Professional Documents

Culture Documents

Official Confined Space Entry Checklist

Official Confined Space Entry Checklist

Uploaded by

Saim Ali0 ratings0% found this document useful (0 votes)

110 views2 pagesThe document is a checklist for confined space entry that contains 20 items to check regarding safety precautions. It addresses ensuring hazardous materials are removed, energy sources are isolated, ventilation is provided, atmospheric testing is conducted, illumination and monitoring are in place, emergency equipment and trained personnel are available, hot work and combustion equipment are properly handled, and personal protective equipment is worn. The checklist aims to comprehensively cover safety measures for confined space entry work.

Original Description:

Check list

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a checklist for confined space entry that contains 20 items to check regarding safety precautions. It addresses ensuring hazardous materials are removed, energy sources are isolated, ventilation is provided, atmospheric testing is conducted, illumination and monitoring are in place, emergency equipment and trained personnel are available, hot work and combustion equipment are properly handled, and personal protective equipment is worn. The checklist aims to comprehensively cover safety measures for confined space entry work.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

110 views2 pagesOfficial Confined Space Entry Checklist

Official Confined Space Entry Checklist

Uploaded by

Saim AliThe document is a checklist for confined space entry that contains 20 items to check regarding safety precautions. It addresses ensuring hazardous materials are removed, energy sources are isolated, ventilation is provided, atmospheric testing is conducted, illumination and monitoring are in place, emergency equipment and trained personnel are available, hot work and combustion equipment are properly handled, and personal protective equipment is worn. The checklist aims to comprehensively cover safety measures for confined space entry work.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Page 1 of 2

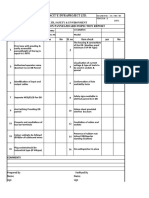

Confined Space Entry Checklist Ref:

Contractor: Inspected by:

Equipment Model: Job Title:

Site Location: Inspection Date:

S. N Description YE No N/A Remarks

S

1. Are confined spaces completely emptied of any hazardous

substances & materials, such as acids, asbestos prior entry?

2. Are all energizer/power supply lines to a confined space, having,

highly toxic, flammable, or corrosive materials and or materials cut

off, isolated, disconnected before entry?

3. Are all rotating component, parts, and equipment (impellers)

inside confined spaces locked-out if they present a serious hazard

to operators/technicians?

4. Is either natural or mechanical ventilation & exhaust system is

provided and or installed before confined space entry?

5. Are essential atmospheric tests conducted to know oxygen

deficiency, toxic substances, chemicals and explosive

concentrations in the confined space prior entry?

6. Is enough required illumination provided for the work activity/task

to be performed in the confined space?

7. Is the atmosphere inside the confined space regularly tested &

monitored during the work?

8. Is there a responsible appointed HSE standby personal outside of

the confined space when needed, whose core responsibility is to

continuously watch and monitor the work in progress, sound an

alarm if required, and provide assistance?

9. Is the standby employee competent and experienced and well

trained and equipped to handle any emergency?

10. Are the standby personal or other employees restricted from

entering the confined space without proper and essential

recommended PPE’s such as lifelines and respiratory equipment if

there is any emergency exist?

11. Is approved (from national and international governing bodies, or

Government intuitions) respiratory equipment needed if the

atmosphere inside the confined space cannot be made acceptable

for work?

12. Is all Portable Electrical Equipment (PEE), machinery, devices used

inside confined spaces either grounded and insulated, or equipped

with Ground-fault Circuit Interrupters (GFCI)?

13. Prior any hot work activity is started in a confined space, are hoses

inspected, checked and tested for any leaks, compressed gas

bottles forbidden inside of the confined space, lights always keep

outside of the confined area and the confined area tested for an

explosive atmosphere each time before a lighted torch is to be

taken into the confined space?

14. If workforce using Oxygen Consuming Equipment (OCE) eg, lights

or another heating system in a confined space, is sufficient air

provided to assure combustion without reducing the oxygen

concentration of the atmosphere below 19.5 per cent by volume

as per required standards?

15. While combustion-type equipment is used in a confined space,

always make sure the exhaust gases are vented outside of the

confined space?

16. Is each confined space inspected, and appropriately observed for

decaying vegetation or animal waste which may produce

methane?

17. Is the confined space examined for possible industrial waste which

could contain highly toxic and flammable properties?

18. If the confined space is underground and near areas where

gasoline fuel consumer vehicles will be operating, is it possible for

vehicle exhaust or carbon monoxide to enter the space?

19. Is confined space Entrants technicians/workers wearing proper

PPE’s (for example hardhats, boots, etc.)?

20. Do you know the location of the nearest operation

centre/emergency phone numbers?

Name Job Title Signatures Date

Inspected by:

Reviewed by:

You might also like

- TLB Daily ChecklistDocument1 pageTLB Daily ChecklistDuvan BenceNo ratings yet

- Davis Cline - Design A GreenIsland Packet (Student)Document9 pagesDavis Cline - Design A GreenIsland Packet (Student)Barney The DinosaurNo ratings yet

- Man Riding Checklist: HSE - 7474.0 - Rev 0 - (16-Dec-2020)Document1 pageMan Riding Checklist: HSE - 7474.0 - Rev 0 - (16-Dec-2020)MARIO LEALNo ratings yet

- Rolls Royce TT Thrusters - EAL LubricantsDocument2 pagesRolls Royce TT Thrusters - EAL Lubricantsjohn smithNo ratings yet

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- Towed Scraper Checklist V0810.1 PDFDocument1 pageTowed Scraper Checklist V0810.1 PDFcherifNo ratings yet

- Illumination Monitoring ChecklistDocument1 pageIllumination Monitoring ChecklistibrahimNo ratings yet

- DSTI Supervisors Daily Safet Task Instruction PDFDocument1 pageDSTI Supervisors Daily Safet Task Instruction PDFRicoNo ratings yet

- EHS VI 08 FaranaDocument2 pagesEHS VI 08 Faranashamshad ahamedNo ratings yet

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- Checklist For Crawler CraneDocument1 pageChecklist For Crawler CraneSafety ManagerNo ratings yet

- Vibratory Compactor Maintenance Checklist: Carwill Construction IncDocument2 pagesVibratory Compactor Maintenance Checklist: Carwill Construction IncCarwill Tesda100% (1)

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Installation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListDocument1 pageInstallation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListZulfequar R. Ali Khan100% (1)

- Excavator Daily Inspection Check List Rev 0Document1 pageExcavator Daily Inspection Check List Rev 0Zhafran diniyNo ratings yet

- NDT - Visual Inspection Checklist Page 1 of 4Document4 pagesNDT - Visual Inspection Checklist Page 1 of 4thindmanmohanNo ratings yet

- Ppe Issue RegisterDocument1 pagePpe Issue RegisterAnsarMahmoodNo ratings yet

- Workplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredDocument7 pagesWorkplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredUlviyye ElesgerovaNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- Ohs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordDocument1 pageOhs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordShafie ZubierNo ratings yet

- MS Working at HeightsDocument15 pagesMS Working at HeightsNauval FadliNo ratings yet

- Certificate 1Document2 pagesCertificate 1Ravikant PandeyNo ratings yet

- Checklist For Equipment Inspection TRANSIT MIXERDocument2 pagesChecklist For Equipment Inspection TRANSIT MIXERIdada EzekielNo ratings yet

- Site Access Request Form (ACBA - 0105 (BGW00174) )Document1 pageSite Access Request Form (ACBA - 0105 (BGW00174) )Maijul Islam Sarkar JituNo ratings yet

- HIRA RCC Work (3) Approed by ClientDocument11 pagesHIRA RCC Work (3) Approed by ClientHARSHADNo ratings yet

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- 1 Hse Management ResponsibilityDocument13 pages1 Hse Management ResponsibilityRATAN BHATIANo ratings yet

- Shovel ChecklistDocument2 pagesShovel Checklistjamal motaNo ratings yet

- Risk Assessment - PPE - ClothingDocument2 pagesRisk Assessment - PPE - Clothingbearingworks123No ratings yet

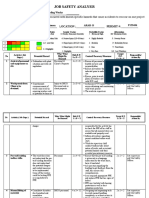

- JSA Cutting and Bending SteelDocument3 pagesJSA Cutting and Bending SteelthayounkNo ratings yet

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- F 016 Accommodation Inspection ChecklistDocument4 pagesF 016 Accommodation Inspection Checklistngomsia parfaitNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Induction and Tool Box Meeting Report: Soundarya Decorators PVT LTD Site: Hilton DATE: - TIMEDocument3 pagesInduction and Tool Box Meeting Report: Soundarya Decorators PVT LTD Site: Hilton DATE: - TIMErajarathinam_workNo ratings yet

- EHS 2-F8 PTW LiftingDocument2 pagesEHS 2-F8 PTW LiftingLee Xiao YuNo ratings yet

- F.hse.07 Work PermitDocument4 pagesF.hse.07 Work PermitMOJIBNo ratings yet

- RCCB Testing Format - HSE-CTN-HPP-FMT-001Document1 pageRCCB Testing Format - HSE-CTN-HPP-FMT-001Radha Buildtech100% (1)

- Safety Training Attendence List: Umm Wu'Al Phosphate Project U&I Multidiscipline PackageDocument1 pageSafety Training Attendence List: Umm Wu'Al Phosphate Project U&I Multidiscipline PackageJayvee Baradas ValdezNo ratings yet

- Contractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedDocument3 pagesContractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedJayvee Baradas ValdezNo ratings yet

- 1 WAH ChecklistDocument3 pages1 WAH ChecklistCristiane RibeiroNo ratings yet

- Abrasive Blasting Check ListDocument2 pagesAbrasive Blasting Check ListSaravanan JambunathanNo ratings yet

- Daily Angle Grinder Pre - Use Checklist - 2024 (Copy)Document1 pageDaily Angle Grinder Pre - Use Checklist - 2024 (Copy)papisdieng282No ratings yet

- First Aid Kid ListDocument4 pagesFirst Aid Kid ListHairul Nizam Bin Mohd SalimNo ratings yet

- MSF Safety Alert 16.16Document1 pageMSF Safety Alert 16.16divan semestaNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- Excavation Work Checklist: Saline Water Desalination Plant On The West CoastDocument2 pagesExcavation Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- Nirali H. Patel, MD Pediatric Emergency Medicine Children's Hospital Medical Center of AkronDocument31 pagesNirali H. Patel, MD Pediatric Emergency Medicine Children's Hospital Medical Center of Akronmarsan12No ratings yet

- OETC-HSE-O-COP-F-010 Daily HSE Report PDFDocument1 pageOETC-HSE-O-COP-F-010 Daily HSE Report PDFKing_of_SenseNo ratings yet

- FC 4.1.8 - Critical Lift PlanDocument1 pageFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeNo ratings yet

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocument1 pageHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (3)

- JSA Form - Installation of ATS atDocument4 pagesJSA Form - Installation of ATS atDarren OscarNo ratings yet

- Daily Safety Report TemplateDocument1 pageDaily Safety Report TemplateMarkNo ratings yet

- Excavator Daily Inspection ChecklistDocument2 pagesExcavator Daily Inspection ChecklistFira KurniatyNo ratings yet

- Building Works at Hougang Town: Daily Housekeeping ChecklistDocument4 pagesBuilding Works at Hougang Town: Daily Housekeeping ChecklistALFREDO JR. ARIOS CLARONo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- Grader Weekly Inspection ChecklistDocument2 pagesGrader Weekly Inspection ChecklistSiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Daily Observation SheetDocument2 pagesDaily Observation Sheetarun100% (2)

- ChecklistDocument1 pageChecklistMuhamad HasbiNo ratings yet

- CertificateDocument1 pageCertificateSaim AliNo ratings yet

- S8Document1 pageS8Saim AliNo ratings yet

- 05-Division 2-Section 02200 GRP Pipelines MateriaDocument3 pages05-Division 2-Section 02200 GRP Pipelines MateriaSaim AliNo ratings yet

- Sukkur Iba Testing Services: Merit - Transparency - TechnologyDocument1 pageSukkur Iba Testing Services: Merit - Transparency - TechnologySaim AliNo ratings yet

- S9Document1 pageS9Saim AliNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- HSE Risk Assessment (Contractor)Document9 pagesHSE Risk Assessment (Contractor)Saim AliNo ratings yet

- Saim Ali Abbasi (Sep 2022) (1)Document1 pageSaim Ali Abbasi (Sep 2022) (1)Saim AliNo ratings yet

- 0022B74E-7D4F-4489-B498-D8471A596157Document2 pages0022B74E-7D4F-4489-B498-D8471A596157Saim AliNo ratings yet

- SikaProof P Method Statement 13.11.20Document34 pagesSikaProof P Method Statement 13.11.20Saim AliNo ratings yet

- ENGR10004 Engineering Technology and Society Semester 1, 2022Document12 pagesENGR10004 Engineering Technology and Society Semester 1, 2022Eric HeNo ratings yet

- BKC On Economizer & WHRDocument56 pagesBKC On Economizer & WHRB K. ChoudhuryNo ratings yet

- Iso 4305 2014Document11 pagesIso 4305 2014rodolfo.brameriNo ratings yet

- Vol I - Electrical IlluminationDocument280 pagesVol I - Electrical IlluminationVeena NageshNo ratings yet

- KX-TD1232 - TD816 - Power ConsumptionDocument2 pagesKX-TD1232 - TD816 - Power ConsumptionDaniel De PianoNo ratings yet

- Osda Solar Module - Installation ManualDocument21 pagesOsda Solar Module - Installation ManualIOZEF1No ratings yet

- Intimidator Utv Owners ManualDocument104 pagesIntimidator Utv Owners ManualClyde FairbanksNo ratings yet

- Item 6.2 - 560PSU01 - DS - enDocument4 pagesItem 6.2 - 560PSU01 - DS - enTiennghia BuiNo ratings yet

- C37.82 GTD For Qualification Stwgear Assemblies For Class 1E App in Nuclear Pow Gen StationsDocument13 pagesC37.82 GTD For Qualification Stwgear Assemblies For Class 1E App in Nuclear Pow Gen StationsJulian AngeloNo ratings yet

- Dry Type Transformer Maintenance ChecklistDocument14 pagesDry Type Transformer Maintenance ChecklistMohib Ullah KhanNo ratings yet

- RyobiHp721UsersManual658446 1320965137Document14 pagesRyobiHp721UsersManual658446 1320965137chezsnailNo ratings yet

- IUC India - Kochi Baseline Study For Solid Waste ManagementDocument63 pagesIUC India - Kochi Baseline Study For Solid Waste ManagementIshwarya SNo ratings yet

- Efficient Motor Control With Power Drives SystemsDocument66 pagesEfficient Motor Control With Power Drives SystemsVic Rizenn Isidore BobilesNo ratings yet

- What Does A Flyback Converter DoDocument12 pagesWhat Does A Flyback Converter DojackNo ratings yet

- H. Min.: Electric Powered Forklift 8FBE 1.0 To 2.0 TonDocument2 pagesH. Min.: Electric Powered Forklift 8FBE 1.0 To 2.0 Tonguillermo garciaNo ratings yet

- PREAMBLE (NOT P-WPS OfficeDocument4 pagesPREAMBLE (NOT P-WPS OfficeMehbub JadejaNo ratings yet

- Lecture - 6 EDocument33 pagesLecture - 6 ETung HoNo ratings yet

- Fuel Injection Pump - InstallDocument8 pagesFuel Injection Pump - Installedwin100% (1)

- Pummelish Word Formation Practice SheetDocument2 pagesPummelish Word Formation Practice SheetHoang LongNo ratings yet

- 00a Abbreviations 2Document2 pages00a Abbreviations 2Juan RiveraNo ratings yet

- TCM Forklifts Range BrochureDocument4 pagesTCM Forklifts Range BrochureGeorge YapNo ratings yet

- FinderDocument844 pagesFinderPablo lopezNo ratings yet

- Ucg250 12Document2 pagesUcg250 12Guillermo HernánNo ratings yet

- BS 1965-1Document19 pagesBS 1965-1Fenner ElectromechanicalNo ratings yet

- Dokumen - Tips - Airfel Air Conditioner Inverter enDocument2 pagesDokumen - Tips - Airfel Air Conditioner Inverter enRivle potNo ratings yet

- Company Profile 2013 - ENDocument10 pagesCompany Profile 2013 - ENounkimheng17No ratings yet

- VIII Science MSDocument2 pagesVIII Science MSASHUTOSH MOHAPATRA ROLL 24 VINo ratings yet

- Deye 16KW Hybrid InverterDocument2 pagesDeye 16KW Hybrid InverterkresennnNo ratings yet