Professional Documents

Culture Documents

Submittal Fan Coils 2023-08-21

Submittal Fan Coils 2023-08-21

Uploaded by

Ian OsorioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Submittal Fan Coils 2023-08-21

Submittal Fan Coils 2023-08-21

Uploaded by

Ian OsorioCopyright:

Available Formats

SUBMITTAL

Project

WORLD BANK

Date

Wednesday, April 6, 2022

Table Of Contents

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

SALA DE REUNON 20 3

Unit Report 4

Certified Drawing 5

Performance Summary 6

Guide Specifications 7

SALA DE REUNON 40 10

Unit Report 11

Certified Drawing 12

Performance Summary 13

Guide Specifications 14

CAFETERIA 17

Unit Report 18

Certified Drawing 19

Performance Summary 20

Guide Specifications 21

Fan Coil Builder 4.10i Page 2 of 23

SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

SALA DE REUNON 20

SALA DE REUNON 20

Tag Cover Sheet

Unit Report

Certified Drawing

Performance Report

Guide Specification

Fan Coil Builder 4.10i Page 3 of 23

Unit Report For SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Unit Report

Unit Parameters Dimensions

Tag Name: SALA DE REUNON 20 Unit Length: 29.50 in

Quantity: 1 Unit Width: 37.00 in

Unit Model: 42DCA12BRJYKCYBR Unit Height: 16.38 in

Unit Type:42DC Ducted, Ceiling, Furred-In with Plenum Shipping Weight: 129 lb

Unit Size: 1200 CFM

Shipping Options: Standard

Fan Speed: High

Motor/Drive: ECM Motor Variable Air Flow

Coil Parameters Electrical

System Type: 2-Pipe Cooling Only Motor Voltage:208-1-60 ECM V2 Variable Airflow for 0-

Cooling Coil: Cold Fluid Cooling 10VDC input V-Ph-Hz

Cooling Coil Rows: 4 rows

Coil Hand: Right Hand

Hydronic Coil Test Pressure:350 psig Coil Test Pressure

Warranty Information

First Year - Parts Only (Standard)

Ordering Information

Part Number Description Quantity

Base Unit

42DCA12BRJYKCYBR 1

42DCA12:Ducted, Ceiling, Furred-In with Plenum Fan Coil Unit 1200

CFM Cooling 208-1-60 ECM V2 Variable Airflow for 0-10VDC input

1" Pleated MERV 8 filter

208-1-60 ECM V2 Variable Airflow for 0-10VDC input

Extended Main Drain Pan

Drip Lip

Unit Arrangement 5 + Closed Cel Insulation

24V Controls by other

Not all valve components are rated for the selected Hydronic Coil Test Pressure. Refer to the valve component cut sheets in the

Product Library, under Help.

Fan Coil Builder 4.10i Page 4 of 23

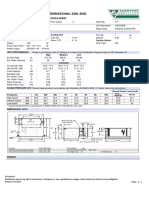

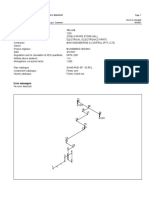

Certified Drawing for SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Certified Drawing

Fan Coil Builder 4.10i Page 5 of 23

Performance Summary For SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Performance Summary

Unit Parameters Unit Performance

Tag Name: SALA DE REUNON 20 Actual Airflow: 1,165.0 CFM

Quantity: 1 Altitude: 0 ft

Unit Model: 42DCA12BRJYKCYBR External Static Pressure: .64 in wg

Unit Type:42DC Ducted, Ceiling, Furred-In with Plenum Voltage:208-1-60 ECM V2 Variable Airflow for 0-10VDC

Unit Size: 1200 CFM input V-Ph-Hz

System Type: 2-Pipe Cooling Only

Cooling Coil: Cold Fluid Cooling External Static Pressure includes .14 in wg for filter static.

Cooling Coil Rows: 4 rows

Coil Hand: Right Hand

Coil Wrapping: None

Shipping Options: Standard

Fan Speed: High

Motor/Drive: ECM Motor Variable Air Flow

Cooling Data

Coil Type: Cold Fluid Cooling

Coil Rows: 4 rows

Fluid Type: Fresh Water

Total Capacity: 36,926 BTU/hr

Sensible Capacity: 26,264 BTU/hr

Entering Air Dry Bulb Temperature: 79.8 F

Entering Air Wet Bulb Temperature: 67.6 F

Leaving Air Dry Bulb Temperature: 59.4 F

Leaving Air Wet Bulb Temperature: 57.7 F

Fluid Flow Rate: 7.3 gpm

Fluid Pressure Drop: 6.62 ft wg

Fluid Entering Temperature: 45.0 F

Fluid Leaving Temperature: 55.0 F

Electrical Data

Motor Voltage:208-1-60 ECM V2 Variable Airflow for 0-10VDC input V-Ph-Hz

Motor FLA: 6.3

Unit MCA: 7.10

MFS: 15.0

Acoustical Data:

Octave Band Center Frequency, Hz 125 250 500 1k 2k 4k 8k dBA

Sound Power Data

Radiated Sound Power, dB 69 65 63 61 59 55 47 67

Discharge Sound Power, dB 64 61 61 60 54 50 41 64

Factory-Installed Options

Unit Arrangement: Bottom Return / Front Supply

Filters: 1" Pleated MERV 8 filter

Drain Pans: Extended Drain Pan

Tell-Tale / Drip Lip: Drip Lip Only

Coil Hand: Right Hand

AAV / Drains: Manual Air Vents only

Control Packages: 24V Controls by other

Insulation: Closed Cell Insulation

Packaging: Units shipped on treated wood pallet

Fan Coil Builder 4.10i Page 6 of 23

Guide Specification for SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Guide Specifications

Fan Coil Unit — Ducted Models

HVAC Guide Specifications — 42D

Size Range: 600 to 2000 Nominal Cfm

Carrier Model Numbers:

42DA (Ceiling Furred-in)

42DC (Ceiling Furred-in with Plenum)

42DD (Vertical with Galvanized Casing)

42DE (Ceiling with Galvanized Casing)

42DF (Ceiling Exposed Cabinet)

General

· SYSTEM DESCRIPTION

Horizontal, 2-pipe or 4-pipe or electric heat fan coil unit for ducted installations; horizontal furred-in or exposed ceiling model,

ceiling cabinet, or vertical model with galvanized casing for closet or utility room installation.

· QUALITY ASSURANCE

Units shall be ETL approved. All units shall be CSA (Canadian Standards Association) approved. Each coil shall be factory

tested for leakage at 300 psig air pressure with coil submerged in water. Insulation and adhesive shall meet NFPA (National Fire

Protection Association) 90A requirements for flame spread and smoke generation. All equipment wiring shall comply with NEC

(National Electrical Code) requirements. The 42DF model shall be tested and certified in accordance with AHRI (Air-

Conditioning, Heating and Refrigeration Institute) Standard 440, latest edition.

· DELIVERY, STORAGE AND HANDLING

Unit shall be handled and stored in accordance with the manufacturer’s instructions.

Products

· EQUIPMENT

· General:

Factory assembled, horizontal or vertical blow-thru ducted fan coil unit. Unit shall be complete with water coil(s), fan(s),

motor(s), drain pan, and all required wiring, piping, controls and special features. Standard insulation shall be dual density

fiberglass insula-tion.

· Horizontal, Furred-in Base Unit (42DA):

· Outside panels shall be galvanized steel, lined on the inside with 1/2-in. thick fiberglass insulation and a 1-in. long collar for

supply duct connection.

· The drain pan shall be constructed of galvanized steel extending the entire length and width of coil(s) and pitched for

drainage. The inside surface of the drain pan shall be coated with a 2-part closed cell foam insulation.

· Horizontal Base Unit with Plenum for Concealed Installation (42DC):

Unit shall have a factory-installed, heavy-gage steel plenum section and 1-in. throwaway filter. The plenum shall be either

bottom or rear return, lined with 1/2-in. thick fiberglass insulation and include a removable panel to provide access to the

fan/motor assembly.

· Horizontal, Enclosed Unit for Concealed Installation (42DE):

Fan Coil Builder 4.10i Page 7 of 23

Guide Specification for SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Unit shall be constructed of galvanized steel with removable panels for access to internal components. Units have 1/2-in.

fiberglass insulation, filter track with 1-in. throwaway filter, 1-in. supply collar, and 1-in. return-air collar on rear of unit for duct

connection.

· Horizontal Cabinet Unit for Exposed Installation (42DF):

Unit shall be constructed of steel with Arctic White powder-coat finish. Cabinet shall be lined with 1/2-in. fiberglass insulation.

Unit shall include hinged bar type return-air grille on rear of unit with 1-in. throwaway filter and integral double deflection

supply-air grille.

· Vertical, Enclosed Unit for Closet Installation (42DD):

Unit shall be constructed of galvanized steel with 1/2-in. fiberglass insulation. Unit shall include front return-air opening with 1-

in. throwaway filter and 1-in. supply-air duct collar.

· Fans:

Direct-driven, double-width fan wheels shall have forward-curved blades, and be statically and dynamically balanced, with

scrolls and fans constructed of galvanized steel.

· Coils:

Standard base unit shall be equipped with a 4-row coil for installation in a 2-pipe system. Additional coil depth and circuiting

shall be provided for installation in a 4-pipe system as described in the Special Features section. All coils shall have 1/2-in.

copper tubes and aluminum fins (10 fins per inch) spacing; Coil fins are mechanical bonded to tube joints. The copper tubes

comply with the ASTM (American Society for Testing and Materials) B-75. The fin thickness is 0.0045-in. and tube thickness is

0.016-inch. All coils shall be leak tested with air at 300 psig under water.

· Controls and Safeties:

The fan motor(s) shall be equipped with integral, automatic reset thermal overload motor protection.

· Operating Characteristics:

A single-circuit coil unit installed in a 2-pipe system shall be capable of providing heating or cooling as determined by the

operating mode of the central water supply system. A double circuit coil unit installed in a 4-pipe system shall be capable of

providing sequenced heating and cooling.

· Electrical Requirements:

Standard unit shall operate on 115-v, single-phase, 60-Hz electric power, and all exposed wiring shall be in a flexible conduit.

· Motor(s):

Fan motors shall be 3-speed permanent split capacitor type, 115 volts, permanently lubricated with sleeve bearings. Motor shall

have thermal overload protection with automatic reset and be connected with quick connect electrical plug.

· Special Features:

Certain standard features are not applicable when the features designated by * are specified. See your local Carrier Sales Office

for amending specifications.

· Unit coil(s) shall be equipped with automatic air vents.

· Unit shall be equipped with a 3-row, 4-row or 6-row cooling coil for installation in a 2-pipe chilled water system or direct

expansion (DX R-410A) system.

· For installation in a 4-pipe chilled water system or direct expansion (DX R-410A) system, unit shall be equipped with

either a 3-row cooling/1-row heating split circuit, or 3/2 split circuit or 4/1 split circuit, or a 4/2 split circuit or a 6/1 split

circuit (except 42DD) as required.

· Fan motor(s) shall be permanent split capacitor type, 208, 230, or 277 volts for low-static applications (42DF) or 208, 230

or 277 volts for high-static applications (42DA, DC, DD, and DE). 220-volt fan motor shall be available for 50 Hz

applications.

Fan Coil Builder 4.10i Page 8 of 23

Guide Specification for SALA DE REUNON 20

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

· Fan motor shall be constant torque electrically commutated type, 115, 208, 220, 240, or 277-v, single phase, 50 or 60 Hz as

specified on the equipment schedule. The operating sequence shall be one of the following, as specified:

· 3 Discrete Speed Input, Potentiometer Field Speed Adjustment. For use with a 3-speed thermostat.

· 4 Discrete Speed Input, Potentiometer Field Speed Adjustment. For use with a 3-speed thermostat.

· Variable Airflow for 0 to 10 VDC / 4 to 20 mA Input. Requires a 0 to 10 VDC input signal and is not compatible with a

3-speed thermostat.

· Electric Heat:

· Unit shall be equipped with electric resistance strip heaters mounted on the entering air side of the water coil.

· Heaters shall include automatic reset high limit cutout, contactor, factory-furnished junction box and fuse to protect the

motor.

· Heaters shall be single-stage, single-phase, 120, 208, 220, 240 or 277 volts, for 50 Hz or 60 Hz applications. Capacity

shall be as shown on the equipment schedule.

· Control circuit for single power source connection is available and must be used when motors and heaters are of the

same voltage.

· Filter track and cleanable filter shall be installed in the plenum (42DC, DD, and DE only).

· Drain pan shall include a second drain connection located above the main drain connection to act as an indicator that the

main drain is plugged.

· Removable drain pan extension (drip lip) shall be available for field installation under electric water valves.

· Balancing and combination balance and stop (ball) and flow control valves shall be factory furnished.

· Motorized 2-way and 3-way valves shall be wired to the unit. In order to prevent shipping damage, they shall be factory

assembled in the valve package. The valve packages shall terminate with belled ends or unions for field attachment to the

coil.

· Heating and/or cooling thermostat (SPDT) shall be factory furnished for field installation (2-pipe system).

· Automatic changeover device(s) shall be factory wired for field installation on supply piping (2-pipe system).

· Sequenced heating and cooling wall thermostat shall be factory furnished for field installation (4-pipe system).

· Cabinet of 42DF unit shall be painted with the color specified on the equipment schedule.

· A stainless steel drain pan shall be available for factory installation.

· Factory-installed insulation options shall include foil faced fiberglass or closed cell insulation.

· Control Options:

· 3-speed, 4-position manual fan switch on a wall plate for field-mounting.

· Factory-installed 24-v transformer and relay board for use, with 24-v controls by others.

· Carrier’s Debonair® 24-v digital display programmable or non-programmable thermostat, including factory-installed

24-v transformer, relay board, and changeover sensors, as required. Provides automatic fan speed control based on

demand.

· Factory-Installed Carrier Fan Coil Open Controller: BACnet based communicating controller with pre-programmed

control algorithms; including factory-installed 24-v transformer, relay board, supply air sensor, return air sensor and

changeover sensor (as required). Provides automatic fan speed control based on demand.

Fan Coil Builder 4.10i Page 9 of 23

SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

SALA DE REUNON 40

SALA DE REUNON 40

Tag Cover Sheet

Unit Report

Certified Drawing

Performance Report

Guide Specification

Fan Coil Builder 4.10i Page 10 of 23

Unit Report For SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Unit Report

Unit Parameters Dimensions

Tag Name: SALA DE REUNON 40 Unit Length: 37.75 in

Quantity: 1 Unit Width: 47.00 in

Unit Model: 42DHA16LRDMYYYCAJW Unit Height: 21.50 in

Unit Type: 42DH Horizontal Drive Drive Operating Weight: 234 lb

Unit Size: 1600 CFM

Shipping Options: Standard

Fan Speed: High

Motor/Drive:ECM Motor 0-10v Proportional Control

Coil Parameters Electrical

System Type: 2-Pipe Cooling Only Motor Voltage: 208-1-60 V-Ph-Hz

Cooling Coil: Cold Fluid Cooling

Cooling Coil Rows: 6 Rows

Coil Hand: Right Hand

Warranty Information

First Year - Parts Only (Standard)

Ordering Information

Part Number Description Quantity

Base Unit

42DHA16LRDMYYYCAJW 1

42DHA16:Horizontal Direct-Drive Fan Coil 1600 CFM Cooling 208-1-

60

208-1-60 Motor Voltage

Stainless steel coil wrapper, end sheets, and baffle

4 in. MERV 13 Pleated Filter

Automatic Air Vents

40A Fused Disconnect Switch

1 in. Closed Cell Insulation

6-Row Coil in lieu of standard 4-Row. For a 2-pipe system

Fan Coil Builder 4.10i Page 11 of 23

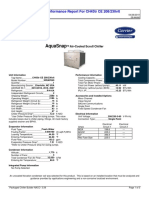

Certified Drawing for SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Certified Drawing

Fan Coil Builder 4.10i Page 12 of 23

Performance Summary For SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Performance Summary

Unit Parameters Unit Performance

Tag Name: SALA DE REUNON 40 Actual Airflow: 1,780.0 CFM

Quantity: 1 Altitude: 0 ft

Unit Model: 42DHA16LRDMYYYCAJW External Static Pressure: .35 in wg

Unit Type: 42DH Horizontal Drive Drive Total Static Pressure: .95 in wg

Unit Size: 1600 CFM Voltage: 208-1-60 V-Ph-Hz

System Type: 2-Pipe Cooling Only

Cooling Coil: Cold Fluid Cooling

Cooling Coil Rows: 6 Rows

Coil Hand: Right Hand

Shipping Options: Standard

Fan Speed: High

Motor/Drive:ECM Motor 0-10v Proportional Control

Cooling Data

Coil Type: Cold Fluid Cooling

Coil Rows: 6 Rows

Fluid Type: Fresh Water

Total Capacity: 66,035 BTU/hr

Sensible Capacity: 44,461 BTU/hr

Entering Air Dry Bulb Temperature: 80.1 F

Entering Air Wet Bulb Temperature: 67.9 F

Leaving Air Dry Bulb Temperature: 57.5 F

Leaving Air Wet Bulb Temperature: 56.2 F

Fluid Flow Rate: 13.1 gpm

Fluid Pressure Drop: 10.68 ft wg

Fluid Entering Temperature: 45.0 F

Fluid Leaving Temperature: 55.0 F

Electrical Data

Motor Voltage: 208-1-60 V-Ph-Hz

Motor FLA: 6.3

Fan and Drive Data

Fan RPM: 1,151

BHP: .64 BHP

Motor Nominal HP: 1

Acoustical Data:

Octave Band Center Frequency, Hz 125 250 500 1k 2k 4k 8k dBA

Sound Power Data

Radiated Sound Power, dB 73 69 62 64 60 55 48 68

Discharge Sound Power, dB 72 68 69 70 68 68 63 75

Factory-Installed Options

Coil Connections: Same end

Coil Wrapper: Stainless steel coil wrapper, end sheets, and baffle

Filters: 4 in. MERV 13 Pleated Filter

Coil Options: Automatic Air Vents

Hydronic Coil Test Pressure: 350 psig Coil Test Pressure

Coil Hand: Right Hand

Disconnect Switches: 40A Fused Disconnect Switch

Cabinet Construction: 1 in. Closed Cell

Packaging: Units shipped on treated wood pallet

Fan Coil Builder 4.10i Page 13 of 23

Guide Specification for SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Guide Specifications

Fan Coil Unit — Direct Drive Blower Coil Models

HVAC Guide Specifications

Size Range: 600 to 3000 Nominal Cfm

Carrier Model Numbers:

42DHA Horizontal Direct Drive Blower Coil

42DVA Vertical Direct Drive Blower Coil

General

· SYSTEM DESCRIPTION

Direct Drive Blower Coil Units, 2-pipe, 4-pipe, or 2-pipe with electric heat. Horizontal and vertical cabinets.

· QUALITY ASSURANCE

Coils shall be tested in accordance with AHRI Standard 410. Each coil shall be factory tested for leakage at 300 psig air

pressure with coil submerged in water. Insulation and adhesive shall meet NFPA-90A requirements for flame spread and smoke

generation.

Base or “standard” units shall be ETL listed.

· DELIVERY, STORAGE AND HANDLING

Unit shall be handled and stored in accordance with the manufacturer’s instructions.

Products

· EQUIPMENT

· Configuration:

Complete with galvanized cabinet, coils, blower section, sloped stainless steel drain pan, insulation, with 2 or 4-pipe unit

configuration. Heating to be hydronic or total electric.

· Certification:

Units are listed by Intertek Testing Services (ITS). Units comply with the minimum requirements of the U.S. and Canadian

national product safety standard, UL 1995/CSA C22.2 No. 236.

· Materials:

· Coils:

· Copper tube, aluminum fin (copper fin), 1/2 in. staggered tube design, rated at 250 psig at 200°F, and leak tested at 300

psig.

· Provide manual (automatic) air vent.

· Provide end sheets and bottom coil baffles fabricated with galvanized (stainless) steel.

· Optional R-410A DX evaporator duty coil.

· Blowers:

· Statically and dynamically balanced, and of indicated capacity.

· Provide centrifugal, forward curved wheel.

· Bearings shall be ball bearing type (no sleeve bearings allowed), permanently lubricated and sealed for life.

· Blower/motor assembly isolated from cabinet.

Fan Coil Builder 4.10i Page 14 of 23

Guide Specification for SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

· Motors:

· Provide Electronically Commutated, [single-phase, 3-phase] open drip proof, permanently lubricated ball bearing

motor. Motor size 1/2 HP and 1 HP shall have integrated control module with overload and short circuit protection.

Motor size 1 1/2 HP and 3 HP shall have remote mounted control with overload and short circuit protection. Control

module is mounted in cabinet interior.

· Motors shall be RPM controlled, UL recognized or equivalent, continuous duty rated.

· Factory wired to unit control box.

· Motor protected with thermal overload.

· Motor bearings shall be permanently lubricated.

· Motor installed on same side as coil connections for ease of service.

· Electric Heaters:

· When indicated in the schedule shall perform at indicated voltage, phase, and wattage in the specified number of stages.

· Protect by automatic reset cutout and manual reset backup.

· Cabinets:

· Fabricate from heavy gauge galvanized steel, single wall construction.

· Insulation to be 1 in. fiberglass [1 in. premium IAQ fiberglass, 1 in. Foil Face, or 1 in. Closed Cell].

· Furnish with access panels on both sides of unit, easily removable without tools.

· Holes for through-hanger rods are located at top and bottom 4 corners of cabinet.

· Optional double wall construction with 1 in. fiberglass insulation with solid or perforated inner liners.

· Drain Pans:

· Standard with Type 304 stainless steel.

· Externally isolated with 2-part closed cell foam insulation.

· Double-sloped toward outlets.

· Inside is smooth for easy cleaning.

· Furnished with primary 3/4 in. male NPT and “tell-tale” 1/2 in. male NPT secondary drain connections on same end with

coil connections. Secondary drain connection must be capped by installer if not used.

· Drain pan is removable from cabinet from same end as coil connections for ease of cleaning.

· Filters:

· Standard 2 in. pleated MERV 8 filters (options: 1 in. pleated MERV 8, set of 2 each 1 in. non-woven synthetic

throwaway, 2 in. pre-filter with 2 in. MERV 11 filter, 4 in. MERV 11, 4 in. MERV 13).

· Removable from either side or bottom of filter rack without tools.

· Controls:

· Unit mounted, factory installed and wired motor control board that adjust RPM/CFM for High, Medium and Low speed

operation.

· Single-phase or 3-phase motors.

· Option: door interlocking disconnect switch with lock-out tag-out feature.

· Electric heat controls include transformer, electric heat contactors, electric heat fuses and terminal strip.

· Electric heat available in single and 3-phase, and controlled in [single, 2, 3] stages of operation.

Fan Coil Builder 4.10i Page 15 of 23

Guide Specification for SALA DE REUNON 40

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

· Fuses shall comply with NFPA 70E/IP20.

· Special Features:

· Unit shall be equipped with nichrome wire strip electric heaters as specified on the equipment schedule.

· Heaters shall be protected by an automatic reset safety cutout switch and a manual reset backup.

· Heater capacity and stages shall be as specified on the equipment schedule.

· Heaters shall be single-phase [115] [208] [230] [277] or three-phase [208] [230] [460] volts as specified on the

equipment schedule.

· Units shall be equipped with 24V controls.

· Units shall be equipped with 24V controls and optional high-level condensate switch.

· Optional Service Light shall provide a source of illumination in the main unit cabinet and the control box during routine

maintenance and troubleshooting. Light turns “ON” when access panel or control box door is open, but unit is not powered.

Service Light assembly shall include 2 LED lights, rechargeable battery and charger.

Fan Coil Builder 4.10i Page 16 of 23

CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

CAFETERIA

CAFETERIA

Tag Cover Sheet

Unit Report

Certified Drawing

Performance Report

Guide Specification

Fan Coil Builder 4.10i Page 17 of 23

Unit Report For CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Unit Report

Unit Parameters Dimensions

Tag Name: CAFETERIA Unit Length: 40.25 in

Quantity: 1 Unit Width: 48.00 in

Unit Model: 42DHA22LRNMYYYCAJW Unit Height: 24.00 in

Unit Type: 42DH Horizontal Drive Drive Operating Weight: 327 lb

Unit Size: 2200 CFM

Shipping Options: Standard

Fan Speed: High

Motor/Drive:ECM Motor 0-10v Proportional Control

Coil Parameters Electrical

System Type: 2-Pipe Cooling Only Motor Voltage: 208-3-60 V-Ph-Hz

Cooling Coil: Cold Fluid Cooling

Cooling Coil Rows: 6 Rows

Coil Hand: Right Hand

Warranty Information

First Year - Parts Only (Standard)

Ordering Information

Part Number Description Quantity

Base Unit

42DHA22LRNMYYYCAJW 1

42DHA22:Horizontal Direct-Drive Fan Coil 2200 CFM Cooling 208-3-

60

208-3-60 Motor Voltage

Stainless steel coil wrapper, end sheets, and baffle

4 in. MERV 13 Pleated Filter

Automatic Air Vents

40A Fused Disconnect Switch

1 in. Closed Cell Insulation

6-Row Coil in lieu of standard 4-Row. For a 2-pipe system

Fan Coil Builder 4.10i Page 18 of 23

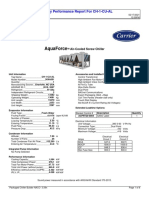

Certified Drawing for CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Certified Drawing

Fan Coil Builder 4.10i Page 19 of 23

Performance Summary For CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Performance Summary

Unit Parameters Unit Performance

Tag Name: CAFETERIA Actual Airflow: 2,154.0 CFM

Quantity: 1 Altitude: 0 ft

Unit Model: 42DHA22LRNMYYYCAJW External Static Pressure: .75 in wg

Unit Type: 42DH Horizontal Drive Drive Total Static Pressure: 1.46 in wg

Unit Size: 2200 CFM Voltage: 208-3-60 V-Ph-Hz

System Type: 2-Pipe Cooling Only

Cooling Coil: Cold Fluid Cooling

Cooling Coil Rows: 6 Rows

Coil Hand: Right Hand

Shipping Options: Standard

Fan Speed: High

Motor/Drive:ECM Motor 0-10v Proportional Control

Cooling Data

Coil Type: Cold Fluid Cooling

Coil Rows: 6 Rows

Fluid Type: Fresh Water

Total Capacity: 78,635 BTU/hr

Sensible Capacity: 55,028 BTU/hr

Entering Air Dry Bulb Temperature: 79.0 F

Entering Air Wet Bulb Temperature: 66.6 F

Leaving Air Dry Bulb Temperature: 55.8 F

Leaving Air Wet Bulb Temperature: 54.8 F

Fluid Flow Rate: 15.6 gpm

Fluid Pressure Drop: 11.23 ft wg

Fluid Entering Temperature: 45.0 F

Fluid Leaving Temperature: 55.0 F

Electrical Data

Motor Voltage: 208-3-60 V-Ph-Hz

Motor FLA: 4.4

Fan and Drive Data

Fan RPM: 1,077

BHP: .84 BHP

Motor Nominal HP: 1-1/2

Acoustical Data:

Octave Band Center Frequency, Hz 125 250 500 1k 2k 4k 8k dBA

Sound Power Data

Radiated Sound Power, dB 73 69 60 60 58 53 45 66

Discharge Sound Power, dB 73 68 65 67 64 63 57 72

Factory-Installed Options

Coil Connections: Same end

Coil Wrapper: Stainless steel coil wrapper, end sheets, and baffle

Filters: 4 in. MERV 13 Pleated Filter

Coil Options: Automatic Air Vents

Hydronic Coil Test Pressure: 350 psig Coil Test Pressure

Coil Hand: Right Hand

Disconnect Switches: 40A Fused Disconnect Switch

Cabinet Construction: 1 in. Closed Cell

Packaging: Units shipped on treated wood pallet

Fan Coil Builder 4.10i Page 20 of 23

Guide Specification for CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

Guide Specifications

Fan Coil Unit — Direct Drive Blower Coil Models

HVAC Guide Specifications

Size Range: 600 to 3000 Nominal Cfm

Carrier Model Numbers:

42DHA Horizontal Direct Drive Blower Coil

42DVA Vertical Direct Drive Blower Coil

General

· SYSTEM DESCRIPTION

Direct Drive Blower Coil Units, 2-pipe, 4-pipe, or 2-pipe with electric heat. Horizontal and vertical cabinets.

· QUALITY ASSURANCE

Coils shall be tested in accordance with AHRI Standard 410. Each coil shall be factory tested for leakage at 300 psig air

pressure with coil submerged in water. Insulation and adhesive shall meet NFPA-90A requirements for flame spread and smoke

generation.

Base or “standard” units shall be ETL listed.

· DELIVERY, STORAGE AND HANDLING

Unit shall be handled and stored in accordance with the manufacturer’s instructions.

Products

· EQUIPMENT

· Configuration:

Complete with galvanized cabinet, coils, blower section, sloped stainless steel drain pan, insulation, with 2 or 4-pipe unit

configuration. Heating to be hydronic or total electric.

· Certification:

Units are listed by Intertek Testing Services (ITS). Units comply with the minimum requirements of the U.S. and Canadian

national product safety standard, UL 1995/CSA C22.2 No. 236.

· Materials:

· Coils:

· Copper tube, aluminum fin (copper fin), 1/2 in. staggered tube design, rated at 250 psig at 200°F, and leak tested at 300

psig.

· Provide manual (automatic) air vent.

· Provide end sheets and bottom coil baffles fabricated with galvanized (stainless) steel.

· Optional R-410A DX evaporator duty coil.

· Blowers:

· Statically and dynamically balanced, and of indicated capacity.

· Provide centrifugal, forward curved wheel.

· Bearings shall be ball bearing type (no sleeve bearings allowed), permanently lubricated and sealed for life.

· Blower/motor assembly isolated from cabinet.

Fan Coil Builder 4.10i Page 21 of 23

Guide Specification for CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

· Motors:

· Provide Electronically Commutated, [single-phase, 3-phase] open drip proof, permanently lubricated ball bearing

motor. Motor size 1/2 HP and 1 HP shall have integrated control module with overload and short circuit protection.

Motor size 1 1/2 HP and 3 HP shall have remote mounted control with overload and short circuit protection. Control

module is mounted in cabinet interior.

· Motors shall be RPM controlled, UL recognized or equivalent, continuous duty rated.

· Factory wired to unit control box.

· Motor protected with thermal overload.

· Motor bearings shall be permanently lubricated.

· Motor installed on same side as coil connections for ease of service.

· Electric Heaters:

· When indicated in the schedule shall perform at indicated voltage, phase, and wattage in the specified number of stages.

· Protect by automatic reset cutout and manual reset backup.

· Cabinets:

· Fabricate from heavy gauge galvanized steel, single wall construction.

· Insulation to be 1 in. fiberglass [1 in. premium IAQ fiberglass, 1 in. Foil Face, or 1 in. Closed Cell].

· Furnish with access panels on both sides of unit, easily removable without tools.

· Holes for through-hanger rods are located at top and bottom 4 corners of cabinet.

· Optional double wall construction with 1 in. fiberglass insulation with solid or perforated inner liners.

· Drain Pans:

· Standard with Type 304 stainless steel.

· Externally isolated with 2-part closed cell foam insulation.

· Double-sloped toward outlets.

· Inside is smooth for easy cleaning.

· Furnished with primary 3/4 in. male NPT and “tell-tale” 1/2 in. male NPT secondary drain connections on same end with

coil connections. Secondary drain connection must be capped by installer if not used.

· Drain pan is removable from cabinet from same end as coil connections for ease of cleaning.

· Filters:

· Standard 2 in. pleated MERV 8 filters (options: 1 in. pleated MERV 8, set of 2 each 1 in. non-woven synthetic

throwaway, 2 in. pre-filter with 2 in. MERV 11 filter, 4 in. MERV 11, 4 in. MERV 13).

· Removable from either side or bottom of filter rack without tools.

· Controls:

· Unit mounted, factory installed and wired motor control board that adjust RPM/CFM for High, Medium and Low speed

operation.

· Single-phase or 3-phase motors.

· Option: door interlocking disconnect switch with lock-out tag-out feature.

· Electric heat controls include transformer, electric heat contactors, electric heat fuses and terminal strip.

· Electric heat available in single and 3-phase, and controlled in [single, 2, 3] stages of operation.

Fan Coil Builder 4.10i Page 22 of 23

Guide Specification for CAFETERIA

Project: WORLD BANK 08/21/2023

Prepared By: 12:54AM

· Fuses shall comply with NFPA 70E/IP20.

· Special Features:

· Unit shall be equipped with nichrome wire strip electric heaters as specified on the equipment schedule.

· Heaters shall be protected by an automatic reset safety cutout switch and a manual reset backup.

· Heater capacity and stages shall be as specified on the equipment schedule.

· Heaters shall be single-phase [115] [208] [230] [277] or three-phase [208] [230] [460] volts as specified on the

equipment schedule.

· Units shall be equipped with 24V controls.

· Units shall be equipped with 24V controls and optional high-level condensate switch.

· Optional Service Light shall provide a source of illumination in the main unit cabinet and the control box during routine

maintenance and troubleshooting. Light turns “ON” when access panel or control box door is open, but unit is not powered.

Service Light assembly shall include 2 LED lights, rechargeable battery and charger.

Fan Coil Builder 4.10i Page 23 of 23

You might also like

- Gree Dehumidifier Service ManualDocument58 pagesGree Dehumidifier Service Manualjdv1234No ratings yet

- Datasheet LV Motor Rev 0Document4 pagesDatasheet LV Motor Rev 0wado11No ratings yet

- LCM 500 Presentation - 2Document55 pagesLCM 500 Presentation - 2baoHVLAB100% (9)

- Fan Coil Unit - SaiverDocument8 pagesFan Coil Unit - SaiverRyan Au YongNo ratings yet

- Fcu 2Document2 pagesFcu 2Usman ShaikhNo ratings yet

- Tech-Qatar (Fcu 01)Document1 pageTech-Qatar (Fcu 01)Viswa VichuNo ratings yet

- BPGDE - 15 Tons - Consolidated Customer PackageDocument7 pagesBPGDE - 15 Tons - Consolidated Customer Packagetc01No ratings yet

- Tech-Fcu (42DCD12)Document1 pageTech-Fcu (42DCD12)BDMNo ratings yet

- Condensing Unit - SelectionDocument2 pagesCondensing Unit - Selectionfuad aliNo ratings yet

- BHNT-AMNT-EVT-ME-DSH-00800-REV.B - DAF Tank Datasheet - ADocument11 pagesBHNT-AMNT-EVT-ME-DSH-00800-REV.B - DAF Tank Datasheet - ADevy MangimbaNo ratings yet

- 44ab7440-1400-P.02-1402-A4 - CDocument3 pages44ab7440-1400-P.02-1402-A4 - CariyakkannaaNo ratings yet

- Up SubmittalDocument13 pagesUp SubmittalerickNo ratings yet

- Etk - 01e (DenHollander10)Document11 pagesEtk - 01e (DenHollander10)Eloy Hernandez GonzalezNo ratings yet

- Engineering Data (Design Manual) - EDTRAU342315-D - RXYQ-BYMDocument104 pagesEngineering Data (Design Manual) - EDTRAU342315-D - RXYQ-BYMignatiusglenNo ratings yet

- Tech-Fcu (42DCD008)Document1 pageTech-Fcu (42DCD008)afzal_aabNo ratings yet

- 39mwe029jx2 USSDocument8 pages39mwe029jx2 USSIvan Cristopher Tiburcio GuerreroNo ratings yet

- Technical Data Compressor: SC12CLDocument6 pagesTechnical Data Compressor: SC12CLKokoNo ratings yet

- Performance CH 43tr CEDocument3 pagesPerformance CH 43tr CECarlos HoyosNo ratings yet

- Tech-Fcu (42cet03)Document1 pageTech-Fcu (42cet03)sridharNo ratings yet

- PM-2491 AB FINAL - Documentation PDFDocument260 pagesPM-2491 AB FINAL - Documentation PDFEnder ZenginobuzNo ratings yet

- 42CV 2012Document10 pages42CV 2012Mhd Garry LuthfiNo ratings yet

- Selection Output 30RB039SDocument1 pageSelection Output 30RB039SSinggih KurniawanNo ratings yet

- MC-001-DS-M-004-110 DS For Liquor Filter Rev ADocument4 pagesMC-001-DS-M-004-110 DS For Liquor Filter Rev AHeldiyan RamdhanNo ratings yet

- Air Conditioner SpecificationDocument3 pagesAir Conditioner SpecificationsaiNo ratings yet

- VAV Honeywell Tech SubmittalDocument1 pageVAV Honeywell Tech SubmittalMUHAMMED SHAFEEQNo ratings yet

- J & E Hall Refrigeration Sdn. BHD.: Dmahu Technical ReportDocument4 pagesJ & E Hall Refrigeration Sdn. BHD.: Dmahu Technical ReportIm ChinithNo ratings yet

- CGAM - CGAM-1 - Consolidated Customer PackageDocument19 pagesCGAM - CGAM-1 - Consolidated Customer PackageAmeli RNo ratings yet

- Aquaforce: Summary Performance Report For Ch-1-Cu-AlDocument6 pagesAquaforce: Summary Performance Report For Ch-1-Cu-AlHVAC SimplifiedNo ratings yet

- UCCA - UCCA-1 - Consolidated Customer PackageDocument23 pagesUCCA - UCCA-1 - Consolidated Customer PackageVincent Aarón RodríguezNo ratings yet

- Technical Manual For Air-Cooled Modular Chiller - (FCH01-2020,21E)Document34 pagesTechnical Manual For Air-Cooled Modular Chiller - (FCH01-2020,21E)yusuf mohd sallehNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Awgte 12 C 2Document102 pagesAwgte 12 C 2warlof26No ratings yet

- Euroklimat Centrifugal Chiller Ekdc750b3Document3 pagesEuroklimat Centrifugal Chiller Ekdc750b3EddieNo ratings yet

- Fcu Pressure Drop PDFDocument18 pagesFcu Pressure Drop PDFvishalNo ratings yet

- 3 Out Ts Omm Mec HVC 3771 01 Eh 210320947 Omm of Hvac System For Kaw PlantDocument145 pages3 Out Ts Omm Mec HVC 3771 01 Eh 210320947 Omm of Hvac System For Kaw PlantMohamed AbdelmoneimNo ratings yet

- 30XA200Document3 pages30XA200Leonardo Martinho DobrianskyjNo ratings yet

- dw20 Asko DishwasherDocument46 pagesdw20 Asko DishwasherZeigt100% (1)

- Data Sheet For Level Transmitter Radar Non-Contact TypeDocument3 pagesData Sheet For Level Transmitter Radar Non-Contact TypeSri Kanth100% (1)

- Tqm-221105-c - 220kw Tech & Drawing (Tradeone)Document2 pagesTqm-221105-c - 220kw Tech & Drawing (Tradeone)Louie FernandezNo ratings yet

- MC-001-DS-M-005-110 DS For Liquor Filter Rev ADocument4 pagesMC-001-DS-M-005-110 DS For Liquor Filter Rev AHeldiyan RamdhanNo ratings yet

- FCU Performance Data SheetDocument5 pagesFCU Performance Data Sheettomeu_vanrellNo ratings yet

- Caracteristicas ChillerDocument21 pagesCaracteristicas ChillerJoe Israel V-Red SkidNo ratings yet

- IJLDS - FAN COIL UNITS - Performance Data SheetDocument16 pagesIJLDS - FAN COIL UNITS - Performance Data SheetDennis MendozaNo ratings yet

- SINGLE - VV-14 Con Cal - Consolidated Customer PackageDocument7 pagesSINGLE - VV-14 Con Cal - Consolidated Customer PackageLuis Miguel Perez PertuzNo ratings yet

- TM - Midea - Rooftop Package - T3 - 7.5-20 Ton - 220V - 60Hz - 20200526 - V1Document132 pagesTM - Midea - Rooftop Package - T3 - 7.5-20 Ton - 220V - 60Hz - 20200526 - V1gcarbajalhNo ratings yet

- Seleção SALA 5Document10 pagesSeleção SALA 5Gustavo RomeroNo ratings yet

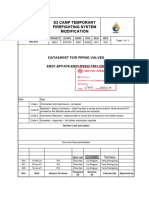

- 3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesDocument5 pages3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesRedhaa .kNo ratings yet

- Gunasekar Ramesh-External 2023.01.21 10:09:29 +05'30'Document106 pagesGunasekar Ramesh-External 2023.01.21 10:09:29 +05'30'Satish KumarNo ratings yet

- Enclosure Cooling Unit Model User's GuideDocument24 pagesEnclosure Cooling Unit Model User's GuideAgus CahyonoNo ratings yet

- Carrier - 38ye009 AllegroDocument34 pagesCarrier - 38ye009 AllegroJOSENo ratings yet

- manualsserviceGVH Service GVH24AM-K6DNC7A GVH48AL-K6DNC7A TSM PDFDocument98 pagesmanualsserviceGVH Service GVH24AM-K6DNC7A GVH48AL-K6DNC7A TSM PDFKovacsNo ratings yet

- Zone 8 CustomerDocument8 pagesZone 8 Customeramnaakram996No ratings yet

- Mphahlele TJ 219080587Document30 pagesMphahlele TJ 219080587ThabangNo ratings yet

- Package ACDocument52 pagesPackage ACWee WeeNo ratings yet

- Selectie FWE05DATNDocument5 pagesSelectie FWE05DATNkatcordesignNo ratings yet

- F&C CarrierDocument15 pagesF&C Carriercarmen hernandezNo ratings yet

- 2.1 WDHT-CN100.1 Chiller ClivetDocument6 pages2.1 WDHT-CN100.1 Chiller ClivetTony NguyenNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- STG G60 Protection Settings - 120606Document6 pagesSTG G60 Protection Settings - 120606niyop4allNo ratings yet

- Mucho Rojo: Resistors Capacitors Transistors Parts ListDocument1 pageMucho Rojo: Resistors Capacitors Transistors Parts ListPaulo MonteiroNo ratings yet

- Opti517 Optical Quality 2014Document137 pagesOpti517 Optical Quality 2014Lucía Suárez AndrésNo ratings yet

- L14G2 PDFDocument4 pagesL14G2 PDFsameed raheelNo ratings yet

- Sticker-HC 3530Document1 pageSticker-HC 3530JANS MARIO LLACUA TOSCANONo ratings yet

- Transistor Mje 2955Document6 pagesTransistor Mje 2955Jesus UrrietaNo ratings yet

- pc1616 pc1832 pc1864 V42 Inst PDFDocument68 pagespc1616 pc1832 pc1864 V42 Inst PDFelmakedonNo ratings yet

- Rajalakshmi Engineering College, ChennaiDocument51 pagesRajalakshmi Engineering College, ChennaiM ranganNo ratings yet

- Definition of Heat DetectorDocument5 pagesDefinition of Heat Detectormuhammad zulfikriNo ratings yet

- 5611BH XiltxDocument4 pages5611BH XiltxSergio CalviNo ratings yet

- Pointers To Rev Iew For Sum 2.3Document7 pagesPointers To Rev Iew For Sum 2.3Ru TyNo ratings yet

- V.252 Series AddressableDocument3 pagesV.252 Series AddressableSwapnil SangodkarNo ratings yet

- 08140h PDFDocument12 pages08140h PDFAmine EmineNo ratings yet

- What Is Electronically Controlled Microwave OvenDocument2 pagesWhat Is Electronically Controlled Microwave OvenJames L FloresNo ratings yet

- What Is Capacitor Start Induction Motor A Complete GuideDocument5 pagesWhat Is Capacitor Start Induction Motor A Complete GuideIzzan FirdausNo ratings yet

- Case Study For Ece Board ExamDocument14 pagesCase Study For Ece Board ExamSM MecregNo ratings yet

- Ujt Circuits - Power ElectronicsDocument7 pagesUjt Circuits - Power ElectronicsMoh OkoeNo ratings yet

- Sony CDX-S2250-S2250SDocument48 pagesSony CDX-S2250-S2250Sfunky_john100% (1)

- "Orange Line": AC Contactors, AC OperatedDocument2 pages"Orange Line": AC Contactors, AC OperatedfelipeffcNo ratings yet

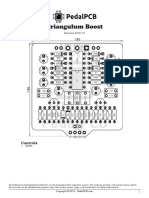

- PedalPCB TriangulumDocument5 pagesPedalPCB TriangulumYann RossiNo ratings yet

- SVC Implementation Using Neural Networks For An AC Electrical RailwayDocument11 pagesSVC Implementation Using Neural Networks For An AC Electrical RailwayAhmad TaheriNo ratings yet

- AD633Document20 pagesAD633zampradeepNo ratings yet

- Lecture 2 Rely Logic Diagram (Mud)Document17 pagesLecture 2 Rely Logic Diagram (Mud)Omar YehiaNo ratings yet

- Ds Bps 700dnc40 12 XG SeriesDocument6 pagesDs Bps 700dnc40 12 XG Seriesricardogaravito3353No ratings yet

- 2 Synchronous Generator WithansDocument19 pages2 Synchronous Generator WithansIncst Bhai50% (2)

- Insulators & String EfficiencyDocument17 pagesInsulators & String Efficiencyketan adhwanNo ratings yet

- OptiX RTN 900 V1R1 Installation Guide-VDFDocument40 pagesOptiX RTN 900 V1R1 Installation Guide-VDFsrasool_2No ratings yet

- GCB Application GuideDocument61 pagesGCB Application GuideAnonymous fbeCwgBFYNo ratings yet