Professional Documents

Culture Documents

00628068, Faizan Abdul Aziz, 1446-Gulf Academy of Safety

00628068, Faizan Abdul Aziz, 1446-Gulf Academy of Safety

Uploaded by

Mohammad Awees SanadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

00628068, Faizan Abdul Aziz, 1446-Gulf Academy of Safety

00628068, Faizan Abdul Aziz, 1446-Gulf Academy of Safety

Uploaded by

Mohammad Awees SanadiCopyright:

Available Formats

Unit IG2: Risk assessment

Declaration: By submitting this assessment (Parts 1 – 4) for marking I declare that it is entirely my own work. I understand that falsely claiming that the work is

my own is malpractice and can lead to NEBOSH imposing severe penalties (see the NEBOSH Malpractice Policy for further information).

Important note: You must refer to the document ‘Unit IG2: risk assessment – Guidance and information for learners and Learning Partners’ while completing all

parts of this assessment. Your Learning Partner should provide you with a copy, but it can also be downloaded from the relevant resources section for this

qualification on the NEBOSH website.

Part 1: Background

You should aim to complete this section in 150 - 200 words.

Topic Comments

Name of organisation* SK Fabrications Pvt Ltd.

Site location* Navi Mumbai, Maharshtra, India.

The organizations consists of manager, Lead project Engineer, safety Supervisor, design engineer, fire

Number of workers Officer, Fabricator, fitter, helper, welder, crane and forklift operator,Other workers

and admin staffs which sumps upto strenght of 75 workers.

Date of inspection:- 12th June 2023.

Objective of this inspection:- The objective of this inspection is to inspect and identify the hazards and risk

associated with the work activities which are performed in the the oganisation so as to provide sufficient

and adequate control measures againts them in order to prevent and avoid any accidents or incidents in near

future simultaneously improving the safety standard of the company.

The organisation works in followig shift patterns:- 1.

06.00AM to 03.00PM

General description of the organisation 2. 02.00PM to 11.00PM

Description of SK Fabricatiions Pvt Ltd:- Sk Fabrications is a Leading manufacturer of steel structures

with ISO 9001:2007 . With a vast, spacious warehouse and a two-story building with a bottom level

designated for a fabrication yard, a store room, and a dining area, the property is

27,000 square feet. The design department is assigned to the first floor, while the administration and other

cabinets are on the second story. Being a 27-year-old company, They have extensive

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 1 of 21

knowledge in this industry, as well as the most cutting-edge facilities and room to handle any volume of

work. It performs steel structure canopy work, including I-beam, Angles, Channels, Flat Bars, etc., for

various kinds of factories and buildings. The organization produces roughly 150 structural canopies per

month and consumes 20 tons of steel per month.

Major Activities Performed are as follows

WELDING: Steel fabrication is a whole of welding, Used for joining two elements together with a strong

connection.

GRINDING:-Grinding process is an abrasive machining process that uses a grinding wheel as the cutting

tool to get high quality surface finish, accuracy in the dimension and shape of the workpiece.

SHOT BLASTING: Steel sections are blasted with shots in order to prepare them for fabrication and

provide clean finish.

COATING/PAINTING: It is carried out towards the end of the fabrication process to protect the steel

against corrosion and fire.

BENDING: Bending process is carried out by a press brake machine to get the specified radius required for

work.

CUTTING: Steel sections are easier to work with when they are cut to length prior to fabrication which is

done here by using a power hacksaw.

CRANE OPERATION: Cranes are used for lifting equipment for overhead works. FORKLIFT

OPERATION: forklift are used for loading and unloading of the metal parts.

Equipments which are used in the organisation are:- Press brake machine, Power Hacksaw,Flux core

welding machine, Power drill press, Grinding machine, Lathe machine, Crane and forklift.

I have covered the following site for my risk assessment.

Fabrication yard

Work at height site

Description of the area to be included in the risk

Grinding cutting site

assessment Crane operaitng site

Welfare area.

Kitchen area.

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 2 of 21

The company is particularly dedicated to ensuring client happiness. where productivity and quality

Any other relevant information are never compromised. The firm places a high priority on employee health and safety. Regular health

checks are performed with associated labs.

* If you’re worried about confidentiality, you can invent a false name and location for your organisation but, all other information provided must be factual.

You should aim to complete this section in 100 - 200 words.

Note: this section can be completed after you have competed your risk assessment.

To carry out the risk assessment I have gone through the below website

https://www.hse.gov.uk/simple-health-safety/risk/steps-needed-to-manage-risk.htm

Steps for the risk assessment:-

1. Identify the hazards

2. Who might be harmed

3. Evaluate the risk

4. Record the findings

Outline how the risk assessment was

5. Review

carried out this should include:

sources of information Before physically inspecting the workplace, I spoke with the manager, design engineers, and safety supervisor to

consulted; learn more about the work activities and their procedures. I also looked through the organization's safety manual,

who you spoke to; and which contains previous risk assessments, SOPs, and PtWs, as well as accident and illness records.

how you identified:

- the hazards; In order to establish appropriate control measures, I have also spoken with the workers who are executing their

- what is already being individual responsibilities to learn about the genuine difficulties and worries they are experiencing.

done; and

- any additional I have looked to the following websites to determine the best controls for the occupational hazards that have been

identified:

controls/actions that may

be required. FIRE HAZARD CONTROL MEASURES

https://www.hseblog.com/control-measures-to-minimize-the-risk-of-fire-in-a-workplace/

HAZARDOUS SUBSTANCE CONTROL MEASURES

https://www.hse.gov.uk/coshh/basics/control.htm

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 3 of 21

ELECTRIC HAZARD CONTROL MEASURES

https://www.safetynotes.net/electrical-hazards-and-control-measures/ NOISE

HAZARD CONTROL MEASURES

https://www.osha.gov/noise/exposure- controls#:~:text=Choose%20low%2Dnoise%20tools%20and,or%20isolate

%20the%20noise%20source.

VIBRATION HAZARD CONTROL MEASURES

https://www.hse.gov.uk/vibration/hav/advicetoemployers/controlrisks.htm

SLIP AND TRIP CONTROL MEASURES

https://www.highspeedtraining.co.uk/hub/preventing-slips-trips-falls/

HEALTH HAZARD CONTROL MEASURES

https://nchh.org/information-and-evidence/learn-about-healthy-housing/health-hazards-prevention-and- solutions/

WORK EQUIPMENT HAZARD CONTROL MEASURES

https://www.hseblog.com/the-mechanical-machinery-hazards/

MSD HAZARD CONTROL MEASURES

https://www.msdprevention.com/MSD-Hazards-and-Controls/

Already applied control measures are as follows

Fire extinguisher and fire watcher are availible

Banks man and riggers are available

Restriction to authorized entried for dangerous equipments.

Sufficient PPE are provided

Trainings are given to the workers regarding their respective task Break

and job rotation system implemented

Additional control measures are as follows

1. Repairing the pipeline leak in the hydrant system

Learner number: Learner Faizan Abdul Page 4 of

Supplying double insulation wire for welding equipment

Providing soundproof chambers where employees can unwind during breaks

Ensuring that roads are in good shape 5.Installation of a suitable ventilation system

Health examinations will be conducted every two months.

Instead of the fixed chairs, use moving, arm, and footrest chairs that may be adjusted in height

Switching to disposable glasses from steel ones

Installing interlocking systems, including laser safety equipment.

Learner number: Learner Faizan Abdul Page 5 of

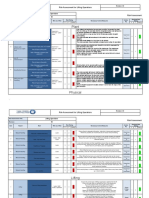

Part 2: Risk Assessment

Organisation name: SK Fabrications Pvt Ltd.

Date of assessment: 12th June 2023

Scope of risk assessment: Fabrication Area,Work at height site,Grinding cutting site,Crane operaitng site,Welfare area and Kitchen area.

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

1. Hazard Who might be harmed? 1. Fire extinguishers are 1. Repairing the leakage in the 25 Days Manager

category: installed at appropriate areas hydrant system’s pipeline

Nearly all of the employees in

the company, including the 2. Fire watchers are 2. Providing fire hose at the missing 7 Days Manager

management, the safety appointed at hot work area that is store room site

Fire Hazard:

members, the staff, and all other activitie

employees, are affected when a 3. Scheduled checklist to be

fire spreads accidentally. 3. Safe instructions and training maintain for checking electricity, 7 Days Fire Officer

It was discovered given to the workers. pressure and water level in the tank

that the fire hose How: Due to a leak in the for hydrant system.

is missing from pipeline of the hydrant system,

the store site and there is a possibility of a fire 4. Scheduled inspection of auto

that there is a leak danger at work since it will not start control of Hydrant Fire 7 Days Fire Officer

in the pipeline of function in an emergency, which Fighting system

the hydrant fire could result in a serious fire that

results in injuries or fatalities.

fighting system,

which is

preventing the

maintenance of

Learner number: Learner Faizan Abdul Page 6 of

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

the required

pressure.

2. Hazard Who might be harmed? 1. Appropriate PPE’S are 1. Maintenance and repair of the 15 Days Project

Category: been provided to the dustsuction pipe Engineer

operator such as

Hazardous respiratory mask, safety 2. Provision of proper Manager

1. Shotblasting machine 25 Days

Substance goggle,apron and hand ventilationsystem

hazard operator

gloves

3. Scheduled inspection for Safety

2. Otherworkers working themachine to be organized 1 Week Supervisor

I checked it out around the machine 2. Frequent breaks and

and discovered jobrotation to be Safety

that the shot scheduled 4. Safe training and instructions to 20 Days Supervisor

blasting How :As the dust leakage has begiven

machine's dust been observed from the

suction hose has machineit might cause Safety

5. Health checks should be 2 Months

a defect, which inhalation of dust resulting in Supervisor

health issues to the workers arrangedonce in a two month

has caused dust

leakage to be exposed to it such as lungs

seen. problem, Eye problem and skin

problem

3.Hazard Who might be harmed? 1. Stop the welding 1. Competent welder to be 15 Days Manager

Category: activityimmediately appointed

1. Welder

Electricity 2. Supervisor 2. Discussing the issue with 2. Provision of double insulation 10 Days Manager

Hazard thesupervisor wireof welding machine

3. Other Workers

Learner number: Learner Faizan Abdul Page 7 of

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

At the welding 3.Monthly inspection of 1 Month Safety

site, it was noticed weldingmachine by Supervisor

that the insulation How: There is a danger of 3.Fire watch appointed authorized Person

on the welding electrocution because the live 4.Appropriate PPE are 15 Days Safety

4.Providing proper training

wire had been cut, component is exposed as a result provided to the welder such Supervisor

of the wire's insulation being andcommunication to the

exposing the live asrubber gloves and safety welder

part of the wire. severed, which can result in goggle

shock, paralysis, and even

fatality.

4.Hazard Who might be harmed? 1. Grinding workers are 1. Provision of sound proof 45 Days Manager

Category: beenprovided with PPE cabinswhere workers can rest

1. Grinding machine

Such as earplug or ear when on breaks

Noise Hazrad operator muffs

2. Regular inspection and

During the maintenance to be carried out 10 Days Safety

2. Other workers

examination, it 2. Individual dosimeter forgrinding machine Supervisor

was discovered working around. given tothe workers to

that the grinding detect the abnormal

area's machine 3. Clients and visitors 3. Provide safety training and

noise in case

was producing instructions to the workers 20 Days Safety

noise that was How: The grinding 3. Frequent breaks to be regardingnoise hazard. Supervisor

over 85 dB. machine is making an scheduled for workers

abnormally high amount 4. Health examniation to be

of noise—more than 85 done once in every three

dB. month. 3 Months Safety

Above persons Supervisor

exposed to this noise

may experience

temporary and

permanent hearing

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 8 of 21

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

loss, ringing in the

ears, tinnitus, and

stress.

5.Hazard Who Might be harmed? 1. Providing appropriate PPE 1. Maintenance of the drill 1 Week Safety

Category suchas vibration absorption machineto be done periodically Supervisor

1. Drill machine workers

gloves, safety shoes and safety

Vibration Safety

goggles 15 Days

hazard 2. Providing training to the Supervisor

How::Workers exposure to workersregarding vibration risk

I saw that the

excessive vibration brought on

power drill 2. Vibration meters provided

by constant usage of a drill 2 Months Safety

machine at the to theoperator for safe 3. Health checks to be

machine may cause a number Supervisor

fabrication yard working organizedonce in two month

of health problems, including

had considerable

joint discomfort, soft tissue

vibration and that 4. Providing job rotation and 1 Day

damage to the whites of the

the workers were frequentbreaks to the workers Manager

fingers from vibration,

working

shoulder pain, and nerve

nonstop..

damage.

6.Hazard Who Might be harmed? 1. Barricading and putting 1. Spillage plan to be properly 10 Days Safety

Category signage around the area where implemented Supervisor

1. Machine

cables andmetal parts are lying

operators Safety

2. Regular and proper Daily

2. Providing information housekeepingto be maintained Supervisor

Slip trip 2. Supervisor

and safetraining to the

hazard Safety

3.pedestrians

Daily Supervisor

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 9 of 21

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

During the workers before entering 3. Restrict unauthorized entries at

inspection, it was the site thesite.

found that some How :Workers may become Daily Safety

scrap metal parts caught in the trailing cables and Supervisor

were left in the metal components and trip or 3.Providing appropriate 4. Supervision to be ensured that

walkways and fall, which could result in PPE to theworkers like theproper housekeeping is been 10 Days

that the drill and fractures, sprains, and bruises.. antiskid shoes done Manager.

grinding

machine's cable 5. Provision of Sufficient

wires were Illuminationin the walkways

trailing in the

walkways.

7. Hazard Who might be harmed? 1. Properly housekeeping to 1. Replacing steel glasses 10 Days Manager

category: be doneproperly of the with disposable glasses

1.All the workers in the eating utensils

organization

10 Days Manager

2. Provision of sufficient number

Health hazard

2. Instructions given to the of dustbin

During my How : Due to an outdated workersregarding personal

hygiene like washing and 1 Week Manager

inspection, I water filter, water is not 3. New and proper standard filter

discovered that appropriately filtered and may sanitizing hand properly

tobe installed in the water purifier

the water cause health problems like

purifier's filter diarrhea, cholera, and typhoid.

life had expired Viruses or diseases may spread 4. Monthly water testing to

25 Days Safety

and steel drinking through steel drinking glasses. beorganized by affiliated supervisor

glasses were labs

being

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 10 of 21

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

utilized in the Safety

dining room. supervisor

5. Sanitizing and cleaning of Daily

theeating area to be done on

dailybasis

Safety

4 Months supervisor

6. Pest control to be done

twice ayear

7 Days Safety

7. Proper instruction and training supervisor

tobe provided to the workers and

theeating area staff.

8. Hazard Who might be harmed? 1. Competent crane 1. Fixing and repairing outriggers 7 Days Safety

category: operator isappointed properly Supervisor

1.Crane Operator

Work Safety

Equipment 2.Riggers Daily

2. Informed the 2. To organize weekly inspection Superviso

Hazard supervisor about the of the crane

3.Other workers

workingaround the issue

crane Crane

3. Proper supervision during the Operator

Daily

3. Banks man and activity should be provided

During the How:Due to the crane's riggers areprovided

inspection at the instability, it is possible for

crane operation 4. Barricading the area when crane Daily Safety

it to topple over and for Superviso

site, it was 4. Safe training and operations are carried out

cargo or objects to fall on

discovered that workers, inflicting severe instructions aregiven to Crane

one of the injuries such fractures and the operator Daily Operator

four outriggers is

not extending

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 11 of 21

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

and is not crushing, as well as maybe 5.Pre use inspection of the crane

functioning fatalities. to be done before the use of the

properly, which crane Safety

could impair the Supervisor

Dialy

stability of the

crane. 3.Removing unnecessary people

from the site during the operation

9. Hazard Who might be harmed? 1. Stop the continuous DSE 1. Replace the fixed chairs with height 15 Days Manager

Category: activities adjusting, revolving and arm and

1.Admin Staff footrest chairs

MSD Hazard 2. Give frequent breaks

2.Design Engineer

2. Provision of met finish on desk 10 Days Manager

It had been noted 3. Train the workers

that the DSE regarding MSD’S 3. Scheduled breaks to be

stations' seats How: The utilization of fixed organizedfor workers 5 Days Safety

were not seats that cannot be adjusted in Supervisor

ergonomically height or rotated can lead to 4. Health checks to be organized

designed, which MSDs like back discomfort, once in a two month for the 3 Months Safety

made it neck pain, eye strain, shoulder workers Supervisor

uncomfortable for pain, slide discs, and weariness.

the staff members

working there

without regular

breaks.

10. Hazard Who might be harmed? 1. Stop the forklift activity 7 Days Safety

1. Provision of safety speed limit

Category: Supervisor

1. Forklift Operator signs indicating 5km/hr at

Vehicle vehiclepathways

Movement 2. Pedestrian 2. Appoint a competent driver

Hazard Manager

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 12 of 21

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

3. Visitors and Clients 2. Providing proper condition of 15 Days

road

It was noted that 3.Training and instructions Safety

the routes are aboutsafe driving is given. Supervisor

slightly uneven 3. Maintenance of the forklift 8 Days

and the forklift How:The forklift may periodically

was driven down overturn or it may strike a Forklift

them at a high pedestrian or fixed structure, Operator

rate of speed. inflicting injuries and 4. Pre use checks to be carried

Daily

property damage because the outbefore use Manager

pathways where it was 5. Ensuring proper illumination in 10 Days

driven are uneven and it was thepathways

moving at an irregular pace.

11. Hazard Who might be harmed? Manager

1. Stop the press brake 1. Installins interlocking device

Category: 1 Month

1. Press Brake machine machineoperation such as laser system device

operator 2. Regular inspection and

Work Safety

2. supervisor 2. Appoint a competent maintenance of the machine to Supervisor

Equipment 7 Days

operator bedone by authorized person

Hazard

3. Making SOP for press

How:Unintentional movement brakemachine operation Safety

3. Provison of adequate 7 Days

During the can lead to serious injuries, Supervisor

PPE

examination, I including crushing, nipping,

and amputation, if the 4. Proper illumination to be

saw that the

operator's hand or loose ensuredaround the working site for

press brake 4. Instruction and safe 10 Days Manager

clothing safe working condition

equipment at the training to beprovided

cutting area

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 13 of 21

Hazard Who might be harmed and What are you already What further controls/actions Timescales

category and how? doing? are required? for further Responsible

hazard actions to be person’s job

completed title

(within …)

had no safety become caught in the press

devices fitted. brake machine's teeth.

5.Restricting the use of the 5.Maintaining procedure for Safety

15 Days

machineonly for the reporting and replacing Supervisor

authorized person only damagedtools

Learner number: Learner Faizan Abdul Page 14 of

Part 3: Prioritise 3 actions with justification for the selection

Suggested word counts

Moral, general legal and financial arguments for all actions: 300 to 350 words

For EACH action:

Specific legal arguments: 100 to 150 words

Likelihood AND severity: 75 to 150 words

How effective the action is likely to be in controlling the risk: 100 to 150 words

Moral, general legal and financial arguments for ALL actions

Moral, general legal and financial Moral Arguments: It is critical for a organization to guarantee that its employees have adequate health and

arguments safety protections. As whoever joins the organization hopes for a safe and secured workplace to work with.

Employers, on the other hand, the organization have a moral obligation to offer health and safety precautions

in the workplace, as well as to provide adequate working conditions for their employees. Workers in the

company feel comfortable when they work in a safe environment. They will eventually want to work in such

setting and will contribute to the organization's increased performance as well as improved safety culture.

Moral justifications are one reason a business should implement a workplace health and safety policy.

Accidents at work could result in fatalities or very serious injuries. Furthermore, disregarding a worker's life

for any organizational purposes is immoral. Employees are entitled to a safe workplace, but it is also their

responsibility to act in a safe manner while at work. Due to a pipeline failure in the hydrant system, there is

inadequate pressure for the three priorities indicated. It could fail to put out the fire in the event of an

emergency at work, leaving practically all employees with severe burns or even death. Second, a cut in the

insulation of the welding wire may result in fatalities or serious shocks for the operator or any nearby

workers. The third priority mentioned in which the safety device is missing in the press brake machine, In

case of any any unintentional movement it may result in a severe accident where the operator may lose his

hand, may suffer fractures or amputation due to which he will no longer be able to work in the future, Thus

all these factors are not morally correct as per safety perspective and humanity ground.

Legal Arguments: According to a legal argument, if safety regulations are not observed while executing

work-related tasks that could cause serious injuries, illness, loss of life, and property loss, certain laws may

be imposed on the organization. Additionally, the company could be subject to harsh legal penalties like

fines, prohibitions, or jail time, as well as enforcement visits where the

Learner number: Learner Faizan Abdul Page 15 of

authorities could issue a notice of improvement or a warning, which would have an effect on the company's

reputation in the market. Therefore, following the law should be seen as one of the organization's top

priorities in order to avoid legal disputes.

Financial Arguments: Workplace accidents cost the company money in the form of medical and hospital

bills, insurance, compensation, fines, and other expenses. Organizations must invest in putting control

systems in place to prevent such mishaps in order to prevent severe financial damage.

Fixing the hose at the store room location and maintaining the pipelines in the hydrant system will cost

25,000 INR. While a significant fire mishap at work might cause the company to lose 55 lakhs inr in

revenue

The organization will spend 40k INR to install the laser safety device in the press brake machine, which is 60

times less than the expense the organization would incur in the event of an accident while using the press

brake machine.

Providing double insulating wire for a welding machine will only cost 6k inr, but an accident caused by a

live part that was exposed in the wire will cost more than 40 times as much.

In addition to the fees listed above, the Organization would also be required to pay fines as required by law.

coverage for the employees, compensation for the employee, Paid overtime, incentives for

employees to meet goals, and legal representation for cases involving workplace accidents

Justification for action 1

Action Make plans to fix the fire hose at the storage room site and the leak in the hydrant fire fighting system's

pipeline.(Hazard Category 1)

Specific legal arguments The organization is required to ensure that all protective and control measures are taken and maintained in

accordance with ILO recommendation R164 and Section 38 of the 1948 Factory Act in order to control and

prevent the outbreak and spread of fire at the workplace and to provide safe working conditions for the

employees. The employer is legally required to ensure that all corrective and comprehensive measures are

taken at the workplace to control the fire hazard if there is a major fire at work as a result of negligence in the

control measures. These strict actions by the legal

authorities may include fines, imprisonment, and prohibition.

Consideration of likelihood AND severity LIKELIHOOD: Due to a leak in the hydrant fire fighting system's pipeline and the absence of a fire hose at

the store room site, it is possible that a major fire outbreak and spread would occur at the

Learner number: Learner Faizan Abdul Page 16 of

workplace. In this case, the organization might be unable to put out the fire because it lacks the pressure and

force needed to do so, and the fire at the store room site would not be contained because the fire hose was

missing.

SEVERITY: The severity of the fire hazard is also high because a malfunctioning fire hydrant system might

result in a fire outbreak and large explosions as the required pressure is not maintained as well as missing fire

hose the fire outbreak will not be controlled leading to a fire

accident which might result into serious injuries, burns, property damage and even fatalities.

How effective the action is likely to be in

1. By repairing and fixing the leaks in the fire hose and hydrant pipelines at the store room site, respectively,

controlling the risk. This should include:

the firefighting system will perform better and be more effective. In the event of a major fire or explosion,

the intended impact of the action; the pipeline will maintain the necessary pressure and force, allowing the fire to be easily controlled and

justification for the timescale that you prevented.

indicated in your risk assessment; and 2. Taking into account the possibility and seriousness of the hazard, a 25-day timeframe is recommended for

whether you think the action will fully repairing the pipeline leak and repairing the fire hose. As it would also require purchase department

control the risk. approval as well as it will take time to find a competent contractor to perform the task.

3. By repairing the leakage in the hydrant fire fighting system pipeline and fixing the hose, It will help to

control the fire at the workplace and will control the risk fully.

Justification for action 2

Action Action of installing the press brake machine with a interlocking device such as laser safety device.( Hazard

Category 11)

Specific legal arguments According to the DANGEROUS MACHINE ACT 1983 and the DRAFT OCCUPATIONAL SAFETY

AND WORKING CONDITION CODE OF 2019, the employer has a responsibility to make sure that no

employee hired to work at their place of business suffers harm. They should also make sure that any

dangerous machines used at the workplace have all necessary safeguards and safety measures in place to

prevent this. Therefore, installing a laser safety device in the press brake

machine will protect the worker from suffering severe injuries like crushing and amputation, and it

Learner number: Learner Faizan Abdul Page 17 of

will also provide safe working conditions so as to avoid any legal strict actions such as penalties,

Prohibition and imprisonment

Consideration of likelihood AND severity Likelihood:- Since there are no safety devices put in the press brake machine, the likelihood of this accident

is very high. There is no restriction for the inadvertent movement of the machine, thus the worker could

damage himself by catching his hand or a piece of loose cloth between the teeth. This could cause crushing

injuries or even an amputation.

Severity:- The severity of this risk is very high because any unintentional movement while operating the

press brake machine could result in the operator injuring himself by catching his hands or loose clothing in

the machine, which could crush the operator's hand and require an

amputation. Additionally, workers who are injured in this accident may never again be able to use their hands

for work.

How effective the action is likely to be in

1. The intended impact of installing a laser safety device in the press brake machine will ensure the safety of

controlling the risk. This should include:

the operator operating the press brake machine from an accident which may cause severe injuries, crushing

the intended impact of the action; and amputation due to any unintentional movement of the machine.

justification for the timescale that you

2. The timescale suggested for installing a laser safety device in the press brake machine is 1 month as it

indicated in your risk assessment; and

needs approval from the manager and also from other departments for purchasing and installing it.

whether you think the action will fully

control the risk. 3. The action of installing the laser safety device in the press brake machine will fully control the risk to the

operator against trapping his hand or loose clothes in the machine and causing severe injuries.

Justification for action 3

Action Making the arrangement for double insulating wire of welding machine .( Hazard Category 3)

Specific legal arguments According to ILO Convention C155 and Recommendation R164, it is the responsibility of the employer to

provide the safe working conditions to the employees and ensure their safety. ICE 61140 applies to the

protection of people and animals against electric shock and provides fundamental principles and safety

requirements to the worker against electric hazards. If a workplace accident occurs as a result of a live part

being exposed in the welding machine's wire, it

means that the employer failed to take the necessary safety precautions, which is a violation for which the

organization risked harsh penalties like suspension, fines, and imprisonment.

Learner number: Learner Faizan Abdul Page 18 of

Consideration of likelihood AND severity Likelihood:- Since welding is the most frequent activity at the workplace, the likelihood of the hazard is very

significant. The operator and other workers around may come into contact with the live part of the welding

machine wire, which could cause a serious accident. The live component of the welding machine's wire,

which is exposed owing to a cut in the insulation, could hurt the operator and other nearby workers and result

in serious injuries like shock and electrocution as well as fatalities if the wire is not replaced with double

insulating wire.

Severity:- The severity of this hazard is very high because the operator and other nearby workers could be

exposed to the welding machine's live wire, which could cause serious health problems

like shock, electrocution, and paralysis, which could permanently damage a worker's body parts or even

cause death.

How effective the action is likely to be in

1. By providing the double insulating wire for the welding machine will prevent the operator and other

controlling the risk. This should include:

workers working around from getting electric shock, paralysis and also loss of life as there will be no live

the intended impact of the action; part exposed in the wire of the welding machine.

justification for the timescale that you

2. This action should be done on immediate basworker is as it is highly dangerous and life threatening

indicated in your risk assessment; and

to the operator and the workers working around the welding machine, So the time scale suggested for

whether you think the action will fully

control the risk. the same is of 10 days.

3. The action of providing the double insulating wire for the welding machine will fully control the risk to

operator and other workers working around the welding machine from getting electrocution as there will be

no live part exposed in wire, Thus will save from severe injuries and major accident

Part 4: Review, communicate and check

Suggested word counts for each section:

Planned review date or period and reasoning for this: 50 - 100 words

How the risk assessment findings will be communicated and who needs to know the information: 100 - 150 words

Follow up on the risk assessment: 100 - 150 words.

Planned review date/period with By reviewing the risk assessment, it is possible to determine the success and shortcomings of the hazards

reasoning control measures provided to the organization. The review period schedule for this organization would be 8

months considering the high-risk activities, so the review will be done on 11th February 2024 to see if the

control measures are adequate to prevent the accident. This is

because the workforce and equipment at the organization change as per the requirement.

Learner number: Learner Faizan Abdul Page 19 of

I will make sure that the risk assessment is assessed before the review date, though, if certain occurrences

take place before that time.

1. Increase in the number of accidents and incidents

2. Installation of new machinery and equipments

3. Changes in the rules and regulations.

4. Change in working pattern

5. Too much hiring of new employees.

How the risk assessment findings will be The risk assessment will be communicated in three ways

communicated AND who you need to tell

Verbally:-

I will personally meet with the production manager to discuss the key findings of my risk assessment.

During this meeting, I will go over the risk assessment and the necessary control measures that must be put

in place to lower the risk. I will also recommend that they give the employees who will be implementing the

control measures the task specified in the risk assessment.

In order to explain and summarize the risk assessment to the workers who will start the tasks in person, I will

also hold a toolbox talk for them. I will invite feedback from the workers during the talk to make sure that

everyone is aware of the key findings of the risk assessment.

Written:-

1.I will give the designated team hard and digital copies of the risk assessment during the team meeting, and

meeting minutes will be taken.

2. The organization's workers will receive a summary of the risk assessment, and the full report will be

made available upon request and on the intranet of the business.

3. The main findings of the risk assessment will, if necessary, be sent to the employees' individual email

addresses.

Visually:-

Learner number: Learner Faizan Abdul Page 20 of

1. To ensure that employees can see the risk assessment summary every day, I will display it on the

organization's notice board.

2. During the team meeting, I will make a PowerPoint presentation to the specified team members.

How you will follow up on the risk The organization's risk assessment will be followed up on by maintaining a checklist for each specific task to

assessment to check that the actions determine whether management and employees are putting control measures into place. Examples of items

have been carried out on the checklist include PPEs, PTWs, barricades, defects, etc.

By examining task sites and speaking with the workers, the suggested steps would determine whether the

necessary resources and financial aid from the respective departments have been provided to do the

assignment before the time period ends.

If the task is going to be delayed from the due date, I will investigate the reason for the delay, ask the

designated person why it has been delayed, and determine whether additional resources are

required to do it on time.

Learner number: 00628068 Learner name: Faizan Abdul Aziz Page 21 of 21

You might also like

- Only For Reference Do No Copy 4Document24 pagesOnly For Reference Do No Copy 4Sindhi ChowkrowNo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document18 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Mohammad Awees Sanadi83% (6)

- Audit Manual Version 7Document276 pagesAudit Manual Version 7Tousief Naqvi50% (2)

- Shivshrishti Co-Operative Housing Society LTDDocument6 pagesShivshrishti Co-Operative Housing Society LTDMohammad Awees Sanadi67% (3)

- Risk Comm Plan TemplateDocument2 pagesRisk Comm Plan TemplateSean City-boy Pitt75% (4)

- Open Book Examination: Answer TemplateDocument9 pagesOpen Book Examination: Answer TemplatesuniNo ratings yet

- FenilDocument16 pagesFenilasamrat582No ratings yet

- IG2 06NS Professional Construction Salman 001Document19 pagesIG2 06NS Professional Construction Salman 001NishanthNo ratings yet

- Prince ProjectDocument18 pagesPrince Projectanandmg41No ratings yet

- Ig2 Forms Electronic Submission v5.1 2Document21 pagesIg2 Forms Electronic Submission v5.1 2khanji33383No ratings yet

- Attock Oil Refinery-1Document16 pagesAttock Oil Refinery-1ubaid shahNo ratings yet

- Ali Hussain Learner No, 00804682Document15 pagesAli Hussain Learner No, 00804682Adeniran IdrisNo ratings yet

- Open Book Examination: NeboshDocument4 pagesOpen Book Examination: NeboshRazvan-Teodor PuscasuNo ratings yet

- Part 1Document2 pagesPart 1Mock ProjectNo ratings yet

- Ig2 Forms Electronic Submission v5.1Document14 pagesIg2 Forms Electronic Submission v5.1khalifa983No ratings yet

- Kiran K Aries International Maritime Research Institute 2Document23 pagesKiran K Aries International Maritime Research Institute 2kiranbabuambuNo ratings yet

- Ritesh Ig2 Forms Electronic Submission v3 28.07.2021Document19 pagesRitesh Ig2 Forms Electronic Submission v3 28.07.2021NishanthNo ratings yet

- Risk Assessment IG 2 Arsh 1Document21 pagesRisk Assessment IG 2 Arsh 1NishanthNo ratings yet

- Saeed Sarwar 00574059 ReportDocument20 pagesSaeed Sarwar 00574059 ReportSajidNo ratings yet

- Report 1234Document13 pagesReport 1234Qaisar khanNo ratings yet

- Only For Reference Do No Copy 1Document25 pagesOnly For Reference Do No Copy 1Sindhi ChowkrowNo ratings yet

- Attachment 1Document7 pagesAttachment 1mohammed a.malekNo ratings yet

- Ig2-Mohsin Bashir Report 2Document13 pagesIg2-Mohsin Bashir Report 2Mohsin BashirNo ratings yet

- IG2 OCT Completion Extract PDFDocument9 pagesIG2 OCT Completion Extract PDFNishanthNo ratings yet

- Petroleum RADocument26 pagesPetroleum RAchivalry164No ratings yet

- 1G2 10 Engro@786Document20 pages1G2 10 Engro@786Odoka J Khan100% (1)

- National General Certificate in Occupational Health and Safety Unit NG2: Risk AssessmentDocument17 pagesNational General Certificate in Occupational Health and Safety Unit NG2: Risk Assessmentdeycallmebud100% (1)

- UNIT IG2: Risk Assessment: Global Professional Training CentreDocument3 pagesUNIT IG2: Risk Assessment: Global Professional Training Centrevivek vNo ratings yet

- Assessment IG2 PART-1&2Document27 pagesAssessment IG2 PART-1&2Qais Bani OrabaNo ratings yet

- Ig2 Forms Electronic Submission v5.1Document20 pagesIg2 Forms Electronic Submission v5.1Muhammad Ahmad100% (2)

- Highway RADocument25 pagesHighway RAchivalry164No ratings yet

- Abish Sukumaran .Document18 pagesAbish Sukumaran .Nayanthara VarmaNo ratings yet

- Unit IG2: Risk AssessmentDocument9 pagesUnit IG2: Risk AssessmentVinoth KumarNo ratings yet

- Masoud OssamaDocument24 pagesMasoud OssamaMuhammad IqbalNo ratings yet

- Final DocumentDocument16 pagesFinal DocumentNishanthNo ratings yet

- Mock Exam Questions For Dec 2023 & Jan 2024 BatchDocument4 pagesMock Exam Questions For Dec 2023 & Jan 2024 BatchSefiu JamiuNo ratings yet

- N-CHANNEL 100V - 0.115 - 14A TO-220 Low Gate Charge Stripfet™ Ii Power MosfetDocument8 pagesN-CHANNEL 100V - 0.115 - 14A TO-220 Low Gate Charge Stripfet™ Ii Power Mosfetq_man2512No ratings yet

- 1ig2 Forms Electronic SubmissionDocument20 pages1ig2 Forms Electronic SubmissionAejaz MujawarNo ratings yet

- Task 01 Complete (A, B, C)Document3 pagesTask 01 Complete (A, B, C)Mohd Sami Uddin100% (1)

- Ig1 Igc1 0021 Eng Obe Answer Sheet v1Document3 pagesIg1 Igc1 0021 Eng Obe Answer Sheet v1aslamshajahan20020% (1)

- NEBOSH NGC in Occupational HS Syllabus GuideDocument14 pagesNEBOSH NGC in Occupational HS Syllabus GuideAnushka Seebaluck100% (1)

- Risk Assessment Template 2019Document1 pageRisk Assessment Template 2019baba bebo100% (1)

- Only For Reference Do No Copy 3Document17 pagesOnly For Reference Do No Copy 3Sindhi ChowkrowNo ratings yet

- Design and Implementation of PLC and SCADA Based Monitoring and Control System For Radiological Once Through Ventilation System at BARCDocument17 pagesDesign and Implementation of PLC and SCADA Based Monitoring and Control System For Radiological Once Through Ventilation System at BARCInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dawn FoodDocument19 pagesDawn FoodOdoka J Khan50% (2)

- Nebosh Igc1 SolutionsDocument20 pagesNebosh Igc1 SolutionsAz CorkerNo ratings yet

- HSE Officer NAVEED CV PDFDocument13 pagesHSE Officer NAVEED CV PDFJohn TuriNo ratings yet

- Ig2 Forms Electronic Submission v2Document12 pagesIg2 Forms Electronic Submission v2Thomas UkorNo ratings yet

- Q5: Based On The Scenario, These Are The Roles and Responsibilities That Needs To Be Done Within SC Company in Health and Safety Management SystemDocument2 pagesQ5: Based On The Scenario, These Are The Roles and Responsibilities That Needs To Be Done Within SC Company in Health and Safety Management SystemMohamed saidNo ratings yet

- 1ig2 Sample v5.2Document18 pages1ig2 Sample v5.2Maher50% (2)

- Report 14 I Given To IDocument18 pagesReport 14 I Given To IRashid JamilNo ratings yet

- OPS - GC2 Element 2Document11 pagesOPS - GC2 Element 2Marius AlexandruNo ratings yet

- My ResumeDocument4 pagesMy Resumeengrsaidnawab2020No ratings yet

- Part 1 ReadyDocument2 pagesPart 1 ReadyMock Project100% (1)

- Unit IG2: Risk Assessment Part 1: Background Topic Comments: You Should Aim To Complete This Section in 150 To 200 WordsDocument8 pagesUnit IG2: Risk Assessment Part 1: Background Topic Comments: You Should Aim To Complete This Section in 150 To 200 WordsKEERTHANANo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document12 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1ahmed alzubierNo ratings yet

- Muhammad - Ahmad - 00720183 - IG - 2023 04 26 08 41 23Document2 pagesMuhammad - Ahmad - 00720183 - IG - 2023 04 26 08 41 23Muhammad AhmadNo ratings yet

- IG Mock Exam Suggested Self Mark AnswersDocument7 pagesIG Mock Exam Suggested Self Mark AnswersOSEIKWADWO SYLVESTERNo ratings yet

- HSE ALERT NO. 14-Benefits of HousekeepingDocument1 pageHSE ALERT NO. 14-Benefits of HousekeepingClark Angelo JuanNo ratings yet

- Ig2 Forms Electronic Submission v3Document8 pagesIg2 Forms Electronic Submission v3Jayaghosh JayapalanNo ratings yet

- Practical Assessment GuidanceDocument19 pagesPractical Assessment GuidanceEULET RICHARDNo ratings yet

- 00628068, Faizan Abdul Aziz, 1446-Gulf Academy of SafetyDocument21 pages00628068, Faizan Abdul Aziz, 1446-Gulf Academy of SafetyMohammad Awees SanadiNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Final Master List of Records - 2023Document5 pagesFinal Master List of Records - 2023Mohammad Awees SanadiNo ratings yet

- Form o Medical FormatDocument3 pagesForm o Medical FormatMohammad Awees SanadiNo ratings yet

- 10th History Revision TestDocument8 pages10th History Revision TestMohammad Awees SanadiNo ratings yet

- Computer Practical Filee-Term 1Document8 pagesComputer Practical Filee-Term 1Mohammad Awees SanadiNo ratings yet

- Nebosh International Technical Certificate in Oil and Gas Operational SafetyDocument2 pagesNebosh International Technical Certificate in Oil and Gas Operational SafetyMohammad Awees Sanadi100% (1)

- Shaikh, Arsalan, Ayub, 00626820,1446 GulfacademyDocument24 pagesShaikh, Arsalan, Ayub, 00626820,1446 GulfacademyMohammad Awees Sanadi100% (1)

- Chapter 7: Constraints On Managers'Document34 pagesChapter 7: Constraints On Managers'Mehdi MohmoodNo ratings yet

- TensileDocument7 pagesTensiledayglisNo ratings yet

- Market Opportunities and Challenges: A Case Study of TescoDocument10 pagesMarket Opportunities and Challenges: A Case Study of TescoGohan SayanNo ratings yet

- Assesment-Rev1-21 June 2021Document10 pagesAssesment-Rev1-21 June 2021Ahmed EL-OsailyNo ratings yet

- Shahnawaz Alam1Document11 pagesShahnawaz Alam1Shahnawaz SiddiqueNo ratings yet

- IRMSA Guideline On Integrating Strategy, Risk and Resilience (ISRR) 2022Document71 pagesIRMSA Guideline On Integrating Strategy, Risk and Resilience (ISRR) 2022Bruce ROBERTSONNo ratings yet

- Primary Plant Production Checklist Edition 9Document235 pagesPrimary Plant Production Checklist Edition 9elflaquito80No ratings yet

- Insurance OperationsDocument12 pagesInsurance OperationsIsunni AroraNo ratings yet

- Survey Companion GuideDocument21 pagesSurvey Companion GuidemaklemzNo ratings yet

- 2.2 HseDocument438 pages2.2 HseAhmed ElhakimyNo ratings yet

- Module B Corporate Financing - Part 1Document500 pagesModule B Corporate Financing - Part 1Darren Lau100% (1)

- Deemer On 4 Yr Cycle UpdateDocument9 pagesDeemer On 4 Yr Cycle UpdatediannebNo ratings yet

- Unit 11 Decentralisation and Delegation: 11.1 Decentralisation As A Structured Mechanism of EmpowermentDocument8 pagesUnit 11 Decentralisation and Delegation: 11.1 Decentralisation As A Structured Mechanism of EmpowermentRavi SinghNo ratings yet

- WHO - TRS - 996 - Annex05 Guidance On Good Data and Record Management PracticesDocument46 pagesWHO - TRS - 996 - Annex05 Guidance On Good Data and Record Management PracticesAlfonso ZavaletaNo ratings yet

- CLO 3 - Contemporary (Best) Practices in SCM - Dr. Walid SmewDocument19 pagesCLO 3 - Contemporary (Best) Practices in SCM - Dr. Walid SmewREEMNo ratings yet

- Cave Rescue CaseDocument11 pagesCave Rescue CaseAneeq TahirNo ratings yet

- Question Paper & Key of First Class Unrestricted Under MMR - Mine Management Legislation and General SafetyDocument23 pagesQuestion Paper & Key of First Class Unrestricted Under MMR - Mine Management Legislation and General SafetyRammesh100% (1)

- Checklist 200806 Medicolegal Checklist PhysiciansDocument4 pagesChecklist 200806 Medicolegal Checklist PhysiciansIkhsan El-SonadorNo ratings yet

- Why RC - Mr. Vijay Bukkawar, ICCDocument38 pagesWhy RC - Mr. Vijay Bukkawar, ICChariNo ratings yet

- Chap 3Document55 pagesChap 3Belayneh Tadesse100% (1)

- Yesfin PDFDocument226 pagesYesfin PDFAnupriya NagpalNo ratings yet

- ACPO Manager GuideDocument117 pagesACPO Manager Guidemsaamir115851No ratings yet

- Internship ReportDocument53 pagesInternship ReportShohanur Rahman100% (1)

- Imdrf Tech 151002 Samd QmsDocument34 pagesImdrf Tech 151002 Samd QmsErnestoAlcoleaGonzálezNo ratings yet

- Chapter 1: The Investment Environment: Problem SetsDocument5 pagesChapter 1: The Investment Environment: Problem SetsGrant LiNo ratings yet

- Law and Ethics For Autonomous Weapon SystemsDocument32 pagesLaw and Ethics For Autonomous Weapon SystemsHoover Institution100% (3)

- Literature Review On Motor Insurance UnderwritingDocument5 pagesLiterature Review On Motor Insurance Underwritingc5sdvcgdNo ratings yet

- Plant 6 3: Risk Assessment For Lifting OperationsDocument4 pagesPlant 6 3: Risk Assessment For Lifting OperationsIdris AdeniranNo ratings yet