Professional Documents

Culture Documents

Broken Needle Change Process Flow

Broken Needle Change Process Flow

Uploaded by

Kamal NayanarangaCopyright:

Available Formats

You might also like

- Costco QA ManualDocument29 pagesCostco QA ManualKamal NayanarangaNo ratings yet

- Sample Structural PlanDocument1 pageSample Structural PlanJeric Sarte100% (1)

- SOW For Wire Rope Inspection and MaintenanceDocument12 pagesSOW For Wire Rope Inspection and MaintenanceParviz Nasirov100% (2)

- Survey Check ListDocument11 pagesSurvey Check Listjothi subraNo ratings yet

- UNIT 4 Raman Spectroscopy 12309Document24 pagesUNIT 4 Raman Spectroscopy 12309NathanianNo ratings yet

- Impt of Mun HallDocument3 pagesImpt of Mun HallWing BasconNo ratings yet

- Ae94.3a Gas TurbineDocument685 pagesAe94.3a Gas TurbineALINo ratings yet

- Side Door ElevatorDocument3 pagesSide Door ElevatorMuhammed AthaullahNo ratings yet

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha83% (6)

- Unserviceable: ExpendableDocument1 pageUnserviceable: ExpendableFemi AgbanaNo ratings yet

- 7villa-Om-Me-02 DX Hi Wall Split Ac UnitsDocument60 pages7villa-Om-Me-02 DX Hi Wall Split Ac UnitsAravindhan ANo ratings yet

- 00701-BCC-XXX-ZZZ-DWG-CW-006003 Rev.00 - INSPECTION CHAMBERDocument1 page00701-BCC-XXX-ZZZ-DWG-CW-006003 Rev.00 - INSPECTION CHAMBERmohan sirNo ratings yet

- 5051 - TR & Tool Kit CAMP CardsDocument2 pages5051 - TR & Tool Kit CAMP CardsMarty SmallwoodNo ratings yet

- TSMH4MD1 H4 01 TG T 31 TG0 002003213391Document39 pagesTSMH4MD1 H4 01 TG T 31 TG0 002003213391hamidrezaNo ratings yet

- Unserviceable: ExpendableDocument1 pageUnserviceable: ExpendableFemi AgbanaNo ratings yet

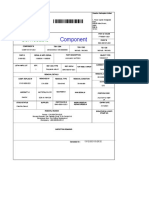

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Mockup 1BR 140323 (1) - ModelDocument1 pageMockup 1BR 140323 (1) - ModelAgil AziziNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- U123 DD N EL 73 0016 00 E Panel Arrangement DrawingsDocument6 pagesU123 DD N EL 73 0016 00 E Panel Arrangement DrawingsJovan JovanovićNo ratings yet

- Asbuilt Plan-Rosario Heights SS-PS1Document1 pageAsbuilt Plan-Rosario Heights SS-PS1gdgdgdgdgdgNo ratings yet

- Petrofac: Side View B-BDocument1 pagePetrofac: Side View B-BNikhil chaundkarNo ratings yet

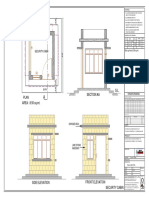

- Security CabinDocument1 pageSecurity CabinAravindNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Gac RampDocument4 pagesGac Rampsterspinx55No ratings yet

- Technical Specification N3 Wind Conditions: Design NotesDocument1 pageTechnical Specification N3 Wind Conditions: Design NotesMinh HoNo ratings yet

- Boiler PumpsDocument1 pageBoiler PumpsriyasudheenmhNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- Project Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LWD-08 54 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Document54 pagesProject Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LWD-08 54 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Fatholla SalehiNo ratings yet

- 5n-Lee - Serviceable TagDocument1 page5n-Lee - Serviceable TagFemi AgbanaNo ratings yet

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Asbuilt Plan-Rosario Heights SS-M2Document1 pageAsbuilt Plan-Rosario Heights SS-M2gdgdgdgdgdgNo ratings yet

- Main Substation PDFDocument45 pagesMain Substation PDFFatholla SalehiNo ratings yet

- 80-1-20218-CAM-002-F0_Code ADocument3 pages80-1-20218-CAM-002-F0_Code Atrantien2407No ratings yet

- Act SS MT1 El DT 0003Document4 pagesAct SS MT1 El DT 0003oukkas saidNo ratings yet

- BI-2018050 Sanitary System Connection From Berth 71/72 To Berth 69 Sp3 Treatment UnitDocument2 pagesBI-2018050 Sanitary System Connection From Berth 71/72 To Berth 69 Sp3 Treatment UnitAdnanNo ratings yet

- Improvement Upgrading of Coco Fiber Processing FacilityDocument103 pagesImprovement Upgrading of Coco Fiber Processing FacilityErwinBasconNo ratings yet

- 145kV SA Outline DrawingDocument3 pages145kV SA Outline Drawingrey pamelo navarroNo ratings yet

- 5n-Tup Serviceable TagDocument1 page5n-Tup Serviceable TagFemi AgbanaNo ratings yet

- General Notes:: Swimmin Schematic Diagram 1Document1 pageGeneral Notes:: Swimmin Schematic Diagram 1Mohammed NadeemNo ratings yet

- Dfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Document1 pageDfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Electrical PCBL TeamNo ratings yet

- Typical Medim Voltage Single Line DiagramDocument5 pagesTypical Medim Voltage Single Line DiagramFatholla Salehi100% (1)

- Sand Blasting MachineDocument3 pagesSand Blasting MachineCarl Diaz100% (1)

- Tkii Doc. No. 706 3M0038 e 001 25Document167 pagesTkii Doc. No. 706 3M0038 e 001 25pcfssbelectrical sectionNo ratings yet

- Elevator LinkDocument2 pagesElevator LinkMuhammed AthaullahNo ratings yet

- Bny JV 2a RD de 0006Document1 pageBny JV 2a RD de 0006harihfclNo ratings yet

- ST-20-21 Raft Sections-St-20Document1 pageST-20-21 Raft Sections-St-20cdnaveenNo ratings yet

- Drawing Contour CS - 010858 Rev1Document1 pageDrawing Contour CS - 010858 Rev1Akhmad Immamul AzizNo ratings yet

- P010501-NML-70-ELE-LAY-009 70kV AND 20kV BUILDING FIRE ALARM AND SMOKE DETECTOR LAYOUTDocument3 pagesP010501-NML-70-ELE-LAY-009 70kV AND 20kV BUILDING FIRE ALARM AND SMOKE DETECTOR LAYOUTTristanNo ratings yet

- Beckman: 30862 Date: OstoalaaatDocument1 pageBeckman: 30862 Date: OstoalaaatBrahmananda ChakrabortyNo ratings yet

- 5N-BSK - Serviceable TagDocument1 page5N-BSK - Serviceable TagFemi AgbanaNo ratings yet

- B-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteDocument3 pagesB-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteMuhammad TeguhNo ratings yet

- Lighting GeneralDocument1 pageLighting GeneralHassan RazaNo ratings yet

- Break Down Maintenance Process Flow Diagram: Start FinishDocument1 pageBreak Down Maintenance Process Flow Diagram: Start FinishfahadNo ratings yet

- 4M Change Summary Sheet - PRFDocument4 pages4M Change Summary Sheet - PRFkumar QANo ratings yet

- TerrainDocument1 pageTerrainMarty SmallwoodNo ratings yet

- KPC-F-QAC-018_Weekly Quality ReportDocument2 pagesKPC-F-QAC-018_Weekly Quality ReportmarckeNo ratings yet

- 13.2kV Incomin G Meralco Service 13.2kV Incomin G Meralco ServiceDocument1 page13.2kV Incomin G Meralco Service 13.2kV Incomin G Meralco ServicelanNo ratings yet

- 2.7 Inspection Test PlanDocument53 pages2.7 Inspection Test PlanLeo FirstsonNo ratings yet

- Drawing Title Design General NotesDocument25 pagesDrawing Title Design General NotesSaid Ahmed Salem100% (1)

- Wo Add PK - LHM Di BTHDocument3 pagesWo Add PK - LHM Di BTHrockmansatuNo ratings yet

- R-3 - C and T Rice MillDocument4 pagesR-3 - C and T Rice MillJonathan RodolfoNo ratings yet

- MTP132-Daily Report 15 April 2023Document3 pagesMTP132-Daily Report 15 April 2023Bambang ArdiansyahNo ratings yet

- QA and QC Achievement Plan and Strategy For January and February 2023Document9 pagesQA and QC Achievement Plan and Strategy For January and February 2023Kamal NayanarangaNo ratings yet

- CA Factory KPI Jan 2023Document6 pagesCA Factory KPI Jan 2023Kamal NayanarangaNo ratings yet

- CA Factory KPI DecDocument5 pagesCA Factory KPI DecKamal NayanarangaNo ratings yet

- 1) Weekly FI Report 2020Document4 pages1) Weekly FI Report 2020Kamal NayanarangaNo ratings yet

- 1.1) 01P 01 601 How To Inspect SketchesDocument7 pages1.1) 01P 01 601 How To Inspect SketchesKamal NayanarangaNo ratings yet

- Factory Evaluation Score Criteria Aug 2019Document10 pagesFactory Evaluation Score Criteria Aug 2019Kamal NayanarangaNo ratings yet

- Packaging-Costco Smart Screening Protocol V4 - ApprovedDocument3 pagesPackaging-Costco Smart Screening Protocol V4 - ApprovedKamal NayanarangaNo ratings yet

- 1.01 General GuidelinesDocument4 pages1.01 General GuidelinesKamal NayanarangaNo ratings yet

- Table of ContentsDocument9 pagesTable of ContentsKamal NayanarangaNo ratings yet

- QMS CodesDocument10 pagesQMS CodesKamal NayanarangaNo ratings yet

- CFT TrainingDocument1 pageCFT TrainingKamal NayanarangaNo ratings yet

- Apparel and Home Textiles-Costco Smart Screening Protocol V16-Approved - 28 Nov 2019Document13 pagesApparel and Home Textiles-Costco Smart Screening Protocol V16-Approved - 28 Nov 2019Kamal NayanarangaNo ratings yet

- Courses ContentDocument22 pagesCourses ContentMwanamarundiNo ratings yet

- Triangular Pile Cap StructvilleDocument13 pagesTriangular Pile Cap Structvillemanoj_mousamNo ratings yet

- 7 ZXUN USPP (HLR) BC en Commissioning and Debugging (Basic Data Configuration) 2 PDF 201008 (Draft) 164Document164 pages7 ZXUN USPP (HLR) BC en Commissioning and Debugging (Basic Data Configuration) 2 PDF 201008 (Draft) 164arun_sakre100% (2)

- Full FormsDocument6 pagesFull Formsathul aswanthNo ratings yet

- Devilbiss 240 Pump Parts BreakdownDocument2 pagesDevilbiss 240 Pump Parts BreakdownjoeyNo ratings yet

- Applicant Details: Applicant Photo Applicationid:2122Sjs1002147815Document8 pagesApplicant Details: Applicant Photo Applicationid:2122Sjs1002147815vinayak tiwariNo ratings yet

- Adapt To The Changing Validation Landscape in A Cloud EnvironmentDocument8 pagesAdapt To The Changing Validation Landscape in A Cloud EnvironmentReza AriandiNo ratings yet

- Manual de Servicio Aiwa+Nsx Sz80+Nsx Sz83+Nsx Aj80+Nsx Sz80eDocument47 pagesManual de Servicio Aiwa+Nsx Sz80+Nsx Sz83+Nsx Aj80+Nsx Sz80eCarlos Jesus SerranoNo ratings yet

- Michael Mattson PHD - OO Frameworks PDFDocument129 pagesMichael Mattson PHD - OO Frameworks PDFCarlos E. CuestaNo ratings yet

- Ansi MV Ovcb Sdv7 Enclosure Im enDocument56 pagesAnsi MV Ovcb Sdv7 Enclosure Im enrhap_0925060No ratings yet

- Bridge Erection MethodDocument9 pagesBridge Erection MethodChi-chi Rahayu HarikeNo ratings yet

- Exit SignDocument3 pagesExit SignAzarudeen AzarudeenNo ratings yet

- Logic Pro X 10.4: Exam Preparation GuideDocument19 pagesLogic Pro X 10.4: Exam Preparation Guidemik logicNo ratings yet

- 05 ShaftsDocument37 pages05 ShaftsJay Ann TondoNo ratings yet

- TH 3530Document56 pagesTH 3530Ian BurnettNo ratings yet

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- Abrasive Jet Machining (AJM)Document31 pagesAbrasive Jet Machining (AJM)Abhishek KumarNo ratings yet

- Ktu NotesDocument36 pagesKtu NotesmknairNo ratings yet

- NRJED315626EN - PCOB 36 (Web)Document4 pagesNRJED315626EN - PCOB 36 (Web)Jaks JaksNo ratings yet

- Que Papers For Cbse Class 12Document3 pagesQue Papers For Cbse Class 12Bhagyaraj PandabNo ratings yet

- FDocument10 pagesFSans lucas HoyamaNo ratings yet

- Multifunction Strobe Instruction Manual For Looms With NCP System Rapier and Air JetDocument23 pagesMultifunction Strobe Instruction Manual For Looms With NCP System Rapier and Air Jetpacheco bNo ratings yet

- Quick Check Method For PCD-David Mills PDFDocument11 pagesQuick Check Method For PCD-David Mills PDFAarti ChameNo ratings yet

- Chapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinDocument8 pagesChapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinchatxxnoirNo ratings yet

- Your Palletizing SolutionDocument8 pagesYour Palletizing SolutionKien Nguyen TrungNo ratings yet

- EjectorsDocument7 pagesEjectorsashirwad shetty50% (2)

Broken Needle Change Process Flow

Broken Needle Change Process Flow

Uploaded by

Kamal NayanarangaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Broken Needle Change Process Flow

Broken Needle Change Process Flow

Uploaded by

Kamal NayanarangaCopyright:

Available Formats

Document:

Section:

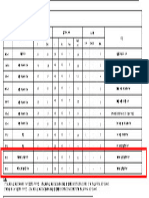

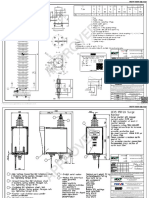

BROKEN NEEDLE CHANGE PROCESS FLOW CHART Revision No.:

Effective Date:

Page No.:

Operator Mechanic Line Leader Metal Detection Factory Manager/QA Needle Change In-charge

Manager

A B C D E F

TAKE OFF THE REMAINING BROKEN PUT THE BROKEN NEEDLE PEICES IN TO TAKE THE RESPONSIBILITY FOR STICK THE BROKEN NEEDLE IN THE

NEEDLE IN THE MACHINE AND PUT IN SCAN ALL AVAILABLE CUT PANELS

BROKEN NEEDLE THE MINI BOX FROM PREVIOUS OPERATOR AND TO SIGNING OFF THE NEEDLE RECORDS. BROKEN NEEDLE REPORT

THE MINI BOX.

NEXT OPERATOR WHERE THE BROKEN

NEEDLE OCCURS.

FIND THE BROKEN NEEDLE PIECES IN COMPLETE NEEDLE

TURN OFF SEWING MACHINE THE MACHINE CHANGE NEW NEEDLE

F

Decision

Decision

CALL THE ATTENTION OF THE LINE

LEADER AND MECHANIC FAILED PASSED

END OF PROCESS

USE HAND HELD DETECTOR MACHINE RECORD RESULT AND SCANNED

TO FIND THE BROKEN NEEDLE PIECE QUANTITY IN THE INCOMPLETE

NEEDLE CHANGE REPORT.

INCOMPLETE

NEEDLE

PUT THE CUT PANELS IN THE

C

CONTAINER BOX FOR METAL

DETECTION

PREPARE INCOMPLETE CHANGE

NEEDLE REPORT

Prepared By: Approved By: Remarks:

APPROVED

Mr.Kamal -QA Manager: Mr.Andy Lam - Genaral Manager

You might also like

- Costco QA ManualDocument29 pagesCostco QA ManualKamal NayanarangaNo ratings yet

- Sample Structural PlanDocument1 pageSample Structural PlanJeric Sarte100% (1)

- SOW For Wire Rope Inspection and MaintenanceDocument12 pagesSOW For Wire Rope Inspection and MaintenanceParviz Nasirov100% (2)

- Survey Check ListDocument11 pagesSurvey Check Listjothi subraNo ratings yet

- UNIT 4 Raman Spectroscopy 12309Document24 pagesUNIT 4 Raman Spectroscopy 12309NathanianNo ratings yet

- Impt of Mun HallDocument3 pagesImpt of Mun HallWing BasconNo ratings yet

- Ae94.3a Gas TurbineDocument685 pagesAe94.3a Gas TurbineALINo ratings yet

- Side Door ElevatorDocument3 pagesSide Door ElevatorMuhammed AthaullahNo ratings yet

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha83% (6)

- Unserviceable: ExpendableDocument1 pageUnserviceable: ExpendableFemi AgbanaNo ratings yet

- 7villa-Om-Me-02 DX Hi Wall Split Ac UnitsDocument60 pages7villa-Om-Me-02 DX Hi Wall Split Ac UnitsAravindhan ANo ratings yet

- 00701-BCC-XXX-ZZZ-DWG-CW-006003 Rev.00 - INSPECTION CHAMBERDocument1 page00701-BCC-XXX-ZZZ-DWG-CW-006003 Rev.00 - INSPECTION CHAMBERmohan sirNo ratings yet

- 5051 - TR & Tool Kit CAMP CardsDocument2 pages5051 - TR & Tool Kit CAMP CardsMarty SmallwoodNo ratings yet

- TSMH4MD1 H4 01 TG T 31 TG0 002003213391Document39 pagesTSMH4MD1 H4 01 TG T 31 TG0 002003213391hamidrezaNo ratings yet

- Unserviceable: ExpendableDocument1 pageUnserviceable: ExpendableFemi AgbanaNo ratings yet

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Mockup 1BR 140323 (1) - ModelDocument1 pageMockup 1BR 140323 (1) - ModelAgil AziziNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- U123 DD N EL 73 0016 00 E Panel Arrangement DrawingsDocument6 pagesU123 DD N EL 73 0016 00 E Panel Arrangement DrawingsJovan JovanovićNo ratings yet

- Asbuilt Plan-Rosario Heights SS-PS1Document1 pageAsbuilt Plan-Rosario Heights SS-PS1gdgdgdgdgdgNo ratings yet

- Petrofac: Side View B-BDocument1 pagePetrofac: Side View B-BNikhil chaundkarNo ratings yet

- Security CabinDocument1 pageSecurity CabinAravindNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Gac RampDocument4 pagesGac Rampsterspinx55No ratings yet

- Technical Specification N3 Wind Conditions: Design NotesDocument1 pageTechnical Specification N3 Wind Conditions: Design NotesMinh HoNo ratings yet

- Boiler PumpsDocument1 pageBoiler PumpsriyasudheenmhNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- Project Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LWD-08 54 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Document54 pagesProject Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LWD-08 54 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Fatholla SalehiNo ratings yet

- 5n-Lee - Serviceable TagDocument1 page5n-Lee - Serviceable TagFemi AgbanaNo ratings yet

- Serviceable: ComponentDocument1 pageServiceable: ComponentFemi AgbanaNo ratings yet

- Asbuilt Plan-Rosario Heights SS-M2Document1 pageAsbuilt Plan-Rosario Heights SS-M2gdgdgdgdgdgNo ratings yet

- Main Substation PDFDocument45 pagesMain Substation PDFFatholla SalehiNo ratings yet

- 80-1-20218-CAM-002-F0_Code ADocument3 pages80-1-20218-CAM-002-F0_Code Atrantien2407No ratings yet

- Act SS MT1 El DT 0003Document4 pagesAct SS MT1 El DT 0003oukkas saidNo ratings yet

- BI-2018050 Sanitary System Connection From Berth 71/72 To Berth 69 Sp3 Treatment UnitDocument2 pagesBI-2018050 Sanitary System Connection From Berth 71/72 To Berth 69 Sp3 Treatment UnitAdnanNo ratings yet

- Improvement Upgrading of Coco Fiber Processing FacilityDocument103 pagesImprovement Upgrading of Coco Fiber Processing FacilityErwinBasconNo ratings yet

- 145kV SA Outline DrawingDocument3 pages145kV SA Outline Drawingrey pamelo navarroNo ratings yet

- 5n-Tup Serviceable TagDocument1 page5n-Tup Serviceable TagFemi AgbanaNo ratings yet

- General Notes:: Swimmin Schematic Diagram 1Document1 pageGeneral Notes:: Swimmin Schematic Diagram 1Mohammed NadeemNo ratings yet

- Dfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Document1 pageDfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Electrical PCBL TeamNo ratings yet

- Typical Medim Voltage Single Line DiagramDocument5 pagesTypical Medim Voltage Single Line DiagramFatholla Salehi100% (1)

- Sand Blasting MachineDocument3 pagesSand Blasting MachineCarl Diaz100% (1)

- Tkii Doc. No. 706 3M0038 e 001 25Document167 pagesTkii Doc. No. 706 3M0038 e 001 25pcfssbelectrical sectionNo ratings yet

- Elevator LinkDocument2 pagesElevator LinkMuhammed AthaullahNo ratings yet

- Bny JV 2a RD de 0006Document1 pageBny JV 2a RD de 0006harihfclNo ratings yet

- ST-20-21 Raft Sections-St-20Document1 pageST-20-21 Raft Sections-St-20cdnaveenNo ratings yet

- Drawing Contour CS - 010858 Rev1Document1 pageDrawing Contour CS - 010858 Rev1Akhmad Immamul AzizNo ratings yet

- P010501-NML-70-ELE-LAY-009 70kV AND 20kV BUILDING FIRE ALARM AND SMOKE DETECTOR LAYOUTDocument3 pagesP010501-NML-70-ELE-LAY-009 70kV AND 20kV BUILDING FIRE ALARM AND SMOKE DETECTOR LAYOUTTristanNo ratings yet

- Beckman: 30862 Date: OstoalaaatDocument1 pageBeckman: 30862 Date: OstoalaaatBrahmananda ChakrabortyNo ratings yet

- 5N-BSK - Serviceable TagDocument1 page5N-BSK - Serviceable TagFemi AgbanaNo ratings yet

- B-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteDocument3 pagesB-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteMuhammad TeguhNo ratings yet

- Lighting GeneralDocument1 pageLighting GeneralHassan RazaNo ratings yet

- Break Down Maintenance Process Flow Diagram: Start FinishDocument1 pageBreak Down Maintenance Process Flow Diagram: Start FinishfahadNo ratings yet

- 4M Change Summary Sheet - PRFDocument4 pages4M Change Summary Sheet - PRFkumar QANo ratings yet

- TerrainDocument1 pageTerrainMarty SmallwoodNo ratings yet

- KPC-F-QAC-018_Weekly Quality ReportDocument2 pagesKPC-F-QAC-018_Weekly Quality ReportmarckeNo ratings yet

- 13.2kV Incomin G Meralco Service 13.2kV Incomin G Meralco ServiceDocument1 page13.2kV Incomin G Meralco Service 13.2kV Incomin G Meralco ServicelanNo ratings yet

- 2.7 Inspection Test PlanDocument53 pages2.7 Inspection Test PlanLeo FirstsonNo ratings yet

- Drawing Title Design General NotesDocument25 pagesDrawing Title Design General NotesSaid Ahmed Salem100% (1)

- Wo Add PK - LHM Di BTHDocument3 pagesWo Add PK - LHM Di BTHrockmansatuNo ratings yet

- R-3 - C and T Rice MillDocument4 pagesR-3 - C and T Rice MillJonathan RodolfoNo ratings yet

- MTP132-Daily Report 15 April 2023Document3 pagesMTP132-Daily Report 15 April 2023Bambang ArdiansyahNo ratings yet

- QA and QC Achievement Plan and Strategy For January and February 2023Document9 pagesQA and QC Achievement Plan and Strategy For January and February 2023Kamal NayanarangaNo ratings yet

- CA Factory KPI Jan 2023Document6 pagesCA Factory KPI Jan 2023Kamal NayanarangaNo ratings yet

- CA Factory KPI DecDocument5 pagesCA Factory KPI DecKamal NayanarangaNo ratings yet

- 1) Weekly FI Report 2020Document4 pages1) Weekly FI Report 2020Kamal NayanarangaNo ratings yet

- 1.1) 01P 01 601 How To Inspect SketchesDocument7 pages1.1) 01P 01 601 How To Inspect SketchesKamal NayanarangaNo ratings yet

- Factory Evaluation Score Criteria Aug 2019Document10 pagesFactory Evaluation Score Criteria Aug 2019Kamal NayanarangaNo ratings yet

- Packaging-Costco Smart Screening Protocol V4 - ApprovedDocument3 pagesPackaging-Costco Smart Screening Protocol V4 - ApprovedKamal NayanarangaNo ratings yet

- 1.01 General GuidelinesDocument4 pages1.01 General GuidelinesKamal NayanarangaNo ratings yet

- Table of ContentsDocument9 pagesTable of ContentsKamal NayanarangaNo ratings yet

- QMS CodesDocument10 pagesQMS CodesKamal NayanarangaNo ratings yet

- CFT TrainingDocument1 pageCFT TrainingKamal NayanarangaNo ratings yet

- Apparel and Home Textiles-Costco Smart Screening Protocol V16-Approved - 28 Nov 2019Document13 pagesApparel and Home Textiles-Costco Smart Screening Protocol V16-Approved - 28 Nov 2019Kamal NayanarangaNo ratings yet

- Courses ContentDocument22 pagesCourses ContentMwanamarundiNo ratings yet

- Triangular Pile Cap StructvilleDocument13 pagesTriangular Pile Cap Structvillemanoj_mousamNo ratings yet

- 7 ZXUN USPP (HLR) BC en Commissioning and Debugging (Basic Data Configuration) 2 PDF 201008 (Draft) 164Document164 pages7 ZXUN USPP (HLR) BC en Commissioning and Debugging (Basic Data Configuration) 2 PDF 201008 (Draft) 164arun_sakre100% (2)

- Full FormsDocument6 pagesFull Formsathul aswanthNo ratings yet

- Devilbiss 240 Pump Parts BreakdownDocument2 pagesDevilbiss 240 Pump Parts BreakdownjoeyNo ratings yet

- Applicant Details: Applicant Photo Applicationid:2122Sjs1002147815Document8 pagesApplicant Details: Applicant Photo Applicationid:2122Sjs1002147815vinayak tiwariNo ratings yet

- Adapt To The Changing Validation Landscape in A Cloud EnvironmentDocument8 pagesAdapt To The Changing Validation Landscape in A Cloud EnvironmentReza AriandiNo ratings yet

- Manual de Servicio Aiwa+Nsx Sz80+Nsx Sz83+Nsx Aj80+Nsx Sz80eDocument47 pagesManual de Servicio Aiwa+Nsx Sz80+Nsx Sz83+Nsx Aj80+Nsx Sz80eCarlos Jesus SerranoNo ratings yet

- Michael Mattson PHD - OO Frameworks PDFDocument129 pagesMichael Mattson PHD - OO Frameworks PDFCarlos E. CuestaNo ratings yet

- Ansi MV Ovcb Sdv7 Enclosure Im enDocument56 pagesAnsi MV Ovcb Sdv7 Enclosure Im enrhap_0925060No ratings yet

- Bridge Erection MethodDocument9 pagesBridge Erection MethodChi-chi Rahayu HarikeNo ratings yet

- Exit SignDocument3 pagesExit SignAzarudeen AzarudeenNo ratings yet

- Logic Pro X 10.4: Exam Preparation GuideDocument19 pagesLogic Pro X 10.4: Exam Preparation Guidemik logicNo ratings yet

- 05 ShaftsDocument37 pages05 ShaftsJay Ann TondoNo ratings yet

- TH 3530Document56 pagesTH 3530Ian BurnettNo ratings yet

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- Abrasive Jet Machining (AJM)Document31 pagesAbrasive Jet Machining (AJM)Abhishek KumarNo ratings yet

- Ktu NotesDocument36 pagesKtu NotesmknairNo ratings yet

- NRJED315626EN - PCOB 36 (Web)Document4 pagesNRJED315626EN - PCOB 36 (Web)Jaks JaksNo ratings yet

- Que Papers For Cbse Class 12Document3 pagesQue Papers For Cbse Class 12Bhagyaraj PandabNo ratings yet

- FDocument10 pagesFSans lucas HoyamaNo ratings yet

- Multifunction Strobe Instruction Manual For Looms With NCP System Rapier and Air JetDocument23 pagesMultifunction Strobe Instruction Manual For Looms With NCP System Rapier and Air Jetpacheco bNo ratings yet

- Quick Check Method For PCD-David Mills PDFDocument11 pagesQuick Check Method For PCD-David Mills PDFAarti ChameNo ratings yet

- Chapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinDocument8 pagesChapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinchatxxnoirNo ratings yet

- Your Palletizing SolutionDocument8 pagesYour Palletizing SolutionKien Nguyen TrungNo ratings yet

- EjectorsDocument7 pagesEjectorsashirwad shetty50% (2)