Professional Documents

Culture Documents

4.1.1.5 Design of WT Wall

4.1.1.5 Design of WT Wall

Uploaded by

vijay kumar yadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.1.1.5 Design of WT Wall

4.1.1.5 Design of WT Wall

Uploaded by

vijay kumar yadavCopyright:

Available Formats

4.1.

2 Design Water Tank Wall

X bar

A. Stress Summary

Y bar

y

z

y

z x

y

z

y

z x

Y

X

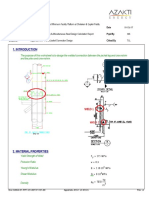

Sign Convention of Element forces Plate Local Axis in STAAD.PRO Model

Stress Summary for LRFD load combination

Element Forces D= 0.200 m (thickness of Mat)

Shear

Bending Shear

OUT-PLANE In-Plane

Plate No. L/C

SQX SQY SXY Mx My Vux Vuy

kN/m2 kN/m2 kN/m2 kNm/m kNm/m kN/m kN/m

Max Qx 674 105 149.57 -88.16 0 - - 29.91 17.63

Min Qx 735 109 -182.57 -211.74 0 - - 36.51 42.35

Max Qy 753 111 -96.39 390.00 0 - - 19.28 78.00

Min Qy 753 106 61.85 -350.00 0 - - 12.37 70.00

Max Mx 753 112 - - - 5.07 15.34 - -

Min Mx 753 105 - - - -5.06 -20.26 - -

Max My 753 111 - - - 4.61 15.59 - -

Min My 736 109 - - - -3.09 -22.10 - -

Unit : kNm/m, kN/m

Bending Shear

X bar Y bar X bar Y bar

Top 5.07 15.59

36.51 78.00

Bottom 5.06 22.10

B. Strength Design of Mat Rebar(X-direction)

a. Design forces

Mu, bottom = 5.06 kN-m

Mu, top = 5.07 kN-m

Vu = 36.51 kN

b. Flexure Design

Section Properties Material Strength

b = 1000 mm fc' = 20 N/mm2 fs = 333 N/mm2 ( s= )

D = 200 mm fy = 500 N/mm2

1. Main Reinforcement (ACI 318-08 10.5.1)

a. Bottom reinforcement

Mu = 5.06 kN-m

Vu = 36.51 kN D d

d

cc = 55 mm : Concrete cover = (50+0.5d b )

d= 145 mm : Effective depth = (D-cc)

ω(1 - 0.59ω) = Mu / (0.90 fc'bd²) = 5.06*1000*1000 / [ 0.90*20*1000*145² ] = 0.01333

ω - 0.59ω2 = 0.01333 , 0.59ω² - ω + 0.01333 = 0

ω = 0.01344

Calculation of ρ,

ρmin = max [1.4/fy, 0.25(fc')0.5/fy] = 0.0028

ρ' = ω fc' / fy = 0.01344*20 / 500 = 0.00054 < 0.0028 (ρmin)

Since (ρ' < ρmin), check for 4/3ρ' = 0.00072

So, ρ = [min(4/3ρ' , ρmin)] = 0.00072

Asreq'd = ρbd = 0.00072*1000*145 = 105 mm2

Provide : D10 @ 175 Nominal dia = 9.50 mm

Assup'd = (9.5² *π/4)*(1000/175) = 405 mm2 ok

Asreq'd/Assup'd = 0.26

b. Top reinforcement

Mu = 5.07 kN-m

Vu = 36.51 kN

D d

cc = 55 mm : Concrete cover = (50+0.5d b ) d

d= 145 mm : Effective depth = (D-cc)

ω(1 - 0.59ω) = Mu / (0.90 fc'bd²) = 5.07*1000*1000 / [ 0.90*20*1000*145² ] = 0.01336

ω - 0.59ω2 = 0.01336 , 0.59ω² - ω + 0.01336 = 0

ω = 0.01347

Calculation of ρ,

ρmin = max [1.4/fy, 0.25(fc')0.5/fy] = 0.0028

ρ' = ω fc' / fy = 0.01347*20 / 500 = 0.00054 < 0.0028 (ρmin)

Since (ρ' < ρmin), check for 4/3ρ' = 0.00072

So, ρ = [min(4/3ρ' , ρmin)] = 0.00072

Asreq'd = ρbd = 0.00072*1000*145 = 105 mm2

Provide : D10 @ 175 Nominal dia = 9.50 mm

Assup'd = (9.5² *π/4)*(1000/175) = 405 mm2 ok

Asreq'd/Assup'd = 0.26

2. Check for Spacing of rebar (ACI 318-08 10.6.4) c = 50 mm

Smax = min[ 380*(280 / fs) - 2.5 c, 300*(280/fs)]

= 194.2 mm > 175 mm ok

3. Minimum Shrinkage & Temperature Requirement (ACI 318-08 7.12)

Asreq'd = 0.0018bD = 0.0018*1000*200

= 360 mm2 < 810 mm2 ok

( 2 layers of rebar, top and bottom)

Asreq'd/Assup'd = 0.44

c. Check for Shear

1. Beam Shear (One way shear) (ACI 318-08 11.2.1.1, 11.4.7.2)

Vu = 36.51 kN d = 145 mm

øVc = 0.75*0.17*λ*fc0.5 bd

= 0.75*0.17*1*(20)^0.5*1000*145/1000

= 82.79 kN > 36.51 kN ok

Vu/øVc = 0.44

C. Strength Design of Mat Rebar (Y-direction)

a. Design forces

Mu, bottom = 22.10 kN-m

Mu, top = 15.59 kN-m

Vu = 78.00 kN

b. Flexure Design

Section Properties Material Strength

b = 1000 mm fc' = 20 N/mm2 fs = 333 N/mm2 ( s= )

D = 200 mm fy = 500 N/mm2

1. Main Reinforcement (ACI 318-08 10.5.1)

a. Bottom reinforcement

Mu = 22.10 kN-m

Vu = 78.00 kN D d

d

cc = 55 mm : Concrete cover = (50+0.5d b )

d= 145 mm : Effective depth = (D-cc)

ω(1 - 0.59ω) = Mu / (0.90 fc'bd²) = 22.10*1000*1000 / [ 0.90*20*1000*145² ] = 0.05824

ω - 0.59ω2 = 0.05824 , 0.59ω² - ω + 0.05824 = 0

ω = 0.06039

Calculation of ρ,

ρmin = max [1.4/fy, 0.25(fc')0.5/fy] = 0.0028

ρ' = ω fc' / fy = 0.06039*20 / 500 = 0.00242 < 0.0028 (ρmin)

Since (ρ' < ρmin), check for 4/3ρ' = 0.00323

So, ρ = [min(4/3ρ' , ρmin)] = 0.0028

Asreq'd = ρbd = 0.00280*1000*145 = 407 mm2

Provide : D10 @ 150 Nominal dia = 9.50 mm

2

Assup'd = (9.5² *π/4)*(1000/150) = 473 mm ok

Asreq'd/Assup'd = 0.86

b. Top reinforcement

Mu = 15.59 kN-m

Vu = 78.00 kN D d

d

cc = 55 mm : Concrete cover = (50+0.5d b )

d= 145 mm : Effective depth = (D-cc)

ω(1 - 0.59ω) = Mu / (0.90 fc'bd²) = 15.59*1000*1000 / [ 0.90*20*1000*145² ] = 0.04109

ω - 0.59ω2 = 0.04109 , 0.59ω² - ω + 0.04109 = 0

ω = 0.04214

Calculation of ρ,

ρmin = max [1.4/fy, 0.25(fc')0.5/fy] = 0.0028

ρ' = ω fc' / fy = 0.04214*20 / 500 = 0.00169 < 0.0028 (ρmin)

Since (ρ' < ρmin), check for 4/3ρ' = 0.00225

So, ρ = [min(4/3ρ' , ρmin)] = 0.00225

Asreq'd = ρbd = 0.00225*1000*145 = 327 mm2

Provide : D10 @ 150 Nominal dia = 9.50 mm

Assup'd = (9.5² *π/4)*(1000/150) = 473 mm2 ok

Asreq'd/Assup'd = 0.69

2. Check for Spacing of rebar (ACI 318-08 10.6.4) c = 50 mm

Smax = min[ 380*(280 / fs) - 2.5 c, 300*(280/fs)]

= 194.2 mm > 150 mm ok

3. Minimum Shrinkage & Temperature Requirement (ACI 318-08 7.12)

Asreq'd = 0.0018bD = 0.0018*1000*200

= 360 mm2 < 945 mm2 ok

( 2 layers of rebar, top and bottom)

Asreq'd/Assup'd = 0.38

c. Check for Shear

1. Beam Shear (One way shear) (ACI 318-08 11.2.1.1, 11.4.7.2)

Vu = 78.00 kN d = 145 mm

0.5

øVc = 0.75*0.17*λ*fc bd

= 0.75*0.17*1*(20)^0.5*1000*145/1000

= 82.79 kN > 78.00 kN ok

Vu/øVc = 0.94

You might also like

- Factura Comercial DHLDocument2 pagesFactura Comercial DHLLorena Velásquez71% (7)

- Y3 - Module 1 - Installing Electrical Lighting SystemDocument110 pagesY3 - Module 1 - Installing Electrical Lighting SystemHarold Vernon Martinez100% (2)

- Problems For Stresses Under Combined Loads PDFDocument13 pagesProblems For Stresses Under Combined Loads PDFshyam venkatNo ratings yet

- 4.1.1.6 Design of WT SlabDocument5 pages4.1.1.6 Design of WT Slabvijay kumar yadavNo ratings yet

- 5.B Modal AnalysysisDocument5 pages5.B Modal Analysysisvijay kumar yadavNo ratings yet

- Prokon FootingDocument15 pagesProkon FootingShaikh Muhammad AteeqNo ratings yet

- Water Tank Design - B-300mmDocument59 pagesWater Tank Design - B-300mmrachana0% (1)

- Bracket WeldDocument6 pagesBracket Weldlim kang haiNo ratings yet

- ME 219 - Spring 2016 - Week04 HandoutDocument7 pagesME 219 - Spring 2016 - Week04 HandoutHassan KhalidNo ratings yet

- Chapter13 ProblemsDocument7 pagesChapter13 ProblemsHarishNo ratings yet

- SteelChk - Strut (Rev. D) 20190508Document5 pagesSteelChk - Strut (Rev. D) 20190508hessian123No ratings yet

- Experiment 5: StatementDocument7 pagesExperiment 5: StatementabubakarNo ratings yet

- Muk 56754 5Document1 pageMuk 56754 5Suresh MahalingamNo ratings yet

- Practical Application 01 W1 ERDocument14 pagesPractical Application 01 W1 ERenrico.michelatoNo ratings yet

- Foundation F1Document36 pagesFoundation F1Kamal FayazNo ratings yet

- Tabla PerfilesDocument39 pagesTabla PerfilesAna Carolina Félix CamachoNo ratings yet

- Chapter 4 Deflection and BucklingDocument64 pagesChapter 4 Deflection and BucklingHamlity SaintataNo ratings yet

- VMH AnchorDocument4 pagesVMH Anchormohamed rafiNo ratings yet

- Bertagnoli Carbone Giordano Mancini 1Document8 pagesBertagnoli Carbone Giordano Mancini 1deba_jyoti_dasNo ratings yet

- Column Design BS 8110.1985Document114 pagesColumn Design BS 8110.1985aries pambudiNo ratings yet

- Macromechanics of A LaminateDocument45 pagesMacromechanics of A LaminateAvinash ShindeNo ratings yet

- RC08 Shear1Document13 pagesRC08 Shear1Ce WinNo ratings yet

- Raft DesignDocument14 pagesRaft DesignGautham AllimuthuNo ratings yet

- 04 - Shear of Thin Walled Sections and Shear CentreDocument23 pages04 - Shear of Thin Walled Sections and Shear CentrePythonraptorNo ratings yet

- JEE Main 2021 - Kinematics of A Particle - SolutionsDocument4 pagesJEE Main 2021 - Kinematics of A Particle - SolutionsSuraj KumarNo ratings yet

- Errata 2Document11 pagesErrata 2Morpheus SunNo ratings yet

- Beam and Beam Deflection Singularity MethodDocument43 pagesBeam and Beam Deflection Singularity Methodjundi qowiNo ratings yet

- Finite Element Method For Structural Dynamic and Stability AnalysesDocument49 pagesFinite Element Method For Structural Dynamic and Stability AnalysesabimalainNo ratings yet

- Rct08 Column RectangularDocument4 pagesRct08 Column RectangularRuy ST GuerraNo ratings yet

- Base Plate TopDocument7 pagesBase Plate TopUpendra WalinjkarNo ratings yet

- Welding CheckingDocument1 pageWelding Checkingxlw955597No ratings yet

- Punching Shaer For Corner Slab PDFDocument1 pagePunching Shaer For Corner Slab PDFAnonymous koR9VtfNo ratings yet

- Formulas DstsDocument16 pagesFormulas DstsGrey AsusNo ratings yet

- N. Prabhakar: Job No.: Design By: Date: Page NoDocument22 pagesN. Prabhakar: Job No.: Design By: Date: Page NoVikram GaikwadNo ratings yet

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocument5 pagesThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNo ratings yet

- Design of Beam (Classical Approach) .1Document24 pagesDesign of Beam (Classical Approach) .1Udhasu NayakNo ratings yet

- HW9 SolutionDocument11 pagesHW9 SolutionKuya Jay Criz DeloNo ratings yet

- Wailing Check (203x203x60 UC)Document2 pagesWailing Check (203x203x60 UC)hessian123100% (1)

- Fundamentals of Structural Analysis 5th Edition by Leet Uang Lanning ISBN Solution ManualDocument111 pagesFundamentals of Structural Analysis 5th Edition by Leet Uang Lanning ISBN Solution Manualjames100% (28)

- Solution Manual For Fundamentals of Structural Analysis 5Th Edition by Leet Uang Lanning Isbn 0073398004 9780073398006 Full Chapter PDFDocument36 pagesSolution Manual For Fundamentals of Structural Analysis 5Th Edition by Leet Uang Lanning Isbn 0073398004 9780073398006 Full Chapter PDFsusan.lemke155100% (10)

- 10 - Design of PurlinsDocument27 pages10 - Design of Purlinssherif IbrahimNo ratings yet

- STRL Calc For Gusset Plate Its ConnectionDocument25 pagesSTRL Calc For Gusset Plate Its ConnectionZeeZ HNo ratings yet

- 148841505-Verificare-StalpDocument50 pages148841505-Verificare-StalpkrmeenNo ratings yet

- Section1 P2Document1 pageSection1 P2Cashew PandaramNo ratings yet

- Cambodia - Arpartment Composite Beam Analysis Q18-050 Son Tu Nguyen ASD Astm A36 V120x120x11 315 1 y CX TDocument3 pagesCambodia - Arpartment Composite Beam Analysis Q18-050 Son Tu Nguyen ASD Astm A36 V120x120x11 315 1 y CX TNguyễnTúSơnNo ratings yet

- Finite Element Method For Structural Dynamic and Stability AnalysesDocument52 pagesFinite Element Method For Structural Dynamic and Stability AnalysesabimalainNo ratings yet

- Connections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)Document14 pagesConnections 1 - Ch.6 Bolted Shear Connections - Exercise Solutions (2 of 2) (233-248)travis8zimmermannNo ratings yet

- Foundation 1 Design ReportDocument9 pagesFoundation 1 Design ReportSameer KmNo ratings yet

- Shear and Moment Diagrams Shear and Moment DiagramsDocument9 pagesShear and Moment Diagrams Shear and Moment DiagramsRajkamal AroraNo ratings yet

- Section CapacityDocument8 pagesSection CapacityНемања КараклајићNo ratings yet

- Designof Slabsusing Shear Friction BirkleetalDocument11 pagesDesignof Slabsusing Shear Friction BirkleetalDavide GiannuzziNo ratings yet

- Column Design With ExcelDocument47 pagesColumn Design With ExcelMatiur Rahman BasumNo ratings yet

- Full Fundamentals of Structural Analysis 5Th Edition Leet Solutions Manual PDF Docx Full Chapter ChapterDocument36 pagesFull Fundamentals of Structural Analysis 5Th Edition Leet Solutions Manual PDF Docx Full Chapter Chapterownerexhibit.eedjfs100% (21)

- Design of CoverDocument2 pagesDesign of CoverAmanNo ratings yet

- Column Base Design: Default Single Column Example: Working Load Stability ChecksDocument12 pagesColumn Base Design: Default Single Column Example: Working Load Stability Checksmarlin hidayatNo ratings yet

- Chapter Iv: Pure BendingDocument48 pagesChapter Iv: Pure BendingEsra'a SmadiNo ratings yet

- Tutorial Sheet-3 (Centroid, Moment of Inertia) AM11101Document2 pagesTutorial Sheet-3 (Centroid, Moment of Inertia) AM11101NewtonNo ratings yet

- ACI-350 P-M Interaction 1.1Document6 pagesACI-350 P-M Interaction 1.1Edgardo ArriesgadoNo ratings yet

- A-Bottom-Bracket ReportDocument4 pagesA-Bottom-Bracket ReportMohammed AyeshNo ratings yet

- Type 1Document1 pageType 1EakJhuanNo ratings yet

- Example 09 11Document1 pageExample 09 11Ecem AtamanNo ratings yet

- 6.1.1 Abutment Stability Check - With WPDocument7 pages6.1.1 Abutment Stability Check - With WPvijay kumar yadavNo ratings yet

- Section 9Document27 pagesSection 9vijay kumar yadavNo ratings yet

- 4.3.8 Design of B8Document1 page4.3.8 Design of B8vijay kumar yadavNo ratings yet

- StairDocument2 pagesStairvijay kumar yadavNo ratings yet

- 3.1 Summary of CalculationsDocument4 pages3.1 Summary of Calculationsvijay kumar yadavNo ratings yet

- Section 4.2 To 4.3Document115 pagesSection 4.2 To 4.3vijay kumar yadavNo ratings yet

- 4.3 Design of Girder and Beam 4.3.1 Design of B1Document1 page4.3 Design of Girder and Beam 4.3.1 Design of B1vijay kumar yadavNo ratings yet

- 4.4 Slab DesignDocument6 pages4.4 Slab Designvijay kumar yadavNo ratings yet

- Member Name: B1: All SectionDocument1 pageMember Name: B1: All Sectionvijay kumar yadavNo ratings yet

- 5.B Modal AnalysysisDocument4 pages5.B Modal Analysysisvijay kumar yadavNo ratings yet

- 5.B Modal AnalysysisDocument5 pages5.B Modal Analysysisvijay kumar yadavNo ratings yet

- LF 1Document1 pageLF 1vijay kumar yadavNo ratings yet

- P5Document1 pageP5vijay kumar yadavNo ratings yet

- 5.2 Design of ColumnDocument3 pages5.2 Design of Columnvijay kumar yadavNo ratings yet

- B) RoofDocument1 pageB) Roofvijay kumar yadavNo ratings yet

- 5.B Modal AnalysysisDocument1 page5.B Modal Analysysisvijay kumar yadavNo ratings yet

- Top of FTG: DB12 (Ok.) @200 (Ratio 0.12)Document9 pagesTop of FTG: DB12 (Ok.) @200 (Ratio 0.12)vijay kumar yadavNo ratings yet

- 5.B Modal AnalysysisDocument4 pages5.B Modal Analysysisvijay kumar yadavNo ratings yet

- Member Name: P1: 1. General InformationDocument6 pagesMember Name: P1: 1. General Informationvijay kumar yadavNo ratings yet

- 4.5.3 Design of Pedestal, P3A/BDocument1 page4.5.3 Design of Pedestal, P3A/Bvijay kumar yadavNo ratings yet

- RG1Document1 pageRG1vijay kumar yadavNo ratings yet

- P 02Document1 pageP 02vijay kumar yadavNo ratings yet

- 4.5.2 Design of Pedestal, P2A/BDocument1 page4.5.2 Design of Pedestal, P2A/Bvijay kumar yadavNo ratings yet

- Ramp DetailDocument1 pageRamp Detailvijay kumar yadavNo ratings yet

- A.2 Out Put Data of Fa TankDocument12 pagesA.2 Out Put Data of Fa Tankvijay kumar yadavNo ratings yet

- A.1 FA Tank FDN Input DataDocument24 pagesA.1 FA Tank FDN Input Datavijay kumar yadavNo ratings yet

- 3.1.1a Chemical Dosing Equipment Shed GeometryDocument8 pages3.1.1a Chemical Dosing Equipment Shed Geometryvijay kumar yadavNo ratings yet

- 3.3 Chemical Dosing Equipment Shed Load Calc - Closed - ShedDocument22 pages3.3 Chemical Dosing Equipment Shed Load Calc - Closed - Shedvijay kumar yadavNo ratings yet

- Medical Lab ReportDocument2 pagesMedical Lab Reportvijay kumar yadavNo ratings yet

- Etabs 2016 16.2.0 12/5/2020Document1 pageEtabs 2016 16.2.0 12/5/2020vijay kumar yadavNo ratings yet

- Estonia JobsDocument8 pagesEstonia JobsMd JonayedNo ratings yet

- 1) Un-Alloyed Steel: Rutile and Cellulosic: 48SP 51 54 55 D6 160 Galva 46 RR B7Document151 pages1) Un-Alloyed Steel: Rutile and Cellulosic: 48SP 51 54 55 D6 160 Galva 46 RR B7Ricardo DonselaarNo ratings yet

- OYENUGA1Document15 pagesOYENUGA1Henry DiyokeNo ratings yet

- Tcbe 1202-5 LimeDocument48 pagesTcbe 1202-5 LimeshafikNo ratings yet

- US4241370 ReleDocument13 pagesUS4241370 ReleJosé Paulo Pereira de SouzaNo ratings yet

- Dampness Treatment in Interior WallDocument2 pagesDampness Treatment in Interior WallAbu Shahadat Muhammad SayeemNo ratings yet

- Prestresed ConcreteDocument6 pagesPrestresed ConcreteSantoshNo ratings yet

- SRM 320 DAÑOS (2) EstructuraDocument138 pagesSRM 320 DAÑOS (2) EstructurajhonNo ratings yet

- Brochure Schuetz Cormaster enDocument12 pagesBrochure Schuetz Cormaster enAnu ChandranNo ratings yet

- (Atkinson 2000) Artikel Fundamental Aspects of Hot Isostatic Pressing - An OverviewDocument20 pages(Atkinson 2000) Artikel Fundamental Aspects of Hot Isostatic Pressing - An OverviewChristian MohammadNo ratings yet

- Masterflow 885: High-Precision, Non-Shrink Metallic Aggregate Grout With Extended Working TimeDocument4 pagesMasterflow 885: High-Precision, Non-Shrink Metallic Aggregate Grout With Extended Working TimeSky MoonNo ratings yet

- Neopolen Sup ® Sup +P+9255Document4 pagesNeopolen Sup ® Sup +P+9255Bradz TalpoNo ratings yet

- Answer RQ CHAPTER 2Document8 pagesAnswer RQ CHAPTER 2MirunNo ratings yet

- VinodDocument5 pagesVinodUdaykumar PhatakNo ratings yet

- Rebar Contract VS ExecutedDocument3 pagesRebar Contract VS ExecutedAbdulselam MaruNo ratings yet

- TDS - Total - Synolan Barrier Fluids 5 y 15Document1 pageTDS - Total - Synolan Barrier Fluids 5 y 15lenninNo ratings yet

- Method Statement WallDocument11 pagesMethod Statement WalldeviesrigatiNo ratings yet

- Plastocrete - N: Waterproofing Concrete AdmixtureDocument2 pagesPlastocrete - N: Waterproofing Concrete AdmixtureAhmed AbdallahNo ratings yet

- PriceListHirePurchase Normal10thJan2020 PDFDocument60 pagesPriceListHirePurchase Normal10thJan2020 PDFUsman AliNo ratings yet

- Karakterisasi Bioplastik Dari Rumput Laut (Eucheuma Cottonii) Dan Pati Singkong Dengan Penambahan Pati Dari Limbah Biji DurianDocument10 pagesKarakterisasi Bioplastik Dari Rumput Laut (Eucheuma Cottonii) Dan Pati Singkong Dengan Penambahan Pati Dari Limbah Biji DurianANMANo ratings yet

- GRP 14 P Block CHEMHACK - 26cf7734 Ccd7 4b3d Aa3e 0d7baf6cf9d8Document7 pagesGRP 14 P Block CHEMHACK - 26cf7734 Ccd7 4b3d Aa3e 0d7baf6cf9d8aastha.v.patil03No ratings yet

- Saudi Aramco Oil Company: SECTION 03200Document6 pagesSaudi Aramco Oil Company: SECTION 03200saneela bibiNo ratings yet

- Tin and Its AlloysDocument2 pagesTin and Its AlloysSri GowthamNo ratings yet

- Carbon Enrichment in Mo SteelDocument50 pagesCarbon Enrichment in Mo SteelDhananjay ShimpiNo ratings yet

- Strongcoat ConductiveDocument83 pagesStrongcoat ConductiveAhmed AssafNo ratings yet

- A 3 Defects of Concrete StructureDocument26 pagesA 3 Defects of Concrete StructureCass LimNo ratings yet

- Armaflex Tuffcoat Application GuideDocument12 pagesArmaflex Tuffcoat Application GuideLeonardo GiarolaNo ratings yet

- Transmaterial 3 PDFDocument16 pagesTransmaterial 3 PDFSulman KhalidNo ratings yet