Professional Documents

Culture Documents

Rising Mail Design

Rising Mail Design

Uploaded by

Bhupendra KumarCopyright:

Available Formats

You might also like

- Michael Begon, Colin R. Townsend - Ecology - From Individuals To Ecosystems (2021, Wiley) - Libgen - LiDocument861 pagesMichael Begon, Colin R. Townsend - Ecology - From Individuals To Ecosystems (2021, Wiley) - Libgen - LiTadeo Talbot-Wright SiraqyanNo ratings yet

- DVZ BrochureDocument40 pagesDVZ BrochureResul UygunNo ratings yet

- Pump Head Losses and TDH Calculation: 10.65 Q 1.852 L HF - C 1.852 D 4.87Document15 pagesPump Head Losses and TDH Calculation: 10.65 Q 1.852 L HF - C 1.852 D 4.87dsdeshpandeNo ratings yet

- SurgeDocument3 pagesSurgeSrinivas ReddyNo ratings yet

- Rising MainDocument2 pagesRising MainJitesh KumarNo ratings yet

- NdrcrossRD29RPcrossaug7 eDocument110 pagesNdrcrossRD29RPcrossaug7 epmu hmhNo ratings yet

- Chattara Check DamDocument6 pagesChattara Check DamSandeep VaishnavNo ratings yet

- Diameter Pasir Min. 0.088Document6 pagesDiameter Pasir Min. 0.088Eko SupoyoNo ratings yet

- Design of Outlets - JaboriDocument7 pagesDesign of Outlets - JaboriHaji Ahmad BhattiNo ratings yet

- Project Location: Diversion StructureDocument5 pagesProject Location: Diversion Structureelec310No ratings yet

- Canals and Related Structures: Design Standards No. 3Document254 pagesCanals and Related Structures: Design Standards No. 3Edelyn Lindero AmbosNo ratings yet

- Drip Design at SolDocument13 pagesDrip Design at SolVan BGNo ratings yet

- Is Code Criteria For Design of Anchor Block For Penstock With Expansion JointDocument13 pagesIs Code Criteria For Design of Anchor Block For Penstock With Expansion Jointduldar docNo ratings yet

- Chattara Check DamDocument22 pagesChattara Check DamAzaan zaimiNo ratings yet

- Design of BandharaDocument21 pagesDesign of BandharaNeil Agshikar100% (1)

- Solid Roller BucketDocument5 pagesSolid Roller BucketnaveenaeeNo ratings yet

- Ar-2006 (6 3 07)Document271 pagesAr-2006 (6 3 07)gsr_svsNo ratings yet

- OFM (Sections)Document4 pagesOFM (Sections)Hari RamNo ratings yet

- Design of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Document20 pagesDesign of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Souvik DasNo ratings yet

- Broad Vrested WeirDocument5 pagesBroad Vrested WeirdsanandaNo ratings yet

- Design of Drain at KM. 0.600Document5 pagesDesign of Drain at KM. 0.600Sameer AhmadNo ratings yet

- Hazen WilliamsDocument2 pagesHazen WilliamssushilkumarNo ratings yet

- Bucket DesignDocument6 pagesBucket Designוויסאם חטארNo ratings yet

- 1 Hydraulic Calculations PHOLAIDocument1 page1 Hydraulic Calculations PHOLAInc mathurNo ratings yet

- Design of Vertical Type Drop On Permeable Foundation Hydraulic ParticularsDocument17 pagesDesign of Vertical Type Drop On Permeable Foundation Hydraulic Particularsprasadnn2001No ratings yet

- Design of Pipelines and Pumping SystemsDocument21 pagesDesign of Pipelines and Pumping SystemsRaghuveer Rao PallepatiNo ratings yet

- Water - Hammer Damper Tank Hydropack-ExampleDocument30 pagesWater - Hammer Damper Tank Hydropack-ExampleChirag ShahNo ratings yet

- Aqueduct at Km:7.782 at Gundlakamma Reservoir Project: Design of SuperstructureDocument58 pagesAqueduct at Km:7.782 at Gundlakamma Reservoir Project: Design of Superstructurep_ignatiusNo ratings yet

- DLRB DesignDocument31 pagesDLRB DesignVenkat LekkalaNo ratings yet

- Discharge Left DrainDocument2 pagesDischarge Left DrainGangesh Kumar ThakurNo ratings yet

- Salient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Document3 pagesSalient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Bidur GautamNo ratings yet

- DRAIN LHS HazaribaghDocument12 pagesDRAIN LHS HazaribaghEr navneet jassiNo ratings yet

- 5 Glacis FallDocument6 pages5 Glacis FallSahil ThakurNo ratings yet

- Annexure 9.7 - Head Loss in Water Conductor SystemDocument2 pagesAnnexure 9.7 - Head Loss in Water Conductor SystemKshitij ThakurNo ratings yet

- NetafimDocument67 pagesNetafimxtianNo ratings yet

- Head Loss CalculationDocument7 pagesHead Loss CalculationswabrightNo ratings yet

- Surge TankDocument26 pagesSurge TankAmar WadoodNo ratings yet

- Spillway RatingDocument22 pagesSpillway Ratingguildkey0% (1)

- EE (Bridge) / SE (P&D) / E.I.C.: 1 X 20.00 1X19.35 PileDocument4 pagesEE (Bridge) / SE (P&D) / E.I.C.: 1 X 20.00 1X19.35 PileAshish GNo ratings yet

- Economic Diameter CalDocument28 pagesEconomic Diameter CaldsdeshpandeNo ratings yet

- Design-Retaining Wall2 9555Document27 pagesDesign-Retaining Wall2 9555SureshSawantNo ratings yet

- Septic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)Document1 pageSeptic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)manojNo ratings yet

- Head Race CanalDocument12 pagesHead Race CanalKeshab BadalNo ratings yet

- Khani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalDocument10 pagesKhani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalAsmita KoiralaNo ratings yet

- Design - Pipe Cause WayDocument1 pageDesign - Pipe Cause WaysudhirsoniNo ratings yet

- Abut. Screen WallDocument17 pagesAbut. Screen WallAakash RastogiNo ratings yet

- Calculation of Inlet Bell DiameterDocument6 pagesCalculation of Inlet Bell DiameterVardhanNo ratings yet

- CE404 06 Syphon HydraulicsDocument9 pagesCE404 06 Syphon HydraulicsKatyayini NelliNo ratings yet

- Calculate Pipe Dia.Document2 pagesCalculate Pipe Dia.Dalveer SinghNo ratings yet

- Head Reg (Final) UNGATEDDocument6 pagesHead Reg (Final) UNGATEDsushilkumarNo ratings yet

- Min Pattern: Icrc/Wathab Demand Analysis 10/19/2017Document3 pagesMin Pattern: Icrc/Wathab Demand Analysis 10/19/2017GJ CCNo ratings yet

- Canal FallsDocument20 pagesCanal FallsRajesh KhadkaNo ratings yet

- Design of Vertical Drop Fall: Surface FlowDocument3 pagesDesign of Vertical Drop Fall: Surface FlowMohammed100% (1)

- Stability of Floating BodiesDocument2 pagesStability of Floating BodiesEmejoi TemblacoNo ratings yet

- Design of Head Regulator: Name of Project: LMC Offtaking From Parwan DamDocument7 pagesDesign of Head Regulator: Name of Project: LMC Offtaking From Parwan DamshwetaNo ratings yet

- Escape PipeDocument3 pagesEscape PipeVidya ShankarNo ratings yet

- PUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Document1 pagePUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Bimal DeyNo ratings yet

- Economic Size of Pumping Main-R3Document11 pagesEconomic Size of Pumping Main-R3srikanth0924No ratings yet

- Building Template 16x9Document52 pagesBuilding Template 16x9Zamanoden D. UndaNo ratings yet

- Examination Notes: 1. Answer ALL The Questions 2. Encircle of Highlight Your Answer With Yellow ColorDocument18 pagesExamination Notes: 1. Answer ALL The Questions 2. Encircle of Highlight Your Answer With Yellow ColorDovah KiinNo ratings yet

- UASB Booster Pressure CalculationDocument143 pagesUASB Booster Pressure CalculationJayakrishnan RadhakrishnanNo ratings yet

- Economical Design of RMDocument2 pagesEconomical Design of RMPrakash J VaghasiyaNo ratings yet

- Material Safety Data Sheet Ethylene CompleteDocument7 pagesMaterial Safety Data Sheet Ethylene CompleteReiVanNo ratings yet

- Evidence 1 - Life ScienceDocument9 pagesEvidence 1 - Life ScienceMelanie Joselyn Lucio MoralesNo ratings yet

- Basrah Water Supply Improvement Project: FulltechDocument17 pagesBasrah Water Supply Improvement Project: FulltechAhmad MohammadNo ratings yet

- Bsbsus 401 Implement and MonitorDocument16 pagesBsbsus 401 Implement and MonitorÇrox Rmg PunkNo ratings yet

- Modul SRG Pak BilalDocument49 pagesModul SRG Pak Bilalsalwaramadhanti30No ratings yet

- India Urban Infrastructure Report 2020: ResearchDocument87 pagesIndia Urban Infrastructure Report 2020: ResearchgeetNo ratings yet

- Ecología Urbana en Ciudades de ChileDocument8 pagesEcología Urbana en Ciudades de ChileAndres Muñoz PedrerosNo ratings yet

- Population Growth Biology Science Presentation in Blue Yellow Hand Drawn StyleDocument28 pagesPopulation Growth Biology Science Presentation in Blue Yellow Hand Drawn Styletoltol011002No ratings yet

- B8 Soc WK1 1Document2 pagesB8 Soc WK1 1nanayawasamoahduah6No ratings yet

- Sistem Jaringan Transportasi Logistik Kawasan Perbatasan Provinsi Papua Dengan Papua New GuineaDocument12 pagesSistem Jaringan Transportasi Logistik Kawasan Perbatasan Provinsi Papua Dengan Papua New GuineaIkal M YasinNo ratings yet

- 6 MossDocument2 pages6 MossSHELTON DOMINIC D'ROZARIONo ratings yet

- EIA EMP For Gumma Fediz Section ofDocument207 pagesEIA EMP For Gumma Fediz Section ofDevesh SawantNo ratings yet

- WELL Building StandardDocument48 pagesWELL Building StandardNdia2007No ratings yet

- The Story of Stuff Activity Guide and Worksheet: Unit 9: Waste Not, Want NotDocument6 pagesThe Story of Stuff Activity Guide and Worksheet: Unit 9: Waste Not, Want NotNancy GomezNo ratings yet

- Marine Pollution Bulletin: Nur Hazimah Mohamed Nor, Jeffrey Philip ObbardDocument6 pagesMarine Pollution Bulletin: Nur Hazimah Mohamed Nor, Jeffrey Philip ObbardAwinda NurNo ratings yet

- Basic... 1st MidDocument54 pagesBasic... 1st MidNaafNo ratings yet

- Envioremnental Management UpstreamDocument162 pagesEnvioremnental Management UpstreamSham Aran100% (1)

- Material Safety Data SheetDocument5 pagesMaterial Safety Data Sheetadem selaluNo ratings yet

- Sustainable Development: " The Pathway To The Future We Want For All. "Document14 pagesSustainable Development: " The Pathway To The Future We Want For All. "Roshan Kumar LohaniNo ratings yet

- CR Key Check 5 - FINALdraftDocument35 pagesCR Key Check 5 - FINALdraftRomally Antonette TagnipezNo ratings yet

- R.A. No. 6969 - Brown GroupDocument35 pagesR.A. No. 6969 - Brown GroupAngelNo ratings yet

- Evs Unit IDocument25 pagesEvs Unit IVainapriya RNo ratings yet

- Cartography 6 - Hydrographic SurveyingDocument2 pagesCartography 6 - Hydrographic SurveyingGie Marie GuarinoNo ratings yet

- DisasterDocument15 pagesDisasterAjs CreationsNo ratings yet

- Roles of Tourism Ecotourism in ConservatDocument13 pagesRoles of Tourism Ecotourism in ConservatYvan Kwidja DjamiNo ratings yet

- Air PollutionDocument29 pagesAir PollutionKUSHAGRA SRIVASTAVANo ratings yet

- Kaushik Chanda Assistant Professor Organic Chemistry Division, SAS, VIT University, Vellore - 14Document21 pagesKaushik Chanda Assistant Professor Organic Chemistry Division, SAS, VIT University, Vellore - 14RiajiminNo ratings yet

- BSD 323 - Building Systems DesignDocument15 pagesBSD 323 - Building Systems DesignEloisa Belle RomuloNo ratings yet

Rising Mail Design

Rising Mail Design

Uploaded by

Bhupendra KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rising Mail Design

Rising Mail Design

Uploaded by

Bhupendra KumarCopyright:

Available Formats

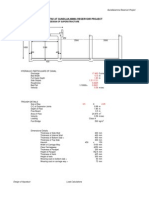

ECONOMIC DESIGN OF RISING MAIN from TW-4 to TW-3

A. Design Data:

1 Water Requirement:

Population Year Water Demand

A) Initial 252.00 KLD

B) Intermediate 252.00 KLD

C) Ultimate 252.00 KLD

2 Actual Length of Rising Main: 300.00 m

3 Length of Rising Main considered for Design : 300 m

4 RL at Tube Well Site (TW-4): 96.00 m

5 Suction Depth: 40.00 m

6 RL at Suction Level: 56 m

7 Destination of rising main: 121.000 m

8 Static head for pump (St. Head): 65 m

9 Static head on pump considered for Design: 65 m

10 Design Period (Years): 30 yrs

11 Combined Eff. Of pump set: 50 %

12 Cost of pumping unit per KW: 15000 Rs.

13 Interest rate: 12 %

14 Life of electric motor: 15 yrs

15 Energy charges/KWH unit: 6 Rs.

16 Pumping hours for discharge : 14 hrs

17 Pump Standby : 0 %

CALCULATIONS:

1st 15 years 2nd 15 years

Discharge at starting of period Qs1 252 KLD Qs2 252 KLD

Discharge at ending of 10 yrs Qe1 252 KLD Qe2 252 KLD

Average discharge Qav1 252 KLD Qav2 252 KLD

Average pumping hours

T1 14.00 hrs T2 14 hrs

during period

V = 143.534 CR r0.6575S0.5525

h = [L(Q / CR)1.81]/994.62D4.81

in which,

V = velocity of flow in m/s.

CR = pipe roughness coefficient, ( 1 for smooth pipes; < 1 for rough pipes);

r = hydraulic radius in m;

s = friction slope;

D = internal diameter of pipe in m;

h = friction head loss in m;

L = length of pipe in m; and

Q = flow in pipe in m3 / s

Roughnes

Dia of Hydraulic Head

1 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.005 100 0.1 0.03 1 4.44 0.64 1.333

2 0.005 150 0.15 0.04 1 0.632 0.28 0.190

3 0.005 200 0.2 0.05 1 0.159 0.16 0.048

4 0.005 250 0.25 0.06 1 0.055 0.10 0.017

5 0.005 300 0.3 0.08 1 0.023 0.07 0.007

Roughnes

Dia of Hydraulic Head

2 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.005 100 0.1 0.03 1 4.441 0.64 1.333

2 0.005 150 0.15 0.04 1 0.632 0.28 0.190

3 0.005 200 0.2 0.05 1 0.159 0.16 0.048

4 0.005 250 0.25 0.06 1 0.055 0.10 0.017

5 0.005 300 0.3 0.08 1 0.023 0.07 0.007

Prepared By:Shubh Consultants, Raipur

Velocity and Head loss for Different Pipe sizes

Total head (m) for

Frictional head loss per 1000m Velocity in m/s Length(m)

300 ; Static head(m)= 65

=

S.No Diameter of

1st stage flow 2nd stage flow

. Pipe

1st stage 2nd stage Total

1st stage flow 2nd stage flow Frictional Total Head Frictional Other

flow flow Other Losses Head

Losses (H1) Losses Losses

(H2)

1 100 4.441 4.441 0.637 0.637 1.333 0.133 66.466 1.333 0.133 66.466

2 150 0.632 0.632 0.283 0.283 0.190 0.019 65.209 0.190 0.019 65.209

3 200 0.159 0.159 0.160 0.160 0.048 0.005 65.053 0.048 0.005 65.053

4 250 0.055 0.055 0.103 0.103 0.017 0.002 65.019 0.017 0.002 65.019

5 300 0.023 0.023 0.072 0.072 0.007 0.001 65.008 0.007 0.001 65.008

B. KW required at 60% combined efficiency of pumping set

KW 1 = Qe1 x 106 x H1 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 1 = 6.373

KW 2 = Qe2 x 106 x H2 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 2 = 6.373

KW Required = (QxH)/(102 x η x T)

Kilowatts & cost of pump sets required for different pipe diameter and pipe cost

1st stage flow 2st stage flow Total

Cost of

Diameter of cost of

S.No. Class of pipe Pumping Total Pumping pipe per

Pipe KW pipe Rs.

Total Losses (H1) cost Rs. Losses KW required cost Rs. unit m

required Lacs

Lacs (H2) Lacs

1 100 DI K9 66.466 6.516 0.977 66.466 6.516 0.977 1,191.41 3.574

2 150 DI K9 65.209 6.393 0.959 65.209 6.393 0.959 1,728.48 5.185

3 200 DI K9 65.053 6.378 0.957 65.053 6.378 0.957 2,332.32 6.997

4 250 DI K9 65.019 6.374 0.956 65.019 6.374 0.956 3,103.50 9.311

5 300 DI K9 65.008 6.373 0.956 65.008 6.373 0.956 3,877.60 11.633

C. Annual Cost in Rs. Of electrical energy @ Rs.6.00 per unit (KWT hours of pumping x average days per year x 6.00)

1st Stage Flow

30680.16 x KW 1

=

2nd Stage

30680.16 x KW 2

Flow =

Pump Cost

D.

Capitalized

Pn = C =

Po(1+r)n

Po = C/(1+r)n

Where,

Po = Initial Capitalized Investment

C = Amount needed after 10 years to purchase the second stage Pumping set

r = Rate of Compound Interest = 10% per year

n = no. of

years = 10

Po = C/ 2.594

E. Energy charges capitalized

CC = CR {(1-

(1+r)-n)/n}

For values r = 10% and n = 10 years

CC = 7.606 CR

Therefore,

CC 1st Stage = 7.606 CR 1st Stage

CC 2nd Stage = 7.606 CR 2nd Stage

Present Energy Charges (CP) for 2nd stage capitalized value i.e. for CC 2nd stage

CP = CC 2nd Stage/2.594

Prepared By:Shubh Consultants, Raipur

Comparative statement of overall cost structure of pumping main for different pipe sizes

1st Stage 2st Stage Grand

Annual Capitalize Annual Total of OD in

Cost of pump Capitalized Energy Cost of Capitalized Capitalized

Energy d total Energy Capitalize (mm)

sets Charges pump sets Energy Charges total cost

charges cost charges d cost for

0.977 1.999 15.206 19.758 0.977 1.999 15.206 16.183 35.941 100

0.959 1.961 14.918 21.063 0.959 1.961 14.918 15.877 36.940 150

0.957 1.957 14.883 22.836 0.957 1.957 14.883 15.839 38.676 200

0.956 1.956 14.875 25.141 0.956 1.956 14.875 15.831 40.972 250

0.956 1.955 14.872 27.461 0.956 1.955 14.872 15.828 43.289 300

50.000

Total of Capitalized cost for 20 years

43.29

45.000 40.97

38.68

40.000 35.94 36.94

35.000

30.000

25.000

20.000

15.000

10.000

5.000

0.000

100 150 200 250 300

Dia of Pipe in mm

Minimum Cost of Rising Main is 35.941 Lacs

Most economical size is 100 mm

Adopted Size (outer diameter) 100 mm

PROPOSED 300 m DI K9 100 mm Pipe from TW-4 to TW-3

Prepared By:Shubh Consultants, Raipur

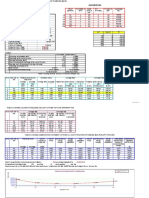

ECONOMIC DESIGN OF RISING MAIN from TW-3 to TW-2

A. Design Data:

1 Water Requirement:

Population Year Water Demand

A) Initial 504.00 KLD

B) Intermediate 504.00 KLD

C) Ultimate 504.00 KLD

2 Actual Length of Rising Main: 300.00 m

3 Length of Rising Main considered for Design : 300 m

4 RL at Tube Well Site (TW-3): 97.00 m

5 Suction Depth: 40.00 m

6 RL at Suction Level: 57 m

7 Destination of rising main: 121.000 m

8 Static head for pump (St. Head): 64 m

9 Static head on pump considered for Design: 64 m

10 Design Period (Years): 30 yrs

11 Combined Eff. Of pump set: 50 %

12 Cost of pumping unit per KW: 15000 Rs.

13 Interest rate: 12 %

14 Life of electric motor: 15 yrs

15 Energy charges/KWH unit: 6 Rs.

16 Pumping hours for discharge : 14 hrs

17 Pump Standby : 0 %

CALCULATIONS:

1st 15 years 2nd 15 years

Discharge at starting of period Qs1 504 KLD Qs2 504 KLD

Discharge at ending of 10 yrs Qe1 504 KLD Qe2 504 KLD

Average discharge Qav1 504 KLD Qav2 504 KLD

Average pumping hours

T1 14.00 hrs T2 14 hrs

during period

V = 143.534 CR r0.6575S0.5525

h = [L(Q / CR)1.81]/994.62D4.81

in which,

V = velocity of flow in m/s.

CR = pipe roughness coefficient, ( 1 for smooth pipes; < 1 for rough pipes);

r = hydraulic radius in m;

s = friction slope;

D = internal diameter of pipe in m;

h = friction head loss in m;

L = length of pipe in m; and

Q = flow in pipe in m3 / s

Roughnes

Dia of Hydraulic Head

1 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.01 100 0.1 0.03 1 15.57 1.27 4.672

2 0.01 150 0.15 0.04 1 2.215 0.57 0.665

3 0.01 200 0.2 0.05 1 0.556 0.32 0.167

4 0.01 250 0.25 0.06 1 0.190 0.20 0.057

5 0.01 300 0.3 0.08 1 0.079 0.14 0.024

Roughnes

Dia of Hydraulic Head

2 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.01 100 0.1 0.03 1 15.572 1.27 4.672

2 0.01 150 0.15 0.04 1 2.215 0.57 0.665

3 0.01 200 0.2 0.05 1 0.556 0.32 0.167

4 0.01 250 0.25 0.06 1 0.190 0.20 0.057

5 0.01 300 0.3 0.08 1 0.079 0.14 0.024

Prepared By:Shubh Consultants, Raipur

Velocity and Head loss for Different Pipe sizes

Total head (m) for

Frictional head loss per 1000m Velocity in m/s Length(m)

300 ; Static head(m)= 64

=

S.No Diameter of

1st stage flow 2nd stage flow

. Pipe

1st stage 2nd stage Total

1st stage flow 2nd stage flow Frictional Total Head Frictional Other

flow flow Other Losses Head

Losses (H1) Losses Losses

(H2)

1 100 15.572 15.572 1.273 1.273 4.672 0.467 69.139 4.672 0.467 69.139

2 150 2.215 2.215 0.566 0.566 0.665 0.067 64.732 0.665 0.067 64.732

3 200 0.556 0.556 0.319 0.319 0.167 0.017 64.184 0.167 0.017 64.184

4 250 0.190 0.190 0.204 0.204 0.057 0.006 64.063 0.057 0.006 64.063

5 300 0.079 0.079 0.141 0.141 0.024 0.002 64.026 0.024 0.002 64.026

B. KW required at 60% combined efficiency of pumping set

KW 1 = Qe1 x 106 x H1 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 1 = 12.549

KW 2 = Qe2 x 106 x H2 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 2 = 12.549

KW Required = (QxH)/(102 x η x T)

Kilowatts & cost of pump sets required for different pipe diameter and pipe cost

1st stage flow 2st stage flow Total

Cost of

Diameter of cost of

S.No. Class of pipe Pumping Total Pumping pipe per

Pipe KW pipe Rs.

Total Losses (H1) cost Rs. Losses KW required cost Rs. unit m

required Lacs

Lacs (H2) Lacs

1 100 DI K9 69.139 13.557 2.034 69.139 13.557 2.034 1,191.41 3.574

2 150 DI K9 64.732 12.692 1.904 64.732 12.692 1.904 1,728.48 5.185

3 200 DI K9 64.184 12.585 1.888 64.184 12.585 1.888 2,332.32 6.997

4 250 DI K9 64.063 12.561 1.884 64.063 12.561 1.884 3,103.50 9.311

5 300 DI K9 64.026 12.554 1.883 64.026 12.554 1.883 3,877.60 11.633

C. Annual Cost in Rs. Of electrical energy @ Rs.6.00 per unit (KWT hours of pumping x average days per year x 6.00)

1st Stage Flow

30680.16 x KW 1

=

2nd Stage

30680.16 x KW 2

Flow =

Pump Cost

D.

Capitalized

Pn = C =

Po(1+r)n

Po = C/(1+r)n

Where,

Po = Initial Capitalized Investment

C = Amount needed after 10 years to purchase the second stage Pumping set

r = Rate of Compound Interest = 10% per year

n = no. of

years = 10

Po = C/ 2.594

E. Energy charges capitalized

CC = CR {(1-

(1+r)-n)/n}

For values r = 10% and n = 10 years

CC = 7.606 CR

Therefore,

CC 1st Stage = 7.606 CR 1st Stage

CC 2nd Stage = 7.606 CR 2nd Stage

Present Energy Charges (CP) for 2nd stage capitalized value i.e. for CC 2nd stage

CP = CC 2nd Stage/2.594

Prepared By:Shubh Consultants, Raipur

Comparative statement of overall cost structure of pumping main for different pipe sizes

1st Stage 2st Stage Grand

Annual Capitalize Annual Total of OD in

Cost of pump Capitalized Energy Cost of Capitalized Capitalized

Energy d total Energy Capitalize (mm)

sets Charges pump sets Energy Charges total cost

charges cost charges d cost for

2.034 4.159 31.635 37.243 2.034 4.159 31.635 33.669 70.911 100

1.904 3.894 29.618 36.708 1.904 3.894 29.618 31.522 68.230 150

1.888 3.861 29.368 38.252 1.888 3.861 29.368 31.255 69.508 200

1.884 3.854 29.312 40.507 1.884 3.854 29.312 31.196 71.703 250

1.883 3.852 29.296 42.812 1.883 3.852 29.296 31.179 73.990 300

75.000 73.99

Total of Capitalized cost for 20 years

74.000

73.000

71.70

72.000 70.91

71.000

69.51

70.000

69.000 68.23

68.000

67.000

66.000

65.000

100 150 200 250 300

Dia of Pipe in mm

Minimum Cost of Rising Main is 68.230 Lacs

Most economical size is 150 mm

Adopted Size (outer diameter) 150 mm

PROPOSED 300 m DI K9 150 mm Pipe from TW-3 to TW-2

Prepared By:Shubh Consultants, Raipur

ECONOMIC DESIGN OF RISING MAIN from TW-2 to TW-1

A. Design Data:

1 Water Requirement:

Population Year Water Demand

A) Initial 756.00 KLD

B) Intermediate 756.00 KLD

C) Ultimate 756.00 KLD

2 Actual Length of Rising Main: 300.00 m

3 Length of Rising Main considered for Design : 300 m

4 RL at Tube Well Site (TW-2): 98.00 m

5 Suction Depth: 40.00 m

6 RL at Suction Level: 58 m

7 Destination of rising main: 121.000 m

8 Static head for pump (St. Head): 63 m

9 Static head on pump considered for Design: 63 m

10 Design Period (Years): 30 yrs

11 Combined Eff. Of pump set: 50 %

12 Cost of pumping unit per KW: 15000 Rs.

13 Interest rate: 12 %

14 Life of electric motor: 15 yrs

15 Energy charges/KWH unit: 6 Rs.

16 Pumping hours for discharge : 14 hrs

17 Pump Standby : 0 %

CALCULATIONS:

1st 15 years 2nd 15 years

Discharge at starting of period Qs1 756 KLD Qs2 756 KLD

Discharge at ending of 10 yrs Qe1 756 KLD Qe2 756 KLD

Average discharge Qav1 756 KLD Qav2 756 KLD

Average pumping hours

T1 14.00 hrs T2 14 hrs

during period

V = 143.534 CR r0.6575S0.5525

h = [L(Q / CR)1.81]/994.62D4.81

in which,

V = velocity of flow in m/s.

CR = pipe roughness coefficient, ( 1 for smooth pipes; < 1 for rough pipes);

r = hydraulic radius in m;

s = friction slope;

D = internal diameter of pipe in m;

h = friction head loss in m;

L = length of pipe in m; and

Q = flow in pipe in m3 / s

Roughnes

Dia of Hydraulic Head

1 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.015 100 0.1 0.03 1 32.44 1.91 9.732

2 0.015 150 0.15 0.04 1 4.614 0.85 1.385

3 0.015 200 0.2 0.05 1 1.157 0.48 0.348

4 0.015 250 0.25 0.06 1 0.396 0.31 0.119

5 0.015 300 0.3 0.08 1 0.165 0.21 0.050

Roughnes

Dia of Hydraulic Head

2 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.015 100 0.1 0.03 1 32.440 1.91 9.732

2 0.015 150 0.15 0.04 1 4.614 0.85 1.385

3 0.015 200 0.2 0.05 1 1.157 0.48 0.348

4 0.015 250 0.25 0.06 1 0.396 0.31 0.119

5 0.015 300 0.3 0.08 1 0.165 0.21 0.050

Prepared By:Shubh Consultants, Raipur

Velocity and Head loss for Different Pipe sizes

Total head (m) for

Frictional head loss per 1000m Velocity in m/s Length(m)

300 ; Static head(m)= 63

=

S.No Diameter of

1st stage flow 2nd stage flow

. Pipe

1st stage 2nd stage Total

1st stage flow 2nd stage flow Frictional Total Head Frictional Other

flow flow Other Losses Head

Losses (H1) Losses Losses

(H2)

1 100 32.440 32.440 1.910 1.910 9.732 0.973 73.705 9.732 0.973 73.705

2 150 4.614 4.614 0.849 0.849 1.385 0.139 64.524 1.385 0.139 64.524

3 200 1.157 1.157 0.478 0.478 0.348 0.035 63.383 0.348 0.035 63.383

4 250 0.396 0.396 0.306 0.306 0.119 0.012 63.131 0.119 0.012 63.131

5 300 0.165 0.165 0.213 0.213 0.050 0.005 63.055 0.050 0.005 63.055

B. KW required at 60% combined efficiency of pumping set

KW 1 = Qe1 x 106 x H1 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 1 = 18.529

KW 2 = Qe2 x 106 x H2 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 2 = 18.529

KW Required = (QxH)/(102 x η x T)

Kilowatts & cost of pump sets required for different pipe diameter and pipe cost

1st stage flow 2st stage flow Total

Cost of

Diameter of cost of

S.No. Class of pipe Pumping Total Pumping pipe per

Pipe KW pipe Rs.

Total Losses (H1) cost Rs. Losses KW required cost Rs. unit m

required Lacs

Lacs (H2) Lacs

1 100 DI K9 73.705 21.678 3.252 73.705 21.678 3.252 1,191.41 3.574

2 150 DI K9 64.524 18.978 2.847 64.524 18.978 2.847 1,728.48 5.185

3 200 DI K9 63.383 18.642 2.796 63.383 18.642 2.796 2,332.32 6.997

4 250 DI K9 63.131 18.568 2.785 63.131 18.568 2.785 3,103.50 9.311

5 300 DI K9 63.055 18.546 2.782 63.055 18.546 2.782 3,877.60 11.633

C. Annual Cost in Rs. Of electrical energy @ Rs.6.00 per unit (KWT hours of pumping x average days per year x 6.00)

1st Stage Flow

30680.16 x KW 1

=

2nd Stage

30680.16 x KW 2

Flow =

Pump Cost

D.

Capitalized

Pn = C =

Po(1+r)n

Po = C/(1+r)n

Where,

Po = Initial Capitalized Investment

C = Amount needed after 10 years to purchase the second stage Pumping set

r = Rate of Compound Interest = 10% per year

n = no. of

years = 10

Po = C/ 2.594

E. Energy charges capitalized

CC = CR {(1-

(1+r)-n)/n}

For values r = 10% and n = 10 years

CC = 7.606 CR

Therefore,

CC 1st Stage = 7.606 CR 1st Stage

CC 2nd Stage = 7.606 CR 2nd Stage

Present Energy Charges (CP) for 2nd stage capitalized value i.e. for CC 2nd stage

CP = CC 2nd Stage/2.594

Prepared By:Shubh Consultants, Raipur

Comparative statement of overall cost structure of pumping main for different pipe sizes

1st Stage 2st Stage Grand

Annual Capitalize Annual Total of OD in

Cost of pump Capitalized Energy Cost of Capitalized Capitalized

Energy d total Energy Capitalize (mm)

sets Charges pump sets Energy Charges total cost

charges cost charges d cost for

3.252 6.651 50.586 57.412 3.252 6.651 50.586 53.838 111.250 100

2.847 5.822 44.285 52.317 2.847 5.822 44.285 47.131 99.448 150

2.796 5.719 43.502 53.295 2.796 5.719 43.502 46.298 99.593 200

2.785 5.697 43.329 55.425 2.785 5.697 43.329 46.114 101.539 250

2.782 5.690 43.277 57.691 2.782 5.690 43.277 46.059 103.750 300

114.000

Total of Capitalized cost for 20 years

111.25

112.000

110.000

108.000

106.000 103.75

104.000 101.54

102.000 99.59

99.45

100.000

98.000

96.000

94.000

92.000

100 150 200 250 300

Dia of Pipe in mm

Minimum Cost of Rising Main is 99.448 Lacs

Most economical size is 150 mm

Adopted Size (outer diameter) 150 mm

PROPOSED 300 m DI K9 150 mm Pipe from TW-2 to TW-1

Prepared By:Shubh Consultants, Raipur

ECONOMIC DESIGN OF RISING MAIN from TW-1 to OHT

A. Design Data:

1 Water Requirement:

Population Year Water Demand

A) Initial 1008.00 KLD

B) Intermediate 1008.00 KLD

C) Ultimate 1008.00 KLD

2 Actual Length of Rising Main: 3500.00 m

3 Length of Rising Main considered for Design : 3500 m

4 RL at Tube Well Site (TW-1): 100.00 m

5 Suction Depth: 40.00 m

6 RL at Suction Level: 60 m

7 Destination of rising main: 121.000 m

8 Static head for pump (St. Head): 61 m

9 Static head on pump considered for Design: 61 m

10 Design Period (Years): 30 yrs

11 Combined Eff. Of pump set: 50 %

12 Cost of pumping unit per KW: 15000 Rs.

13 Interest rate: 12 %

14 Life of electric motor: 15 yrs

15 Energy charges/KWH unit: 6 Rs.

16 Pumping hours for discharge : 14 hrs

17 Pump Standby : 0 %

CALCULATIONS:

1st 15 years 2nd 15 years

Discharge at starting of period Qs1 1008 KLD Qs2 1008 KLD

Discharge at ending of 10 yrs Qe1 1008 KLD Qe2 1008 KLD

Average discharge Qav1 1008 KLD Qav2 1008 KLD

Average pumping hours

T1 14.00 hrs T2 14 hrs

during period

V = 143.534 CR r0.6575S0.5525

h = [L(Q / CR)1.81]/994.62D4.81

in which,

V = velocity of flow in m/s.

CR = pipe roughness coefficient, ( 1 for smooth pipes; < 1 for rough pipes);

r = hydraulic radius in m;

s = friction slope;

D = internal diameter of pipe in m;

h = friction head loss in m;

L = length of pipe in m; and

3

Q = flow in pipe in m / s

Roughnes

Dia of Hydraulic Head

1 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.02 100 0.1 0.03 1 54.60 2.55 191.107

2 0.02 150 0.15 0.04 1 7.767 1.13 27.185

3 0.02 200 0.2 0.05 1 1.947 0.64 6.815

4 0.02 250 0.25 0.06 1 0.666 0.41 2.331

5 0.02 300 0.3 0.08 1 0.277 0.28 0.970

Roughnes

Dia of Hydraulic Head

2 st stage Dia of pipe s Total

S.No. pipe Gradient Loss per Velocity (m/s)

Flow (cum/s) (m) Coefficien Losses (m)

(mm) (m) 1000m

t (CR)

1 0.02 100 0.1 0.03 1 54.602 2.55 191.107

2 0.02 150 0.15 0.04 1 7.767 1.13 27.185

3 0.02 200 0.2 0.05 1 1.947 0.64 6.815

4 0.02 250 0.25 0.06 1 0.666 0.41 2.331

5 0.02 300 0.3 0.08 1 0.277 0.28 0.970

Prepared By:Shubh Consultants, Raipur

Velocity and Head loss for Different Pipe sizes

Total head (m) for

Frictional head loss per 1000m Velocity in m/s Length(m)

3500 ; Static head(m)= 61

=

S.No Diameter of

1st stage flow 2nd stage flow

. Pipe

1st stage 2nd stage Total

1st stage flow 2nd stage flow Frictional Total Head Frictional Other

flow flow Other Losses Head

Losses (H1) Losses Losses

(H2)

1 100 54.602 54.602 2.546 2.546 191.107 19.111 271.218 191.107 19.111 271.218

2 150 7.767 7.767 1.132 1.132 27.185 2.719 90.904 27.185 2.719 90.904

3 200 1.947 1.947 0.637 0.637 6.815 0.682 68.497 6.815 0.682 68.497

4 250 0.666 0.666 0.408 0.408 2.331 0.233 63.564 2.331 0.233 63.564

5 300 0.277 0.277 0.283 0.283 0.970 0.097 62.067 0.970 0.097 62.067

B. KW required at 60% combined efficiency of pumping set

KW 1 = Qe1 x 106 x H1 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 1 = 23.922

KW 2 = Qe2 x 106 x H2 x 100 x24 / (60 x 60 x 24 x 102 x η x t)

KW 2 = 23.922

KW Required = (QxH)/(102 x η x T)

Kilowatts & cost of pump sets required for different pipe diameter and pipe cost

1st stage flow 2st stage flow Total

Cost of

Diameter of cost of

S.No. Class of pipe Pumping Total Pumping pipe per

Pipe KW pipe Rs.

Total Losses (H1) cost Rs. Losses KW required cost Rs. unit m

required Lacs

Lacs (H2) Lacs

1 100 DI K9 271.218 106.360 15.954 271.218 106.360 15.954 1,191.41 41.699

2 150 DI K9 90.904 35.648 5.347 90.904 35.648 5.347 1,728.48 60.497

3 200 DI K9 68.497 26.861 4.029 68.497 26.861 4.029 2,332.32 81.631

4 250 DI K9 63.564 24.927 3.739 63.564 24.927 3.739 3,103.50 108.623

5 300 DI K9 62.067 24.340 3.651 62.067 24.340 3.651 3,877.60 135.716

C. Annual Cost in Rs. Of electrical energy @ Rs.6.00 per unit (KWT hours of pumping x average days per year x 6.00)

1st Stage Flow

30680.16 x KW 1

=

2nd Stage

30680.16 x KW 2

Flow =

Pump Cost

D.

Capitalized

Pn = C =

Po(1+r)n

Po = C/(1+r)n

Where,

Po = Initial Capitalized Investment

C = Amount needed after 10 years to purchase the second stage Pumping set

r = Rate of Compound Interest = 10% per year

n = no. of

years = 10

Po = C/ 2.594

E. Energy charges capitalized

CC = CR {(1-

(1+r)-n)/n}

For values r = 10% and n = 10 years

CC = 7.606 CR

Therefore,

CC 1st Stage = 7.606 CR 1st Stage

CC 2nd Stage = 7.606 CR 2nd Stage

Present Energy Charges (CP) for 2nd stage capitalized value i.e. for CC 2nd stage

CP = CC 2nd Stage/2.594

Prepared By:Shubh Consultants, Raipur

Comparative statement of overall cost structure of pumping main for different pipe sizes

1st Stage 2st Stage Grand

Annual Annual Total of OD in

Cost of pump Capitalized Energy Capitalized Cost of Capitalized Capitalized

Energy Energy Capitalize (mm)

sets Charges total cost pump sets Energy Charges total cost

charges charges d cost for

15.954 32.631 248.194 305.848 15.954 32.631 248.194 264.148 569.996 100

5.347 10.937 83.187 149.031 5.347 10.937 83.187 88.534 237.565 150

4.029 8.241 62.682 148.342 4.029 8.241 62.682 66.711 215.053 200

3.739 7.648 58.168 170.530 3.739 7.648 58.168 61.907 232.437 250

3.651 7.468 56.798 196.165 3.651 7.468 56.798 60.449 256.614 300

570.00

600.000

Total of Capitalized cost for 20 years

500.000

400.000

300.000 256.61

237.56 232.44

215.05

200.000

100.000

0.000

100 150 200 250 300

Dia of Pipe in mm

Minimum Cost of Rising Main is 215.053 Lacs

Most economical size is 200 mm

Adopted Size (outer diameter) 200 mm

PROPOSED 3500 m DI K9 200 mm Pipe from TW-1 to OHT

Prepared By:Shubh Consultants, Raipur

You might also like

- Michael Begon, Colin R. Townsend - Ecology - From Individuals To Ecosystems (2021, Wiley) - Libgen - LiDocument861 pagesMichael Begon, Colin R. Townsend - Ecology - From Individuals To Ecosystems (2021, Wiley) - Libgen - LiTadeo Talbot-Wright SiraqyanNo ratings yet

- DVZ BrochureDocument40 pagesDVZ BrochureResul UygunNo ratings yet

- Pump Head Losses and TDH Calculation: 10.65 Q 1.852 L HF - C 1.852 D 4.87Document15 pagesPump Head Losses and TDH Calculation: 10.65 Q 1.852 L HF - C 1.852 D 4.87dsdeshpandeNo ratings yet

- SurgeDocument3 pagesSurgeSrinivas ReddyNo ratings yet

- Rising MainDocument2 pagesRising MainJitesh KumarNo ratings yet

- NdrcrossRD29RPcrossaug7 eDocument110 pagesNdrcrossRD29RPcrossaug7 epmu hmhNo ratings yet

- Chattara Check DamDocument6 pagesChattara Check DamSandeep VaishnavNo ratings yet

- Diameter Pasir Min. 0.088Document6 pagesDiameter Pasir Min. 0.088Eko SupoyoNo ratings yet

- Design of Outlets - JaboriDocument7 pagesDesign of Outlets - JaboriHaji Ahmad BhattiNo ratings yet

- Project Location: Diversion StructureDocument5 pagesProject Location: Diversion Structureelec310No ratings yet

- Canals and Related Structures: Design Standards No. 3Document254 pagesCanals and Related Structures: Design Standards No. 3Edelyn Lindero AmbosNo ratings yet

- Drip Design at SolDocument13 pagesDrip Design at SolVan BGNo ratings yet

- Is Code Criteria For Design of Anchor Block For Penstock With Expansion JointDocument13 pagesIs Code Criteria For Design of Anchor Block For Penstock With Expansion Jointduldar docNo ratings yet

- Chattara Check DamDocument22 pagesChattara Check DamAzaan zaimiNo ratings yet

- Design of BandharaDocument21 pagesDesign of BandharaNeil Agshikar100% (1)

- Solid Roller BucketDocument5 pagesSolid Roller BucketnaveenaeeNo ratings yet

- Ar-2006 (6 3 07)Document271 pagesAr-2006 (6 3 07)gsr_svsNo ratings yet

- OFM (Sections)Document4 pagesOFM (Sections)Hari RamNo ratings yet

- Design of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Document20 pagesDesign of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Souvik DasNo ratings yet

- Broad Vrested WeirDocument5 pagesBroad Vrested WeirdsanandaNo ratings yet

- Design of Drain at KM. 0.600Document5 pagesDesign of Drain at KM. 0.600Sameer AhmadNo ratings yet

- Hazen WilliamsDocument2 pagesHazen WilliamssushilkumarNo ratings yet

- Bucket DesignDocument6 pagesBucket Designוויסאם חטארNo ratings yet

- 1 Hydraulic Calculations PHOLAIDocument1 page1 Hydraulic Calculations PHOLAInc mathurNo ratings yet

- Design of Vertical Type Drop On Permeable Foundation Hydraulic ParticularsDocument17 pagesDesign of Vertical Type Drop On Permeable Foundation Hydraulic Particularsprasadnn2001No ratings yet

- Design of Pipelines and Pumping SystemsDocument21 pagesDesign of Pipelines and Pumping SystemsRaghuveer Rao PallepatiNo ratings yet

- Water - Hammer Damper Tank Hydropack-ExampleDocument30 pagesWater - Hammer Damper Tank Hydropack-ExampleChirag ShahNo ratings yet

- Aqueduct at Km:7.782 at Gundlakamma Reservoir Project: Design of SuperstructureDocument58 pagesAqueduct at Km:7.782 at Gundlakamma Reservoir Project: Design of Superstructurep_ignatiusNo ratings yet

- DLRB DesignDocument31 pagesDLRB DesignVenkat LekkalaNo ratings yet

- Discharge Left DrainDocument2 pagesDischarge Left DrainGangesh Kumar ThakurNo ratings yet

- Salient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Document3 pagesSalient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Bidur GautamNo ratings yet

- DRAIN LHS HazaribaghDocument12 pagesDRAIN LHS HazaribaghEr navneet jassiNo ratings yet

- 5 Glacis FallDocument6 pages5 Glacis FallSahil ThakurNo ratings yet

- Annexure 9.7 - Head Loss in Water Conductor SystemDocument2 pagesAnnexure 9.7 - Head Loss in Water Conductor SystemKshitij ThakurNo ratings yet

- NetafimDocument67 pagesNetafimxtianNo ratings yet

- Head Loss CalculationDocument7 pagesHead Loss CalculationswabrightNo ratings yet

- Surge TankDocument26 pagesSurge TankAmar WadoodNo ratings yet

- Spillway RatingDocument22 pagesSpillway Ratingguildkey0% (1)

- EE (Bridge) / SE (P&D) / E.I.C.: 1 X 20.00 1X19.35 PileDocument4 pagesEE (Bridge) / SE (P&D) / E.I.C.: 1 X 20.00 1X19.35 PileAshish GNo ratings yet

- Economic Diameter CalDocument28 pagesEconomic Diameter CaldsdeshpandeNo ratings yet

- Design-Retaining Wall2 9555Document27 pagesDesign-Retaining Wall2 9555SureshSawantNo ratings yet

- Septic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)Document1 pageSeptic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)manojNo ratings yet

- Head Race CanalDocument12 pagesHead Race CanalKeshab BadalNo ratings yet

- Khani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalDocument10 pagesKhani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalAsmita KoiralaNo ratings yet

- Design - Pipe Cause WayDocument1 pageDesign - Pipe Cause WaysudhirsoniNo ratings yet

- Abut. Screen WallDocument17 pagesAbut. Screen WallAakash RastogiNo ratings yet

- Calculation of Inlet Bell DiameterDocument6 pagesCalculation of Inlet Bell DiameterVardhanNo ratings yet

- CE404 06 Syphon HydraulicsDocument9 pagesCE404 06 Syphon HydraulicsKatyayini NelliNo ratings yet

- Calculate Pipe Dia.Document2 pagesCalculate Pipe Dia.Dalveer SinghNo ratings yet

- Head Reg (Final) UNGATEDDocument6 pagesHead Reg (Final) UNGATEDsushilkumarNo ratings yet

- Min Pattern: Icrc/Wathab Demand Analysis 10/19/2017Document3 pagesMin Pattern: Icrc/Wathab Demand Analysis 10/19/2017GJ CCNo ratings yet

- Canal FallsDocument20 pagesCanal FallsRajesh KhadkaNo ratings yet

- Design of Vertical Drop Fall: Surface FlowDocument3 pagesDesign of Vertical Drop Fall: Surface FlowMohammed100% (1)

- Stability of Floating BodiesDocument2 pagesStability of Floating BodiesEmejoi TemblacoNo ratings yet

- Design of Head Regulator: Name of Project: LMC Offtaking From Parwan DamDocument7 pagesDesign of Head Regulator: Name of Project: LMC Offtaking From Parwan DamshwetaNo ratings yet

- Escape PipeDocument3 pagesEscape PipeVidya ShankarNo ratings yet

- PUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Document1 pagePUMP CAPACITY AND POWER CALCULATION (All Pumps) - 16.03.21Bimal DeyNo ratings yet

- Economic Size of Pumping Main-R3Document11 pagesEconomic Size of Pumping Main-R3srikanth0924No ratings yet

- Building Template 16x9Document52 pagesBuilding Template 16x9Zamanoden D. UndaNo ratings yet

- Examination Notes: 1. Answer ALL The Questions 2. Encircle of Highlight Your Answer With Yellow ColorDocument18 pagesExamination Notes: 1. Answer ALL The Questions 2. Encircle of Highlight Your Answer With Yellow ColorDovah KiinNo ratings yet

- UASB Booster Pressure CalculationDocument143 pagesUASB Booster Pressure CalculationJayakrishnan RadhakrishnanNo ratings yet

- Economical Design of RMDocument2 pagesEconomical Design of RMPrakash J VaghasiyaNo ratings yet

- Material Safety Data Sheet Ethylene CompleteDocument7 pagesMaterial Safety Data Sheet Ethylene CompleteReiVanNo ratings yet

- Evidence 1 - Life ScienceDocument9 pagesEvidence 1 - Life ScienceMelanie Joselyn Lucio MoralesNo ratings yet

- Basrah Water Supply Improvement Project: FulltechDocument17 pagesBasrah Water Supply Improvement Project: FulltechAhmad MohammadNo ratings yet

- Bsbsus 401 Implement and MonitorDocument16 pagesBsbsus 401 Implement and MonitorÇrox Rmg PunkNo ratings yet

- Modul SRG Pak BilalDocument49 pagesModul SRG Pak Bilalsalwaramadhanti30No ratings yet

- India Urban Infrastructure Report 2020: ResearchDocument87 pagesIndia Urban Infrastructure Report 2020: ResearchgeetNo ratings yet

- Ecología Urbana en Ciudades de ChileDocument8 pagesEcología Urbana en Ciudades de ChileAndres Muñoz PedrerosNo ratings yet

- Population Growth Biology Science Presentation in Blue Yellow Hand Drawn StyleDocument28 pagesPopulation Growth Biology Science Presentation in Blue Yellow Hand Drawn Styletoltol011002No ratings yet

- B8 Soc WK1 1Document2 pagesB8 Soc WK1 1nanayawasamoahduah6No ratings yet

- Sistem Jaringan Transportasi Logistik Kawasan Perbatasan Provinsi Papua Dengan Papua New GuineaDocument12 pagesSistem Jaringan Transportasi Logistik Kawasan Perbatasan Provinsi Papua Dengan Papua New GuineaIkal M YasinNo ratings yet

- 6 MossDocument2 pages6 MossSHELTON DOMINIC D'ROZARIONo ratings yet

- EIA EMP For Gumma Fediz Section ofDocument207 pagesEIA EMP For Gumma Fediz Section ofDevesh SawantNo ratings yet

- WELL Building StandardDocument48 pagesWELL Building StandardNdia2007No ratings yet

- The Story of Stuff Activity Guide and Worksheet: Unit 9: Waste Not, Want NotDocument6 pagesThe Story of Stuff Activity Guide and Worksheet: Unit 9: Waste Not, Want NotNancy GomezNo ratings yet

- Marine Pollution Bulletin: Nur Hazimah Mohamed Nor, Jeffrey Philip ObbardDocument6 pagesMarine Pollution Bulletin: Nur Hazimah Mohamed Nor, Jeffrey Philip ObbardAwinda NurNo ratings yet

- Basic... 1st MidDocument54 pagesBasic... 1st MidNaafNo ratings yet

- Envioremnental Management UpstreamDocument162 pagesEnvioremnental Management UpstreamSham Aran100% (1)

- Material Safety Data SheetDocument5 pagesMaterial Safety Data Sheetadem selaluNo ratings yet

- Sustainable Development: " The Pathway To The Future We Want For All. "Document14 pagesSustainable Development: " The Pathway To The Future We Want For All. "Roshan Kumar LohaniNo ratings yet

- CR Key Check 5 - FINALdraftDocument35 pagesCR Key Check 5 - FINALdraftRomally Antonette TagnipezNo ratings yet

- R.A. No. 6969 - Brown GroupDocument35 pagesR.A. No. 6969 - Brown GroupAngelNo ratings yet

- Evs Unit IDocument25 pagesEvs Unit IVainapriya RNo ratings yet

- Cartography 6 - Hydrographic SurveyingDocument2 pagesCartography 6 - Hydrographic SurveyingGie Marie GuarinoNo ratings yet

- DisasterDocument15 pagesDisasterAjs CreationsNo ratings yet

- Roles of Tourism Ecotourism in ConservatDocument13 pagesRoles of Tourism Ecotourism in ConservatYvan Kwidja DjamiNo ratings yet

- Air PollutionDocument29 pagesAir PollutionKUSHAGRA SRIVASTAVANo ratings yet

- Kaushik Chanda Assistant Professor Organic Chemistry Division, SAS, VIT University, Vellore - 14Document21 pagesKaushik Chanda Assistant Professor Organic Chemistry Division, SAS, VIT University, Vellore - 14RiajiminNo ratings yet

- BSD 323 - Building Systems DesignDocument15 pagesBSD 323 - Building Systems DesignEloisa Belle RomuloNo ratings yet