Professional Documents

Culture Documents

Viscoelastic Solid-Repellent Coatings For Extreme Water Saving and Global Sanitation

Viscoelastic Solid-Repellent Coatings For Extreme Water Saving and Global Sanitation

Uploaded by

yiporOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscoelastic Solid-Repellent Coatings For Extreme Water Saving and Global Sanitation

Viscoelastic Solid-Repellent Coatings For Extreme Water Saving and Global Sanitation

Uploaded by

yiporCopyright:

Available Formats

Articles

https://doi.org/10.1038/s41893-019-0421-0

Viscoelastic solid-repellent coatings for extreme

water saving and global sanitation

Jing Wang 1,2, Lin Wang 2,3,6, Nan Sun1,2,6, Ross Tierney4, Hui Li5, Margo Corsetti1, Leon Williams4,

Pak Kin Wong1,5 and Tak-Sing Wong 1,2,5*

Water scarcity threatens over half of the world’s population, yet over 141 billion litres of fresh water are used globally each day

for toilet flushing. This is nearly six times the daily water consumption of the population in Africa. The toilet water footprint is

so large primarily because large volumes of water are necessary for the removal of human faeces; human faeces is viscoelastic

and sticky in nature, causing it to adhere to conventional surfaces. Here, we designed and fabricated the liquid-entrenched

smooth surface (LESS)—a sprayable non-fouling coating that can reduce cleaning water consumption by ~90% compared with

untreated surfaces due to its extreme repellency towards liquids, bacteria and viscoelastic solids. Importantly, LESS-coated

surfaces can repel viscoelastic solids with dynamic viscosities spanning over nine orders of magnitude (that is, three orders of

magnitude higher than has previously been reported for other repellent materials). With an estimated 1 billion or more toilets

and urinals worldwide, incorporating LESS coating into sanitation systems will have significant implications for global sanita-

tion and large-scale wastewater reduction for sustainable water management.

W

ater shortage is one of today’s most pressing global orders of magnitude higher than was previously reported for other

issues1. In 2016, 4 billion people in the world faced severe repellent materials. To our knowledge, no state-of-the-art liquid

water scarcity2. With the growing world population, repellent surfaces have shown repellency against viscoelastic solids

fresh water supply continues to be in high demand, with typical con- with dynamic viscosity higher than ~100 Pa s (refs. 19–26).

sumption ranging from everyday household to industrial activities3. LESS consists of a nanoscopically smooth solid surface that is

To address the water shortage issue, mainstream research has been functionalized with molecularly grafted polymers that stabilize a

focused on finding new methods for sourcing fresh water, such as thin layer of lubricant through intermolecular forces. In addition,

water desalination and treatment4–6, and techniques for harvesting LESS can be applied onto various hydrophilic surfaces (for exam-

water from air7–10. Methods for reducing water waste by minimizing ple, ceramic, vitreous china, carbon steel, and so on) and complex

wastewater generation from daily household and industrial activi- geometries within minutes under ambient conditions. Additionally,

ties, such as toilet flushing, have received relatively less attention. we have shown that LESS can maintain non-stickiness towards

In the United States, toilet flushing accounts for 24% of all indoor human faeces, outperforming other commercially available mate-

domestic wastewater-producing activities, and is the largest con- rials. We have further demonstrated that LESS possesses excellent

tributor of indoor household wastewater production11. Globally, it anti-biofouling properties, which could reduce the use of aggressive

is estimated that over 141 billion litres of water—nearly six times the chemicals currently used for sterilization. For a standard toilet using

daily water consumption of the entire population in Africa12—are 1.6 gallons flush−1 (~6 l flush−1), our characterization and analysis

used each day for toilet flushing alone13. A number of approaches show that every 1 ml of LESS coating fluid could potentially save

have been proposed to reduce fresh water consumption for toilet >1,000 l of water. Our coating is highly scalable and can easily be

flushing that range from the use of rainwater for flushing14 to the incorporated into used or existing ceramic- and metal-based toilets

use of self-contained dry toilets15. Owing to a great variety of com- and urinals to improve global sanitation and reduce wastewater

plex factors, such as local environment16, resource availability17 and production—a challenge that is listed as one of the 17 Sustainable

user preference18, none of these approaches can completely address Development Goals by the United Nations (that is, clean water

the water consumption issue. A relatively unexplored approach is and sanitation).

to engineer the material interface of toilet surfaces to significantly

weaken the adhesion of human faeces and urine in order to reduce Results and discussion

the amount of flushing water for waste removal. Our LESS coatings have been designed through interfacial adhesion

Here, we report the design, fabrication and performance (relating and thermodynamic analyses to effectively repel liquid, bacteria

to sanitation and water reduction) of a liquid-entrenched smooth and viscoelastic solids, and have been characterized under relevant

surface (LESS)—a sprayable, multifunctional surface coating that experimental conditions related to sanitation and water conserva-

can reduce cleaning water consumption by ~90% compared with an tion applications.

uncoated surface. The LESS is designed to repel aqueous fluids, bac-

teria and viscoelastic solids with dynamic viscosities spanning over Design criteria of LESS. Reducing the adhesion between viscoelas-

nine orders of magnitude (that is, from ~10−3 to ~105 Pa s)—three tic solid and substrate surfaces would require lowering the work of

1

Department of Mechanical Engineering, The Pennsylvania State University, University Park, PA, USA. 2Materials Research Institute, The Pennsylvania

State University, University Park, PA, USA. 3Department of Materials Science and Engineering, The Pennsylvania State University, University Park, PA, USA.

4

Centre for Competitive Creative Design, Cranfield University, Cranfield, UK. 5Department of Biomedical Engineering, The Pennsylvania State University,

University Park, PA, USA. 6These authors contributed equally: Lin Wang, Nan Sun. *e-mail: tswong@psu.edu

Nature Sustainability | www.nature.com/natsustain

Articles Nature Sustainability

1.3 nm

Uncoated surface PDMS-grafted surface LESS

Substrate Lubricant Silane

Spray silane solution Spray lubricant Test with dyed water

Fig. 1 | Fabrication of LESS. a, Schematic showing the two-step spray-coating process to form the LESS coating. The molecularly grafted polymer layer

creates chemical affinity to the lubricant. b, Optical images showing the individual coating processes on glass. The lubricant used was silicone oil,

and the blue testing liquid was dyed water.

adhesion, wa. Specifically, the work of adhesion can be expressed Fabrication and characterization of LESS. Based on these design

as wa = R(γ13 + γ23 − γ12), which can be further simplified by the criteria, we have developed a number of LESS coatings for silica-

Girifalco and Good equation27 as wa = 2R(γ13 × γ23)1/2, where R is sur- based materials, such as glass, silicon, china, and so on. These

face roughness, defined as the ratio between apparent and projected substrates were chosen based on their inherent smoothness (with

surface areas of the solid substrate, and γij is the interfacial energy Ra = ~1 nm) and their hydroxyl group availability, which made

at the i–j interface, and 1, 2 and 3 refer to the solid substrate, visco- surface functionalization facile36. We further functionalized these

elastic solid and air, respectively. Therefore, minimizing wa can be surfaces with dimethyldimethoxysilane to create a polydimeth-

achieved: (1) physically by reducing the surface roughness, R; and ylsiloxane (PDMS)-grafted chemical layer (γ13 = ~21 mJ m−2). In

(2) chemically by reducing the interfacial energies of the underlying addition, silicone oil was chosen as the lubricating fluid due to its

solid–air interface (γ13) and the viscoelastic solid–air interface (γ23) strong chemical affinity towards the PDMS-grafted surfaces, as well

simultaneously. as its excellent chemical stability37 and low environmental impact38.

Accordingly, we designed LESS based on the above physical and Furthermore, our calculations of spreading parameters and

chemical criteria. To reduce wa physically, a nanoscopically smooth Hamaker constants A have shown that this specific material com-

solid substrate was used (that is, R = ~1), since the total work of bination (that is, silicone oil and the PDMS-grafted surface) satis-

adhesion between two surfaces is directly proportional to their fies the requirement for a stable lubricant film formation (that is,

respective contact area, which could be significantly increased by S ≥ 0 and A > 0; Supplementary Note 3 and Supplementary Tables 1

the presence of roughness27. Specifically, Dahlquist28 showed experi- and 2), which are consistent with our experimental observations

mentally that when the storage modulus of an adherent material is (Supplementary Video 1).

below a certain critical value (that is, typically 0.3 MPa), the mate- Our LESS can be formed on a range of substrates through a two-

rial will begin to flow and form conformal contact with the surface step spray-coating process (Fig. 1 and Supplementary Video 2).

roughness of the adherent, regardless of the applied pressure. Our The first step generates a covalently bonded chemical layer on the

adhesion measurements have further confirmed that the surface substrate, and the second step creates an overcoat lubricant layer.

adhesion of viscoelastic solids increases with the surface rough- Before the surface functionalization, the surfaces need to be rinsed

ness (with average roughness, Ra ranges from 0.87 ± 0.06 nm to with isopropanol and deionized water to remove surface contami-

4.12 ± 0.26 µm; Supplementary Note 1), indicating that a relatively nants and expose the hydroxyl groups. Once the surface is clean and

smooth surface is important in reducing surface adhesion with dry, a solution containing dimethyldimethoxysilane is sprayed onto

viscoelastic solids. the surface under ambient conditions, allowing these molecules to

Reducing wa chemically can be achieved conventionally by react with the hydroxyl groups, and forming a covalently bonded

functionalizing a smooth solid substrate with a low surface PDMS-grafted layer on the substrate. After rinsing with ethanol

energy coating (that is, reducing γ13), or by adding lubricant to and isopropanol to remove the excess PDMS, the silanized substrate

be absorbed by viscoelastic solid29 (that is, reducing γ23). To fur- then becomes hydrophobic and can repel both water and alkanes26.

ther reduce wa, both γ13 and γ23 can be reduced simultaneously This step is modified from the method developed by Wang and

by creating a stable lubricant layer between the substrate and the McCarthy26 without the need for oxygen plasma treatment, which

viscoelastic solid (Supplementary Fig. 1a and Supplementary allows for a simpler and more scalable fabrication process. The

Note 2). Unlike wetting of a liquid film on rough solids30,31, formation of the new surface functional group was confirmed by

achieving super-wetting of a liquid film on a smooth surface is X-ray photoelectron spectroscopy measurements showing the for-

more challenging and requires the use of intermolecular forces mation of Si–O bonds associated with dimethyldimethoxysilane

to stabilize the thin liquid film24,32. Thermodynamically, to (Supplementary Fig. 2). The thickness of the PDMS-grafted layer

achieve this condition, the lubricant should have a non-nega- was estimated to be ~1.3 nm from the X-ray photoelectron spectros-

tive spreading parameter S on the solid substrate and a positive copy measurement39 (Supplementary Note 4), and the water contact

disjoining pressure П(e)33–35 in the presence of both air and the angle hysteresis of the surface is 6.8 ± 0.5° (Supplementary Table 3).

foreign immiscible liquid of interest (that is, S ≥ 0 and П(e) > 0), In the second step, the PDMS-grafted surface is preferentially

respectively (Methods). wetted by silicone oil, forming a stable lubricating layer. The thickness

Nature Sustainability | www.nature.com/natsustain

Nature Sustainability Articles

a Substrate Lubricant

Silane Viscoelastic solid

Uncoated Superhydrophobic PDMS-grafted SLIPS LESS

Before

Faeces impact

Rinsing

b

Regime 1: Regime 2:

Conventional surfaces

liquid repellency solid repellency

LESS

10–3 10–2 10–1 1 10 10 2

103 104 105

Dynamic viscosity (Pa s)

Ref. 19 Ref. 20 Ref. 21

Ref. 22 Ref. 24 Ref. 25 Current work

Fig. 2 | Overview of state-of-the-art liquid and viscoelastic solid repellent surfaces. a, Schematic and optical images showing the comparison of adhesion

between viscoelastic solids and different engineered surfaces, including (left to right) an uncoated glass, a superhydrophobic glass, a PDMS-grafted

glass, a SLIPS-coated glass and a LESS-coated glass. The superhydrophobic glass was created using a commercially available superhydrophobic coating

(NeverWet). The SLIPS-coated glass had an underlying surface roughness of ~1 µm. Synthetic faeces with a solid content percentage of 30% (dynamic

viscosity = ~2,406 Pa s) was used in these experiments. b, Plot showing the reported dynamic viscosity range of liquids and viscoelastic solids that can be

repelled by the state-of-the-art liquid repellent surfaces and the LESS-coated surface.

of the lubricant can be controlled by either spin coating or spray (Fig. 2 and Supplementary Video 4)19–26. Furthermore, we have dem-

coating. In our experiments, the typical thickness of the lubricant onstrated that our LESS coating can be applied onto complex geome-

was controlled to be ~1 µm to ~10 µm. tries under room conditions without the use of advanced equipment.

Distinct from other fabrication methods to create liquid-infused As a demonstration, we applied LESS coating onto a toilet bowl

slippery surfaces, which generally take on the order of hours to surface through a spray-coating process. This coating could repel

complete32,40–42, our two-step fabrication process takes less than both dyed water and synthetic faeces more effectively than a com-

~5 min (Supplementary Video 2), and can be applied to other mercial hydrophobic glaze-coated toilet (Fig. 3 and Supplementary

hydrophilic materials such as ceramic, carbon steel, titanium, Videos 5 and 6).

and so on (Supplementary Video 3 and Supplementary Table 4).

LESS can effectively repel rainwater, soapy water and hard water Adhesion of LESS against viscoelastic synthetic faeces. To quan-

(Supplementary Note 5, Supplementary Fig. 3 and Supplementary tify the anti-adhesion performance of the LESS-coated surface, we

Tables 5–8), as well as synthetic faeces (Fig. 2a, Methods and performed surface adhesion measurements using synthetic faeces

Supplementary Video 2) with dynamic viscosities spanning over against other control surfaces. We prepared synthetic faeces with an

nine orders of magnitude (that is, from ~10−3 to ~105 Pa s) com- organic solid content similar to that of human faeces43 for adhesion

pared with other control surfaces including an uncoated surface, characterization (Methods and Supplementary Tables 9 and 10). The

a superhydrophobic surface, a PDMS-grafted smooth surface and solid contents of the synthetic faeces ranged from 10–60 wt%, which

a slippery liquid-infused porous surface (SLIPS)-coated surface corresponds to a storage modulus of between ~1 Pa (~10 wt%) and

Nature Sustainability | www.nature.com/natsustain

Articles Nature Sustainability

Commercial hydrophobic toilet LESS-coated toilet

Dyed water

Synthetic faeces

Fig. 3 | Comparison of liquid and synthetic faeces repellency between a state-of-the-art commercial hydrophobic glaze-coated toilet (SloanTec

hydrophobic glaze) and a LESS-coated toilet. Dyed water and synthetic faeces at 30% solid content were used in these tests. The thin arrows indicate the

sliding direction of the dyed water droplets. Scale bars: 5 cm. See also Supplementary Videos 5 and 6 for details.

~105 Pa (~60 wt%) (Supplementary Fig. 4). These values closely stresses generated by these flows range from 0.093 Pa (at 1 gal-

emulate those of fresh human faeces44,45. lon min−1) to 0.60 Pa (at 2.5 gallons min−1), which are similar to

First, we investigated the importance of a stable lubricant layer those of typical toilets (that is, ~0.11 to ~0.78 Pa47; Supplementary

for reducing surface adhesion. The control surfaces in these tests Note 6 and Supplementary Table 11). To simulate the adhesion of

included uncoated bare glass with and without lubrication of silicone faeces to toilet surfaces during defecation, we dropped the syn-

oil, and PDMS-grafted glass. We normalized the work of debonding thetic faeces (~5 g) from a height of ~400 mm onto the test surfaces

of the synthetic faeces on lubricated surfaces (lubricated glass and at a tilting angle of 45°. We then put the surfaces inside our open-

LESS) to that of the uncoated bare glass. Our results showed that channel flow system to determine the amount of water required

lubrication on bare glass can reduce the surface adhesion by ~41% to completely remove the faeces and their residues (Methods and

for synthetic faeces with 40% solid content (that is, the stickiest Supplementary Fig. 6). We verified the complete removal of the fae-

sample in the test). In comparison, grafted-PDMS glass can reduce ces residues using fluorescent trace dye, which was mixed with the

the surface adhesion by ~75%, while the LESS coating can reduce synthetic faeces during our tests (Supplementary Fig. 7). Compared

the adhesion by ~90% (Supplementary Fig. 1b). These experimen- with uncoated glass surfaces, LESS-coated surfaces reduced water

tal results are consistent with the predictions of work of adhesion, consumption to clean the surface by up to 90% for various synthetic

showing up to 46% reduction on lubricated glass, 74% reduction faeces at different solid contents (Fig. 4b,c). We also conducted sim-

on silanized glass and 86% reduction on LESS-coated glass com- ilar characterizations on SLIPS samples and found that the water

pared with untreated glass, respectively (Supplementary Note 2). consumption increased with increasing underlying substrate rough-

Our results indicate that the presence of a stable lubricating layer on ness—a trend consistent with the observations in the adhesion tests

the underlying solid substrate is critical to reduce surface adhesion. (Supplementary Figs. 5 and 6).

In the second set of tests, we investigated the influence of the

underlying surface roughness of the lubricated substrates on the Adhesion against human faeces. We further compared the adhe-

overall adhesion performance. The control surfaces in these tests sion characteristics of human faeces on LESS and other state-of-the-

included uncoated glass and silicone oil-infused SLIPS samples with art commercially available surfaces (Fig. 5a,b and Supplementary

either microscale (Ra= ~4 µm) or nanoscale roughness (Ra < 1 µm) Video 7). Specifically, we used glazed ceramic (a typical toilet mate-

on the underlying substrates (Supplementary Note 1). Our mea- rial), Teflon and silicone as the control surfaces. For these tests, we

surements showed that adhesion increased with increasing under- used a setup that allows human faeces samples to be released from

lying surface roughness (Supplementary Fig. 5 and Supplementary a drop rig at the same height onto an acrylic support where the test

Table 4). In general, the LESS-coated surface outperformed the con- coating is placed. When the support pin for the acrylic surface is

trol surfaces, including uncoated surfaces with or without lubrica- removed, the surface drops from a horizontal position to a vertical

tion, and SLIPS with different underlying roughnesses. According position, where the faeces are expected to slide down the face of the

to these tests (Fig. 4a), LESS coating can lead to 90% adhesion surface. In our tests, all of the commercial surfaces showed extreme

reduction in synthetic faeces (~40% solid content, with viscoelastic stickiness towards the human faeces samples. However, LESS-coated

characteristics similar to a type 3–4 healthy human faeces44,45) com- glass was the only surface showing non-stickiness towards the fae-

pared with uncoated surfaces. ces sample, and no noticeable residue was left behind (Fig. 5b).

Furthermore, we have shown in a different set of faeces impact tests

Water consumption of LESS. To investigate the volume of water that traces of faeces were left on a SLIPS-coated surface (with an

that would be required to clean LESS after contamination with the underlying surface roughness of ~1 µm) (Supplementary Fig. 8).

synthetic faeces, we built a simplified open-channel experimental Therefore, our tests further show that the LESS coating outperforms

setup to emulate the toilet-flushing process. Specifically, our setup various state-of-the-art surfaces when repelling human faeces.

is capable of generating a flow rate from 1 gallon min−1 (that is,

3.8 l min−1 with Reynolds number, Re = ~4,570, calculated based on Anti-bacterial performance of LESS. One important reason that

the hydraulic diameter46; Supplementary Note 6) to 2.5 gallons min−1 urinals or toilets need to be flushed and cleaned regularly is to

(that is, ~9.5 l min−1 with Re = ~11,600). The estimated wall shear prevent the growth of bacteria and the spread of infectious diseases

Nature Sustainability | www.nature.com/natsustain

Nature Sustainability Articles

a

Uncoated glass

1.2

LESS-coated glass

Normalized work of debonding

1.0

0.8

0.6

0.4

0.2

0

20 40 60

Solid content percentage (%)

b c

Flow rate Uncoated glass

Uncoated glass

4 (gallons min−1) 1.2 LESS-coated glass

LESS-coated glass

1.0

Normalized water consumption

Water consumption (gallons)

1.5 1.0

3 2.0

2.5

0.8

2

0.6

1 0.4

0.2

0

0

10 20 30 40 50 60 10 20 30 40 50 60

Solid content percentage (%) Solid content percentage (%)

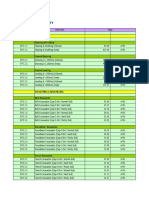

Fig. 4 | Work of adhesion and water consumption characterizations. a, Work of debonding of synthetic faeces of varying solid contents on uncoated

bare glass and LESS-coated glass. Data were normalized to the work of debonding of the synthetic faeces on uncoated glass. b, Water consumption

measurements on uncoated and LESS-coated glass under different flow rates after being impacted by ~5 g of synthetic faeces with different solid content

percentages. Error bars represent standard deviations of four independent measurements. c, Cleaning water consumption performance of different

surfaces after synthetic faeces impact. The data were normalized to the cleaning water consumption on uncoated glass for each solid weight percentage of

synthetic faeces. All error bars represent standard deviations of four to six independent measurements.

and odour generation. In certain regions (for example, Brazil), rain- substrates can repel all bacteria-contaminated synthetic urine with

water is used as the source for toilet flushing. However, rainwater a sliding angle of a droplet (10 µl) of <5° (Supplementary Fig. 10).

can contain bacteria that may contaminate the sanitation facilities14. In cases where all lubricant is depleted, we have shown that it is

Owing to the presence of the mobile lubricant interface of LESS, much easier to sterilize LESS than other liquid-infused surfaces

we hypothesize that LESS may have a strong anti-biofouling perfor- with underlying surface roughness (Supplementary Fig. 11).

mance towards bacteria23,48,49. To verify this, we performed biofoul- In addition to rainwater and contaminated urine, we have also

ing analyses on LESS-coated substrates using natural rainwater and tested bacterial fouling on LESS-coated and untreated glass using

bacteria-contaminated synthetic urine. Specifically, we collected synthetic faecal waste of different solid content percentages (10,

rainwater from a house roof in State College, Pennsylvania and mea- 30 and 50%) spiked with 108 colony-forming units ml−1 E. coli

sured its bacteria content and concentration (Methods). We identi- (Supplementary Fig. 12). Following the procedures described in

fied the bacteria in the rainwater50 using a MALDI Biotyper system Supplementary Note 8, we counted the bacteria colony numbers on

(Fig. 5c, Supplementary Note 7 and Supplementary Table 12). We these substrates after 24 h of incubation. Specifically, no visible bac-

rinsed the LESS-coated substrate and uncoated bare glass with the teria colonies were found on the LESS-coated substrate while up to

collected rainwater for 1 min, then immediately incubated the sub- ~2.5 × 105 colonies m−2 of bacteria were observed on untreated glass

strates by attaching solid agar onto the surfaces in an incubator. (Fig. 5d and Supplementary Fig. 13).

After 36 h of incubation, we counted the bacterial colonies on these All of these results indicate that LESS has excellent anti-

surfaces. Specifically, no observable bacteria colonies were found biofouling performance and could therefore reduce the use of dis-

on all LESS-coated substrates, whereas the untreated glass surfaces infectants or other aggressive chemicals currently used for cleaning

were contaminated with the bacteria in the rainwater (Fig. 5c). and sterilization.

In a different scenario, 10 ml Escherichia coli-contaminated syn-

thetic urine was sprayed onto the test surfaces, followed by the afore- Durability of LESS. We have investigated the durability of the LESS

mentioned procedures for the biofouling characterizations. Our test coating against continuous shear flow, the impact of synthetic faeces

results are similar to those found in the rainwater tests, where all and mechanical abrasion. In the first test, we quantified the change of

LESS-coated samples showed no observable bacteria colonies while lubricant thickness by applying continuous shear flow with flow rates

the glass substrate showed significant contamination with bacteria at 1.0 and 2.5 gallons min−1, which correspond to shear stresses of

(Supplementary Fig. 9). We have further shown that LESS-coated ~0.1 and ~0.6 Pa, respectively (Fig. 6a and Supplementary Table 11).

Nature Sustainability | www.nature.com/natsustain

Articles Nature Sustainability

a c

Dropping faeces

Bacterial density (colony m−2)

1.5 × 104

Stick or slip

Side view Faeces impact depending on surfaces

Testing surface

1.0 × 104 2 µm

0.5 × 104

Shaft Surface holder Holding pin

0

b Glass LESS

d

3.5 × 105

10% solid faeces

Bacterial density (colony m−2)

Ceramic Teflon Silicone LESS

3.0 × 105

30% solid faeces

2.5 × 105

Front view

50% solid faeces

2.0 × 105

E. coli

1.5 × 105

1.0 × 105 2 µm

5

0.5 × 10

0

Glass LESS

Fig. 5 | Anti-fouling performance of LESS. a,b, Human faeces dropping test on commercially available surfaces and a LESS-coated surface. a, Schematic

showing the human faeces dropping test procedure: (1) faeces are dropped from a height of 75 mm; (2) faeces impact onto the test surfaces; and (3) the

surfaces are released from horizontal to vertical orientation to determine whether faeces will adhere onto the surface or not. b, Optical images showing

the test results for different surfaces. The human faeces adhered onto ceramic, Teflon and silicone, but slid off the LESS-coated glass. c,d, Anti-bacterial

performance comparison. c, Bacteria adhesion test with rainwater on glass (control) and LESS-coated glass. Inset: scanning electron microscope images

show two types of bacteria found in the rainwater sample. The dimensions of the inset optical image showing bacteria colonies are 10 mm by 10 mm.

d, Bacteria adhesion test with E. coli-spiked synthetic faeces (10, 30 and 50% solid content) on different surfaces. Inset: scanning electron microscope

image of E. coli. Error bars in c and d represent standard deviations of three independent measurements.

Under these flow conditions, we identified two regimes of lubri- of 0.5 kg onto sandpaper (grit size: P400) and slid the sandpaper

cant depletion depending on the initial lubricant thickness. In the against the LESS-coated sample (Methods). Our results showed that

first regime, when the lubricant thickness is >1 µm, the lubricant the LESS coating can withstand ~300 abrasion cycles before show-

depletion rate is relatively high, and is typically on the order of ing signs of degradation in liquid repellency performance (Fig. 6c).

~0.01 µm s−1. In the second regime, when the lubricant thickness We note that since the PDMS-grafted substrate of LESS is

is <1 µm, the lubricant depletion rate is significantly reduced to designed to adhere the silicone oil as opposed to aqueous liquids,

<0.01 µm s−1. Note that a typical dual flush toilet consumes either it is possible to replenish the lubricant layer by incorporating small

0.8 or 1.6 gallons flush−1, and each flush takes on the order of 5 s47. amounts of silicone oil in the flushing water so that the silicone

Based on our experimental measurements, we estimate that our oil can preferentially wet the surface through displacement wet-

LESS coating with an initial thickness of ~1 µm can sustain >500 ting (Fig. 6d and Supplementary Note 9). Experimentally, we have

flushes in typical toilet environments. shown that silicone oil wets the PDMS-grafted ceramic surface even

In the second test, we evaluated the lubricant durability using when the surface has been pre-wetted by water, and subse-

a water jet to simulate urination. It is known that the initial flow quently forms a functional layer to repel the water (Fig. 6d and

velocity of human urine ranges from 0.28–0.52 m s−1 (ref. 51). Based Supplementary Video 8).

on Bernoulli’s equation, we can estimate that the velocity of urine

impacting the surface is ~3 m s−1 (Methods and Supplementary Potential water-saving and environmental impacts. To further

Fig. 14). A water jet setup was built to achieve such an impact estimate the potential water saving of LESS coating on commer-

velocity. We designed each urination cycle to consist of a continu- cial toilets, we conducted a minimal flush water test on a 1.6 gal-

ous flow of liquid jet for ~20 s since it has been reported that all lons flush−1 (or 6 l flush−1) toilet to estimate the minimum water

mammals above 3 kg urinate for a constant time (~21 ± 13 s) regard- needed to flush the waste through the toilet trapway and drain line

less of their size52. Contact angle hysteresis and lubricant thickness (Supplementary Note 10 and Supplementary Fig. 17). In the test,

were measured after every five urination cycles. Our results showed we gradually reduced the water volume in the tank to flush the

that the LESS coating can withstand at least 50 urination cycles synthetic faeces until they could no longer be completely flushed

before further replenishment of the lubricant layer is necessary down the toilet. Our results showed that ~2.2 ± 0.1 l of flushing

(Supplementary Fig. 15). water are needed. This is equivalent to a potential water saving of up

Furthermore, we tested the durability of the LESS coating by to ~63 ± 2%. Using our experimental characterization results with

impacting synthetic faeces of various solid contents, and we found ~1 ml coating fluid to coat a toilet surface (~600 cm2), it is estimated

that the LESS coating can sustain ~10 to ~35 impact cycles (Fig. 6b that one could save up to >1,000 l of water for every ml of coat-

and Supplementary Fig. 16). The loss of durability of our coating ing fluid used for a typical 1.6 gallons flush−1 toilet. Furthermore,

was mainly due to lubricant loss caused by faeces adsorption at the we estimated the upper limit concentrations of the silicone oil in

point of contact. In addition, we characterized the robustness of our the flushed water to be on the order of ~0.03 parts per million

coating against mechanical abrasion. In our tests, we placed a mass (Supplementary Note 11). Recent studies have shown that silicone

Nature Sustainability | www.nature.com/natsustain

Nature Sustainability Articles

a b

10

Flow rate

(gallons min−1)

8 1.0

Lubricant thickness (µm)

30

Maximum number of

flush-to-clean cycles

2.5

6

20

4

2

10

0 10 20 30 40 50 60 10 20 30 40 50 60

Time (min) Solid content percentage (%)

0.5 kg

0.1 m s–1 d

LESS-coated glass Sandpaper

Droplet pinned Displacement wetting Droplet sliding

60

Phase 1 Phase 2 Phase 3

50

Sliding angle (°)

40

30

20

10

0

0 50 100 150 200 250 300 350 400

Abrasion cycle

Fig. 6 | Durability characterizations and lubricant replenishment of LESS-coated surfaces. a, Durability of the lubricant layer (silicone oil with a viscosity

of 20 cSt) under different shear flow conditions. The weight difference between LESS-coated and non-lubricated surfaces was measured and used to

estimate the lubricant thickness. b, Durability of the LESS coating under continuous faeces impact-and-flushing cycles. Error bars represent standard

deviations of three independent measurements. c, Abrasion characterization on LESS-coated glass. Phase 1 indicates that excess lubricant was removed

from the LESS-coated substrate. Phase 2 indicates that the thickness of the lubricant reached equilibrium with consistent liquid repellency performance for

up to ~300 abrasion cycles. Phase 3 indicates that gradual degradation of the coating and small particle accumulation from the sandpaper scratches began

to induce droplet pinning. Error bars represent standard deviations of three independent measurements. d, Schematic showing the displacement wetting

phenomenon on PDMS-grafted glass. Optical images show a facile lubricant replenishment process.

oil can be decomposed through various mechanisms in the envi- function53. The ability to prevent the fouling of faecal matter and

ronment38. More importantly, our LESS coating is not limited to bacteria will further reduce odour generation, which will make

grafted-PDMS and silicone oil systems, and can be formulated shared toilets more appealing to the public and could further pro-

using natural oils as the lubrication layer. mote safe and dignified sanitation. With an estimated >1 billion

toilets and urinals around the world13, it is anticipated that incorpo-

Summary rating LESS coating into sanitation systems worldwide could lead to

In summary, we have created a scalable, multifunctional LESS significant water saving and improved global sanitation, providing a

coating specifically designed to reduce adhesion to soft viscoelas- key technological solution to one of the United Nations’ Sustainable

tic solids (for example, human faeces) with applications aimed to Development Goals in clean water and sanitation.

minimize water consumption for sanitation and waste manage-

ment. We have shown that the LESS coating is capable of reduc- Methods

ing adhesion up to ~90% for soft viscoelastic solids, and requires Experimental details on the design and fabrication of the LESS coatings and

only ~10% of the cleaning water required for an untreated control preparation of synthetic faeces, as well as the experimental characterizations and

measurement procedures of the LESS coatings, are presented below.

surface. The significant adhesion and water consumption reduction

are due to the ability of the LESS coating to repel liquids, bacte-

LESS coating solution preparation. The LESS coating can be prepared by first

ria and viscoelastic solids with dynamic viscosities spanning over applying a PDMS-grafted layer onto a substrate, followed by the addition of a

nine orders of magnitude. Our LESS coating can be applied onto lubricant. Specifically, the PDMS-grafted layer was prepared by spraying a silane

various hydrophilic surfaces within minutes under ambient condi- solution onto a clean and dry hydrophilic substrate (for example, glass or ceramic)

tions through a spray-coating process. Furthermore, the excellent using a modified version of the process reported in ref. 26. The key ingredients

anti-biofouling property of LESS could minimize the use of aggres- of the silane solution comprise dimethyldimethoxysilane and a small amount of

sulfuric acid (Sigma–Aldrich). The silicone oil (with a viscosity of 20 cSt and the

sive chemicals currently used for sterilization, thus reducing envi- chemical formula (–Si(CH3)2O–)n) was used as the lubricant.

ronmental impacts. Our analysis indicates that it is possible to save

up to >1,000 l of flushing water for every ml of coating fluid used Synthetic faeces preparation. The recipe of synthetic human faeces was developed

for a standard 1.6 gallons flush−1 toilet. Our coating can also be from the original recipe developed at the University of KwaZulu-Natal in South

incorporated with novel waterless toilets to further enhance their Africa. The synthetic human faeces were composed of yeast, psyllium, peanut

Nature Sustainability | www.nature.com/natsustain

Articles Nature Sustainability

oil, miso, polyethylene glycol, calcium phosphate, cellulose and water. All solid and Enterococcus mundtii, which are commonly found in rainwater. E. coli 137 was

components were expressed as dry mass, and the corresponding percentages are collected from an infected urine sample with approval from Stanford University’s

shown in Supplementary Table 9. The compositions of the synthetic faeces were Institutional Review Board and the Veterans Affairs Palo Alto Health Care System

biologically very similar to human faeces43 (Supplementary Table 10). Note that Research and Development Committee. After liquid agar culturing, we diluted the

human faeces can be classified into seven categories based on their solid content bacteria sample with synthetic urine (Thermo Fisher Scientific) to a concentration

percentages and viscosities54. This specific classification, known as the Bristol stool representative of urine sample from someone with a urinary tract infection.

scale, ranges from type 1 (hard solids) to type 7 (entirely liquid). The viscosity of

the synthetic faeces can be tuned by the percentage of solid contents. We made Durability tests. Shear flow test. To test the durability of the LESS-coated surfaces

synthetic faeces with solid percentages of 10, 20, 30, 40, 50 and 60%. Note that under shear flow, we put LESS-coated glass under different shear flow conditions

synthetic faeces with ~40% solid content have viscoelastic characteristics similar for 1 h (that is, at shear stresses of 0.1 and 0.6 Pa at 1.0 and 2.5 gallons min−1,

to type 3–4 healthy human faeces. These synthetic faeces were used within 5 h respectively). The corresponding lubricant loss was measured at 5-min intervals,

of preparation for the viscoelasticity measurements, adhesion tests and water corresponding to ~60 toilet flushes as a typical toilet flush takes approximately 5 s.

consumption tests.

Simulated urination test. The LESS-coated surface was placed vertically (parallel to

Spreading parameter and Hamaker constant. We defined the spreading gravity), and the water jet impacted on the surface at ~45° in the same spot during

parameter of the lubricant on the solid substrate in the presence of air as Sls, and the test (see Supplementary Fig. 14). The height (h) between the water level and the

that in the presence of the foreign immiscible fluid droplet as Slsf. Specifically, these impacting point was ~450 mm, and the flow diameter (D) was ~6 mm.

spreading parameters can be expressed as Sls = σs − (σls + σl) and Slsf = σsf − (σls + σlf ),

where σs, σls, σl, σsf and σlf are the interfacial tensions of solid–air, lubricant–solid, Synthetic faeces dropping and flushing test. Around 5 g of synthetic human faeces

lubricant–air, solid–immiscible fluid and lubricant–immiscible fluid interfaces, was dropped from a height of 400 mm onto the surface at a tilting angle of 45°.

respectively. In addition, the disjoining pressure of the lubricant film can be Then, the LESS-coated surface was put into the flow system for cleaning at a flow

expressed as П(e) = A/6πe3, where e is the lubricant film height and A is the rate of 1 gallon min−1. Before and after the impact-and-flushing cycle, we measured

Hamaker constant expressed as27: the sliding angle of the surface using a 10-µl water drop (Supplementary Fig. 16).

The LESS-coated surface was considered to be fully degraded if the sliding angle

A ¼ 34 kT εεs �ε

þε

l

s

εf �εl

ε þε þ

l

3hv

f

pffiffie

l 8 2

was > 65°.

ð Þðnf �nl Þ1=2

n2s �n2l 2 2

ð

1=2

Þ ð

n2s þn2l 2 2

nf þnl

1=2

Þ ðn2s þn2l Þ þðn2f þn2l Þ

1=2 Abrasion test. To test the robustness of the LESS-coated surfaces, we abraded the

sample (area: 75 mm × 25 mm) with sandpaper (P400; average particle diameter:

where k is the Boltzmann constant, T is the absolute temperature, h is the Planck’s 35 μm) under a normal force of ~5 N. The sample was pulled in at ~0.1 m s−1 for

constant, and ve = ~ 4 × 1015 s−1 is the plasma frequency of free electron gas, while ~0.1 m cycle−1. We measured the sliding angle of a 10-µl water drop on the sample

εs/l/f and ns/l/f are the dielectric constants and refractive indices of the solid, lubricant for every ten cycles. The performance of the LESS-coated surface was considered to

and immiscible fluid of interest (air or water in our case), respectively. be degraded when the sliding angle dramatically increased in tens of cycles. In our

test, we observed that the sliding angle started to increase after ~300 cycles.

Viscoelasticity and adhesion measurement. The viscoelasticity of synthetic

human faeces with different solid content percentages (10, 20, 30, 40, 50 and Data availability

60%) was measured using a rheometer (DHR-2; TA instruments). The adhesion The authors declare that the data supporting the findings of this study are available

measurements were performed using the rheometer by recording the axial within the paper and its Supplementary Information files. Additional data that

force and displacement distance. These measurements consisted of three steps, support the findings of this study are available from the corresponding author

including compression, contact and debonding from the synthetic faeces. The upon request.

synthetic faeces were first preloaded on the test stage with a sample testing area

of 25 mm × 25 mm. The axial force was kept below 110% of the average faeces Received: 8 January 2019; Accepted: 9 October 2019;

impact force. To measure the average impact force of the faeces, we dropped a

piece of synthetic faeces with a certain weight (~5 g) from a height of 400 mm and

Published: xx xx xxxx

used a high-speed camera (Phantom Miro M320S) to measure the impact time.

Transparent Cartesian graph papers were used to measure the corresponding

impact area (Supplementary Table 13). After compressing the faeces samples, the References

test probe remained in contact with the faeces for 5 min before the debonding step. 1. Eliasson, J. The rising pressure of global water shortages. Nature 517,

Finally, the probe surface was pulled away at a constant velocity of 10 µm s−1. The 6–7 (2015).

work of debonding was calculated as the integral of the axial force and distance. 2. Mekonnen, M. M. & Hoekstra, A. Y. Four billion people facing severe water

More than five independent measurements were performed for each adhesion scarcity. Sci. Adv. 2, e1500323 (2016).

measurement. 3. Attari, S. Z. Perceptions of water use. Proc. Natl Acad. Sci. USA 111,

5129–5134 (2014).

Water consumption measurement. To measure the water consumption to 4. Shannon, M. A. et al. Science and technology for water purification in the

clean the surfaces after faeces impact, a custom open-channel flow system coming decades. Nature 452, 301–310 (2008).

was built, which consisted of a water tank (McMaster-Carr), soft tubes with 5. Surwade, S. P. et al. Water desalination using nanoporous single-layer

an inner diameter of 12.7 mm, a valve and a pump (PMP-450S; Koolance), a graphene. Nat. Nanotechnol. 10, 459–464 (2015).

flowmeter (McMaster-Carr) with a range of 3.5 gallons min−1, and a rectangle tube 6. Chiavazzo, E., Morciano, M., Viglino, F., Fasano, M. & Asinari, P. Passive

(50.8 mm × 50.8 mm) (McMaster-Carr). The flow rate was manually controlled solar high-yield seawater desalination by modular and low-cost distillation.

with the valve, the pump and the flowmeter. Nat. Sustain. 1, 763–772 (2018).

7. Parker, A. R. & Lawrence, C. R. Water capture by a desert beetle. Nature 414,

Human faecal waste test. An 8-mm-thick Teflon sheet (Direct Plastics) was cut 33–34 (2001).

into a tile of 80 mm × 80 mm. A silicone sheet (Silicon Engineering) with a Shore 8. Ju, J. et al. A multi-structural and multi-functional integrated fog collection

hardness of 40 A was cut to 80 mm × 80 mm. The ceramic used in the experiment system in cactus. Nat. Commun. 3, 1247 (2012).

was a gloss ceramic-glazed bathroom tile purchased from a hardware store. The 9. Park, K.-C. et al. Condensation on slippery asymmetric bumps. Nature 531,

human faeces were all donated anonymously from three different people. All three 78–82 (2016).

stool samples were between type 3 and type 5 according to the Bristol stool scale, 10. Kim, H. et al. Water harvesting from air with metal-organic frameworks

indicating that the samples had solid content between 15 and 40 wt%. Human powered by natural sunlight. Science 356, 430–434 (2017).

faeces rated type 3–5 on the Bristol stool scale system are considered normal for a 11. DeOreo, W. B., Mayer, P. W., Dziegielewski, B. & Kiefer, J. Residential End

healthy adult. Uses of Water, Version 2 (Water Research Foundation, 2016).

12. Human Development Report (United Nations Development

Bacteria preparation and culture. The rainwater was collected from the roof of Programme, 2006).

a house in State College, Pennsylvania, then stored in a refrigerator at 4 °C. We 13. Progress on Sanitation and Drinking Water—2015 Update and MDG

tested the concentration of bacteria in rainwater by diluting the rainwater by 10× Assessment (World Health Organization and UNICEF, 2015).

with sterilized deionized water, and spread 10 µl of the rainwater and the diluted 14. Ghisi, E. & Ferreira, D. F. Potential for potable water savings by using

solution on solid agar. After culturing these samples at 37 °C in an incubator rainwater and greywater in a multi-storey residential building in southern

for 36 h, we counted the number of bacterial colonies on the agar surface to Brazil. Build. Environ. 42, 2512–2522 (2007).

determine the concentrations. We identified the bacteria in the rainwater using 15. The United Nations World Water Development Report 2016: Water and Jobs

a MALDI Biotyper system. These included Staphylococcus aureus, Enterobacter (United Nations Educational, Scientific and Cultural Organization & World

cloacae, Escherichia vulneris, Escherichia hermannii, Acinetobacter calcoaceticus Water Assessment Programme, 2016).

Nature Sustainability | www.nature.com/natsustain

Nature Sustainability Articles

16. Mahdavinejad, M., Bemanian, M., Farahani, S. F. & Tajik, A. Role of toilet 45. Woolley, S., Buckley, C., Pocock, J. & Foutch, G. Rheological modelling of

type in transmission of infections. Acad. Res. Int. 1, 110–113 (2011). fresh human faeces. J. Water Sanit. Hyg. Dev. 4, 484–489 (2014).

17. Paterson, C., Mara, D. & Curtis, T. Pro-poor sanitation technologies. 46. Yunus, A. C. & Cimbala, J. M. Fluid Mechanics Fundamentals and

Geoforum 38, 901–907 (2007). Applications International Edition (McGraw Hill Publication, 2006).

18. Lin, J. et al. Qualitative and quantitative analysis of volatile constituents from 47. Vickers, A. Water-use efficiency standards for plumbing fixtures: benefits of

latrines. Environ. Sci. Technol. 47, 7876–7882 (2013). national legislation. J. Am. Water Works Assoc. 82, 51–54 (1990).

19. Tuteja, A. et al. Designing superoleophobic surfaces. Science 318, 48. Awad, T. S., Asker, D. & Hatton, B. D. Food-safe modification of stainless

1618–1622 (2007). steel food processing surfaces to reduce bacterial biofilms. ACS Appl. Mater.

20. Tuteja, A., Choi, W., Mabry, J. M., McKinley, G. H. & Cohen, R. E. Robust Interfaces 10, 22902–22912 (2018).

omniphobic surfaces. Proc. Natl Acad. Sci. USA 105, 18200–18205 (2008). 49. Halvey Alex, K., Macdonald, B., Dhyani, A. & Tuteja, A. Design of surfaces for

21. Liu, T. L. & Kim, C.-J. C. Turning a surface superrepellent even to completely controlling hard and soft fouling. Phil. Trans. R. Soc. A 377, 20180266 (2019).

wetting liquids. Science 346, 1096–1100 (2014). 50. Evans, C., Coombes, P. J. & Dunstan, R. Wind, rain and bacteria: the effect of

22. Wong, T.-S. et al. Bioinspired self-repairing slippery surfaces with pressure- weather on the microbial composition of roof-harvested rainwater. Water Res.

stable omniphobicity. Nature 477, 443–447 (2011). 40, 37–44 (2006).

23. Epstein, A. K., Wong, T.-S., Belisle, R. A., Boggs, E. M. & Aizenberg, J. 51. Segura, C. G. Urine flow in childhood: a study of flow chart parameters based

Liquid-infused structured surfaces with exceptional anti-biofouling on 1,361 uroflowmetry tests. J. Urol. 157, 1426–1428 (1997).

performance. Proc. Natl Acad. Sci. USA 109, 13182–13187 (2012). 52. Yang, P. J., Pham, J., Choo, J. & Hu, D. L. Duration of urination does not

24. Leslie, D. C. et al. A bioinspired omniphobic surface coating on medical change with body size. Proc. Natl Acad. Sci. USA 111, 11932–11937 (2014).

devices prevents thrombosis and biofouling. Nat. Biotechnol. 32, 53. Hennigs, J. et al. Field testing of a prototype mechanical dry toilet flush.

1134–1140 (2014). Sci. Total Environ. 668, 419–431 (2019).

25. Wang, J., Kato, K., Blois, A. P. & Wong, T.-S. Bioinspired omniphobic coatings 54. Lewis, S. & Heaton, K. Stool form scale as a useful guide to intestinal transit

with a thermal self-repair function on industrial materials. ACS Appl. Mater. time. Scand. J. Gastroenterol. 32, 920–924 (1997).

Interfaces 8, 8265–8271 (2016).

26. Wang, L. & McCarthy, T. J. Covalently attached liquids: instant omniphobic Acknowledgements

surfaces with unprecedented repellency. Angew. Chem. 128, 252–256 (2016). We thank V. Bojan and J. Shallenberger at the Materials Research Institute of The

27. Israelachvili, J. N. Intermolecular and Surface Forces (Academic Press, 2011). Pennsylvania State University for help with the X-ray photoelectron spectroscopy

28. Dahlquist, C. A. in Treatise on Adhesion and Adhesives Vol. 2 (ed. Patrick, R. L.) measurements and data processing, L. Andersson for help with the longevity test, B.

219–260 (Marcel Dekker, 1969). Boschitsch Stogin for help with manuscript preparation, and A. Turrigiano for discussion.

29. Gent, A. & Schultz, J. Effect of wetting liquids on the strength of adhesion of We thank T. Laremore (director of the Huck Institutes of the Life Sciences Proteomics and

viscoelastic material. J. Adhes. 3, 281–294 (1972). Mass Spectrometry Core Facility) for assistance with the MALDI Biotyper microorganism

30. Wenzel, R. N. Resistance of solid surfaces to wetting by water. Ind. Eng. identification. We thank J. C. Liao from Stanford University for providing the urine

Chem. 28, 988–994 (1936). sample. We acknowledge funding support from the National Science Foundation

31. Drelich, J. & Chibowski, E. Superhydrophilic and superwetting surfaces: (CAREER Award number 1351462; I-Corps numbers 1757165 and 1735627), Wormley

definition and mechanisms of control. Langmuir 26, 18621–18623 (2010). Family Early Career Professorship and Humanitarian Materials Initiative Award,

32. Tenjimbayashi, M. et al. Liquid-infused smooth coating with transparency, sponsored by Covestro and the Materials Research Institute at The Pennsylvania State

super-durability, and extraordinary hydrophobicity. Adv. Funct. Mater. 26, University. Part of the work was conducted at the Penn State node of the National Science

6693–6702 (2016). Foundation-funded National Nanotechnology of Infrastructure Network.

33. Daniel, D., Timonen, J. V., Li, R., Velling, S. J. & Aizenberg, J. Oleoplaning

droplets on lubricated surfaces. Nat. Phys. 13, 1020–1025 (2017).

34. De Gennes, P.-G., Brochard-Wyart, F. & Quéré, D. Capillarity and Wetting Author contributions

Phenomena: Drops, Bubbles, Pearls, Waves (Springer Science & Business J.W. and T.-S.W. designed the overall experiments. J.W. designed the LESS coating. J.W.

Media, 2013). and L.Wang fabricated the LESS coating. J.W. and N.S. designed the adhesion tests. J.W.,

35. Preston, D. J., Song, Y., Lu, Z., Antao, D. S. & Wang, E. N. Design of lubricant N.S. and M.C. performed the adhesion tests. J.W., L.Wang, H.L. and P.K.W. designed

infused surfaces. ACS Appl. Mater. Interfaces 9, 42383–42392 (2017). the anti-biofouling tests. J.W., L.Wang and H.L. performed the anti-biofouling tests.

36. Zhuravlev, L. Concentration of hydroxyl groups on the surface of amorphous R.T. and L.Williams designed and performed the human faeces tests. J.W. and L.Wang

silicas. Langmuir 3, 316–318 (1987). designed and performed the durability tests. J.W., L.Wang, N.S., M.C., H.L., R.T. and

37. Crisp, A., de Juan, E. & Tiedeman, J. Effect of silicone oil viscosity on T.-S.W. analysed and processed the data. J.W. and T.-S.W. wrote the manuscript.

emulsification. Arch. Ophthalmol. 105, 546–550 (1987). All authors reviewed the manuscript.

38. Graiver, D., Farminer, K. & Narayan, R. A review of the fate and effects of

silicones in the environment. J. Polym. Environ. 11, 129–136 (2003). Competing interests

39. Seah, M. P. An accurate and simple universal curve for the energy-dependent J.W. and T.-S.W. are the inventors on a patent application (PCT/US2017/062206)

electron inelastic mean free path. Surf. Interface Anal. 44, 497–503 (2012). submitted by the Penn State Research Foundation that describes the LESS coating

40. Liu, H., Zhang, P., Liu, M., Wang, S. & Jiang, L. Organogel-based thin films technology. T.-S.W. is a co-founder of the start-up company spotLESS Materials, which

for self-cleaning on various surfaces. Adv. Mater. 25, 4477–4481 (2013). commercializes the LESS coating technology. N.S. is currently employed by spotLESS

41. Zhang, C., Xia, Y., Zhang, H. & Zacharia, N. S. Surface functionalization for a Materials. All other authors have no competing interests.

nontextured liquid-infused surface with enhanced lifetime. ACS Appl. Mater.

Interfaces 10, 5892–5901 (2018).

42. Urata, C., Cheng, D. F., Masheder, B. & Hozumi, A. Smooth, transparent and Additional information

nonperfluorinated surfaces exhibiting unusual contact angle behavior toward Supplementary information is available for this paper at https://doi.org/10.1038/

organic liquids. RSC Adv. 2, 9805–9808 (2012). s41893-019-0421-0.

43. Rose, C., Parker, A., Jefferson, B. & Cartmell, E. The characterization of feces Correspondence and requests for materials should be addressed to T.-S.W.

and urine: a review of the literature to inform advanced treatment Reprints and permissions information is available at www.nature.com/reprints.

technology. Crit. Rev. Environ. Sci. Technol. 45, 1827–1879 (2015).

44. Woolley, S., Cottingham, R., Pocock, J. & Buckley, C. Shear rheological Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in

properties of fresh human faeces with different moisture content. Water SA published maps and institutional affiliations.

40, 273–276 (2014). © The Author(s), under exclusive licence to Springer Nature Limited 2019

Nature Sustainability | www.nature.com/natsustain

You might also like

- Flexibility Matrix MethodDocument36 pagesFlexibility Matrix MethodAnuja Jape100% (6)

- Research Papers On Constructed WetlandsDocument6 pagesResearch Papers On Constructed Wetlandsfvf8zrn0100% (1)

- Sustainable RO Desalination - Energy Demand and Environmental ImpactDocument7 pagesSustainable RO Desalination - Energy Demand and Environmental ImpactFrancisca Rojas100% (1)

- Dow Chemical. Materials Science Contributions To Membrane ProductionDocument39 pagesDow Chemical. Materials Science Contributions To Membrane ProductionJafar EhsaniNo ratings yet

- Polyoxadiazole Hollow Fibers For Produced Water Treatment by Direct Contact Membrane Distillation PDFDocument8 pagesPolyoxadiazole Hollow Fibers For Produced Water Treatment by Direct Contact Membrane Distillation PDFalabdulgaderNo ratings yet

- 2016 Aug25 1781296-1304 FPS ChangsangYunDocument10 pages2016 Aug25 1781296-1304 FPS ChangsangYunAliAkbarPamungkasNo ratings yet

- A Report On The Exceptional Superhydrophobicity of Slippery Liquid Infused Porous Surface and The Recent Advancements in Boosting Its DurabilityDocument38 pagesA Report On The Exceptional Superhydrophobicity of Slippery Liquid Infused Porous Surface and The Recent Advancements in Boosting Its DurabilityBangla BoyNo ratings yet

- Assessment of Greywater Quality and Performance of A Pilot-Scale Decentralised Hybrid Rainwater-Greywater SystemDocument7 pagesAssessment of Greywater Quality and Performance of A Pilot-Scale Decentralised Hybrid Rainwater-Greywater SystemJane PayoranNo ratings yet

- Microestrutura de ConcretoDocument14 pagesMicroestrutura de ConcretoJôbersonCavalcantiNo ratings yet

- Final Draft Lit ReviewDocument7 pagesFinal Draft Lit ReviewEmilyBottNo ratings yet

- Journal of Colloid and Interface Science: Mingming Liu, Yuanyuan Hou, Jing Li, Lu Tie, Zhiguang GuoDocument7 pagesJournal of Colloid and Interface Science: Mingming Liu, Yuanyuan Hou, Jing Li, Lu Tie, Zhiguang GuomitrasatapathyNo ratings yet

- Geosynthetic Lining System For Modern Waste Facilities - Experiences in Developing AsiaDocument8 pagesGeosynthetic Lining System For Modern Waste Facilities - Experiences in Developing AsiaSweetyy KumariNo ratings yet

- Theortical PartDocument64 pagesTheortical PartAbdelsalam MahmoudNo ratings yet

- LA County LID ManualDocument72 pagesLA County LID Manualstings_ary1556No ratings yet

- Bio-Inspired Drag ReductionDocument12 pagesBio-Inspired Drag ReductionIsidora SandovalNo ratings yet

- Che 2017Document9 pagesChe 2017GinpachiNo ratings yet

- Oil-Water Separation: A Gift From The Desert: WWW - Advmatinterfaces.deDocument7 pagesOil-Water Separation: A Gift From The Desert: WWW - Advmatinterfaces.deTaha Lemdjed BelahçeneNo ratings yet

- Constructed Wetland ThesisDocument4 pagesConstructed Wetland Thesisbsq39zpf100% (2)

- Membrane Bioreactors MBR For Municipal WastewaterDocument12 pagesMembrane Bioreactors MBR For Municipal WastewaterAlvaro HueteNo ratings yet

- Hydrophobic Concrete Using Waste Paper Sludge AshDocument12 pagesHydrophobic Concrete Using Waste Paper Sludge AshNiroshanNo ratings yet

- Research Paper - Recycling Waste Plastics Into Paving Tiles PDFDocument7 pagesResearch Paper - Recycling Waste Plastics Into Paving Tiles PDFMaricel Eliang OlivaNo ratings yet

- 2017 - Reduction of Rammed Earth's Hygroscopic Performance Under Stabilisation An ExperimentDocument10 pages2017 - Reduction of Rammed Earth's Hygroscopic Performance Under Stabilisation An ExperimentCesioSantosNo ratings yet

- Bad Ruz Zaman 2009Document8 pagesBad Ruz Zaman 2009Abraham Becerra AranedaNo ratings yet

- Super-Hydrophobicity On Textiles - A Review: Chinchwade S.S. Landage S.M. Bonsule S.Document9 pagesSuper-Hydrophobicity On Textiles - A Review: Chinchwade S.S. Landage S.M. Bonsule S.Andi MusdalifahNo ratings yet

- CE News Article Harper Green Building 9 09Document4 pagesCE News Article Harper Green Building 9 09Dedy KristiantoNo ratings yet

- Jsemat20120200001 83555761Document19 pagesJsemat20120200001 83555761VanessaCamposNo ratings yet

- Constructed WetlandsDocument9 pagesConstructed WetlandsAnna GrichtingNo ratings yet

- Adapting Dissolved Air Flotation For The Clarification of SeawaterDocument5 pagesAdapting Dissolved Air Flotation For The Clarification of SeawaterAndreia FalcoNo ratings yet

- REDDYDocument6 pagesREDDYசமுத்திரக் KANINo ratings yet

- Designing of Geotextile Baffle Contact Systems (GBCS) For The Treatment of First Flush of Stormwater Runoff, Yaman, C., Korkut, E. (2008) .Document8 pagesDesigning of Geotextile Baffle Contact Systems (GBCS) For The Treatment of First Flush of Stormwater Runoff, Yaman, C., Korkut, E. (2008) .Cevat YamanNo ratings yet

- 20 Surface Modification of Plastics: Kenth S. JohanssonDocument45 pages20 Surface Modification of Plastics: Kenth S. JohanssonLuis Alberto Escalante PradoNo ratings yet

- Journal Pre-Proof: Journal of Membrane ScienceDocument34 pagesJournal Pre-Proof: Journal of Membrane SciencemNo ratings yet

- New MainDocument53 pagesNew Maindhaya chandhran100% (2)

- Preparation of Silane-Functionalized...Document7 pagesPreparation of Silane-Functionalized...VanessaCamposNo ratings yet

- Modification of Subgrade Properties Using Waste Material: January 2017Document8 pagesModification of Subgrade Properties Using Waste Material: January 2017Besim QelajNo ratings yet

- مقالته 1 والاهمDocument5 pagesمقالته 1 والاهمDhurghammNo ratings yet

- Guide To Rational Membrane Selection For Oily Wastewater Treatment by Membrane Distillation - ScienceDirectDocument14 pagesGuide To Rational Membrane Selection For Oily Wastewater Treatment by Membrane Distillation - ScienceDirectMOH AMANNo ratings yet

- A Literature Review of Environmental Impacts of Synthetic Based Drilling FluidsDocument7 pagesA Literature Review of Environmental Impacts of Synthetic Based Drilling FluidsafdtsdeceNo ratings yet

- Materials Today: Proceedings: Deepanjana Adak, Raghunath Bhattacharyya, Hiranmay Saha, Pradipta Sankar MaitiDocument5 pagesMaterials Today: Proceedings: Deepanjana Adak, Raghunath Bhattacharyya, Hiranmay Saha, Pradipta Sankar MaitiAAKIB QURESHINo ratings yet

- Graphene Membranes For Water DesalinationDocument16 pagesGraphene Membranes For Water DesalinationToshikaNo ratings yet

- A Novel Polyester Amide Loose Composite Nanofiltration Membr - 2022 - Journal ofDocument10 pagesA Novel Polyester Amide Loose Composite Nanofiltration Membr - 2022 - Journal ofFelipe Leyva HaroNo ratings yet

- Innovations - Scopus 4Document23 pagesInnovations - Scopus 4chandan adhikariNo ratings yet

- Application of Low Fouling RO Membrane Elements For Reclamation of Municipal WastewaterDocument17 pagesApplication of Low Fouling RO Membrane Elements For Reclamation of Municipal Wastewaterzerocool86No ratings yet

- Landfill Design ThesisDocument5 pagesLandfill Design Thesisdwsjyt34100% (2)

- Desalination: I.G. Wenten, KhoiruddinDocument14 pagesDesalination: I.G. Wenten, KhoiruddinAlief AnggaNo ratings yet

- Sewage Sludge To Landfill Some Pertinent Engineering PropertiesDocument8 pagesSewage Sludge To Landfill Some Pertinent Engineering PropertiesIvana CipranicNo ratings yet

- 7.aljallis 2013 Experimental Study ofDocument15 pages7.aljallis 2013 Experimental Study ofrezaNo ratings yet

- Wettability Behavior of XLPE Nanocomposite With Surface Modified NanofillerDocument7 pagesWettability Behavior of XLPE Nanocomposite With Surface Modified NanofillerAnuar AtanNo ratings yet

- Lubricants 08 00011 PDFDocument13 pagesLubricants 08 00011 PDFفايق العرودNo ratings yet

- Chandra FinalDocument47 pagesChandra FinalGadige Chandra100% (1)

- Process Simulation of Modelled Reverse Osmosis For Desalination of SeawaterDocument16 pagesProcess Simulation of Modelled Reverse Osmosis For Desalination of SeawaterMohammed GhanemNo ratings yet

- 1 s2.0 S0300944023005477 MainextDocument14 pages1 s2.0 S0300944023005477 Mainextajay reddyNo ratings yet

- All-Natural, Eco-Friendly Composite Foam For Highly Efficient Atmospheric Water HarvestingDocument10 pagesAll-Natural, Eco-Friendly Composite Foam For Highly Efficient Atmospheric Water HarvestingsalemNo ratings yet

- Application of Post-Consumer Recycled High-Impact Polystyrene in The Preparation of Phase-Inversion Membranes For Low-Pressure Membrane ProcessesDocument12 pagesApplication of Post-Consumer Recycled High-Impact Polystyrene in The Preparation of Phase-Inversion Membranes For Low-Pressure Membrane ProcessesAline FlorindoNo ratings yet

- C ProjectDocument6 pagesC ProjectMEGHANA KNo ratings yet

- Leachate PresentationDocument21 pagesLeachate PresentationCarren MarquezNo ratings yet

- Project Report On Soil Pollution 2Document39 pagesProject Report On Soil Pollution 2siddharth shankar74% (23)

- Membranes 11 00042 v2Document15 pagesMembranes 11 00042 v2Matthew GhaffariNo ratings yet

- Submitted To:-Dr. A.B.Gupta: Presented By: - Ankit Mittal 2016UCE1202 C-2 BatchDocument15 pagesSubmitted To:-Dr. A.B.Gupta: Presented By: - Ankit Mittal 2016UCE1202 C-2 BatchNatwar MishraNo ratings yet

- Materials Chemistry A: Journal ofDocument25 pagesMaterials Chemistry A: Journal ofKK SinghNo ratings yet

- Sanitary Ans DrainageDocument40 pagesSanitary Ans DrainageBJ Topenio LibasteNo ratings yet

- F.f.roof1 BeamDocument1 pageF.f.roof1 BeamNikita MeshramNo ratings yet

- Fluids Past Papers PDFDocument65 pagesFluids Past Papers PDFAnushaBheenuck100% (1)

- Earthwork Section 02200Document3 pagesEarthwork Section 02200glendaNo ratings yet

- User PanelDocument14 pagesUser PanelMrinmay GangulyNo ratings yet

- GWP AssignmentDocument36 pagesGWP AssignmentGkou DojkuNo ratings yet

- Boq Batang-Weleri Section 1Document26 pagesBoq Batang-Weleri Section 1Kiky HendrawanNo ratings yet

- GeotextitlesDocument6 pagesGeotextitlesReema NasrNo ratings yet

- Construction Practises: Concrete: Production B. Bhattacharjee Civil Engineering Department Iit DelhiDocument19 pagesConstruction Practises: Concrete: Production B. Bhattacharjee Civil Engineering Department Iit DelhiSadatcharaMoorthi NNo ratings yet

- Fentahun Ayalneh MekonnenDocument117 pagesFentahun Ayalneh MekonnenBiyyaa DagafuuNo ratings yet

- Liege Conference Paper - Booth NA en 1998-1Document8 pagesLiege Conference Paper - Booth NA en 1998-1vsbalintNo ratings yet

- Mesh Stage 1 Embodied Carbon Calculator v4.0Document26 pagesMesh Stage 1 Embodied Carbon Calculator v4.0ginlemon86No ratings yet

- HW 4 - Solution - H.W HW 4 - Solution - H.WDocument10 pagesHW 4 - Solution - H.W HW 4 - Solution - H.WwalacrNo ratings yet

- What Is The Difference Between A Weldolet and A SockoletDocument3 pagesWhat Is The Difference Between A Weldolet and A SockoletWaqas Waqas100% (3)

- EP477 B5 Beam Strengthening Design Check - B5H166 PDFDocument9 pagesEP477 B5 Beam Strengthening Design Check - B5H166 PDFmerpatimerahNo ratings yet

- Design of Vertical Type Drop On Permeable Foundation Hydraulic ParticularsDocument17 pagesDesign of Vertical Type Drop On Permeable Foundation Hydraulic Particularsprasadnn2001No ratings yet

- Equipment ProductivityDocument442 pagesEquipment ProductivityLan Madrona100% (2)

- 137-18 Appendix A - Project DrawingsDocument33 pages137-18 Appendix A - Project DrawingsDiego Martínez FernándezNo ratings yet

- Calculation of Load Carrying Capacity of PileDocument47 pagesCalculation of Load Carrying Capacity of PileAshish GNo ratings yet

- CV Amjad Ahmad KhanDocument15 pagesCV Amjad Ahmad Khannaveedcomsian054No ratings yet

- Universal Cables Price ListDocument6 pagesUniversal Cables Price ListAdnan Anwer0% (4)

- Plumbing Materials, Fittings and FixturesDocument6 pagesPlumbing Materials, Fittings and FixturesJohn michael Del rosarioNo ratings yet

- Direct Shear Test: 1. Importance of The Shear Strength in SoilDocument9 pagesDirect Shear Test: 1. Importance of The Shear Strength in SoilIMJ JNo ratings yet

- MAE 322 Machine Design: Dr. Hodge Jenkins Mercer UniversityDocument20 pagesMAE 322 Machine Design: Dr. Hodge Jenkins Mercer UniversityDuslerinalargaNo ratings yet

- LUSAS Technical Material - 3 Integral BridgeDocument15 pagesLUSAS Technical Material - 3 Integral Bridgenaveen srinivasNo ratings yet

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Document40 pagesChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebNo ratings yet

- Problem1 - Solution 1 - Design of SRCBDocument5 pagesProblem1 - Solution 1 - Design of SRCBRey Joseph IglesiaNo ratings yet

- Black Cotton Soil Methods-FoundationDocument4 pagesBlack Cotton Soil Methods-FoundationMuhammed NaseefNo ratings yet

- Ishihara Liquefaction 2011 PDFDocument19 pagesIshihara Liquefaction 2011 PDFAnonymous D5s00DdUNo ratings yet