Professional Documents

Culture Documents

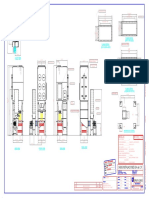

000plan 4

000plan 4

Uploaded by

BeppeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

000plan 4

000plan 4

Uploaded by

BeppeCopyright:

Available Formats

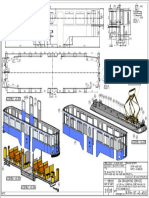

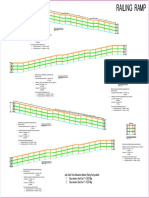

25.4 11.4 Round The Back Edge Of The 5.0 2.5 25.

4 Round The Back Edge Of The

1" 7/16" Bridge. Refer To Longitudinal 3/16" 3/32" 1" Bridge. Refer To Longitudinal

Section Section

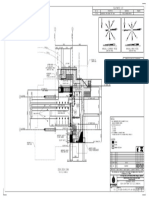

Channel For Bone Saddle: This Channel

1 13/32"

1 13/32"

1 1/4"

1 1/4"

Has To Be Perfectly Flat On The Bottom

32.1

32.1

35.5

35.5

And At The Exact Angle As Shown To

Preserve The Guitar's Intonation. It Is 20.1 20.1

25/32" 25/32"

Best To Use A Channel Routing Jig To

Give You The Micro Adjustment. Also Use 3.6 3.6

15/32"

12.0

A Down-Cut, Solid Carbide Router Bit 3/32" 5/32" 5/32"

(2.4mm) Wide.

Cut The Channel Into The Bridge First And

10.9 10.9 10.9 10.9 10.9

10.9 10.9 10.9 10.9 10.9

7/16" 7/16" 7/16" 7/16" 7/16"

7/16" 7/16" 7/16" 7/16" 7/16"

Sand The Saddle To Fit The Channel.

The Saddle Should Fit Without Play Not Cutting and Gluing The Neck/Head Scarf Joint: This is one of the hardest joints Joining Top & Back Plate Center Joints: After the wood plates are sand to Glue Kerfed Lining: While many types of lining are used for both guitars and

Forced Into Place. to properly glue for strength and accuracy. Here the headpiece is held in place by rough thickness, joint the edges perfectly square and place in a glue jig. The ukulele's, most builders settle on kerfed lining (shown here). This photo shows

3 7/32"

our the Neck Assembly Tool, after it was easily cut on the band saw, using the photo here shows the use of our Plate Jointing Jig, which give quick and kerfed lining held in place with clothes pins and 1/4" rubber bands wrapped

2 17/32"

2 19/32"

2 19/32"

81.5

3 7/32"

3 7/32"

same too.. Note how the joint is captured on all 3 sides to keep it from sliding out consistent glue joints for this often, difficult to glue joint.Place the plate beneath around the pins to supply additional clamping force. Other types of lining include

152.4

152.4

81.5

64.2

81.5

65.8

65.8

of place. the Compression Fence (located in the center of the jig), and run the fence down solid, pre-bent wood and single triangular block, which are usually used for top

R 140.5

6"

6"

5 17/32" to just contact the wood plate. Apply pressure from the cam on the side and apply plates only.

slightly more downward pressure. Finally, if needed, apply final pressure to the

String Ramps: Use A Dremel Router And

cams and fully clamp down the compression fence.

Angle And Curve The Ramps To Transition

From The Saddle To The Bridge Pin.

Countersinking The Bridge Pins Brings Great

15/32"

Detail Into The Bridge.

12.0

Bridge Ramp Wings: These Can Be Sanded Very 6.6 6.6

9/32"

6.8

Evenly And Consistently With The Bridge 1/4" 1/4"

1 13/32"

1 13/32"

Ramp Sanding Jig On A Belt Sander.

35.5

35.5

1 1/4"

32.1

1 1/4"

32.1

Belly Bridge Variation

Belly Bridge Template

106.2

4 3/16"

267.5

10 17/32" 3.5 102.0 7

1/8" 4" 1/32"

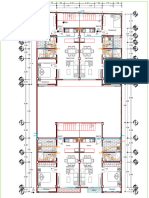

Using The Neck Assembly Jig To Glue Heel Block Stack: While the scarf joint GoBoard Clamping Deck In Action: The photo above shows the Bridge Plate, Fitting Back Binding: Note in this photo, that the tail purfling is installed with

5/16"

is setting up, go ahead and glue up the heel block stack. Prepare the block Sound Hole Reinforcing and Fretboard Reinforcement blocks being glued to the mitered purfling lines ready to accept the side binding and purfling. Fit pre-bent

8.0

lengths and make them all the same width. They are locked into place with the top plate using the GoBoard Clamping Deck Tool and Fiberglass Clamping Rods. binding around the instrument and hold in place with masking tape Mark length of

7/32"

6.0

heel block compression block. Apply some waxed paper beneath the stack and Note the top bracing has been glued and shaped prior to this gluing operation. the binding and cut with a razor saw. Cut purfling (at bottom of binding) with a

267.0 glue the stack. The back braces are glued in a similar manner by using the Arch Mold, which is sharp knife at a 45 degree angle to match the angle of the butt purfling trim detail.

10 1/2" 106.2 part of the GoBoard Plans. This fixture assures a perfect and consistent curvature

4 3/16" will be applied to the back and back plate braces.

59.3 148.4 59.3 3.5 102.0 7

2 11/32" 5 27/32" 2 11/32"

1/8" 4" 1/32"

3/16"

5.0

11/32"

15/32"

9.0

12.0

5/16"

8.0

1/8"

1/8"

3.0

3.0

Note: If You Decide To Use The Truss Rod

Neck Version, Arch This Brace As Shown (2) Of These Braces Are Required. Make Them

Mirror Images Of Each Other.

A To Make Provisions For Bolt Head - Verify

Size And Placement With Truss Rod Config. F

90.1

156.3 8.0 3 9/16"

6 5/32" 5/16"

2.0 87.4 7

145.9 8.0 1/16" 3 7/16" 1/32"

5 3/4" 5/16"

5/16"

8.0

1/4"

6.1

388.8

15 5/16"

90.1 Interior of the Box: Note the channels that are cut in the kerfed lining to receive Back Plate Gluing: This photo shows the side blocked up in the inside form with

9.2 40.5 110.2 181.5 47.5 3 9/16" the back braces. These were carefully marked by fitting the back plate to the spreader jacks keeping the body closely conforming to the shape of the form.

3/8" 1 19/32" 4 11/32" 7 5/32" 1 7/8" sides, while the sides were held in the inside form. The brace channels are cut

2.0 31.0 20.4 36.0 7 After a perfect fit is assured and the centerline of the back lines up exactly with the

11/32"

1/16" 1 7/32" 13/16" 1 13/32" 1/32" on each side with a razor saw and carefully hand-chiseled to the exact profile of sides, apply glue and start clamping. Here we used (2) clamps to clamp the back

9/32" 9.0

3/16"

each brace end. Also note the scalloped top plate bracing shown here, the tone

5.0

to the head and tail block, and 1/4" double rubber bands attached to the side

braces, bridge plate, tail block configuration and the half-lapped x-brace joint.

studs of the inside form.

7.0

5/16"

3/8"

9.7

8.0

13/32"

1/8"

1/8"

10.0

3.0

3.0

Cut This Channel Very Carefully And Precisely. It Is Essential (2) Of These Braces Are Required. Make Them

That This Be A Very Tight Joint - Only Enough Room For Glue. Mirror Images Of Each Other.

B Cut Out With A Dovetail Saw With A Depth Stop G

389.2

15 5/16"

9.5 150.7 225.3 3.8

3/8" 5 15/16" 8 7/8" 5/32"

5/16"

8.0

389.0

15 5/16"

9.2 52.8 67.9 59.3 152.1 44.0 3.8

3/8" 2 3/32" 2 11/16" 2 11/32" 6" 1 23/32" 5/32" Bridge Plate Template

11/32"

9/32"

9/32" 9.0

7.0

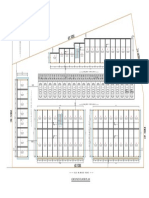

Binding Channel + Purfling Channel: Here you can see the binding and Test Fitting Back Binding: After preliminary fitting and cutting to length, fit both

purfling stepped channels after the routing is finished. Note that the body of the halves of the binding around the instrument, using masking tape and light clamp

7.0

3/8"

9.7

instrument is held in place in the inside form. It is block-up to rise above the pressure at difficult areas, like the waist area. Inspect to make sure the binding is

form top to so the top clears the hardware of the form. These cuts were made pulled tightly to the channels at the plate and the sides. Also check all

13/32"

1/8"

1/8"

10.0

3.0

3.0

with a small laminate router with a carbide tipped 2-blade binding cutter, with intersections of purfling lines at this time. The binding needs pre-bending prior to

roller guide bushings. For the perfect cut, go slowly around the perimeter of the fitting and thereby little clamping effort will be required to seat it properly in the

Coping Out This Brace Is Optional. It Weakens The Structure instrument, to prevent chipping of the top plate wood. channels.

Of The Guitar, But Gives Slightly Better Sound Production.

C

266.6 264.6

10 1/2" 10 13/32"

3.7 261.4 1.5 3.7 256.7 4.2

5/32" 10 9/32" 1/16" 5/32" 10 3/32" 5/32"

5/16"

5/16"

5/16"

8.0

8.0

8.0

266.3 264.3

10 1/2" 10 13/32"

3.5 27.1 206.6 29.1 3.5 27.1 204.6 29.1

1/8" 1 1/16" 8 1/8" 1 5/32" 1/8" 1 1/16" 8 1/16" 1 5/32"

3/16"

3/16"

11/32"

11/32"

4.8

4.8

15/32"

15/32"

9.0

9.0

12.0

12.0

1/32"

1/32"

1/8"

1/4"

1/8"

3.0

1.2

6.0

3.0

1.2

Note: You Should Make All Your Bracing Longer Than It

D Needs To Be, Or As Shown In The Bracing Diagrams Above.

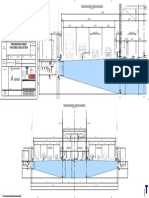

Leave Each Brace At Least 3/8" Long And Trim Back During E Gluing The Tail or Butt Block: After carefully Gluing The Head Block: Prepare the head block by Side Reinforcing: After the linings have been installed

Fitting Of The Back And Top Plates To The Guitar Sites. fitting the tail block to the curvature of the sides, the shaping it, cutting the neck mortise joint and the on the sides (this photo shows kerfed lining), it is time to

tail block centerline is carefully marked on the sides required holes for the neck pins or neck bolts and install the side braces - if required. These braces are

of the instrument. Apply glue to the block, seat the washers. Glue in place in a similar fashion to the tail made from Spruce, Cedar or Mahogany and can

block, and glue to the sides using "C" Clamps and block. After the glue has dried, cut the excess side provide a great alternative to glue soaked cloth often

other clamps as needed for a tight fit. Note the use used by guitar manufacturers. Glue the roughed-out

Top Plate Brace Diagrams

wood from the mortise joint.

of a wood caul to protect the tail block from clamp braces in place as shown here with spring clamps.

damage. Also waxed paper is used between the Shape the braces after the glue has dried and

sides and the form to protect the sides from being completely finish sand the side wood, blocks, lining and

glued to the inside form. the braces prior to plate installation.

Note For Detailed Guitar & Uke Construction Instructions

Refer To Our Book "Guitar & Ukulele Construction

Handbook @ http://shopglss.com

This Drawing or Drawings Are To Used For One Use Only Sheet Number

Date: Jan. 8, 2014

Georgia Luthier Supply

And Not Reproduced For Any Other Purpose Than

Construction Of This Particular Instrument, and a One Time

Reproduction Only is Allowed Revisions: Dec 13, 2013

000 Concert Guitar Plan 03

Reproduction, Distribution or Sales For Any Other Use Is

Strictly Prohibited And Falls Under U.S Copyright Laws For

David VerBurg AIA c 2013 Unless Noted Otherwise,

This Sheet Size Is Metric A0 Size Overall Size is 1189mm x These Plans Are Drawing

841mm With 15mm Borders On All Sides. For USA Full Scale. They Are

Customers Print On Architectural "E" (36" x 48") Without Labeled in mm and

Resizing For 1:1 Printout.

Fractional Inches

You might also like

- Vocal Exercises: For All SingersDocument7 pagesVocal Exercises: For All SingersKedson BessaNo ratings yet

- Greg Howe - Direct InjectionDocument7 pagesGreg Howe - Direct InjectionMarcos Cardoso100% (1)

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- John W Schaum Piano Course A The Red Book - SeowsmiDocument2 pagesJohn W Schaum Piano Course A The Red Book - Seowsmisumit0% (1)

- 06 Uke12tenorplanformsDocument1 page06 Uke12tenorplanformsarantxa16No ratings yet

- Back Plate Layout & Brace Layout: Classical Guitar Plan #3Document1 pageBack Plate Layout & Brace Layout: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- CRL Clear View Glass Wall Office SystemDocument8 pagesCRL Clear View Glass Wall Office SystemSarinNo ratings yet

- Bta502 B501 45 Sheet 07Document1 pageBta502 B501 45 Sheet 07udataashutoshNo ratings yet

- Longitudinal Section: Classical Guitar Plan #3Document1 pageLongitudinal Section: Classical Guitar Plan #3Lutcharguitwaira LibreNo ratings yet

- 000plan 3Document1 page000plan 3BeppeNo ratings yet

- Left Side Elevation: F A B C D EDocument1 pageLeft Side Elevation: F A B C D EVenus PunzalanNo ratings yet

- Tubo 2" Tubo 2"Document1 pageTubo 2" Tubo 2"Idalí CastelánNo ratings yet

- STR 2Document1 pageSTR 2Christian BenitezNo ratings yet

- Bta502 B501 45 Sheet 06Document1 pageBta502 B501 45 Sheet 06udataashutoshNo ratings yet

- Second Floor Lighting Outlet Lay Out: Bedroom 1Document1 pageSecond Floor Lighting Outlet Lay Out: Bedroom 1jhumelNo ratings yet

- Final Submission - DWG - ModelDocument1 pageFinal Submission - DWG - ModelMilanjoshyNo ratings yet

- Steel Roof Framing Plan: Full Truss-1 Half Truss - 2Document1 pageSteel Roof Framing Plan: Full Truss-1 Half Truss - 2Jefferson SubilNo ratings yet

- Calle Interior Sin Nombre: Enrique Arquitecto Madrid 6665569/ TarijaDocument1 pageCalle Interior Sin Nombre: Enrique Arquitecto Madrid 6665569/ TarijaHoracio HerbasNo ratings yet

- GF For Rcc-ModelDocument1 pageGF For Rcc-Modelharshad bahikarNo ratings yet

- Asia Society Top ViewDocument1 pageAsia Society Top ViewPhilip WongNo ratings yet

- Estructuras: Tale Constructora SacDocument1 pageEstructuras: Tale Constructora SacSA ZNo ratings yet

- 21FK0017 PlansDocument1 page21FK0017 Plansliam josef lauditNo ratings yet

- BB3-DEG-GED-10023-1 Functional Cross Section (ID 1257)Document1 pageBB3-DEG-GED-10023-1 Functional Cross Section (ID 1257)onur kantarNo ratings yet

- Subdivision Gayoso ModelDocument1 pageSubdivision Gayoso ModelLindaMarianella Izaga SaldarriagaNo ratings yet

- Classic3plan 2 PDFDocument1 pageClassic3plan 2 PDFarantxa16No ratings yet

- Año Viejo - Score - TromboneDocument1 pageAño Viejo - Score - TromboneCarlos SuquilloNo ratings yet

- Barricade and Construction (BC) Standard Sheets General NotesDocument12 pagesBarricade and Construction (BC) Standard Sheets General NotesEduardo Mendez LavielleNo ratings yet

- RTD - Mechanical - Drawings EnvolvedoraDocument24 pagesRTD - Mechanical - Drawings EnvolvedoraRudecindo GraciaNo ratings yet

- TV UPTC DysonDocument1 pageTV UPTC DysonJean Lindley JosonNo ratings yet

- REVISED LATEST IT HABITAT LAYOUT PLAN ModelDocument1 pageREVISED LATEST IT HABITAT LAYOUT PLAN ModelparvEenNo ratings yet

- Te Amarè Toda La VidaDocument1 pageTe Amarè Toda La VidaJulian Guerrero0% (1)

- Burner AssemblyDocument7 pagesBurner AssemblyИван ВолевNo ratings yet

- In The Mood -Trumpet_4Document2 pagesIn The Mood -Trumpet_4Владимир ЧёрнийNo ratings yet

- Estructuras Modulo A E04-0Document1 pageEstructuras Modulo A E04-0Nelly CervantesNo ratings yet

- Footing Layout Plan LayoutDocument1 pageFooting Layout Plan LayoutCONFIANCE INFRATECH MANAGEMENT PVT LTDNo ratings yet

- DN DN: Main Switchboard Aft 4000x500x1800Document1 pageDN DN: Main Switchboard Aft 4000x500x1800Costel Ava ConstantinNo ratings yet

- A Mover La Colita BassDocument1 pageA Mover La Colita BasshectorNo ratings yet

- 9cm King Block 12cm King Block 14cm King Block 15cm Arcilla King KongDocument1 page9cm King Block 12cm King Block 14cm King Block 15cm Arcilla King KongGerson Maxi MezaNo ratings yet

- (HalcyonMusic) Kenshi Yonezu - KICK BACK (Full Ver.)Document7 pages(HalcyonMusic) Kenshi Yonezu - KICK BACK (Full Ver.)Emil MkrtchyanNo ratings yet

- 263 S Everybody Needs Somebody The Blues BrothersDocument1 page263 S Everybody Needs Somebody The Blues BrothersGeorgios LygeridisNo ratings yet

- BillboardDocument1 pageBillboardmanny laderaNo ratings yet

- 838 Veliero CassinaUSA Cat PDFDocument5 pages838 Veliero CassinaUSA Cat PDFNghia PtNo ratings yet

- DV Seatless Piston Valve AO 3inch - 150 Lbs 5 Inches PEDocument1 pageDV Seatless Piston Valve AO 3inch - 150 Lbs 5 Inches PELUCAS100% (1)

- FH3 6 - OAI10 - AG 01 ModelDocument1 pageFH3 6 - OAI10 - AG 01 Modelomar javier colunga palominoNo ratings yet

- Railing 2Document1 pageRailing 2Riko ArtsNo ratings yet

- Amigos Traigan Cerveza - FlautaDocument2 pagesAmigos Traigan Cerveza - FlautaDavid MeloNo ratings yet

- Projeto Estrutura Metalica CorrigidoDocument1 pageProjeto Estrutura Metalica CorrigidoSup RCHNo ratings yet

- Cortes y FachadasDocument1 pageCortes y FachadasMauricio MeloNo ratings yet

- Framing PlanDocument1 pageFraming PlanKing RickNo ratings yet

- Benedetto17 3Document1 pageBenedetto17 3Thierry QuesimuNo ratings yet

- PVC Elevated Tank: Typical Lightening DetailDocument1 pagePVC Elevated Tank: Typical Lightening DetailMichelito Julca pastorNo ratings yet

- 1东方之珠Document1 page1东方之珠qq787159153No ratings yet

- Schedule of Doors and Windows: D2 D1 D3 D4Document1 pageSchedule of Doors and Windows: D2 D1 D3 D4Jayson PagalNo ratings yet

- School PLAN4Document1 pageSchool PLAN4Osama AbdellatefNo ratings yet

- Detalle de Cimentacion IiDocument1 pageDetalle de Cimentacion IiCarlos RíosNo ratings yet

- Bain - Checkmate - 162 Chess Puzzles To Practice CheckmatesDocument27 pagesBain - Checkmate - 162 Chess Puzzles To Practice Checkmatespablomatus100% (1)

- Equipment List: Esdv Deck PlanDocument1 pageEquipment List: Esdv Deck PlanKhánh TrầnNo ratings yet

- Semana 13 DIBUJO PDFDocument1 pageSemana 13 DIBUJO PDFAngello Hernandez PeñaNo ratings yet

- La Canoa Aranchada ClarinetebbDocument1 pageLa Canoa Aranchada Clarinetebbrafasax69No ratings yet

- S/C 200 KG/CM : Secciones de Cimentacion Esc: 1/30Document1 pageS/C 200 KG/CM : Secciones de Cimentacion Esc: 1/30Allen OretNo ratings yet

- PLANO-GENERAL-DE-SAN-JOSE-2015-CATASTRO-X-PROPIETARIOS (2) - Layout1Document1 pagePLANO-GENERAL-DE-SAN-JOSE-2015-CATASTRO-X-PROPIETARIOS (2) - Layout1David HuberNo ratings yet

- Songs Without Words: Selection for piano lessonsFrom EverandSongs Without Words: Selection for piano lessonsRating: 5 out of 5 stars5/5 (1)

- Tu Me Vulves Loco PDFDocument3 pagesTu Me Vulves Loco PDFdaniel sanchez100% (1)

- Microwave - Pathloss IV TrainingDocument3 pagesMicrowave - Pathloss IV TrainingbantunnaNo ratings yet

- DLLDocument7 pagesDLLEiron AlmeronNo ratings yet

- Tangerine DreamDocument6 pagesTangerine DreamPedro BricenoNo ratings yet

- Leap Music6 q4 Melc14 Week1Document4 pagesLeap Music6 q4 Melc14 Week1Mackie Barcebal100% (1)

- TXDIN70Document1 pageTXDIN70senthilrsenthilNo ratings yet

- Pre-Intermediate LessonDocument5 pagesPre-Intermediate LessonAnja MajstorovicNo ratings yet

- Arban Routine ClassDocument2 pagesArban Routine ClassRafael John RubioNo ratings yet

- Speakout Upper-Intermediate PDFDocument48 pagesSpeakout Upper-Intermediate PDFLucia DominguezNo ratings yet

- Promises Chords by Sanctus Real at Ultimate-GuitarDocument4 pagesPromises Chords by Sanctus Real at Ultimate-GuitarEdwin IxtinNo ratings yet

- Abi Derrick Assessment 1 - Were Going On A Bear Hunt and The ArtsDocument7 pagesAbi Derrick Assessment 1 - Were Going On A Bear Hunt and The Artsapi-458503078No ratings yet

- Grade 4 DLL Quarter 1 Week 3Document31 pagesGrade 4 DLL Quarter 1 Week 3GAY POSERIONo ratings yet

- Where Is My Mind DrumsDocument2 pagesWhere Is My Mind DrumsT SNo ratings yet

- As ISO IEC 14496.14-2004 Information Technology - Coding of Audio-Visual Objects MP4 File FormatDocument10 pagesAs ISO IEC 14496.14-2004 Information Technology - Coding of Audio-Visual Objects MP4 File FormatSAI Global - APACNo ratings yet

- Song ComposersDocument38 pagesSong ComposersMaria Corazon Belarmino Maguigad25% (4)

- Berserk Revenge: A Norse SagaDocument188 pagesBerserk Revenge: A Norse SagaMark Coakley100% (3)

- The Incapacitated Spectator PDFDocument11 pagesThe Incapacitated Spectator PDFG88_No ratings yet

- Teste Exercitii Engleza OnlineDocument3 pagesTeste Exercitii Engleza OnlinevasistaicuNo ratings yet

- Brief History of Dance PE2 (Manalo, Llanza) - 2Document15 pagesBrief History of Dance PE2 (Manalo, Llanza) - 2Geneva ImperialNo ratings yet

- The Seven Learning StylesDocument18 pagesThe Seven Learning StylesarielNo ratings yet

- Crowley Et. Al. - Liber DCCCL, The Rites of EleusisDocument124 pagesCrowley Et. Al. - Liber DCCCL, The Rites of EleusisCelephaïs Press / Unspeakable Press (Leng)100% (5)

- PretestDocument3 pagesPretestapi-317403302No ratings yet

- Mation To Navigation Systems Formation in All Weather ConditionsDocument6 pagesMation To Navigation Systems Formation in All Weather ConditionsUFUKKKNo ratings yet

- FIFA 2014 World Cup Sports MarketingDocument80 pagesFIFA 2014 World Cup Sports MarketingAnjaliThakkarNo ratings yet

- The Lost Battalion Viewing GuideDocument4 pagesThe Lost Battalion Viewing Guidebrendanb2307No ratings yet

- ROCKSCHOOL Brochure 2017 - New PDFDocument14 pagesROCKSCHOOL Brochure 2017 - New PDFAmalia Seruni100% (1)

- AMOR REAL - Alto SaxDocument2 pagesAMOR REAL - Alto Saxjorge maldonadoNo ratings yet