Professional Documents

Culture Documents

Cement - Wikipedia

Cement - Wikipedia

Uploaded by

firosaah0 ratings0% found this document useful (0 votes)

28 views1 pageCement is a binder used in construction that sets and hardens when mixed with water and aggregates like sand and gravel. When cement is mixed with fine aggregates it produces mortar, and when mixed with sand and gravel it produces concrete, which is one of the most widely used materials in the world. There are two main types of cement: hydraulic cement, which sets even when mixed with water, like Portland cement; and non-hydraulic cement, which only sets when dry. World cement production is about four billion tonnes per year, with China producing about half of the global total. Cement production is also a major contributor to climate change due to the carbon emissions from the cement kiln firing process.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCement is a binder used in construction that sets and hardens when mixed with water and aggregates like sand and gravel. When cement is mixed with fine aggregates it produces mortar, and when mixed with sand and gravel it produces concrete, which is one of the most widely used materials in the world. There are two main types of cement: hydraulic cement, which sets even when mixed with water, like Portland cement; and non-hydraulic cement, which only sets when dry. World cement production is about four billion tonnes per year, with China producing about half of the global total. Cement production is also a major contributor to climate change due to the carbon emissions from the cement kiln firing process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

28 views1 pageCement - Wikipedia

Cement - Wikipedia

Uploaded by

firosaahCement is a binder used in construction that sets and hardens when mixed with water and aggregates like sand and gravel. When cement is mixed with fine aggregates it produces mortar, and when mixed with sand and gravel it produces concrete, which is one of the most widely used materials in the world. There are two main types of cement: hydraulic cement, which sets even when mixed with water, like Portland cement; and non-hydraulic cement, which only sets when dry. World cement production is about four billion tonnes per year, with China producing about half of the global total. Cement production is also a major contributor to climate change due to the carbon emissions from the cement kiln firing process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Cement

Article Talk

For other uses, see Cement (disambiguation).

A cement is a binder, a chemical substance used for

construction that sets, hardens, and adheres to other

materials to bind them together. Cement is seldom

used on its own, but rather to bind sand and gravel

(aggregate) together. Cement mixed with fine

aggregate produces mortar for masonry, or with sand

and gravel, produces concrete. Concrete is the most

widely used material in existence and is behind only

water as the planet's most-consumed resource.[2]

Cement powder, here conditioned in

bag, ready to be mixed with aggregates

and water. Dispersing dry cement dust

in the air should be avoided to prevent

health issues.[1]

Cement block construction examples

from the Multiplex Manufacturing

Company of Toledo, Ohio, in 1905

Cements used in construction are usually inorganic,

often lime or calcium silicate based, which can be

characterized as hydraulic or the less common non-

hydraulic, depending on the ability of the cement to

set in the presence of water (see hydraulic and non-

hydraulic lime plaster).

Hydraulic cements (e.g., Portland cement) set and

become adhesive through a chemical reaction between

the dry ingredients and water. The chemical reaction

results in mineral hydrates that are not very water-

soluble and so are quite durable in water and safe from

chemical attack. This allows setting in wet conditions or

under water and further protects the hardened material

from chemical attack. The chemical process for

hydraulic cement was found by ancient Romans who

used volcanic ash (pozzolana) with added lime (calcium

oxide).

Non-hydraulic cement (less common) does not set in

wet conditions or under water. Rather, it sets as it dries

and reacts with carbon dioxide in the air. It is resistant

to attack by chemicals after setting.

The word "cement" can be traced back to the Ancient

Roman term opus caementicium, used to describe

masonry resembling modern concrete that was made

from crushed rock with burnt lime as binder. The

volcanic ash and pulverized brick supplements that

were added to the burnt lime, to obtain a hydraulic

binder, were later referred to as cementum, cimentum,

cäment, and cement. In modern times, organic

polymers are sometimes used as cements in concrete.

World production is about four billion tonnes per year,

[3]

of which about half is made in China.[4][5] If the

cement industry were a country, it would be the third

largest carbon dioxide emitter in the world with up to

2.8 billion tonnes, surpassed only by China and the

United States.[6] The initial calcination reaction in the

production of cement is responsible for about 4% of

global CO2 emissions.[7] The overall process is

responsible for about 8% of global CO2 emissions, as

the cement kiln in which the reaction occurs is typically

fired by coal or petroleum coke because a luminous

flame is required to heat the kiln by radiant heat

transfer.[8] As a result, the production of cement is a

major contributor to climate change.

Chemistry

History

Modern cements

Setting, hardening and curing

Safety issues

Cement industry in the world

Environmental impacts

Ecological cement

See also

References

Further reading

External links

Last edited 1 day ago by 2001:8003:EDE3:970…

Content is available under CC BY-SA 4.0 unless

otherwise noted.

Terms of Use • Privacy policy • Desktop

You might also like

- Design of Cement PlantDocument89 pagesDesign of Cement PlantSabharishMurali100% (6)

- Wet and Dry Installation of Natural Stone CladdingDocument12 pagesWet and Dry Installation of Natural Stone CladdinglakshmiNo ratings yet

- Concrete Log BookDocument2 pagesConcrete Log Bookbhct1987100% (1)

- Cement 1Document2 pagesCement 1joerenne laporeNo ratings yet

- Non-Hydraulic Cement Does Not Set in Wet Conditions or Under Water. Rather, It Sets As ItDocument1 pageNon-Hydraulic Cement Does Not Set in Wet Conditions or Under Water. Rather, It Sets As ItANo ratings yet

- CementDocument4 pagesCementnaeem.soomro13No ratings yet

- Concrete 1Document3 pagesConcrete 1joerenne laporeNo ratings yet

- ConcreteDocument2 pagesConcreteJoerenne LaporeNo ratings yet

- ConcreteDocument1 pageConcreteXairus SureuyNo ratings yet

- Calorific Value of CoalDocument1 pageCalorific Value of CoalVisnu SankarNo ratings yet

- Kevs Hw2 MTLDocument3 pagesKevs Hw2 MTLGerald CatiponNo ratings yet

- Chemistry: Hydraulic BinderDocument5 pagesChemistry: Hydraulic BinderMohit MittalNo ratings yet

- VND Openxmlformats-Officedocument Presentationml Presentation&rendition 1Document29 pagesVND Openxmlformats-Officedocument Presentationml Presentation&rendition 1jeffmugacha6No ratings yet

- UNIT 1 Concrete IngredientsDocument4 pagesUNIT 1 Concrete IngredientsKouame AdjepoleNo ratings yet

- Environmental Impact of Concrete: Dan Babor, Diana Plian and Loredana JudeleDocument9 pagesEnvironmental Impact of Concrete: Dan Babor, Diana Plian and Loredana JudeleggggNo ratings yet

- Chemistry Investigatory Project: Setting of CementDocument17 pagesChemistry Investigatory Project: Setting of CementAnonymous s8OrImv8No ratings yet

- 02 - GNP 19-20 PIK 2 TUGAS KAMIS 26 MARET 2020 - Cement - Wikipedia - YELLOW HIGHLIGHTEDDocument23 pages02 - GNP 19-20 PIK 2 TUGAS KAMIS 26 MARET 2020 - Cement - Wikipedia - YELLOW HIGHLIGHTEDTilana maduraniNo ratings yet

- What Is Concrete?Document5 pagesWhat Is Concrete?tracyvanaNo ratings yet

- Concrete Notes and InformationDocument31 pagesConcrete Notes and InformationkevinNo ratings yet

- Cement (Disambiguation) ConcreteDocument19 pagesCement (Disambiguation) ConcreteDoris RiveraNo ratings yet

- Opus Caementicium: Ancient AdditivesDocument5 pagesOpus Caementicium: Ancient AdditivesShah KhanNo ratings yet

- Cement: Jump To Navigationjump To SearchDocument2 pagesCement: Jump To Navigationjump To SearchJ O M A RNo ratings yet

- Binder Sets Materials Aggregate Mortar Concrete Inorganic Lime Calcium Silicate Hydraulic and Non-Hydraulic Lime PlasterDocument1 pageBinder Sets Materials Aggregate Mortar Concrete Inorganic Lime Calcium Silicate Hydraulic and Non-Hydraulic Lime Plasterpress_jakeNo ratings yet

- Unit - I CCSC NotesDocument8 pagesUnit - I CCSC Notesbhavuk purbiaNo ratings yet

- C2 MAJOR FINAL DOCmentDocument72 pagesC2 MAJOR FINAL DOCmentVamshi ChinthalaNo ratings yet

- Concrete Is ADocument5 pagesConcrete Is Ariz2010No ratings yet

- Introduction of Cement: When Was Cement Begin?Document11 pagesIntroduction of Cement: When Was Cement Begin?مايف سعدونNo ratings yet

- Chemistry of Portland CementDocument30 pagesChemistry of Portland Cementehimegbececilia2307No ratings yet

- Concrete 2Document6 pagesConcrete 2Shah KhanNo ratings yet

- Running Head: CEMENT AND CONCRETE 1Document9 pagesRunning Head: CEMENT AND CONCRETE 1Klick n KonnectNo ratings yet

- Concrete Is A Construction Material Composed ofDocument4 pagesConcrete Is A Construction Material Composed ofCristine CendanaNo ratings yet

- Plastic in ConcreteDocument35 pagesPlastic in ConcretesujithNo ratings yet

- Cement: For Other Uses, See - Not To Be Confused With orDocument1 pageCement: For Other Uses, See - Not To Be Confused With orAya MandiNo ratings yet

- What Is Concretexupum PDFDocument8 pagesWhat Is Concretexupum PDFvoicebeer3No ratings yet

- Effect of Rapidite On Strength of ConcreteDocument66 pagesEffect of Rapidite On Strength of ConcreterizwansstaadNo ratings yet

- Major Prorject DocumentaationDocument20 pagesMajor Prorject DocumentaationNaveen PipperaNo ratings yet

- 4Document64 pages4Sameer RehaanNo ratings yet

- Concrete Technology Dr. Eethar Thanon DawoodDocument8 pagesConcrete Technology Dr. Eethar Thanon DawoodMustafa AhmadNo ratings yet

- Introduction and Composition of Portland CementDocument12 pagesIntroduction and Composition of Portland CementHamidNo ratings yet

- Concrete 12Document3 pagesConcrete 12Joerenne LaporeNo ratings yet

- Advanced CementDocument7 pagesAdvanced CementMohamed AhmedNo ratings yet

- Cement 12Document2 pagesCement 12joerenne laporeNo ratings yet

- Cement ManufacturingDocument63 pagesCement Manufacturingcandan.erkenNo ratings yet

- Concrete 12Document3 pagesConcrete 12joerenne laporeNo ratings yet

- Self Compacting ConcreteDocument101 pagesSelf Compacting ConcreteMOHAMMED RAYYAN N100% (1)

- Opus Caementicium: Eddystone LighthouseDocument5 pagesOpus Caementicium: Eddystone LighthouseShah KhanNo ratings yet

- Why Matters in Concrete: ChemistryDocument6 pagesWhy Matters in Concrete: Chemistryjulianc08No ratings yet

- La Quimica Del ConcretoDocument7 pagesLa Quimica Del ConcretoDAVID EDUARDO GUZMAN ROJASNo ratings yet

- Concrete: Concrete Is A Composite Material Composed of Fine and CoarseDocument36 pagesConcrete: Concrete Is A Composite Material Composed of Fine and CoarseclubmailusNo ratings yet

- Pamantasan NG Lungsod NG Maynila: Cement Industry 1Document23 pagesPamantasan NG Lungsod NG Maynila: Cement Industry 1Tamara HamiltonNo ratings yet

- Concrete Is The Second Most Consumed MaterialDocument5 pagesConcrete Is The Second Most Consumed MaterialJomarie Dela Vega GañalongoNo ratings yet

- 1.what Is Masonry ?Document9 pages1.what Is Masonry ?Nguyễn Đăng MinhNo ratings yet

- Cement and ConcreteDocument14 pagesCement and Concretecarlosfilipegomes3994No ratings yet

- Pamantasan NG Lungsod NG Maynila: Cement IndustryDocument20 pagesPamantasan NG Lungsod NG Maynila: Cement IndustryMaria Cecille Sarmiento GarciaNo ratings yet

- Why Chemistry Matters in ConcreteDocument6 pagesWhy Chemistry Matters in Concreteyinglv100% (1)

- Portland Cement BlendDocument6 pagesPortland Cement Blendnaeem.soomro13No ratings yet

- CementDocument36 pagesCementVignesh RamalingamNo ratings yet

- Binder Romans Masonry Concrete Lime Volcanic Ash BrickDocument1 pageBinder Romans Masonry Concrete Lime Volcanic Ash Brickmeet92No ratings yet

- Problems & Solutions of Cement IndustriesDocument2 pagesProblems & Solutions of Cement Industriesglangstieh50% (4)

- Hydraulic and Non-Hydraulic Lime Plaster: Opus CaementiciumDocument1 pageHydraulic and Non-Hydraulic Lime Plaster: Opus Caementiciumjoshdax2No ratings yet

- Manufacture of CementDocument16 pagesManufacture of CementBalenNo ratings yet

- The end of concrete: Pros and cons of an unsuccesful technologyFrom EverandThe end of concrete: Pros and cons of an unsuccesful technologyRating: 1 out of 5 stars1/5 (1)

- Part IV Earthwork QuantitiesDocument72 pagesPart IV Earthwork QuantitiesAlemayehu Miteku100% (1)

- Chapter11 PDFDocument88 pagesChapter11 PDFShajit KumarNo ratings yet

- W1 W2Document8 pagesW1 W2YesBroker InNo ratings yet

- V Series SDocument18 pagesV Series SAbdul KarimNo ratings yet

- CP6 Troubleshooting Precast Production - FINALDocument54 pagesCP6 Troubleshooting Precast Production - FINALariNo ratings yet

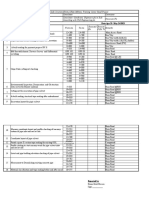

- CHK ListDocument38 pagesCHK Listsanjaya tamangNo ratings yet

- Finsa LeedDocument5 pagesFinsa LeedMahmoud MassadNo ratings yet

- BASF Masterseal 530Document2 pagesBASF Masterseal 530JM SubionNo ratings yet

- Surveying Monthly Report MAY 2023.Document3 pagesSurveying Monthly Report MAY 2023.AshebirNo ratings yet

- M (V) - 8 Er CraneDocument41 pagesM (V) - 8 Er CranehamzehNo ratings yet

- Unit Rates & Cost Establishment For SSIP AGPDocument65 pagesUnit Rates & Cost Establishment For SSIP AGPketemaNo ratings yet

- 10 01 24 Btsfinal-1Document312 pages10 01 24 Btsfinal-1SUMIT GEETENo ratings yet

- Cfi Building Construction Project: Preliminary Progress ReportDocument10 pagesCfi Building Construction Project: Preliminary Progress ReportKarthick NandakumarNo ratings yet

- Presentation On WWR 19-1-2021Document45 pagesPresentation On WWR 19-1-2021Tanvir MahatabNo ratings yet

- JSA IndexDocument2 pagesJSA IndexDie HArdNo ratings yet

- Building/Construction Cost Guidelines: Consumer GuideDocument12 pagesBuilding/Construction Cost Guidelines: Consumer GuideBranZzZzZNo ratings yet

- Is 800 2007Document106 pagesIs 800 2007Gopiram AddalaNo ratings yet

- Take Off SheetDocument3 pagesTake Off SheetIchigo KurosakiNo ratings yet

- Specification A10 Ips FlooringDocument1 pageSpecification A10 Ips Flooringharishram123456No ratings yet

- Roof Top Air Conditioner: Ducted SystemDocument13 pagesRoof Top Air Conditioner: Ducted SystemDesign Group India IndiaNo ratings yet

- Transmission Line Supports.Document37 pagesTransmission Line Supports.ninadpujara2007No ratings yet

- 319 Equipment Installation Course DescriptionDocument2 pages319 Equipment Installation Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- The Factory Manufactures EGA Sheets For RoofingDocument4 pagesThe Factory Manufactures EGA Sheets For Roofingmesfinke100% (1)

- Annex 13 - Case Study On TunnelsDocument31 pagesAnnex 13 - Case Study On TunnelslucaNo ratings yet

- Sppss-rmaeg-Ist-dia-003 Rev - A Vendor Submission For Wiring Diagram For Gas Chromatography SystemDocument7 pagesSppss-rmaeg-Ist-dia-003 Rev - A Vendor Submission For Wiring Diagram For Gas Chromatography SystemFershaalNo ratings yet

- Dealing With Pre-Erection and Erection Issues of Segmental Bridge (S Rastogi AECOM)Document49 pagesDealing With Pre-Erection and Erection Issues of Segmental Bridge (S Rastogi AECOM)ShaileshRastogiNo ratings yet

- ApprovedSchA (Pre-Competence) 201807Document10 pagesApprovedSchA (Pre-Competence) 201807Red AsokaNo ratings yet

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet