Professional Documents

Culture Documents

CIM Course Out Line

CIM Course Out Line

Uploaded by

Ab An0 ratings0% found this document useful (0 votes)

5 views3 pagesThis document provides information about the course "Computer Integrated Manufacturing" offered at Addis Ababa Science and Technology University. The 5 ECTS credit course is offered to undergraduate students in Electro-mechanical engineering. It introduces aspects of high volume production and computer applications in integrated manufacturing systems. Upon completion, students will be able to describe the role of computers in manufacturing processes and identify the basic components of flexible manufacturing systems. The course contents include topics like CIM, material handling systems, integrated manufacturing systems, automated production lines, and NC programming.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about the course "Computer Integrated Manufacturing" offered at Addis Ababa Science and Technology University. The 5 ECTS credit course is offered to undergraduate students in Electro-mechanical engineering. It introduces aspects of high volume production and computer applications in integrated manufacturing systems. Upon completion, students will be able to describe the role of computers in manufacturing processes and identify the basic components of flexible manufacturing systems. The course contents include topics like CIM, material handling systems, integrated manufacturing systems, automated production lines, and NC programming.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

5 views3 pagesCIM Course Out Line

CIM Course Out Line

Uploaded by

Ab AnThis document provides information about the course "Computer Integrated Manufacturing" offered at Addis Ababa Science and Technology University. The 5 ECTS credit course is offered to undergraduate students in Electro-mechanical engineering. It introduces aspects of high volume production and computer applications in integrated manufacturing systems. Upon completion, students will be able to describe the role of computers in manufacturing processes and identify the basic components of flexible manufacturing systems. The course contents include topics like CIM, material handling systems, integrated manufacturing systems, automated production lines, and NC programming.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

ADDIS ABABA SCIENCE AND TECHNOLOGY UNIVERSITY

Course Number EMEg 5221

Course Title Computer Integrated Manufacturing

Degree Program B.Sc. in Electro-mechanical engineering

Module Automation and Control, Machine tool design and NC

Office time Tuesday morning B-64, R-105

Lecturer ELIAS G. (elias.gmichael@aastu.edu.et)

ECTS Credits 5 Credit Points (2-lecture and 3-Tut/lab)

Lecture Tutorial/ Home study

Time Distribution (in

Practice

Hr.)

32 48 54

The general objective of the course is to introduce crucial

aspects of high volume production and computer

applications in integrated manufacturing systems.

After successful completion of this course, students will be

able to:

• Describe the role of computers in design, process

planning, quality control, and Manufacturing

• Identify the elements of Integrated manufacturing

Course Objectives & system

Competences to be • Define the criteria for Flexible Manufacturing System

Acquired (FMS)

• Identify the basic components of Flexible

Manufacturing System (FMS)

• Data communication and networking; Data base management

systems; Artificial intelligence in CIM.

Understand the automation and integration of

manufacturing processes to achieve the ultimate

efficiency of an organization's manufacturing resources.

Course Course Contents:

Description/Course

Contents 1. Introduction CIM, CAD/CAM/CAPP

1.1 Basic definition

1.2 What Are The Benefıts Of Cım?

1.3 Basic Elements Of CIM

1.4 Skills Required For Using CIM

1.5 CAD/CAM/CAPP/CAQA

1.6 DBMs And Computer Networking In CIM

2. Material handling system

2.1 Definition of material handling

2.2 Principle of material handling

2.3 Conveyor system; AGVs

2.4 Automated storage and retrieval system

2.5 Automatic identification and data capturing

3 Integrated manufacturing system

3.1 Flexible Manufacturing Systems

3.1.1 introduction to FMS

3.1.2 types of FMS

3.1.3 components of FMS

3.1.4 FMS layout

3.1.5 FMS computer function

3.2 Other manufacturing system

3.2.4 Lean production

3.2.5 Agile manufacturing

3.3 Group technology

3.4 Work cell design

4 Automated production line

4.1 Automated flow lines

4.2 Assembly System and Line Balancing

4.3 Automated Assembly Systems

5 NC programming

5.1 Introduction to NC and CNC

5.2 Manual Part Programming

5.3 Computer Assisted Part Programming

Pre-requisites Machine tool and NC and material handling

Semester Year 5, Semester II

Status of Course Compulsory

Teaching & Learning Lectures supported by tutorials, assignment and laboratory

Methods exercises.

Assignments 20%,

Assessment/Evaluation Tests 25%

& Grading System Quiz 5%,

Final Examination 50%.

Attendance Minimum of 85% attendance during lecture hours and 100 %

Requirements during laboratory exercise

1. M.P. Groover, (2001) "Automation, Production Systems,

and Computer-Integrated Manufacturing", Second Edition,

Prentice Hall International

2. T.C. Chang, R.A. Wysk, (1985) "An Introduction to

Automated Process Planning Systems", Prentice-Hall

Literature

International,.

3. Powers Jr. Computer-Automated Manufacturing, Mc-

GrawHill, 1987, Singapore

4. Rembold, U. etal Computer-Integrated Manufacturing

and Engineering, Addison Wesley, 1993

You might also like

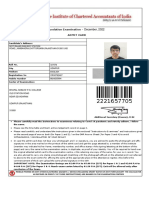

- CA Foundation Admit Card 2022Document9 pagesCA Foundation Admit Card 2022Rajendra KumawatNo ratings yet

- ACP2 - Task 2 SubmissionDocument15 pagesACP2 - Task 2 SubmissionJason JeffaresNo ratings yet

- Modeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationFrom EverandModeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationNo ratings yet

- More On The SMS PDUDocument15 pagesMore On The SMS PDUMukhammad WildanNo ratings yet

- SCBABACSDocument121 pagesSCBABACSmecambNo ratings yet

- Embedded Course ManualDocument5 pagesEmbedded Course ManualAlemayehu AsmareNo ratings yet

- Course Guide Book:: Electrical & Electronics Technology Department Addis AbabaDocument5 pagesCourse Guide Book:: Electrical & Electronics Technology Department Addis AbabaAlemayehu AsmareNo ratings yet

- Course 24. Embedded Systems (Video Course) Faculty Coordinator(s) : 1Document4 pagesCourse 24. Embedded Systems (Video Course) Faculty Coordinator(s) : 1Shaheda JamalNo ratings yet

- Computer Numerical Controlled Machines Constructional Features and Programming 1st Edition Nirmal Kumar MandalDocument70 pagesComputer Numerical Controlled Machines Constructional Features and Programming 1st Edition Nirmal Kumar Mandalguy.martinez816100% (12)

- SystemC - Methodologies and Applications (PDFDrive)Document364 pagesSystemC - Methodologies and Applications (PDFDrive)San DeepNo ratings yet

- Institute - Department - : Uiet MechatronicsDocument10 pagesInstitute - Department - : Uiet Mechatronicsbhav tech vinesNo ratings yet

- B.E. 8th Sem ELE - II-CIMSDocument3 pagesB.E. 8th Sem ELE - II-CIMSSantosh AloneNo ratings yet

- Computer Programing PDFDocument3 pagesComputer Programing PDFEthio Video SchoolNo ratings yet

- CBPM and CIMSDocument4 pagesCBPM and CIMSVikrant GuleriaNo ratings yet

- ECEG-3163 Comp Arch Course OutlineDocument2 pagesECEG-3163 Comp Arch Course OutlineEphraimNo ratings yet

- Lean Manufacturing PrinciplesDocument141 pagesLean Manufacturing PrinciplesNarendrakumar100% (9)

- Data Entry and Office AutomationDocument10 pagesData Entry and Office Automationdata xlNo ratings yet

- Lass Rientation Ession: by Anand Partheeban C.M Asst Professor Mechanical United Institute of TechnologyDocument18 pagesLass Rientation Ession: by Anand Partheeban C.M Asst Professor Mechanical United Institute of TechnologyotakoothanNo ratings yet

- Course Plan:Computer Integrated Manufacturing (TH) : Dr. Syed Farhan Raza CIM 2015 8 3 3Document3 pagesCourse Plan:Computer Integrated Manufacturing (TH) : Dr. Syed Farhan Raza CIM 2015 8 3 3Ali NoraizNo ratings yet

- Se 4Document15 pagesSe 4Nabin TimsinaNo ratings yet

- Embedded System (3-1-2)Document2 pagesEmbedded System (3-1-2)Anil MarsaniNo ratings yet

- NPTEL Phase II - Electrical Engineering - Embedded SystemsDocument4 pagesNPTEL Phase II - Electrical Engineering - Embedded SystemsShalini JainNo ratings yet

- System Software 10CS52Document206 pagesSystem Software 10CS52Firomsa TesfayeNo ratings yet

- Computer Programming I, Course SyllabusDocument3 pagesComputer Programming I, Course SyllabusmujahidNo ratings yet

- Programmig Ad Problem Solvig Through C': RatioaleDocument19 pagesProgrammig Ad Problem Solvig Through C': RatioaleCS and IT Department VBPCNo ratings yet

- Office Automation SystemDocument46 pagesOffice Automation SystemAshim Ranjan BoraNo ratings yet

- Eui Embedded Course Content Website 2Document3 pagesEui Embedded Course Content Website 2mahmooudhelmyy1No ratings yet

- Muzammil Ahmed 15Document100 pagesMuzammil Ahmed 15Saadi FaidNo ratings yet

- MEM30031A Learner Guide V1.1 PDFDocument107 pagesMEM30031A Learner Guide V1.1 PDFAniqaNo ratings yet

- BOEYM2529A - 21z 2021 - 1 - CPA Textbook Upper Sec - 29 Sep 2022 (2) 5Document226 pagesBOEYM2529A - 21z 2021 - 1 - CPA Textbook Upper Sec - 29 Sep 2022 (2) 5chungkaiqingchloeNo ratings yet

- Group TechnologyDocument89 pagesGroup TechnologySatyam KNo ratings yet

- Acm Livro IhcDocument173 pagesAcm Livro IhcElias CacauNo ratings yet

- Birla Institute of Technology & Science, Pilani: Work Integrated Learning ProgrammesDocument8 pagesBirla Institute of Technology & Science, Pilani: Work Integrated Learning ProgrammesRaja KarthikNo ratings yet

- Ict ManualDocument74 pagesIct ManualjohnNo ratings yet

- Introduction To Computers ModuleDocument220 pagesIntroduction To Computers ModuleEdward MurevesiNo ratings yet

- Full Chapter Automation Production Systems and Computer Integrated Manufacturing 5E Mikell P Groover PDFDocument53 pagesFull Chapter Automation Production Systems and Computer Integrated Manufacturing 5E Mikell P Groover PDFyulanda.jones166100% (6)

- 108 Simulation Modeling and Analysis Averill M. Law Edisi 5 2014 (001 400)Document400 pages108 Simulation Modeling and Analysis Averill M. Law Edisi 5 2014 (001 400)Juan Pablo Morales Ortega100% (1)

- Dehoysimulation Modeling and Analysis FIFTH E-1-60Document60 pagesDehoysimulation Modeling and Analysis FIFTH E-1-60Juan Camilo OcampoNo ratings yet

- Textbook System Engineering Practices 1St Edition Ian Faulconbridge Ebook All Chapter PDFDocument53 pagesTextbook System Engineering Practices 1St Edition Ian Faulconbridge Ebook All Chapter PDFgina.bigley995100% (2)

- Mini Project DocumentationDocument38 pagesMini Project DocumentationAbhijith GuptaNo ratings yet

- Computer Organization Course Outline To Be Printed-1Document2 pagesComputer Organization Course Outline To Be Printed-1habtamu fentewNo ratings yet

- Project Doc Part 1Document19 pagesProject Doc Part 1Abdulaziz ShaikhNo ratings yet

- Mechanical - VI. Sem Syllabus GtuDocument115 pagesMechanical - VI. Sem Syllabus GtukishormechNo ratings yet

- Capp PDFDocument201 pagesCapp PDFEdgardo Ed RamirezNo ratings yet

- Unit 4Document13 pagesUnit 4VikasNo ratings yet

- Course Outline CIM 14Document3 pagesCourse Outline CIM 14Bizuayehu TadesseNo ratings yet

- 5101 Manufacturing SystemsDocument2 pages5101 Manufacturing SystemsPhillip ChirongweNo ratings yet

- Embedded Systems and Real-Time SystemsDocument9 pagesEmbedded Systems and Real-Time SystemsMOUNI VARMANo ratings yet

- Textbook Overview of Industrial Process Automation Second Edition K L S Sharma Ebook All Chapter PDFDocument53 pagesTextbook Overview of Industrial Process Automation Second Edition K L S Sharma Ebook All Chapter PDFpeggy.hall505100% (9)

- Cim Short Question and AnswerDocument9 pagesCim Short Question and AnswerMartin De Boras Pragash100% (1)

- Computer As A Comonent - WolfDocument11 pagesComputer As A Comonent - WolfHemant RajakNo ratings yet

- Mini Project PDFDocument6 pagesMini Project PDFManibharathiNo ratings yet

- Design and Implementation of Car Rental SystemDocument113 pagesDesign and Implementation of Car Rental SystemYóshíí Éú Bëël100% (1)

- Cim PDFDocument32 pagesCim PDFVarshaNo ratings yet

- References:: Sl. No. Author Title PublisherDocument1 pageReferences:: Sl. No. Author Title PublisherGayathri BolugodduNo ratings yet

- Visit:: Join Telegram To Get Instant Updates: Contact: MAIL: Instagram: Instagram: Whatsapp ShareDocument137 pagesVisit:: Join Telegram To Get Instant Updates: Contact: MAIL: Instagram: Instagram: Whatsapp SharebgbdbdfNo ratings yet

- Ea ZC412Document8 pagesEa ZC412balaji817150No ratings yet

- Automotive Software Engineering: Principles, Processes, Methods, and ToolsDocument7 pagesAutomotive Software Engineering: Principles, Processes, Methods, and ToolsPhogat AshishNo ratings yet

- 1.cim Text BookDocument18 pages1.cim Text BookVinayakNo ratings yet

- Syllabus Competency No 5Document1 pageSyllabus Competency No 5Infant RajNo ratings yet

- Cse V Systems Software (10cs52) NotesDocument206 pagesCse V Systems Software (10cs52) Notesraagavird7No ratings yet

- Introduction To Computers Module PDFDocument218 pagesIntroduction To Computers Module PDFTinashe ChikariNo ratings yet

- ME0052 Internal Combustion Engines 2014Document9 pagesME0052 Internal Combustion Engines 2014Ab AnNo ratings yet

- Abela Final PDF Tire ChangerDocument53 pagesAbela Final PDF Tire ChangerAb AnNo ratings yet

- Abersh & ZemichaelDocument42 pagesAbersh & ZemichaelAb AnNo ratings yet

- 03 Philippe - Diercxsens - 4.4Document9 pages03 Philippe - Diercxsens - 4.4Ab AnNo ratings yet

- Img20101220 02523121Document1 pageImg20101220 02523121Ab AnNo ratings yet

- SolidWorks Clean Uninstallation GuideDocument2 pagesSolidWorks Clean Uninstallation GuideAb AnNo ratings yet

- Mechatronics 4Document7 pagesMechatronics 4Ab AnNo ratings yet

- Img20101220 02511979Document1 pageImg20101220 02511979Ab AnNo ratings yet

- Img20101220 02482037Document1 pageImg20101220 02482037Ab AnNo ratings yet

- Img20101220 02452515Document1 pageImg20101220 02452515Ab AnNo ratings yet

- Aastu: College of Social and Natural Science Inclusiveness Assignment - 1Document2 pagesAastu: College of Social and Natural Science Inclusiveness Assignment - 1Ab AnNo ratings yet

- Lab. Report Format: o o o oDocument1 pageLab. Report Format: o o o oAb AnNo ratings yet

- Assign ContentDocument1 pageAssign ContentAb AnNo ratings yet

- Work Sheet and Assignment IIDocument11 pagesWork Sheet and Assignment IIAb AnNo ratings yet

- Heat Chapter2Document65 pagesHeat Chapter2Ab AnNo ratings yet

- Hydraulic Jack Chap 1Document14 pagesHydraulic Jack Chap 1Ab AnNo ratings yet

- Chapter-2 Basic Principles of Electrical Machine AnalysisDocument93 pagesChapter-2 Basic Principles of Electrical Machine AnalysisAb AnNo ratings yet

- Python GUI For Impedance Spectroscopy Analysis: Scientia Cum Industria August 2018Document6 pagesPython GUI For Impedance Spectroscopy Analysis: Scientia Cum Industria August 2018Tomás de AlmeidaNo ratings yet

- WUSB600N V20 DS NC-web, 0Document2 pagesWUSB600N V20 DS NC-web, 0cavmfrNo ratings yet

- Hotel Reservation System Final THESISDocument45 pagesHotel Reservation System Final THESISFaheem KhanNo ratings yet

- Doosan. Powerful Solutions.: Portable Air CompressorsDocument24 pagesDoosan. Powerful Solutions.: Portable Air Compressorsjesus finolNo ratings yet

- Mix Design - Qatar Trading & Contracting Group C40 SRC Rev 1Document2 pagesMix Design - Qatar Trading & Contracting Group C40 SRC Rev 1Sudhakar JayNo ratings yet

- Foid Foia Log-Fy2020Document728 pagesFoid Foia Log-Fy2020Spit FireNo ratings yet

- STM R16 - Unit-3Document56 pagesSTM R16 - Unit-3Aparna GattimiNo ratings yet

- 9-6 Error Messages ReferenceDocument2,536 pages9-6 Error Messages ReferenceHarish BandiNo ratings yet

- Modicon MC80 Programmable Logic Controller User ManualDocument151 pagesModicon MC80 Programmable Logic Controller User ManualdeadzzzzzzzzzzzzNo ratings yet

- TR50D Parts BookDocument283 pagesTR50D Parts BookIfan saputroNo ratings yet

- Chapter 2 SMADocument35 pagesChapter 2 SMAandrinaNo ratings yet

- eCAFDocument6 pageseCAFRiffs MusicNo ratings yet

- Virender Singh: Professional SummaryDocument4 pagesVirender Singh: Professional SummaryVirender SinghNo ratings yet

- Some Practical Considerations: ME 222: Kinematics of Machines and MechanismsDocument19 pagesSome Practical Considerations: ME 222: Kinematics of Machines and MechanismsYash KalaNo ratings yet

- Job Description - Automation Test EngineerDocument3 pagesJob Description - Automation Test EngineerEdwin BarretoNo ratings yet

- Kaisai Service Manual PDFDocument215 pagesKaisai Service Manual PDFTom WtomNo ratings yet

- DATASHEET - Onu Gpon E4l 1GDocument2 pagesDATASHEET - Onu Gpon E4l 1GGervasio Souza LemosNo ratings yet

- SanfoundryDocument3 pagesSanfoundryvaishnavi khilariNo ratings yet

- SDR H80 PDFDocument64 pagesSDR H80 PDFelita04No ratings yet

- Csci262 A2 2020Document3 pagesCsci262 A2 2020Joe Ong ZuokaiNo ratings yet

- Applications of Social Research Methods To Questions in Information and Library Science Second Edition Barbara M. WildemuthDocument54 pagesApplications of Social Research Methods To Questions in Information and Library Science Second Edition Barbara M. Wildemuthsara.gleim919100% (19)

- Structural Design of Multi-Story BuildingDocument17 pagesStructural Design of Multi-Story BuildinggundulpNo ratings yet

- USP FriabilityDocument2 pagesUSP Friabilityshdph100% (1)

- IP Project Covid-19 ImpactDocument27 pagesIP Project Covid-19 ImpactSabNo ratings yet

- Turbine - Manual - Revised KSKDocument209 pagesTurbine - Manual - Revised KSKsambhuNo ratings yet

- Booklet 5th YearDocument55 pagesBooklet 5th Yearmauriciomartinez045aNo ratings yet

- Dip in Engg BOOK LIST AND PLAN 2010 All 8 SemesterDocument129 pagesDip in Engg BOOK LIST AND PLAN 2010 All 8 Semestermd mehedi shuvo khan100% (1)