Professional Documents

Culture Documents

IP MS 12 Cement Plaster

IP MS 12 Cement Plaster

Uploaded by

Zubair Ahmed KhaskheliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IP MS 12 Cement Plaster

IP MS 12 Cement Plaster

Uploaded by

Zubair Ahmed KhaskheliCopyright:

Available Formats

Doc No: IP/MS-12

CEMENT PLASTER Rev: 01

Page: 1 of 4

METHOD STATEMENT

FOR

CEMENT PLASTER

01 Introduction of HSE Instructions 12 Oct, 04 M Ashraf MSC AKK

0 Method Statement for Cement Plaster 24 July, 03 M Ashraf MSC AKK

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

Doc No: IP/MS-12

CEMENT PLASTER Rev: 01

Page: 2 of 4

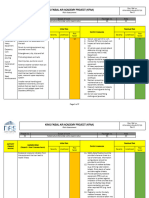

Rev. No. Details Of Revision Date Prepared by Checked by Approved by

1. OBJECTIVE

The objective of this method statement is to provide general guidelines for all plastering

work and related inspection activities.

2. SCOPE

This method statement covers the activities in connection with the application of plaster

at all project sites.

3. REFERENCES

Construction drawings & specifications

4. DEFINITIONS

CAR Corrective Action Request

HSE Health, Safety and Environment

QIP Quality Inspection Plan

Doc. Document

5. RESPONSIBILITIES

Construction Manager shall be responsible for implementation of this method

statement.

6 PROCEDURE

6.1 Quality Inspection Plan (QIP) specific to project requirements shall be made and

inspection activities shall be recorded either on the formats as given under

“Related Documents” or those supplied by customer.

6.2 Portland cement for plaster shall conform to the requirements as specified in

customer’s specifications and for its approval by customer use Doc. No.

QA&QC/FRM-199.

6.3 All sand used in plaster shall also conform to the requirement as specified in the

customer’s specifications and for its approval by customer use Doc. No.

QA&QC/FRM-174, 178,179.

6.4 All the ingredients for plastering shall be proportioned by volume as indicated on

the project specifications. The preparation of mix shall not be in a bulk quantity.

Approval of mix design for mortar use Doc. No. QA&QC/FRM-180.

6.5 Mechanical mixers, mixing boxes, platforms and all related tools shall be cleaned

before and after mixing each mix.

6.6 Plaster mortar shall be thoroughly mixed with the specified amount of water until

uniformity in color and consistency is obtained.

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

Doc No: IP/MS-12

CEMENT PLASTER Rev: 01

Page: 3 of 4

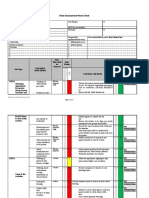

6.7 Prior to the plasterwork ensure that all the conduits for electrical works ducts,

pipes, brackets, doors, windows, ventilators and all other fixtures on the walls

have been fixed in position.

6.8 Smooth concrete surface shall be roughened prior to commencement of

plastering.

6.9 Before commencement on block wall the surface to be plastered shall be treated

with cement sand slurry (one part cement and one part sand by volume)

6.10 The slurry shall be applied with a brush upon the surface previously been well

wetted.

6.11 The treatment of slurry shall be allowed to dry out for 24 hrs.

6.12 The first coat shall be roughened before the finishing coat is applied.

6.13 Make sure the minimum thickness of plaster should be as per project

specifications.

6.14 The plaster surface should not be wavy and should be perfectly in plumb.

6.15 The plaster works shall be cured for at least ten days by sprinkling water or as

mentioned in specifications.

6.16 In case of non-conformity at any stage of inspection, the segregation shall be

covered by method statement No. QA&QC/MS-02 and Corrective Action Request

(CAR) shall be raised as per standard operating procedure No. QA&QC/SOP-04.

7. TOOLS AND EQUIPMENTS

Mixing Pans, Hand Tools For Plaster, Plumb Lines, Water Tank/Bouser and Mixing

Machine.

8. HSE INSTRUCTIONS

8.1 All the workers shall use personal protective equipment during cement plaster

activity.

8.2 A competent assigned person shall supervise the whole work.

8.3 Any person alone shall clean in the presence of a supervisor and the machines

such as mixers etc. never.

8.4 Electric circuit must be disconnected before wetting/curing of the surface

plastered or to be plastered.

8.5 Scaffolding with toe boards & guardrails etc. will be prepared as per approved

specifications if needed.

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

Doc No: IP/MS-12

CEMENT PLASTER Rev: 01

Page: 4 of 4

8.6 Mortar buckets must be in good condition and not to be used for other than

material.

8.7 Cement sand mortar shall not be retained for more than ½ hrs in open air.

8.8 No trash, rapes, shopping bags, papers, cans, bottles or any other litter should

be left in the open.

8.9 Any liquid fuel spills and accidental waste disposal should be avoided and

properly cleaned up.

8.10 Minimize the soil erosion.

8.11 Preserve your natural environment.

9 RELATED DOCUMENTS

9.1 Related Drawings & Customer’s Specifications.

9.2 QA&QC/FRM-165 Quality of Course/Fine Aggregate

9.3 QA&QC/FRM-174 Cement Soundness Test

9.4 QA&QC/FRM-178 Organic Impurities In Sand

9.5 QA&QC/FRM-179 Sand Equivalent Test

9.6 QA&QC/FRM-180 Summary Of Daily Concrete

9.7 QA&QC/FRM-185 Inspection Timing Sheet

9.8 QA&QC/FRM-188 Gradation Chart

9.9 QA&QC/FRM-198 Inspection Sheet For Brick Masonry

9.10 QA&QC/FRM-199 Material Approval Form

9.11 QA&QC/FRM-200 Foundation Inspection Report

9.12 QA&QC/FRM-08 Corrective Action Request

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

You might also like

- 1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsDocument37 pages1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsZubair Ahmed Khaskheli0% (1)

- Concrete Spec (NPQS)Document10 pagesConcrete Spec (NPQS)Win ThanNo ratings yet

- Surface Preparation & Painting ProcedureDocument18 pagesSurface Preparation & Painting ProcedureAAISAT100% (1)

- Drilling FluidsDocument41 pagesDrilling FluidsGogot Pantja Parijogo100% (2)

- 009 RCC Job Procedure 1Document15 pages009 RCC Job Procedure 1Shaarun M RamannNo ratings yet

- Painting ProcedureDocument10 pagesPainting ProcedureLiyakathalikhan Shahjahan50% (2)

- Screed-Method StatementDocument5 pagesScreed-Method StatementTATATAHER100% (3)

- Mimaki UJV-160 Parts ListDocument114 pagesMimaki UJV-160 Parts ListRed Cristian100% (1)

- IP MS 09 GroutingDocument4 pagesIP MS 09 GroutingZubair Ahmed KhaskheliNo ratings yet

- IP MS 07 Cast Insitu PilingDocument5 pagesIP MS 07 Cast Insitu PilingZubair Ahmed KhaskheliNo ratings yet

- IP MS 13 FlooringDocument5 pagesIP MS 13 FlooringZubair Ahmed KhaskheliNo ratings yet

- Interior & Exterior PlasteringDocument7 pagesInterior & Exterior PlasteringGabriel GabeNo ratings yet

- IP MS 19 Embankment ConstructionDocument4 pagesIP MS 19 Embankment ConstructionZubair Ahmed KhaskheliNo ratings yet

- Work Methodology For All Types Flooring Work R1Document19 pagesWork Methodology For All Types Flooring Work R1priyanka k lNo ratings yet

- Sand Blast and Painting Work ProsedurDocument8 pagesSand Blast and Painting Work ProsedurRizki AgustiarNo ratings yet

- Work Procedure FOR ConcretingDocument6 pagesWork Procedure FOR ConcretingRamanathan GnanasambandamNo ratings yet

- Toilet Waterproofing ADocument6 pagesToilet Waterproofing ASagar ParabNo ratings yet

- Cement BlocksDocument8 pagesCement BlocksYannick PrattNo ratings yet

- Method Statement For ConcretingDocument23 pagesMethod Statement For ConcretingVinod MasaniNo ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- GRC SpecDocument8 pagesGRC SpecOttawa CanadaNo ratings yet

- Job Procedure For Concrete 28-4-21Document15 pagesJob Procedure For Concrete 28-4-21Salmaan WasimNo ratings yet

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Document11 pagesJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikNo ratings yet

- Method Statement Water ProofingDocument16 pagesMethod Statement Water ProofingVinod MasaniNo ratings yet

- Tile Works ManualDocument6 pagesTile Works Manualgau shresNo ratings yet

- IP MS 03 General FillDocument5 pagesIP MS 03 General FillZubair Ahmed KhaskheliNo ratings yet

- Bidding Document-Rio-21-01-008Document58 pagesBidding Document-Rio-21-01-008Sen LinNo ratings yet

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDocument10 pagesLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingPrince Jose100% (1)

- Particular Specifications Water Proofing Work: 1.0 General StandardsDocument12 pagesParticular Specifications Water Proofing Work: 1.0 General StandardsManjeet SinghNo ratings yet

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDocument10 pagesLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingEstebanCastellanosBorreroNo ratings yet

- M o S For Grouting-01Document6 pagesM o S For Grouting-01civil.godfatherNo ratings yet

- Appendix G - Specification For FlooringDocument19 pagesAppendix G - Specification For FlooringAnil WadileNo ratings yet

- Methodology 14-2-2022 Brick Bat HardcoreDocument5 pagesMethodology 14-2-2022 Brick Bat HardcoreMohd IrshadNo ratings yet

- Method Statement For PLASTERINGDocument6 pagesMethod Statement For PLASTERINGVinodh Palanichamy100% (1)

- Waterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaDocument6 pagesWaterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaThink itNo ratings yet

- Concrete Quality Control Program Plan AYC-RSLF-CQCP-000Document6 pagesConcrete Quality Control Program Plan AYC-RSLF-CQCP-000nijasNo ratings yet

- IP MS 18 Road PavementDocument12 pagesIP MS 18 Road PavementZubair Ahmed KhaskheliNo ratings yet

- Procedure No.: Procedure Title:: Quality Work Procedure AKS-12 Application of Bituminous Paint 0Document4 pagesProcedure No.: Procedure Title:: Quality Work Procedure AKS-12 Application of Bituminous Paint 0jack262No ratings yet

- Earth Works & Backfilling Method StatmentDocument6 pagesEarth Works & Backfilling Method StatmentPrasanta ParidaNo ratings yet

- WP For Waterproofing - Toilet, Utility, Sit Out or BalconyDocument4 pagesWP For Waterproofing - Toilet, Utility, Sit Out or Balconymounikaboddupally8No ratings yet

- Cem Kote CW PlusDocument6 pagesCem Kote CW Plusconstruct404No ratings yet

- Rigid PavementsDocument70 pagesRigid PavementsJanya AssociatesNo ratings yet

- Blasting Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting Coating Procedure For Fabricated Steel StructureSalman Alfarisi100% (1)

- Brick MasonryDocument8 pagesBrick MasonrybulzaeNo ratings yet

- t14-04 Antistripping GuidelinesDocument7 pagest14-04 Antistripping GuidelinesMILON KUMAR HORENo ratings yet

- 90206-000-CV-SP-107 SPECIFICATION FOR Grouting IN ALL AREAS (Rev.A0) PDFDocument10 pages90206-000-CV-SP-107 SPECIFICATION FOR Grouting IN ALL AREAS (Rev.A0) PDFamini_mohi100% (1)

- Procedure Painting Mps Epoxcy - Final - PT KhiDocument12 pagesProcedure Painting Mps Epoxcy - Final - PT KhisinambeladavidNo ratings yet

- Guide Man SandDocument18 pagesGuide Man SandapocalypsevoidNo ratings yet

- 08 - Method Statement For Tile WorkDocument5 pages08 - Method Statement For Tile WorkAnsar WarraichNo ratings yet

- Methodstament For RCC and PCCDocument6 pagesMethodstament For RCC and PCCDeepak Patil100% (1)

- ATS 5316 Cementitious Mortar and GroutDocument9 pagesATS 5316 Cementitious Mortar and GrouttechNo ratings yet

- EB - 44 - Coal Tar RejuvenationDocument5 pagesEB - 44 - Coal Tar RejuvenationManInTheBushNo ratings yet

- Actual GRC Specification PDFDocument8 pagesActual GRC Specification PDFfazyroshanNo ratings yet

- Surface Preparation and Painting of Structural SteelDocument6 pagesSurface Preparation and Painting of Structural SteelRakesh Ranjan0% (1)

- MS For Brick WorkDocument7 pagesMS For Brick WorkSumit Omar100% (1)

- CP 300 (A) - QCP-039 Installation of Ceramic Floor TilesDocument6 pagesCP 300 (A) - QCP-039 Installation of Ceramic Floor TilestarekNo ratings yet

- Working Procedure Ls1-Ls4Document9 pagesWorking Procedure Ls1-Ls4Tuğrulhan ÖzdemirNo ratings yet

- Method Statement For Waterproofing in CWSTDocument4 pagesMethod Statement For Waterproofing in CWSTHariom guptaNo ratings yet

- Water Works RTADocument15 pagesWater Works RTAalfaza3No ratings yet

- 1 MS - Pouring of ConcreteDocument8 pages1 MS - Pouring of ConcreteFauzi MastamNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Cable Laying of Termination & Installtion Switch Gear PannelsDocument8 pagesCable Laying of Termination & Installtion Switch Gear PannelsZubair Ahmed KhaskheliNo ratings yet

- MS (Fin Fan Coolers)Document3 pagesMS (Fin Fan Coolers)Zubair Ahmed KhaskheliNo ratings yet

- Bolt Tightening Procedure (New)Document1 pageBolt Tightening Procedure (New)Zubair Ahmed KhaskheliNo ratings yet

- MS1 (Painting)Document5 pagesMS1 (Painting)Zubair Ahmed KhaskheliNo ratings yet

- Erection of TanksDocument9 pagesErection of TanksZubair Ahmed KhaskheliNo ratings yet

- MS (Valves)Document1 pageMS (Valves)Zubair Ahmed KhaskheliNo ratings yet

- IP MS 14 Tiling & Flooring (Walls & Floor)Document4 pagesIP MS 14 Tiling & Flooring (Walls & Floor)Zubair Ahmed KhaskheliNo ratings yet

- 18.hot Tapping Preparation & Work.Document11 pages18.hot Tapping Preparation & Work.Zubair Ahmed KhaskheliNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- IP MS 20 Underground PipingDocument7 pagesIP MS 20 Underground PipingZubair Ahmed KhaskheliNo ratings yet

- IP MS 19 Embankment ConstructionDocument4 pagesIP MS 19 Embankment ConstructionZubair Ahmed KhaskheliNo ratings yet

- Installation of Vaporizers JSADocument6 pagesInstallation of Vaporizers JSAZubair Ahmed KhaskheliNo ratings yet

- IP MS 06 Concrete WorkDocument9 pagesIP MS 06 Concrete WorkZubair Ahmed KhaskheliNo ratings yet

- IP MS 09 GroutingDocument4 pagesIP MS 09 GroutingZubair Ahmed KhaskheliNo ratings yet

- IP MS 07 Cast Insitu PilingDocument5 pagesIP MS 07 Cast Insitu PilingZubair Ahmed KhaskheliNo ratings yet

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Document7 pages045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliNo ratings yet

- 3.material Lifting & TransportationDocument5 pages3.material Lifting & TransportationZubair Ahmed KhaskheliNo ratings yet

- IP MS 18 Road PavementDocument12 pagesIP MS 18 Road PavementZubair Ahmed KhaskheliNo ratings yet

- False CeilingDocument19 pagesFalse CeilingZubair Ahmed Khaskheli50% (2)

- Air Conditioning Unit SystemDocument11 pagesAir Conditioning Unit SystemZubair Ahmed KhaskheliNo ratings yet

- Excavator ChecklistDocument1 pageExcavator ChecklistZubair Ahmed KhaskheliNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- 1 To Class-Drilling Machine PDFDocument20 pages1 To Class-Drilling Machine PDFvineethNo ratings yet

- Full Text (Kargin Madi Thesis Bachelor UTM Final Year)Document94 pagesFull Text (Kargin Madi Thesis Bachelor UTM Final Year)madi karginNo ratings yet

- Acumulador de Succion EmersonDocument1 pageAcumulador de Succion EmersonOscar MayorgaNo ratings yet

- TSN - LB - Wall - Construction - Guide-STELL STUD LOAD BEARING WALLDocument30 pagesTSN - LB - Wall - Construction - Guide-STELL STUD LOAD BEARING WALLYang LiNo ratings yet

- Design of Deep BeamsDocument81 pagesDesign of Deep BeamsMayank RajputNo ratings yet

- PS 1-1Document1 pagePS 1-1Mgcini MlangeniNo ratings yet

- 19tooling by Design - Die-Set Guiding Systems - MetalForming MagazineDocument3 pages19tooling by Design - Die-Set Guiding Systems - MetalForming MagazineSIMONENo ratings yet

- A Post-Byzantine Mansion in AthensDocument10 pagesA Post-Byzantine Mansion in AthensLudwigRossNo ratings yet

- Telecom Tower Construction ZTLDocument2 pagesTelecom Tower Construction ZTLNathaniel Williams100% (1)

- Architecture TermsDocument3 pagesArchitecture TermsJoy RedolosaNo ratings yet

- Writing - Describing A Diagram HandoutDocument13 pagesWriting - Describing A Diagram HandoutThu MintuNo ratings yet

- Architectural Licensure Prof Prac Examination ReviewerDocument53 pagesArchitectural Licensure Prof Prac Examination ReviewerMariane PadullaNo ratings yet

- 01.02.2021 - SF 06 - Fire On Terminal and Break Away From JettyDocument4 pages01.02.2021 - SF 06 - Fire On Terminal and Break Away From JettyAlikar Arslan100% (1)

- Installation InstructionsDocument4 pagesInstallation InstructionsPRESS-NEW-BALKANNo ratings yet

- Denah Sebagai Contoh 2Document51 pagesDenah Sebagai Contoh 2Mauditiko PanjiNo ratings yet

- Gin WheelDocument10 pagesGin WheelBarkat Ullah100% (2)

- CarpentryDocument44 pagesCarpentryMelwin MakalintalNo ratings yet

- The Buty Courtyard House at NagpurDocument17 pagesThe Buty Courtyard House at NagpurUday DokrasNo ratings yet

- NCRTC DM0GC PBG ZZZZ TRK RP RT 00001 PDFDocument7 pagesNCRTC DM0GC PBG ZZZZ TRK RP RT 00001 PDFAkshay WahalNo ratings yet

- Detail Estimate of Cross Drainage 2.00MX2.00M Slab CulvertDocument3 pagesDetail Estimate of Cross Drainage 2.00MX2.00M Slab Culvertbharatram dehariyaNo ratings yet

- Causes of Construction DelayDocument6 pagesCauses of Construction DelayxforceNo ratings yet

- Leak Investigation and DetectionDocument5 pagesLeak Investigation and DetectionClarissa Riñon PerezNo ratings yet

- Pre - Qualification Document SampleDocument106 pagesPre - Qualification Document SampleChris EnyinnayaNo ratings yet

- Classification and General Requirement of All Buildings by Use or OccupancyDocument49 pagesClassification and General Requirement of All Buildings by Use or OccupancyMarvin Gagarin0% (1)

- Treasure Hunt Lair of Devo'SsaDocument6 pagesTreasure Hunt Lair of Devo'SsaHnnhnng1311No ratings yet

- Amarna ArticlesDocument19 pagesAmarna ArticlesJames Joel Mendoza Santa CruzNo ratings yet

- SOQ Railway Hospital 205kwDocument3 pagesSOQ Railway Hospital 205kwDebabrata GhoshNo ratings yet

- SCL The Underlying Problem. Ground ConditionsDocument21 pagesSCL The Underlying Problem. Ground Conditionsjscurrie6614100% (1)

- Nitoflor EmeritopDocument4 pagesNitoflor EmeritopVenkata RaoNo ratings yet