Professional Documents

Culture Documents

02 BeltStorageShipping

02 BeltStorageShipping

Uploaded by

Bluemonday BluemondayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 BeltStorageShipping

02 BeltStorageShipping

Uploaded by

Bluemonday BluemondayCopyright:

Available Formats

#2 Belt Storage and Shipping

Modern conveyor belts are very durable products, but they can be adversely affected by improper storage and

shipping practices. The basic recommended practices for belt storage/shipping are as follows:

ALWAYS SHIP AND STORE BELTS IN AN UPRIGHT POSITION, with the core horizontal, ideally

with the core suspended, or with the belt resting on a raised surface such as a skid or platform. Never store belts

on their sides, with the core vertical. This type of storage can result in differential moisture absorption in the

two edges and thus lead to undesirable camber when the belt is used. Even under ideal storage conditions, cut

edge belting may absorb moisture in the edges. When a partial width belt is cut from a wider roll, the original

edge will have absorbed some moisture, more than the freshly cut edge, and thus may cause some camber in the

belt in initial use. However, this type of camber will disappear in a few days as the moisture equalizes in the

two edges.

TEMPERATURE EXTREMES SHOULD BE AVOIDED IN BELT STORAGE. Ideal temperature would

be 50EF (10EC) to 70EF (21EC). Temperatures above 90EF (32EC) should be avoided. Temperatures below

40EF (4EC) may stiffen belts to the extent that they will not trough initially, leading to training problems.

Usually, however, the belts will become acceptably flexible after running for a short time.

Neoprene belts are especially affected by storage under 40EF (4EC), as they become hard and stiff, and this can

only be relieved by lengthy exposure to higher temperatures, generally above 60EF (15EC).

PROTECT STORED BELTS FROM DIRECT SUNLIGHT AND OZONE. These elements can cause

surface hardening and cracking. Ozone is associated with electric motors, generators, and arc welders.

Susceptibility to these conditions varies widely among the various grades of belts, depending on intended use.

Consult your belt manufacturer for help in this area.

COVER AND ELEVATE BELTS STORED OUTSIDE. Set the rolls of belt on a skid or platform to prevent

direct exposure to surface moisture and standing water. The rolls should be covered with a rain and sunlight

restricting material, most commonly black plastic film, perforated to allow ventilation and trapped water

drainage.

AVOID ROLLING BELTS. This usually leads to loosening of the belt wraps, and may result in

Atelescoping@ of the rolls. If necessary, roll belts only in the direction they are wound.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 01 BeltCamberDocument2 pages01 BeltCamberBluemonday BluemondayNo ratings yet

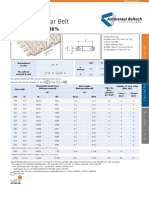

- Datasheet Uni L SNB 36Document4 pagesDatasheet Uni L SNB 36Bluemonday BluemondayNo ratings yet

- Chevron-Cleaners - MANUAL DE INSTALACIÓNDocument12 pagesChevron-Cleaners - MANUAL DE INSTALACIÓNBluemonday BluemondayNo ratings yet

- Design Formulas For Plastics Engineers by Natti S. Rao, Gunter SchumacherDocument8 pagesDesign Formulas For Plastics Engineers by Natti S. Rao, Gunter SchumacherBluemonday BluemondayNo ratings yet

- Volta V and Round BrochureDocument6 pagesVolta V and Round BrochureBluemonday BluemondayNo ratings yet

- Volta Flat Belts Food Trifolder enDocument2 pagesVolta Flat Belts Food Trifolder enBluemonday BluemondayNo ratings yet

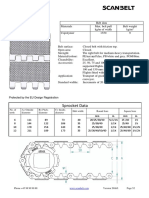

- Sprocket Data: Protected by The EU Design RegistrationDocument1 pageSprocket Data: Protected by The EU Design RegistrationBluemonday BluemondayNo ratings yet

- Sprocket Data: No. of Teeth A Outside Diameter B Pitch-Diameter C Inside - Diameter Hub Width: Round Bore Square BoreDocument1 pageSprocket Data: No. of Teeth A Outside Diameter B Pitch-Diameter C Inside - Diameter Hub Width: Round Bore Square BoreBluemonday BluemondayNo ratings yet

- Rotopalas FAM PDFDocument19 pagesRotopalas FAM PDFBluemonday BluemondayNo ratings yet