1.20

a) Chemical properties BS:970 c. Silicon – 0.10 max 1 samples per 10MT- Manufacturers Test Certificate

Wedges [ 0.6] Raw d. Sulphur- 0.20-0.30

5 e. Phosphorous -0.07max

material EN1A

Batch tests (on finished products)

Sample per charge

Surface Hardness [700 Hv At Heat Treatment Lab / NABL

a) Surface Hardness BBR Strandards (1charge = 250kgs)

1(min) ] accredited Independent Lab

approx – 3300 nos

b) Physical dimensions BBR dwg BBR Strandards 1% Batch Qty Dimensional Report

You might also like

- SANS 10100-3 Design of Concrete Water Retaining Structures PDFDocument34 pagesSANS 10100-3 Design of Concrete Water Retaining Structures PDFNaish Ulassi100% (2)

- Part 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksDocument5 pagesPart 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksErickson Malicsi100% (2)

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDocument2 pagesTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- 694Document1 page694Mauricio Ramirez100% (1)

- ELS Final Module - 5-08082020Document26 pagesELS Final Module - 5-08082020Adonis Besa86% (100)

- Sakhalin LNG-Train GenDocument54 pagesSakhalin LNG-Train GenRobert WatersNo ratings yet

- Pages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesDocument1 pagePages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesPradeepNo ratings yet

- BHEL Creep Test Boiler Tube PDFDocument3 pagesBHEL Creep Test Boiler Tube PDFGopal RamalingamNo ratings yet

- Checklist & QAP Fabrication, Painting of Steel GirderDocument19 pagesChecklist & QAP Fabrication, Painting of Steel GirderSse SteelNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- Modelquality Assuranceplanforpot 1Document8 pagesModelquality Assuranceplanforpot 1mouni9301997No ratings yet

- Methodology For Bitumen MasticDocument6 pagesMethodology For Bitumen MasticSudip MukhopadhyayNo ratings yet

- MPS TemplateDocument4 pagesMPS TemplategaurangNo ratings yet

- PTC Test Program For ASTM A351Document3 pagesPTC Test Program For ASTM A351Deepak DasNo ratings yet

- Component Details:: Fairfield Atlas LimitedDocument3 pagesComponent Details:: Fairfield Atlas LimitedAndras StegerNo ratings yet

- Tube CS179 - MPSDocument3 pagesTube CS179 - MPSgaurangNo ratings yet

- Fairfield Atlas Limited: 6.1 - Minimum 5 Samples Per Heat Batch To Be CheckedDocument3 pagesFairfield Atlas Limited: 6.1 - Minimum 5 Samples Per Heat Batch To Be CheckedAndras StegerNo ratings yet

- Borl Qap R1Document2 pagesBorl Qap R1infoNo ratings yet

- Bharat Gears Limited: PREPARED BY Mr. YogendraDocument13 pagesBharat Gears Limited: PREPARED BY Mr. YogendraAnonymous lzxpjxNo ratings yet

- Al Farabi - 001 CS Castings REV.1Document4 pagesAl Farabi - 001 CS Castings REV.1Kamal ThummarNo ratings yet

- Powergrid Corporation of India Limited: Standard Field Quality Plan For Switchyard Civil WorksDocument18 pagesPowergrid Corporation of India Limited: Standard Field Quality Plan For Switchyard Civil WorksPremBhushanNo ratings yet

- AZ-MSS-919-002 - Rev.0 (SA 516 GR.70 N+SPWHT)Document2 pagesAZ-MSS-919-002 - Rev.0 (SA 516 GR.70 N+SPWHT)omersheikh12No ratings yet

- Salt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDDocument3 pagesSalt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDkayaltharanNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- 07 QAP-DynamicDocument7 pages07 QAP-DynamicEticala RohithNo ratings yet

- Model Quality Assurance Plan For Pot-Ptfe BearingsDocument8 pagesModel Quality Assurance Plan For Pot-Ptfe Bearingsghaghra bridgeNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Fitp For Concrete Works & GabionDocument4 pagesFitp For Concrete Works & GabionSofda ImelaNo ratings yet

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- Product Quality Plan: Customer Manufacturer Conductor Type SizesDocument7 pagesProduct Quality Plan: Customer Manufacturer Conductor Type SizesAvinash LalNo ratings yet

- TATA Painting Specification 40Document1 pageTATA Painting Specification 40Suleman KhanNo ratings yet

- Supplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingDocument22 pagesSupplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingBhavna Acharya100% (1)

- Qap-Al59 DogDocument5 pagesQap-Al59 DogShashikumar SNo ratings yet

- MK Purity (42CrMo4+QT)Document2 pagesMK Purity (42CrMo4+QT)Ертан РемзиевNo ratings yet

- 6 RR FR LSHDocument1 page6 RR FR LSHGaurav MittalNo ratings yet

- F-04 (Ultrasonic Test.) (New) Dated. 25.03.2016 JOKA123Document52 pagesF-04 (Ultrasonic Test.) (New) Dated. 25.03.2016 JOKA123Himanshu SinghNo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- Tata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly ValvesDocument2 pagesTata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly Valveser_sanjaypatelNo ratings yet

- Quality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")Document3 pagesQuality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")sriram.5230No ratings yet

- 1.1 - Customer: FMC: P 6471589-0 1 Stage Carrier: N07210501Document3 pages1.1 - Customer: FMC: P 6471589-0 1 Stage Carrier: N07210501Andras StegerNo ratings yet

- ArmaGelDT - TDS - EN-Dual TempDocument4 pagesArmaGelDT - TDS - EN-Dual TempLee Kok RoyNo ratings yet

- Page 2 Tsi MTC 150x4 (MTC - 247)Document2 pagesPage 2 Tsi MTC 150x4 (MTC - 247)trayojam.rilNo ratings yet

- TDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Document1 pageTDC-STD-PP011, Rev.02 (SA-234 Gr. WPB and WPC)Tanpreet SinghNo ratings yet

- TDCDocument6 pagesTDCalex hutaurukNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- 1.sa 516 110324-NDocument2 pages1.sa 516 110324-Nmahesh kumarNo ratings yet

- Tds PP 30% FV Old Polifor C l30 Gf30 TsDocument2 pagesTds PP 30% FV Old Polifor C l30 Gf30 Tsantonio.sevelarNo ratings yet

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Document1 pageTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNo ratings yet

- ITP-Steel Structure NewDocument5 pagesITP-Steel Structure NewPrasanta ParidaNo ratings yet

- Centre Pivot Assembly (Top & Bottom) (Mod-1) 97049 QM-C-7.1-BOGIE-0001-C-MOD-1Document4 pagesCentre Pivot Assembly (Top & Bottom) (Mod-1) 97049 QM-C-7.1-BOGIE-0001-C-MOD-1kapilparyani100% (1)

- Test ReportDocument1 pageTest ReportSeptyadi NugrohoNo ratings yet

- Guidelines For Source ApprovalDocument24 pagesGuidelines For Source ApprovalvamsiNo ratings yet

- DayeDocument2 pagesDayeJosip JurčićNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Bo 88 20 X 65 RJSDocument2 pagesBo 88 20 X 65 RJSDonny SetiawanNo ratings yet

- Routine & Acceptance Tests - InsulatorsDocument22 pagesRoutine & Acceptance Tests - InsulatorsavgNo ratings yet

- Std. QAP of Expension Joints (March 16)Document6 pagesStd. QAP of Expension Joints (March 16)ghaghra bridgeNo ratings yet

- Encon: Quality Assurance PlanDocument1 pageEncon: Quality Assurance PlanRaj DhuriNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Civil SOR QAP MasterDocument12 pagesCivil SOR QAP MasterKgnconstcorediffmail.com 557786No ratings yet

- Anchorage System ReportDocument4 pagesAnchorage System ReportSambit NayakNo ratings yet

- Wedge En1a Raw Material TCDocument1 pageWedge En1a Raw Material TCSambit NayakNo ratings yet

- Bearing Plate FG 260 Raw Materail MTCDocument1 pageBearing Plate FG 260 Raw Materail MTCSambit NayakNo ratings yet

- Methodology Well Foundation at Yamuna RiverDocument18 pagesMethodology Well Foundation at Yamuna RiverSambit NayakNo ratings yet

- Soil Stablization Methodology Final (After Correction)Document6 pagesSoil Stablization Methodology Final (After Correction)Sambit NayakNo ratings yet

- Rigid Pavement Details - 13.01.2022Document5 pagesRigid Pavement Details - 13.01.2022Sambit NayakNo ratings yet

- Re Wall MethodologyDocument9 pagesRe Wall MethodologySambit NayakNo ratings yet

- MIL DTL 14824 - Amendment1Document32 pagesMIL DTL 14824 - Amendment1conradocoutoNo ratings yet

- Expansion Joints DataDocument52 pagesExpansion Joints DatamehdiNo ratings yet

- ASME General 100 QuestionsDocument54 pagesASME General 100 Questionsatulpatil99100% (2)

- J Type Heat ExchangerDocument5 pagesJ Type Heat ExchangerAhmet Samet ÖzdilekNo ratings yet

- Annurev Ms 25 080195 001455 PDFDocument31 pagesAnnurev Ms 25 080195 001455 PDFVeeturiVarunNo ratings yet

- Day8-Startup Procedure of MIG Welding CellDocument10 pagesDay8-Startup Procedure of MIG Welding CellBala ThebossNo ratings yet

- Sterilization TechniquesDocument10 pagesSterilization Techniqueshassanahmed30011994No ratings yet

- Monoproof Pu 1000: Single Component, Aliphatic, Water Based Exterior Pu Modified, Flexible Water Proofing MembraneDocument5 pagesMonoproof Pu 1000: Single Component, Aliphatic, Water Based Exterior Pu Modified, Flexible Water Proofing MembraneMonarch DigitalNo ratings yet

- Compass Pools EN 2010Document16 pagesCompass Pools EN 2010Compass Ceramic PoolsNo ratings yet

- BASF Glyoxal BrochureDocument8 pagesBASF Glyoxal BrochureMukund KsNo ratings yet

- Cochrane, Nathan - Iatrogenic Damage To Enamel During Fixed Orthodontic TreatmentDocument1 pageCochrane, Nathan - Iatrogenic Damage To Enamel During Fixed Orthodontic TreatmentmalifaragNo ratings yet

- IEEE 56 - 77 - Guía para El Mtto de Aislación GENDocument23 pagesIEEE 56 - 77 - Guía para El Mtto de Aislación GENRaúl LuqueNo ratings yet

- Timber - Flooring - Definitions, Terms and Joinery DetailsDocument53 pagesTimber - Flooring - Definitions, Terms and Joinery DetailsZahra BathoolNo ratings yet

- Chapter 6 Part 3Document31 pagesChapter 6 Part 3Harith ZikryNo ratings yet

- Worksheet On P BlockDocument3 pagesWorksheet On P BlockJoel JohnsonNo ratings yet

- 2 不可靠 摩擦力参考文件 Expansion and Global Buckling Calculation ReportDocument32 pages2 不可靠 摩擦力参考文件 Expansion and Global Buckling Calculation ReportwangNo ratings yet

- AntifreezeDocument7 pagesAntifreezebobNo ratings yet

- Safety Data Sheet: AcetoneDocument4 pagesSafety Data Sheet: AcetoneBuwanah SelvaarajNo ratings yet

- Petrology and Geochemistry of Igneous Rocks in ZarDocument13 pagesPetrology and Geochemistry of Igneous Rocks in ZarHasanuddin NurdinNo ratings yet

- Axel Products, Inc. - Testing and AnalysisDocument2 pagesAxel Products, Inc. - Testing and AnalysisHasif SharifNo ratings yet

- Https WWW - Mitsubishicarbide.com Mmus Catalog PDF Catalog en C006a LDocument12 pagesHttps WWW - Mitsubishicarbide.com Mmus Catalog PDF Catalog en C006a LTungstenCarbideNo ratings yet

- Packaging WHODocument40 pagesPackaging WHOFatimahAhmatNo ratings yet

- Chap 8 Fatiguepart 1Document32 pagesChap 8 Fatiguepart 1Abu Salman Said100% (1)

- US10035781 ArgonDocument12 pagesUS10035781 ArgonMaru LinNo ratings yet

- Laboratorium Geologi Optik: Laporan Resmi Praktikum Mineral Optik Acara: Feldspar Dan KuarsaDocument6 pagesLaboratorium Geologi Optik: Laporan Resmi Praktikum Mineral Optik Acara: Feldspar Dan KuarsaAldi Hendra HermawanNo ratings yet

- Scope and DelimitationsDocument2 pagesScope and DelimitationsMyra Lee Camarista EsmayaNo ratings yet

- IJTRD3668Document3 pagesIJTRD3668Edmar CardenasNo ratings yet