Professional Documents

Culture Documents

Sprocket Series M2500

Sprocket Series M2500

Uploaded by

Maricela Barraza TorresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sprocket Series M2500

Sprocket Series M2500

Uploaded by

Maricela Barraza TorresCopyright:

Available Formats

HabasitLINK®

Sprocket series M2500

M = Modular belts

Belt pitch

S = sprocket one-piece; Z = split sprocket

Number of teeth

Shaft size

Shaft type: Q = square shaft; R = round shaft

Material: 6 = POM; 8 = PA

M 25 S 12 40 Q 6

Sprocket availability

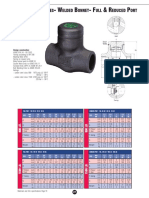

Type Number Diam. of pitch Ø dp A1 Hub width BL Square bore Q Ø Round bore R Standard

of teeth material

mm inch mm inch mm inch mm inch mm inch -

S 7 59.4 2.3 25.5 1.00 20 0.79 25 1 POM

S 8 66.7 2.6 29.3 1.15 30 1.18 25 30 1 POM

S 10 82.5 3.3 37.3 1.47 30 1.18 40 1 / 1.5 30 1 POM

S 12 98.6 3.9 45.4 1.79 30 1.18 40 1 / 1.5 30 / 40 1 POM

S 15 122.7 4.8 57.8 2.28 30 1.18 60 POM

S 16 130.8 5.2 61.9 2.44 30 1.18 40 1.5 30 POM

S 18 146.9 5.8 70.1 2.76 30 1.18 40 / 60 1.5 30 1 / 1 1/4 POM

S 20 163.0 6.4 78.3 3.08 30 1.18 40 / 60 1.5 30 1 POM

Z 12 98.6 3.9 45.4 1.79 40 1.57 40 1.5 POM

Z 18 146.9 5.8 70.1 2.76 47 1.85 40 / 60 POM

Z 20 163.0 6.4 78.3 3.08 40 1.57 40 POM

S, Z: molded sprockets. Other sprocket and hub sizes on request.

Key ways for round bore shape follow European standards for metric sizes and US standards for imperial sizes. For

detailed dimensions see table in the Engineering Guide chapter Design Guide.

Other materials available on request.

Sprocket one-piece ("open window") Split sprocket

Product Data Sheet (Released) 22.12.2020

HabasitLINK®

Sprocket series M2500

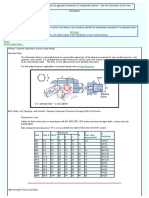

Sprocket arrangement

BE Belt The distance C between the sprocket axis and the slider

RC Retainer support ST is minimal 28 mm (1.1").

SP Sprocket

b0 belt width

Wearstrips

Between driving shaft and idling sprockets or rollers the belt is carried by a slider support furnished with longitudinal

wearstrips (ST) from UHMW Polyethylene or other suitable material.

Product Data Sheet (Released) 22.12.2020

HabasitLINK®

Sprocket series M2500

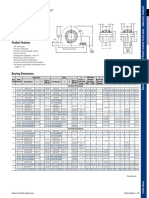

Sprocket positioning

For correct positioning of the center sprocket divide the belt width by the link increment. The rounded result will be

even or an odd number. These numbers are the criteria for offset or no offset, see table:

Belt type Sprocket spacing Sprocket edge Criteria for Result of Offset Remarks

a distance center formula e

(minimal) * sprocket (rounded)

position

minimal maximal XL XR Offset to which side

mm mm mm mm mm mm

inch inch inch inch inch inch

Series M2500 50 100 25 25 b0 / 16.66 even number (2, 8.3 right or left side

except M2540/44 2 4 1 1 b0 / 0.66 4, 6 ...) 0.33

except M2585/86 odd number (3, 0 no offset

5, 7 ...) 0

M2540 50 117 21 29 b0 / 16.66 even number (2, 4.2 right in running direction A

2 4.6 0.8 1.15 b0 / 0.66 4, 6 ...) 0.17 left in running direction B

odd number (3, 4.2 left in running direction A

5, 7 ...) 0.17 right in running direction B

M2540 50 117 54 62 b0 / 16.66 even number (2, 4.2 right in running direction A

with hold down 2 4.6 2.13 2.44 b0 / 0.66 4, 6 ...) 0.17 left in running direction B

tabs odd number (3, 4.2 left in running direction A

5, 7 ...) 0.17 right in running direction B

M2540 MTW 50 117 41 49 b0 / 16.66 even number (2, 4.2 right in running direction A

mold to width and 2 4.6 1.6 1.93 b0 / 0.66 4, 6 ...) 0.17 left in running direction B

bricklayed odd number (3, 4.2 left in running direction A

5, 7 ...) 0.17 right in running direction B

M2544 50 117 33 42 b0 / 16.66 even number (2, 4.2 right in running direction A

2 4.6 1.3 1.65 b0 / 0.66 4, 6 ...) 0.17 left in running direction B

odd number (3, 4.2 left in running direction A

5, 7 ...) 0.17 right in running direction B

M2585-P0 67 135 42 59 b0 / 33.8 even number (2, 8.3 right in running direction A

M2586 2.66 5.3 1.65 2.32 b0 / 1.33 4, 6 ...) 0.33 left in running direction B

odd number (3, 8.3 left in running direction A

5, 7 ...) 0.33 right in running direction B

M2585-S0 67 135 76 59 b0 / 33.8 even number (2, 8.3 right in running direction A

2.66 5.3 3 2.32 b0 / 1.33 4, 6 ...) 0.33 left in running direction B

odd number (3, 8.3 left in running direction A

5, 7 ...) 0.33 right in running direction B

* XL and XR are related to the running direction A and inverse for running direction B.

M2540, left edge XL (M2544 similar) M2585-S0, left edge XL (M2585-P0, M2586 similar)

Product Data Sheet (Released) 22.12.2020

HabasitLINK®

Sprocket series M2500

Number of sprockets and wearstrips for straight running belts

(excluding M2585 / 86: see separate table)

Standard belt width (nominal) Number of sprockets per shaft Number of wearstrips

mm inch min. number Carryway Returnway

(top) (bottom)

150 6 2 2 2

200 8 2 2 2

250 10 3 3 2

300 12 3 3 2

350 14 3 4 3

400 16 3 4 3

450 18 5 4 3

500 20 5 5 3

550 22 5 5 3

600 24 5 5 3

700 28 7 6 4

800 32 7 7 4

900 36 9 7 4

1000 40 9 8 5

1100 43 11 8 5

1200 47 11 9 5

1300 51 13 10 6

1400 55 13 10 6

1600 63 15 11 6

1800 71 17 12 7

2000 79 19 13 7

The number of sprockets depends on the belt load and may be different for driving and idling shafts.

For calculation of correct sprocket number please use LINK-SeleCalc.

Product Data Sheet (Released) 22.12.2020

HabasitLINK®

Sprocket series M2500

Number of sprockets and wearstrips for radius belts M2540, M2544

Standard belt width (nominal) Number of sprockets per shaft Number of wearstrips

mm inch min. number Carryway Returnway

(top) (bottom)

150 6 2 2 2

200 8 2 2 2

250 10 2 3 2

300 12 3 3 2

350 14 3 3 3

400 16 3 3 3

450 18 3 3 3

500 20 3 4 3

550 22 5 4 3

600 24 5 4 3

700 28 5 5 4

800 32 7 5 4

900 36 7 5 4

1000 40 9 6 5

1100 43 9 6 5

1200 47 9 7 5

The number of sprockets depends on the belt load and may be different for driving and idling shafts.

For calculation of correct sprocket number please use LINK-SeleCalc.

Number of sprockets and wearstrips for radius belts M2540 and M2544 with hold down tabs

Standard belt width (nominal) Number of sprockets per shaft Number of wearstrips

mm inch min. number Carryway Returnway

(top) (bottom)

150 6 1 2 2

200 8 2 2 2

250 10 2 3 2

300 12 2 3 2

350 14 3 3 3

400 16 3 3 3

450 18 3 3 3

500 20 3 4 3

550 22 3 4 3

600 24 5 4 3

700 28 5 5 4

800 32 5 5 4

900 36 7 5 4

1000 40 9 6 5

1100 43 9 6 5

1200 47 9 7 5

The number of sprockets depends on the belt load and may be different for driving and idling shafts.

For calculation of correct sprocket number please use LINK-SeleCalc.

Product Data Sheet (Released) 22.12.2020

HabasitLINK®

Sprocket series M2500

Number of sprockets and wearstrips for radius belts M2540 Radius Flush Grid 1" MTW (mold to width and

bricklayed)

Standard belt width (nominal) Number of sprockets per shaft Number of wearstrips

mm inch min. number Carryway Returnway

(top) (bottom)

206 8.11 2 2 2

256 10.08 2 3 2

306* 12.05 3 3 2

406 16 3 3 3

506 19.9 5 4 3

606 23.85 5 4 3

* The belt width 306 mm (12.05") is a non-cut standard mold to width belt. All other belt widths are cut sizes.

Number of sprockets and wearstrips for M2585, M2586

Standard belt width (nominal) Number of sprockets per shaft Number of wearstrips

mm inch min. number Carryway Returnway

(top) (bottom)

305 12 2 2 2

508 20 3 3 2

711 28 5 4 2

914 36 7 6 3

1117 44 7 8 3

1319 52 9 10 4

1522 60 11 10 4

1725 68 13 12 7

1928 76 13 12 7

2131 84 15 13 8

2333 92 17 16 8

2536 100 19 18 9

The number of sprockets depends on the belt load and may be different for driving and idling shafts.

For calculation of correct sprocket number please use LINK-SeleCalc.

Disclaimer

Product Application Disclaimer (valid for ALL Habasit products and mentioned on all PDS)

This disclaimer is made by and on behalf of Habasit and its affiliated companies, directors, employees, agents and contractors (hereinafter

collectively "HABASIT") with respect to the products referred to herein (the "Products"). SAFETY WARNINGS SHOULD BE READ CAREFULLY AND

ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Habasit catalogue as

well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are

recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness,

accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment, running

at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to

re-assessments and modifications within a short period of time and without prior notice.

EXCEPT AS EXPLICITLY WARRANTED BY HABASIT, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED "AS IS". HABASIT DISCLAIMS ALL OTHER WARRANTIES, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

NON-INFRINGEMENT, OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE, ALL OF WHICH ARE HEREBY EXCLUDED TO

THE EXTENT ALLOWED BY APPLICABLE LAW. BECAUSE CONDITIONS OF USE IN INDUSTRIAL APPLICATION ARE OUTSIDE OF HABASIT'S

CONTROL, HABASIT DOES NOT ASSUME ANY LIABILITY CONCERNING THE SUITABILITY AND PROCESS ABILITY OF THE PRODUCTS,

INCLUDING INDICATIONS ON PROCESS RESULTS AND OUTPUT.

Product Data Sheet (Released) 22.12.2020

You might also like

- 2018 End of Term 1 Test Computer Studies Grade 8Document6 pages2018 End of Term 1 Test Computer Studies Grade 8Tahpehs Phiri76% (17)

- Warren Truss Bridge ReportDocument12 pagesWarren Truss Bridge ReportRaaj Chatterjee50% (2)

- Ramniranjan Jhunjhunwala College of Arts, Science and Commerce (Autonomous)Document1 pageRamniranjan Jhunjhunwala College of Arts, Science and Commerce (Autonomous)Angelina JoyNo ratings yet

- Sprocket Series M0800-En-UsDocument3 pagesSprocket Series M0800-En-UsMounir EchineNo ratings yet

- Dimensiuni NPTDocument2 pagesDimensiuni NPTGrosu CosminNo ratings yet

- Technical Information: Iso Thread (Angle 60°)Document3 pagesTechnical Information: Iso Thread (Angle 60°)ARJUNNo ratings yet

- Technical Information: Iso Thread (Angle 60°)Document3 pagesTechnical Information: Iso Thread (Angle 60°)ARJUNNo ratings yet

- Technical Information: Iso Thread (Angle 60°)Document3 pagesTechnical Information: Iso Thread (Angle 60°)Santosh TiwariNo ratings yet

- Bevel GearsDocument4 pagesBevel GearsRobinson PovedaNo ratings yet

- Lap Joint Stub End PDFDocument2 pagesLap Joint Stub End PDFBowo Edhi WibowoNo ratings yet

- C V - W B - F & R P: Heck Alves Elded Onnet ULL Educed ORTDocument1 pageC V - W B - F & R P: Heck Alves Elded Onnet ULL Educed ORTMostafizur RahmanNo ratings yet

- For Cylinder Size Dia 57mm X 55mm StrokeDocument4 pagesFor Cylinder Size Dia 57mm X 55mm StrokesrdNo ratings yet

- Fast'S Gear Couplings AISE Mill Motor CouplingDocument2 pagesFast'S Gear Couplings AISE Mill Motor Couplingsundar301No ratings yet

- Mto N2Document13 pagesMto N2dimas prasetyoNo ratings yet

- Ficha Tecnica GrampasDocument1 pageFicha Tecnica GrampasValentina VelosoNo ratings yet

- Atusa Ds Cf-fc01-Pn16-40 en EsDocument2 pagesAtusa Ds Cf-fc01-Pn16-40 en EsmadalenaNo ratings yet

- RTJ Flange DimensionsDocument25 pagesRTJ Flange DimensionsSaekhuNo ratings yet

- Head ClearancesDocument2 pagesHead ClearancesMohan Rao0% (2)

- BBS ResidanceDocument13 pagesBBS ResidanceBrajendra BisenNo ratings yet

- Accessories MuellerDocument3 pagesAccessories MuellerFabio Moacir KorndoerferNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- Fv-Cat-322-0316 Htaf PDFDocument2 pagesFv-Cat-322-0316 Htaf PDFTaylor RamirezNo ratings yet

- Selection of Thread SystemDocument12 pagesSelection of Thread Systemwilson moNo ratings yet

- Metric Tap and Clearance Drill SizesDocument1 pageMetric Tap and Clearance Drill SizesFahmi SyaifuddinNo ratings yet

- BSW BS AF BA and Metric Tool Size Equivalents PDFDocument5 pagesBSW BS AF BA and Metric Tool Size Equivalents PDFZool HilmiNo ratings yet

- Fusion 322 Series ValvesDocument2 pagesFusion 322 Series ValvesOceanexNo ratings yet

- RULAND BeLLOWS coOuplLingsSDocument6 pagesRULAND BeLLOWS coOuplLingsSduxi1981No ratings yet

- ExtractPage14 15 PDFDocument2 pagesExtractPage14 15 PDFDries VandezandeNo ratings yet

- Cutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Document4 pagesCutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Dries VandezandeNo ratings yet

- ESAB ExtractPage15-16cDocument9 pagesESAB ExtractPage15-16cDries VandezandeNo ratings yet

- ExtractPage14 PDFDocument2 pagesExtractPage14 PDFDries VandezandeNo ratings yet

- Cutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Document2 pagesCutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Dries VandezandeNo ratings yet

- Tap Drill SizesDocument2 pagesTap Drill SizespriecsNo ratings yet

- Standard Tap Drill SizesDocument2 pagesStandard Tap Drill SizesArchie TanglaoNo ratings yet

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs MSS SP97 PDFDocument3 pagesDimensions of Sockolets Pressure Class 3000 and 6000 Lbs MSS SP97 PDFmarkoredsNo ratings yet

- Econ Ball Valves, Carbon Steel, Full Bore DIN PN 500 - 100, Blow-Out Proof StemDocument1 pageEcon Ball Valves, Carbon Steel, Full Bore DIN PN 500 - 100, Blow-Out Proof StemChristianGuerreroNo ratings yet

- 113 PDFDocument1 page113 PDFChristianGuerreroNo ratings yet

- 4 Storey 8 CL (Standard Footing) - FinalDocument106 pages4 Storey 8 CL (Standard Footing) - FinalKaren Balisacan Segundo RuizNo ratings yet

- Catalogo de FresaDocument17 pagesCatalogo de FresaJesus AlmonteNo ratings yet

- Needle Valves-2024 (2024-06-04 00 - 21 - 14)Document25 pagesNeedle Valves-2024 (2024-06-04 00 - 21 - 14)MustafaNo ratings yet

- Hydraulic Nozzles Open Sprinkler Nozzles: ايروس نم يخا يديرب ناونع zerkam@Document1 pageHydraulic Nozzles Open Sprinkler Nozzles: ايروس نم يخا يديرب ناونع zerkam@zakiNo ratings yet

- InsulflexDocument9 pagesInsulflexIwan PrasetyoNo ratings yet

- Atusa Ds Cf-fc01-Pn6-10 en EsDocument2 pagesAtusa Ds Cf-fc01-Pn6-10 en EsmadalenaNo ratings yet

- Fabrication: Socket Head Cap ScrewsDocument3 pagesFabrication: Socket Head Cap Screwsnemi90No ratings yet

- Rexnord 2 Bolt Pillow BlockDocument30 pagesRexnord 2 Bolt Pillow BlockAnonymous qfrYnT7LAQNo ratings yet

- En 13121-3 Bridas Pn10Document1 pageEn 13121-3 Bridas Pn10Ricardo BustamanteNo ratings yet

- Cable Gland Suitable For Armoured Cables: COMET Weatherproof Type Double CompressionDocument1 pageCable Gland Suitable For Armoured Cables: COMET Weatherproof Type Double CompressionAkil VohraNo ratings yet

- Inch and Metric Hex Bolt and Socket Cap Screw Tool Size Chart Northwest FastenerDocument1 pageInch and Metric Hex Bolt and Socket Cap Screw Tool Size Chart Northwest FastenerPankaj MauryaNo ratings yet

- Tabla Tuberia GalvanizadaDocument5 pagesTabla Tuberia GalvanizadaJuliia Mariia Chamorro VergaraNo ratings yet

- Reinforcing Steel and AccessoriesDocument4 pagesReinforcing Steel and AccessoriesTheodore TheodoropoulosNo ratings yet

- Thread Connector IdentificationDocument11 pagesThread Connector IdentificationbearNo ratings yet

- Gate Valve 1.2 2 WeightDocument1 pageGate Valve 1.2 2 WeightИлья БересневNo ratings yet

- Codigo Corrente ISO B A B A KG./MT.: Guia de Correntes em Polietileno Chain Guide Rails in PolyethyleneDocument3 pagesCodigo Corrente ISO B A B A KG./MT.: Guia de Correntes em Polietileno Chain Guide Rails in Polyethylenedimon_tareNo ratings yet

- ANSI B16.5 Class 300 Welding Neck FlangesDocument2 pagesANSI B16.5 Class 300 Welding Neck FlangeslehuyNo ratings yet

- Superman PDFDocument2 pagesSuperman PDFlehuyNo ratings yet

- KVF-B16.48 Spectacle Blind BrochureDocument26 pagesKVF-B16.48 Spectacle Blind Brochurepmech consultantNo ratings yet

- 3"-48" Ductile Iron Mechanical Joint Fittings Class 350Document11 pages3"-48" Ductile Iron Mechanical Joint Fittings Class 350MIGUEL MIGUEL RIVAS SALCEDONo ratings yet

- Lens GasketDocument1 pageLens GasketManoj KumarNo ratings yet

- 545 7489 (Eag349) - IsirDocument2 pages545 7489 (Eag349) - IsirDurai NaiduNo ratings yet

- Tap Drill SizesDocument2 pagesTap Drill SizesSpeld SpeldNo ratings yet

- Calculo de Acero MiguelDocument4 pagesCalculo de Acero MiguelNataly Cruz ColoniaNo ratings yet

- 07 High Speed Steel Drills Metric 2018Document35 pages07 High Speed Steel Drills Metric 2018Aaron NadarNo ratings yet

- Burley StoryboardDocument15 pagesBurley Storyboardapi-361443938No ratings yet

- ICDBME2022 - Book of AbstractsDocument341 pagesICDBME2022 - Book of AbstractsAlev TaskınNo ratings yet

- Prof. Alberto Berizzi: Dipartimento Di Energia Ph. 02 2399 3728 Email: Alberto - Berizzi@polimi - ItDocument32 pagesProf. Alberto Berizzi: Dipartimento Di Energia Ph. 02 2399 3728 Email: Alberto - Berizzi@polimi - ItMohammed OsmanNo ratings yet

- Jurnal AnakDocument6 pagesJurnal AnakWidhi SanglahNo ratings yet

- Training Regulations: Motorcycle/ Small Engine Servicing NC IiDocument102 pagesTraining Regulations: Motorcycle/ Small Engine Servicing NC IiAmit Chopra AmitNo ratings yet

- Deleuze Guattariandthe Indian DiagramDocument19 pagesDeleuze Guattariandthe Indian DiagramManu KhannaNo ratings yet

- RPS Goals December 7 2021Document16 pagesRPS Goals December 7 2021inforumdocsNo ratings yet

- Introduction To Logic Design Experiments 1 Thru 10Document36 pagesIntroduction To Logic Design Experiments 1 Thru 10George Kokkinias100% (1)

- Lines On A Chart Joining Places of Equal Grivation Are Named IsogrivsDocument5 pagesLines On A Chart Joining Places of Equal Grivation Are Named IsogrivsFirdaus92No ratings yet

- Ethics in Nursing ResearchDocument7 pagesEthics in Nursing ResearchMaritoni BargayoNo ratings yet

- ESOL Nexus Teaching MathematicsDocument38 pagesESOL Nexus Teaching MathematicsArnold HoNo ratings yet

- DSA With Java - Unit4Document12 pagesDSA With Java - Unit4Sabin MaharjanNo ratings yet

- 9.08 Solving Systems With Cramer's RuleDocument10 pages9.08 Solving Systems With Cramer's RuleRhea Jane DugadugaNo ratings yet

- Liberty WallDocument12 pagesLiberty WallJason ThompsonNo ratings yet

- Effects of Kinesio Taping On Hemiplegic Hand in Patients With Upper Limb Post-Stroke SpasticityDocument7 pagesEffects of Kinesio Taping On Hemiplegic Hand in Patients With Upper Limb Post-Stroke Spasticityhgood1001No ratings yet

- Mnemonics FinalDocument10 pagesMnemonics Finalapi-285415466No ratings yet

- Tommy Emmanuel - Guitar BoogieDocument13 pagesTommy Emmanuel - Guitar Boogiemadzia7100% (2)

- Bio 50Document28 pagesBio 50Mohammad Shahidullah ChowdhuryNo ratings yet

- AL3451 Machine Learning Lecture Notes 1Document212 pagesAL3451 Machine Learning Lecture Notes 1jonej2005No ratings yet

- 2 HIE ENG HardwareDocument21 pages2 HIE ENG HardwareWalter Lazo100% (1)

- Take Note:: Miracle Light Christian Academy Casilagan, City of Ilagan, Isabela Mathematics 8Document4 pagesTake Note:: Miracle Light Christian Academy Casilagan, City of Ilagan, Isabela Mathematics 8Dennis PacursaNo ratings yet

- Solution To Exam #1 For Chemical Engineering Thermodynamics (2018)Document2 pagesSolution To Exam #1 For Chemical Engineering Thermodynamics (2018)ramesh pokhrelNo ratings yet

- Cyrillan Project Final ReportDocument28 pagesCyrillan Project Final ReportDat Nguyen ThanhNo ratings yet

- 1 - Young Paper On EXW HistoryDocument6 pages1 - Young Paper On EXW Historylastking_king17No ratings yet

- Forensic Chemistry and ToxicologyDocument2 pagesForensic Chemistry and ToxicologyDE GUZMAN VONNo ratings yet

- Always On - Language in An Online and Mobile WorldDocument304 pagesAlways On - Language in An Online and Mobile WorldDanica JerotijevicNo ratings yet

- Conservation of EnergyDocument15 pagesConservation of EnergySreemanth C ReddyNo ratings yet