Professional Documents

Culture Documents

Weld Access Hole (AISC 360 Section J1.6&7)

Weld Access Hole (AISC 360 Section J1.6&7)

Uploaded by

Jovito EdillonCopyright:

Available Formats

You might also like

- Seafastening ExcelDocument13 pagesSeafastening ExcelRiyan EsapermanaNo ratings yet

- Rfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure StripsDocument6 pagesRfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure Stripsvelmurug_bala100% (1)

- Asnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyDocument215 pagesAsnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyTapan Kumar Nayak100% (8)

- Aws C7.2-98Document116 pagesAws C7.2-98venkatesh100% (3)

- Chapter Five, Plate GirdersDocument21 pagesChapter Five, Plate GirdersZeleke TaimuNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- AISC 2022-Capitulo JDocument36 pagesAISC 2022-Capitulo JLeonardo ReynaNo ratings yet

- CH 7 Simple Beam End Connections-9-13Document60 pagesCH 7 Simple Beam End Connections-9-13JakesNo ratings yet

- Skewed CalcsDocument8 pagesSkewed Calcspost boxNo ratings yet

- Mod 1-3Document3 pagesMod 1-3Gopal UttupurathNo ratings yet

- ANSI-AISC 358-20 - C7SA - InglésDocument7 pagesANSI-AISC 358-20 - C7SA - InglésmanuelNo ratings yet

- Chapter M - Design of Fabrication and ErectionDocument5 pagesChapter M - Design of Fabrication and ErectionGirl Who LivedNo ratings yet

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeDocument5 pagesGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaNo ratings yet

- Chapter 7, ConnectionsDocument23 pagesChapter 7, Connectionsetsubdinkabeje3No ratings yet

- End Plate ConnectionsDocument9 pagesEnd Plate ConnectionsJohn PetterNo ratings yet

- Chevron Bracing Details - SteelwiseDocument4 pagesChevron Bracing Details - SteelwiseEugene Afable100% (1)

- Tek 12 03aDocument6 pagesTek 12 03acardusansilniNo ratings yet

- Moment Connection TipsDocument7 pagesMoment Connection TipsManoj JaiswalNo ratings yet

- CHAPTER 2 - Cross Section ClasificationDocument21 pagesCHAPTER 2 - Cross Section ClasificationHalina HamidNo ratings yet

- 001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewDocument10 pages001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewSwati KulkarniNo ratings yet

- Weld Access HolesDocument1 pageWeld Access HolesLINI O VNo ratings yet

- 5 Design of ConnectionsDocument19 pages5 Design of ConnectionsWinnie SayoNo ratings yet

- Conexiones de AceroDocument8 pagesConexiones de AceroRenzo Xavier Chavez HurtadoNo ratings yet

- Bolted Beam Splice: (A) Conventional SpliceDocument11 pagesBolted Beam Splice: (A) Conventional SpliceKimberly Binay-anNo ratings yet

- EJ Fisher BracingwithJoistsDocument6 pagesEJ Fisher BracingwithJoistsGabby KenNo ratings yet

- Design of BoltsDocument18 pagesDesign of BoltsFunny & InformativeNo ratings yet

- WelsDocument1 pageWelsArun NarendranathNo ratings yet

- Design of BeamsDocument28 pagesDesign of BeamsNayan Fatania100% (2)

- Shear Design of Beams: CE 470 - Steel Design ClassDocument16 pagesShear Design of Beams: CE 470 - Steel Design Classcecdesign09No ratings yet

- Design of Connections GateDocument25 pagesDesign of Connections GateShaik Mastan ValiNo ratings yet

- Design of Steel StructureDocument16 pagesDesign of Steel Structuresuraj kumarNo ratings yet

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- Ready Reckoner For Bracket and Column SplicesDocument6 pagesReady Reckoner For Bracket and Column Splicespavan kumar tNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Galvanized Slip-Critical ConnectionsDocument2 pagesGalvanized Slip-Critical Connectionsaams_sNo ratings yet

- Finite Element Analysis of Castellated Steel BeamDocument8 pagesFinite Element Analysis of Castellated Steel BeamTomislav ŠimagNo ratings yet

- Constructability of Embedded Steel Plates in CIP ConcreteDocument7 pagesConstructability of Embedded Steel Plates in CIP ConcreteimranNo ratings yet

- Recent Advances in Design of Steel and Composite Beams With Web OpeningsDocument16 pagesRecent Advances in Design of Steel and Composite Beams With Web OpeningsmokhtazulNo ratings yet

- Mat Chapter 31Document27 pagesMat Chapter 31hemant_durgawaleNo ratings yet

- Course Content A) Bolted ConnectionsDocument18 pagesCourse Content A) Bolted Connectionsram894uNo ratings yet

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- Simple Steel ConnectionsDocument7 pagesSimple Steel ConnectionsShams Abbas NaqviNo ratings yet

- Moment Connections To Column WebsDocument3 pagesMoment Connections To Column WebsAmro Ahmad AliNo ratings yet

- AASTHO Horizontally Curved Steel Girder Highway Bridges 2003 - Part2 PDFDocument28 pagesAASTHO Horizontally Curved Steel Girder Highway Bridges 2003 - Part2 PDFMehedi HasanNo ratings yet

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- Tek 12-03CDocument16 pagesTek 12-03CponjoveNo ratings yet

- Design of Anchor Bolts Embedded in Concrete MasonryDocument16 pagesDesign of Anchor Bolts Embedded in Concrete MasonryRodrigo FonsecaNo ratings yet

- Simple Shear ConnectionsDocument44 pagesSimple Shear ConnectionsAdam JonesNo ratings yet

- Srividya College of Engineering and Technology Question BankDocument6 pagesSrividya College of Engineering and Technology Question BankAravindNo ratings yet

- Steel Interchange: Steel's Monthly Steel Interchange Is For You! Send YourDocument2 pagesSteel Interchange: Steel's Monthly Steel Interchange Is For You! Send Yourgv Sathishkumar KumarNo ratings yet

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyreNo ratings yet

- 6 Connections ModifiedDocument59 pages6 Connections Modifiedkebede amezeneNo ratings yet

- Bracing ConnectionDocument16 pagesBracing ConnectionMa N U VenusNo ratings yet

- 30) - Overall, Abou-Zidan and Liu (2015) Concluded That The AISC Design Method (2011) ProvidesDocument5 pages30) - Overall, Abou-Zidan and Liu (2015) Concluded That The AISC Design Method (2011) Providesmn4webNo ratings yet

- Si 12 2011 PDFDocument2 pagesSi 12 2011 PDFHectorNo ratings yet

- Dec11 Si PDFDocument2 pagesDec11 Si PDFspaceheaterNo ratings yet

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 pagesSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazNo ratings yet

- Detailing Corner-Grade BeamDocument4 pagesDetailing Corner-Grade BeamProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Ci 31 Detallado Del Acero de Refuerzo PDFDocument6 pagesCi 31 Detallado Del Acero de Refuerzo PDFflucayNo ratings yet

- Forces in WeldsDocument8 pagesForces in WeldsBun KunNo ratings yet

- Simple Connections ETOOLKITDocument27 pagesSimple Connections ETOOLKITLesego MatojaneNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonNo ratings yet

- Nutted Anchor BoltDocument1 pageNutted Anchor BoltJovito EdillonNo ratings yet

- 90° Anchor BoltDocument2 pages90° Anchor BoltJovito EdillonNo ratings yet

- Shut It Catalog English Volume Hi Res InteractiveDocument52 pagesShut It Catalog English Volume Hi Res InteractiveJovito EdillonNo ratings yet

- Aisc TablesDocument1 pageAisc TablesJovito EdillonNo ratings yet

- AISC Anchor Bolt Hole SizeDocument1 pageAISC Anchor Bolt Hole SizeJovito EdillonNo ratings yet

- Weldinglectures14 16 Weld DefectsDocument100 pagesWeldinglectures14 16 Weld DefectsAnonymous d23gWCRQNo ratings yet

- Mandatory Appendix 10Document3 pagesMandatory Appendix 10leytonruizNo ratings yet

- EC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Document10 pagesEC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Prasad MagdumNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- General Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesDocument12 pagesGeneral Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesJose Anisio SilvaNo ratings yet

- Final Proposal Presentation ME Project1Document12 pagesFinal Proposal Presentation ME Project1Miguel Paolo LademoraNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- Question Bank 4th SemesterDocument16 pagesQuestion Bank 4th SemesterJeevanandam ShanmugasundaramNo ratings yet

- Naval Blek enDocument12 pagesNaval Blek enGabriela DanaNo ratings yet

- Unit 2 PPT WeldingDocument40 pagesUnit 2 PPT WeldingTushar Singh100% (1)

- Rewari PIPE ERECTION SpecificationDocument71 pagesRewari PIPE ERECTION Specificationkselvan_1100% (1)

- A Review On Hybrid Laser Arc WeldingDocument22 pagesA Review On Hybrid Laser Arc WeldingAkshay AcchuNo ratings yet

- Ineos - Polypropylene Processing GuideDocument18 pagesIneos - Polypropylene Processing GuideStarchyLittleOleMeNo ratings yet

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- Group 8, Welding AssignmentDocument11 pagesGroup 8, Welding AssignmentKavish ChandraNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- DX200 ArcDocument50 pagesDX200 Arcelmacuarro5No ratings yet

- Hardness Test ProcedureDocument5 pagesHardness Test Procedurefebinjohns87100% (1)

- Se 273Document4 pagesSe 273solrac4371No ratings yet

- Wel 12 CDocument7 pagesWel 12 CWilly UioNo ratings yet

- Commentary On Highly Restrained Welded Connections PDFDocument13 pagesCommentary On Highly Restrained Welded Connections PDFDaney EspinozaNo ratings yet

- Readiness of Grade 12 Smaw LearnersDocument11 pagesReadiness of Grade 12 Smaw LearnersJoelouis Sudario100% (2)

- Principles of Brazing and Soldering: Joining TechnologyDocument26 pagesPrinciples of Brazing and Soldering: Joining Technologyyared Belete100% (1)

- BP1 Bolt Connection CapacityDocument22 pagesBP1 Bolt Connection CapacityballisnothingNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- Datasheet For Stainless Steel Super Duplex 2507Document10 pagesDatasheet For Stainless Steel Super Duplex 2507Prem EditsNo ratings yet

Weld Access Hole (AISC 360 Section J1.6&7)

Weld Access Hole (AISC 360 Section J1.6&7)

Uploaded by

Jovito EdillonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Access Hole (AISC 360 Section J1.6&7)

Weld Access Hole (AISC 360 Section J1.6&7)

Uploaded by

Jovito EdillonCopyright:

Available Formats

11 AISC_PART 16_Comm J-K (415-476)_15Ed.

_July_2016 2016-11-09 10:28 AM Page 419 (Black plate)

Comm. J1.] GENERAL PROVISIONS 16.1-419

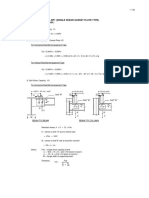

Stress concentrations at web-to-flange intersections of built-up shapes can be

decreased by terminating the weld away from the access hole. Thus, for built-up

shapes with fillet welds or partial-joint-penetration groove welds that join the web to

the flange, the weld access hole may terminate perpendicular to the flange, provided

that the weld is terminated a distance equal to or greater than one weld size away

from the access hole.

7. Placement of Welds and Bolts

Slight eccentricities between the gravity axis of single- and double-angle members

and the center of gravity of connecting bolts or rivets have long been ignored as hav-

ing negligible effect on the static strength of such members. Tests have shown that

similar practice is warranted in the case of welded members in statically loaded

structures (Gibson and Wake, 1942).

Alternate 1 Alternate 2 Alternate 3

Rolled shapes and built-up shapes assembled prior to Built-up shapes assembled

cutting the weld access hole. after cutting the weld access

hole.

Notes: These are typical details for joints welded from one side against steel backing.

Alternative details are discussed in the commentary text.

1. Length: Greater of 1.5tw or 11/2 in. (38 mm)

2. Height: Greater of 1.0tw or 3/4 in. (19 mm) but need not exceed 2 in. (50 mm)

3. R: 3/8 in. min. (10 mm). Grind the thermally cut surfaces of weld access holes in

heavy shapes as defined in Sections A3.1(c) and (d).

4. Slope ‘a’ forms a transition from the web to the flange. Slope ‘b’ may be horizontal.

5. The bottom of the top flange is to be contoured to permit the tight fit of backing bars

where they are to be used.

6. The web-to-flange weld of built-up members is to be held back a distance of at least

the weld size from the edge of the access hole.

Fig. C-J1.2. Weld access hole geometry.

Specification for Structural Steel Buildings, July 7, 2016

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

You might also like

- Seafastening ExcelDocument13 pagesSeafastening ExcelRiyan EsapermanaNo ratings yet

- Rfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure StripsDocument6 pagesRfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure Stripsvelmurug_bala100% (1)

- Asnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyDocument215 pagesAsnt Level Iii Basic Review:: Materials and Processes For NDT TechnologyTapan Kumar Nayak100% (8)

- Aws C7.2-98Document116 pagesAws C7.2-98venkatesh100% (3)

- Chapter Five, Plate GirdersDocument21 pagesChapter Five, Plate GirdersZeleke TaimuNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- AISC 2022-Capitulo JDocument36 pagesAISC 2022-Capitulo JLeonardo ReynaNo ratings yet

- CH 7 Simple Beam End Connections-9-13Document60 pagesCH 7 Simple Beam End Connections-9-13JakesNo ratings yet

- Skewed CalcsDocument8 pagesSkewed Calcspost boxNo ratings yet

- Mod 1-3Document3 pagesMod 1-3Gopal UttupurathNo ratings yet

- ANSI-AISC 358-20 - C7SA - InglésDocument7 pagesANSI-AISC 358-20 - C7SA - InglésmanuelNo ratings yet

- Chapter M - Design of Fabrication and ErectionDocument5 pagesChapter M - Design of Fabrication and ErectionGirl Who LivedNo ratings yet

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeDocument5 pagesGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaNo ratings yet

- Chapter 7, ConnectionsDocument23 pagesChapter 7, Connectionsetsubdinkabeje3No ratings yet

- End Plate ConnectionsDocument9 pagesEnd Plate ConnectionsJohn PetterNo ratings yet

- Chevron Bracing Details - SteelwiseDocument4 pagesChevron Bracing Details - SteelwiseEugene Afable100% (1)

- Tek 12 03aDocument6 pagesTek 12 03acardusansilniNo ratings yet

- Moment Connection TipsDocument7 pagesMoment Connection TipsManoj JaiswalNo ratings yet

- CHAPTER 2 - Cross Section ClasificationDocument21 pagesCHAPTER 2 - Cross Section ClasificationHalina HamidNo ratings yet

- 001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewDocument10 pages001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewSwati KulkarniNo ratings yet

- Weld Access HolesDocument1 pageWeld Access HolesLINI O VNo ratings yet

- 5 Design of ConnectionsDocument19 pages5 Design of ConnectionsWinnie SayoNo ratings yet

- Conexiones de AceroDocument8 pagesConexiones de AceroRenzo Xavier Chavez HurtadoNo ratings yet

- Bolted Beam Splice: (A) Conventional SpliceDocument11 pagesBolted Beam Splice: (A) Conventional SpliceKimberly Binay-anNo ratings yet

- EJ Fisher BracingwithJoistsDocument6 pagesEJ Fisher BracingwithJoistsGabby KenNo ratings yet

- Design of BoltsDocument18 pagesDesign of BoltsFunny & InformativeNo ratings yet

- WelsDocument1 pageWelsArun NarendranathNo ratings yet

- Design of BeamsDocument28 pagesDesign of BeamsNayan Fatania100% (2)

- Shear Design of Beams: CE 470 - Steel Design ClassDocument16 pagesShear Design of Beams: CE 470 - Steel Design Classcecdesign09No ratings yet

- Design of Connections GateDocument25 pagesDesign of Connections GateShaik Mastan ValiNo ratings yet

- Design of Steel StructureDocument16 pagesDesign of Steel Structuresuraj kumarNo ratings yet

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- Ready Reckoner For Bracket and Column SplicesDocument6 pagesReady Reckoner For Bracket and Column Splicespavan kumar tNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Galvanized Slip-Critical ConnectionsDocument2 pagesGalvanized Slip-Critical Connectionsaams_sNo ratings yet

- Finite Element Analysis of Castellated Steel BeamDocument8 pagesFinite Element Analysis of Castellated Steel BeamTomislav ŠimagNo ratings yet

- Constructability of Embedded Steel Plates in CIP ConcreteDocument7 pagesConstructability of Embedded Steel Plates in CIP ConcreteimranNo ratings yet

- Recent Advances in Design of Steel and Composite Beams With Web OpeningsDocument16 pagesRecent Advances in Design of Steel and Composite Beams With Web OpeningsmokhtazulNo ratings yet

- Mat Chapter 31Document27 pagesMat Chapter 31hemant_durgawaleNo ratings yet

- Course Content A) Bolted ConnectionsDocument18 pagesCourse Content A) Bolted Connectionsram894uNo ratings yet

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- Simple Steel ConnectionsDocument7 pagesSimple Steel ConnectionsShams Abbas NaqviNo ratings yet

- Moment Connections To Column WebsDocument3 pagesMoment Connections To Column WebsAmro Ahmad AliNo ratings yet

- AASTHO Horizontally Curved Steel Girder Highway Bridges 2003 - Part2 PDFDocument28 pagesAASTHO Horizontally Curved Steel Girder Highway Bridges 2003 - Part2 PDFMehedi HasanNo ratings yet

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- Tek 12-03CDocument16 pagesTek 12-03CponjoveNo ratings yet

- Design of Anchor Bolts Embedded in Concrete MasonryDocument16 pagesDesign of Anchor Bolts Embedded in Concrete MasonryRodrigo FonsecaNo ratings yet

- Simple Shear ConnectionsDocument44 pagesSimple Shear ConnectionsAdam JonesNo ratings yet

- Srividya College of Engineering and Technology Question BankDocument6 pagesSrividya College of Engineering and Technology Question BankAravindNo ratings yet

- Steel Interchange: Steel's Monthly Steel Interchange Is For You! Send YourDocument2 pagesSteel Interchange: Steel's Monthly Steel Interchange Is For You! Send Yourgv Sathishkumar KumarNo ratings yet

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyreNo ratings yet

- 6 Connections ModifiedDocument59 pages6 Connections Modifiedkebede amezeneNo ratings yet

- Bracing ConnectionDocument16 pagesBracing ConnectionMa N U VenusNo ratings yet

- 30) - Overall, Abou-Zidan and Liu (2015) Concluded That The AISC Design Method (2011) ProvidesDocument5 pages30) - Overall, Abou-Zidan and Liu (2015) Concluded That The AISC Design Method (2011) Providesmn4webNo ratings yet

- Si 12 2011 PDFDocument2 pagesSi 12 2011 PDFHectorNo ratings yet

- Dec11 Si PDFDocument2 pagesDec11 Si PDFspaceheaterNo ratings yet

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 pagesSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazNo ratings yet

- Detailing Corner-Grade BeamDocument4 pagesDetailing Corner-Grade BeamProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Ci 31 Detallado Del Acero de Refuerzo PDFDocument6 pagesCi 31 Detallado Del Acero de Refuerzo PDFflucayNo ratings yet

- Forces in WeldsDocument8 pagesForces in WeldsBun KunNo ratings yet

- Simple Connections ETOOLKITDocument27 pagesSimple Connections ETOOLKITLesego MatojaneNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonNo ratings yet

- Nutted Anchor BoltDocument1 pageNutted Anchor BoltJovito EdillonNo ratings yet

- 90° Anchor BoltDocument2 pages90° Anchor BoltJovito EdillonNo ratings yet

- Shut It Catalog English Volume Hi Res InteractiveDocument52 pagesShut It Catalog English Volume Hi Res InteractiveJovito EdillonNo ratings yet

- Aisc TablesDocument1 pageAisc TablesJovito EdillonNo ratings yet

- AISC Anchor Bolt Hole SizeDocument1 pageAISC Anchor Bolt Hole SizeJovito EdillonNo ratings yet

- Weldinglectures14 16 Weld DefectsDocument100 pagesWeldinglectures14 16 Weld DefectsAnonymous d23gWCRQNo ratings yet

- Mandatory Appendix 10Document3 pagesMandatory Appendix 10leytonruizNo ratings yet

- EC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Document10 pagesEC-SRC-0004 Weldment Visual Inspection Requirements Rev 2.0 (20160708)Prasad MagdumNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- General Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesDocument12 pagesGeneral Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesJose Anisio SilvaNo ratings yet

- Final Proposal Presentation ME Project1Document12 pagesFinal Proposal Presentation ME Project1Miguel Paolo LademoraNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- Question Bank 4th SemesterDocument16 pagesQuestion Bank 4th SemesterJeevanandam ShanmugasundaramNo ratings yet

- Naval Blek enDocument12 pagesNaval Blek enGabriela DanaNo ratings yet

- Unit 2 PPT WeldingDocument40 pagesUnit 2 PPT WeldingTushar Singh100% (1)

- Rewari PIPE ERECTION SpecificationDocument71 pagesRewari PIPE ERECTION Specificationkselvan_1100% (1)

- A Review On Hybrid Laser Arc WeldingDocument22 pagesA Review On Hybrid Laser Arc WeldingAkshay AcchuNo ratings yet

- Ineos - Polypropylene Processing GuideDocument18 pagesIneos - Polypropylene Processing GuideStarchyLittleOleMeNo ratings yet

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- Group 8, Welding AssignmentDocument11 pagesGroup 8, Welding AssignmentKavish ChandraNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- DX200 ArcDocument50 pagesDX200 Arcelmacuarro5No ratings yet

- Hardness Test ProcedureDocument5 pagesHardness Test Procedurefebinjohns87100% (1)

- Se 273Document4 pagesSe 273solrac4371No ratings yet

- Wel 12 CDocument7 pagesWel 12 CWilly UioNo ratings yet

- Commentary On Highly Restrained Welded Connections PDFDocument13 pagesCommentary On Highly Restrained Welded Connections PDFDaney EspinozaNo ratings yet

- Readiness of Grade 12 Smaw LearnersDocument11 pagesReadiness of Grade 12 Smaw LearnersJoelouis Sudario100% (2)

- Principles of Brazing and Soldering: Joining TechnologyDocument26 pagesPrinciples of Brazing and Soldering: Joining Technologyyared Belete100% (1)

- BP1 Bolt Connection CapacityDocument22 pagesBP1 Bolt Connection CapacityballisnothingNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- Datasheet For Stainless Steel Super Duplex 2507Document10 pagesDatasheet For Stainless Steel Super Duplex 2507Prem EditsNo ratings yet