Professional Documents

Culture Documents

Practical Solutions1

Practical Solutions1

Uploaded by

Žarko LazićOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practical Solutions1

Practical Solutions1

Uploaded by

Žarko LazićCopyright:

Available Formats

practical

solutions Externally Applied Post-

Tensioning Systems

By K. Dirk Bondy, S.E.

The commentary to Section 18.22 of ACI-318-02 states that From a construction perspective, providing tendons outside of an

“External attachment of tendons is a versatile method of providing existing member has many advantages. One significant advantage is

E

additional strength, or improving serviceability, or both, in existing that, unlike freshly cast concrete, the anchor will usually be placed

structures.” In my opinion, this is an understatement. Of course against mature, hardened concrete that has much less likelihood of

we can’t expect codes to enthusiastically promote a given type bursting under the bearing loads of the anchorage.

R

of construction or retrofit method, but what method other than Another major advantage to EPT is that the tendons, supports

external post-tensioning (EPT) can add tremendous strength, recover and anchorages can easily be inspected during construction, and at

deflections and actively “balance” loading while adding virtually no

h t any time in the future. This is very valuable not only for the initial

U

weight to the existing system? With all this power, however, comes

y r i

responsibility. The designer and constructor must proceed cautiously

g construction of the EPT system, but for regular maintenance.

T n

C o

and be fully aware of the potential ramifications of cutting into and

©

e

placing large horizontal and vertical forces on an existing system.

U C z i

T R a

S

Unstressed external slab tendons

External versus Internal

a

g Stressing external tendons in an existing structure

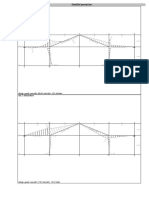

Unlike cast-in-place post-tensioned construction, the equivalent

m

The initial reaction of many engineers to the idea of placing high- or “balance” tendon loads are applied to the structure at discrete

strength tendons outside of a framing system is that the design locations instead of uniformly along the length of the tendon.

principles and guidelines of “normal” post-tensioning may not apply Typically, steel king posts will be used to apply point loads at

anymore. The fact is, however, that there are very few analytical selected locations on the existing structure, with the tendon in a

differences between placing an unbonded tendon inside or outside “harped” or “double-harped” configuration as opposed to the parabolic

of a concrete member. Remember, unbonded tendons placed inside profile typical in cast-in-place construction.

of concrete do not satisfy strain compatibility with the surrounding

concrete because of the fact that they are not bonded to that concrete.

Therefore, when the tendons are placed outside of the concrete, the

incompatibility of the tendons to the concrete remains the same but is

just more visually obvious, leading many to a “gut” reaction that their

thought process about post-tensioning must change.

Final stressed condition of external slab tendons Close-up of the jack stressing the tendons

14 STRUCTURE magazine • July 2005

Coring & Drilling

Virtually all EPT systems applied to an existing concrete struc-

ture will require drilling and/or coring through the existing concrete

members (columns, beams, walls, etc.). It is very important when

first schematically framing the EPT system to verify acceptable

locations to core as well as anchor the tendons. Often these structures

are older and have had many owners. This frequently results in a

loss of the original structural drawings, making the utilization of x-

rays sometimes necessary, particularly for post-tensioned buildings.

In fact, even with the design and shop drawings, x-rays are often

E

necessary for an unbonded post-tensioned structure to prevent

drilling through a tendon. The x-ray operator will use the negatives

to literally draw the rebar and post-tensioning locations on the

R

A typical steel king post concrete beam or slab (Figure 1).

continued on next page

h t

U

y r i g

p

T n

o

Galvanized anchor plate, barrel anchor and cap

C ©

e

The tendons and anchorage hardware used are very similar to that

C

used in internal post-tensioning. Typically a thicker, more durable

sheathing is used for external tendons since they are exposed to

the environment, and the tendons are often galvanized. The

U i

anchor plates are typically flat such that even bearing against the

existing concrete is achieved, and they too, along with the anchors

z

R

themselves, are often galvanized. The wedges do not require any

special treatment, since the hardened wedge metal itself is naturally

T

corrosion resistant; however it is common to treat the cut tendon and

a

anchorage with a corrosion resistant

017_US_R&S_181x127_2 spray before

6/13/05 10:43 capping.

AM Page 1

Figure 1: X-ray results showing post-tensioning and stirrups

S

For Advertiser Information, visit www.structuremag.org

g

a HYDRO AND

m

TUNNELING MARINE STRUCTURES

SLOPE STABILIZATION � �

EXCAVATIONS �

�

COMMERCIAL BUILDINGS

�

DOMESTIC BUILDINGS

�

TANKS

�

MINING SYSTEMS

BRIDGES

� DYWIDAG Repair &

� Strengthening Systems

� Inspection � Engineering and Design

of Repair Solutions

� Non-Destructive Testing

(Impact Echo, � Vacuum Grouting

Ground Penetrating Radar,

� Grouting Remediation

Voids measurement, etc.)

� Repair and Strengthening

� Specialized Limited Invasive

Inspection (special drilling, � Special Products:

videoscope, etc.) DSI Half Pipe, DYNA®-Shield,

DYNA®-Wrap

DYWIDAG-SYSTEMS INTERNATIONAL USA INC.

Repair and Strengthening

4732 Stone Dr., Suite B 11201 Longwood Court 14520 Old Katy Rd., Suite 124 320 Marmon Dr. 3707 S. Godfrey Blvd., Suite 106

Tucker, GA 30084 Bradenton, FL 34209 Houston, TX 77079 Bolingbrook, IL 60440 Spokane, WA 99224

Phone: (770) 934-5331 Phone: (941) 761-4746 Phone: (281) 497-2625 Phone: (630) 972-4091 Phone: (509) 456-0111

Fax: (770) 934-5119 Fax: (941) 795-8781 Fax: (281) 201-9812 Fax: (630) 739-5517 Fax: (509) 267-2730

E-mail: dsiamerica E-mail: dsiamerica E-mail: dsiamerica E-mail: dsiamerica E-mail: dsiamerica

@dsiamerica.com @dsiamerica.com @dsiamerica.com @dsiamerica.com @dsiamerica.com

www.dsiamerica.com

STRUCTURE magazine • July 2005 15

It is imperative that experienced and highly skilled personnel Protection of the EPT System

perform the coring operations. They must be able to immediately

The environment and function of the external post-tensioning

identify when they have encountered rebar, post-tensioning or

system will dictate the necessity for corrosion and fire protection

conduit. An experienced core driller will be able to identify when he

of the tendons and hardware. In moist or corrosive environments

is penetrating the plastic sheathing of a tendon and will stop before

galvanized tendons and anchorage hardware are often used,

rupturing any wires in the strand, whereas a novice core driller could

and the remaining hardware is either painted or also galvanized.

compromise the entire stability of the beam by severing tendons and/

However, the engineer must be aware that the galvanizing process

or critical rebar. An experienced core driller will often place a hole

of the tendons reduces the tendon ultimate strength and this must

by first using a drill to create a pilot hole, and then using a slightly

be accounted for in the design.

larger core drill at the same location. The drill is much less likely

The Commentary to Section 18.22.4 of ACI 318-02 states that

to sever a tendon and is typically not capable of penetrating rebar,

E

“Corrosion protection methods should meet the fire protection

making it a much safer device where the potential for conflict exists.

requirements of the general building code, unless the installation

of external post-tensioning is to only improve serviceability.”

R

Many designers of EPT have argued successfully with the

building official that if the structure has proven or can be shown

h t not to be in danger of collapse without the external tendons, then

U

y r i g fireproofing should not be necessary. Also, in some cases it has been

successfully argued that a new or existing fire sprinkler system is an

p

T n

C o acceptable alternative to applied fireproofing. However, each city

©

e

is different and the building official will ultimately make the final

C

determination regarding fire protection.

R U z i

T a

Coring through an existing beam

Anchoring the Tendons

S g

The horizontal forces are applied at the anchorage locations, and

these locations must be capable of resisting the bearing and shear

forces generated by the anchor plates. Great care must also be taken

a

when coring through columns. The engineer must verify that the Fireproofing on external tendons

column has adequate bracing through dowel action to the slab or

beam for the externally applied anchorage loads, as well as capacity

Stressing Tendons around Existing Obstacles

m

for any new vertical loads that the column may need to resist. When properly designed and placed, the ability of the external

tendons to traverse through the pipes, lights, and partition walls

without disruption to the building function is one of the pri-

mary reasons to consider using an EPT system for strengthening.

However, the designer and the contractor must verify that, when the

tendons are stressed and take on their final taut form, no existing

elements will be damaged. Most experienced EPT contractors will

stress each tendon to approximately 500 pounds in order to verify

that all king posts and supports are aligned correctly, and that ob-

stacles such as utility pipes and lights will not be affected by the

straightened tendons when fully stressed.

When to Use an EPT System

Externally applied tendons should be considered for all of the

Anchoring at a column following conditions:

1. Strengthening an existing structure for added loading or

Avoid Excessive Vertical Forces occupancy change;

Unlike traditional “passive” retrofit or strengthening systems, the 2. Strengthening an existing structure that has lost vertical load

controlling load condition with an EPT (or internal post-tensioning) carrying capacity due to corrosion or deterioration;

system may be the “unloaded” condition. Designers who only analyze 3. When the space below needs to be maintained and cannot

the fully loaded condition and provide post-tensioning that function properly with added structural elements;

“balances” the applied loading may be overlooking an “over-balanced” 4. When alternate strengthening systems would add a significant

condition when the applied loading does not exist. In rare cases, enough amount of weight to affect the existing column,

the existing system has been so severely jacked up that the post- foundation or seismic system capacity;

tensioning has dislodged portions of the floor. 5. For recovering excessive floor or roof deflections (serviceability).

16 STRUCTURE magazine • July 2005

for typical construction often leads to conflict… sometimes much

worse in an EPT project. These projects have proven to be most

successful when the engineer and contractor team together or are

the same entity. Given that the existing conditions can almost

never be totally anticipated in design, the actual design usually

continues to be modified through construction. This mandates

that the contractor and designer work as a team instead of the more

traditional and often adversarial relationship.

A Final Note

E

Based upon our experience, the permitting process on large EPT

projects can vary from receiving an “over the counter” permit to three

months of multiple outside peer reviews. It is almost a guarantee that

R

the building department will not have anyone employed with the

relevant experience to provide a thorough review of the calculations

Avoiding plumbing obstacles

h t and drawings for an EPT system. Therefore, they will either rely

U

Cost Considerations

y r i g heavily on the engineer’s ability to instill confidence in them that the

design is sound and that no harm will come to the building, or go to

p

T n

o

Obviously, the cost of an EPT system depends on numerous

C

an outside firm (or firms) to provide a review. Most cities do not want

©

e

variables. Access, the number of elements requiring strengthening, to be trail-blazers, so they will rely on the engineer to demonstrate

C

the area requiring strengthening, the inadequacy of the existing the past performance of similar strengthening schemes. With all

system, acceptable anchorage locations, required treatment of this in mind, the typical range of cost for a turn-key design-build

the tendon system etc. are all contributors to the cost of the EPT EPT solution by an experienced engineer-contractor team has been

U

system. Additionally, designing and implementing an EPT system between $12.50 and $25 per square foot (excluding fireproofing).

i

is not an endeavor that should be attempted by novice engineers This has proven to be extremely competitive with all other methods

or contractors. In fact, the traditional design and bid process used of strengthening existing buildings.▪

z

R

K. Dirk Bondy, S.E. is President of Seneca Structural Engineering, Inc., a design firm specializing in both internal and external post-

T

tensioning. He is also the president and RMO of The Great American Cable Company II, Inc., a contracting firm specializing in the construction

a

of external post-tensioning systems. Dirk can be reached at Dirk@senecastructural.com

S

STRUCTURE

a

g

m ©ATLAS SYSTEMS, INC.®2004

magazine

For Advertiser Information, visit www.structuremag.org

©ATLAS SYSTEMS, INC.®2004

©ATLAS SYSTEMS, INC.®2004

Visit

www.structuremag.org

for subscription information

STRUCTURE magazine • July 2005 17

You might also like

- Anton Kriel Detailed ReviewDocument4 pagesAnton Kriel Detailed ReviewMus'ab Abdullahi Bulale100% (2)

- CQI 29 Frankin Brazing 2022 SummaryDocument2 pagesCQI 29 Frankin Brazing 2022 SummaryEdward100% (1)

- Circular Flow Model WorksheetDocument2 pagesCircular Flow Model Worksheetapi-320972635No ratings yet

- 2020 - Preliminary Design of Post-Tensioned Transfer GirdersDocument7 pages2020 - Preliminary Design of Post-Tensioned Transfer Girdersryan rakhmatNo ratings yet

- Anchoring Into Housekeeping Pads: ConcreteDocument2 pagesAnchoring Into Housekeeping Pads: ConcreteFredie UnabiaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Group-8 - Ross Abernathy and The Frontier National BankDocument11 pagesGroup-8 - Ross Abernathy and The Frontier National Bankshalini kaushikNo ratings yet

- Final ArticleDocument4 pagesFinal ArticleCarlosAlbertoGrimaldoBarajasNo ratings yet

- D-Product Watch Crigler Post Tension Revisit1Document4 pagesD-Product Watch Crigler Post Tension Revisit1khx2No ratings yet

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 10Document78 pagesPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 10Carlos Alberto Pacheco SierraNo ratings yet

- Determination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsDocument3 pagesDetermination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsklllNo ratings yet

- Repair and RehabilitationDocument22 pagesRepair and RehabilitationConstro FacilitatorNo ratings yet

- STR-Post-Installed Adhesive Anchor SystemsDocument2 pagesSTR-Post-Installed Adhesive Anchor SystemsFWICIPNo ratings yet

- Geometrical Nonlinearity and Length of External Tendons: Marco A. Pisani, M.ASCEDocument10 pagesGeometrical Nonlinearity and Length of External Tendons: Marco A. Pisani, M.ASCEAli OmarNo ratings yet

- Design of Precast Prestressed Concrete Members Using External PrestressingDocument11 pagesDesign of Precast Prestressed Concrete Members Using External Prestressingdoomflare2000xNo ratings yet

- Review On Optimization of Post Tension of Concrete Floor SlabDocument4 pagesReview On Optimization of Post Tension of Concrete Floor SlabSaja AliNo ratings yet

- PDH Post Tensioned Concrete Design PDFDocument8 pagesPDH Post Tensioned Concrete Design PDFabdulmananNo ratings yet

- A Study On Behaviour of Outrigger System On High Rise Steel Structure by Varying Outrigger DepthDocument5 pagesA Study On Behaviour of Outrigger System On High Rise Steel Structure by Varying Outrigger DepthshamkumavatNo ratings yet

- State-of-the-Art of Integral Abutment Bridges: Design and PracticeDocument10 pagesState-of-the-Art of Integral Abutment Bridges: Design and PracticeEduardo Reyes NegreteNo ratings yet

- Post TentioningDocument14 pagesPost TentioningAanchalNo ratings yet

- C StrucTesting Geister March131Document4 pagesC StrucTesting Geister March131Aamir HaideriNo ratings yet

- Évaluation de L'aptitude Au Service Des Ponts À Poutres en Caisson en Béton Post-Tendu, Basée Sur La Fissuration.Document12 pagesÉvaluation de L'aptitude Au Service Des Ponts À Poutres en Caisson en Béton Post-Tendu, Basée Sur La Fissuration.Sebahi LakhalNo ratings yet

- Precast Concrete Buildings in Seismic AreasDocument10 pagesPrecast Concrete Buildings in Seismic AreasAlan100% (1)

- ACI - Handbook 1Document6 pagesACI - Handbook 1CyrilNo ratings yet

- One Engineer's Opinion - Bolted SplicesDocument2 pagesOne Engineer's Opinion - Bolted SplicesDoctoreNo ratings yet

- Earthquake Resistance: Ductility NeedsDocument4 pagesEarthquake Resistance: Ductility NeedssteveassaNo ratings yet

- C EngrNB Antiquated Stuart Sept08 PDFDocument4 pagesC EngrNB Antiquated Stuart Sept08 PDFJason PowellNo ratings yet

- Cyclic Response of Unbonded Posttensioned Precast Columns With Ductile Fiber-Reinforced ConcreteDocument11 pagesCyclic Response of Unbonded Posttensioned Precast Columns With Ductile Fiber-Reinforced ConcreteMarimuthu KaliyamoorthyNo ratings yet

- VG0-Pap - (ASCE) - Shear Behaviour of Joints in Segmental BridgesDocument22 pagesVG0-Pap - (ASCE) - Shear Behaviour of Joints in Segmental BridgesPATHA ADITHSAINo ratings yet

- C StrucDesign Morgan Jun151 PDFDocument3 pagesC StrucDesign Morgan Jun151 PDFkyleNo ratings yet

- (2-6) (ASCE Structure) Experimental and Nonlinear Numerical Analysis of Precast Concrete Column Splices With High-Yield Metal PlatesDocument15 pages(2-6) (ASCE Structure) Experimental and Nonlinear Numerical Analysis of Precast Concrete Column Splices With High-Yield Metal PlatesPhạm Tiến ĐạtNo ratings yet

- Precast Segment Lining DesignDocument11 pagesPrecast Segment Lining DesignM Sajid IqbalNo ratings yet

- Behaviour of Precast Reinforced Concrete Pile CapsDocument6 pagesBehaviour of Precast Reinforced Concrete Pile CapsmdiasNo ratings yet

- 28 AsDocument12 pages28 AsPerson GainableNo ratings yet

- Truss BracingDocument4 pagesTruss BracingTuanQuachNo ratings yet

- 2020 August, Preliminary Design of Post-Tensioned Transfer GirdersDocument7 pages2020 August, Preliminary Design of Post-Tensioned Transfer GirdersMonika jainNo ratings yet

- Ductile Connectors For A Precast Concrete FrameDocument14 pagesDuctile Connectors For A Precast Concrete FrameNELSON TRAQUINHONo ratings yet

- A Precast Segmental Substructure System For Standard BridgesDocument18 pagesA Precast Segmental Substructure System For Standard BridgesJack JackNo ratings yet

- Point Loads On Precast Concrete FloorsDocument19 pagesPoint Loads On Precast Concrete Floorskhemindra narainNo ratings yet

- Install USINCHDocument24 pagesInstall USINCHReigna GuanzonNo ratings yet

- (Extract) Racking Deformation Angle vs. Story Drift Ratio - From CTBUH (2008) Recommendations For The Seismic Design of High-Rise BuildingsDocument2 pages(Extract) Racking Deformation Angle vs. Story Drift Ratio - From CTBUH (2008) Recommendations For The Seismic Design of High-Rise BuildingsO SNo ratings yet

- Finite Elements AnalysisDocument11 pagesFinite Elements Analysissohailpkhan99No ratings yet

- 5022 - KIM S. ELLIOTT - The Stability of Precast Concrete Skeletal StructuresDocument19 pages5022 - KIM S. ELLIOTT - The Stability of Precast Concrete Skeletal StructuressamiNo ratings yet

- Shear Design and Assessment of Reinforced and Prestressed Concrete Beams Based On A Mechanical ModelDocument17 pagesShear Design and Assessment of Reinforced and Prestressed Concrete Beams Based On A Mechanical ModelMohamed EhabNo ratings yet

- (5-1) ASCE Construction Interlocking Mechanical Joints Using CouplersDocument12 pages(5-1) ASCE Construction Interlocking Mechanical Joints Using CouplersPhạm Tiến ĐạtNo ratings yet

- Rational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsDocument13 pagesRational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsRayan MahgoubNo ratings yet

- Shotcrete Nozzleman Basics - Vertical Wall ConstructionDocument4 pagesShotcrete Nozzleman Basics - Vertical Wall ConstructionFroilan AngbengcoNo ratings yet

- Post Tensioning DesignDocument4 pagesPost Tensioning DesignFrancisFengNo ratings yet

- Prestressed Concrete Structures: Under The Guidance Of: Prof. & Head Department of Civil EngineeringDocument42 pagesPrestressed Concrete Structures: Under The Guidance Of: Prof. & Head Department of Civil EngineeringPtp AbyNo ratings yet

- JL 98 September October 6Document19 pagesJL 98 September October 6rohanZorbaNo ratings yet

- CEM - April 2015 A Primer On Rectangular TanksDocument7 pagesCEM - April 2015 A Primer On Rectangular TanksT. LimNo ratings yet

- BQS502 Lec 5 Pre-Stressed Concrete FramesDocument35 pagesBQS502 Lec 5 Pre-Stressed Concrete FramesUMMI KALTHOM NABILAH ISMAILNo ratings yet

- L1 21 How To Avoid Torsion PDFDocument2 pagesL1 21 How To Avoid Torsion PDFdhanya1995100% (1)

- An Investigation On The Behavior of A New Connection For Precast Structures Under Reverse Cyclic LoadingDocument10 pagesAn Investigation On The Behavior of A New Connection For Precast Structures Under Reverse Cyclic LoadingMohammad AkbarNo ratings yet

- Anchor Load Cell Installation GuideDocument18 pagesAnchor Load Cell Installation GuideFrancisco Ordoñez MuñozNo ratings yet

- High Rise BuildingDocument5 pagesHigh Rise Buildingmadina1386No ratings yet

- Engineering Structures: J.S. Du, Francis T.K. Au, Enoch K.H. Chan, L. LiuDocument8 pagesEngineering Structures: J.S. Du, Francis T.K. Au, Enoch K.H. Chan, L. LiuRodrigo ApolinarioNo ratings yet

- Base Isolation For Seismic Retrofitting PDFDocument12 pagesBase Isolation For Seismic Retrofitting PDFErgys PrendiNo ratings yet

- Concrete Construction Article PDF - Tilt-Up in Seismically Active AreasDocument4 pagesConcrete Construction Article PDF - Tilt-Up in Seismically Active AreasVishal Parashuram MiskinNo ratings yet

- Prestressed Concrete Design Prestressed Concrete Design: CBDG Design Guide CBDG Design GuideDocument6 pagesPrestressed Concrete Design Prestressed Concrete Design: CBDG Design Guide CBDG Design GuideKeith GarridoNo ratings yet

- 1 2 ConstructionDocument13 pages1 2 ConstructionLuis Hernán Guillén CardonaNo ratings yet

- Shear Design Consideration For Prestressed Beams: Aci Structural Journal Technical PaperDocument7 pagesShear Design Consideration For Prestressed Beams: Aci Structural Journal Technical PaperKoresh KhalpariNo ratings yet

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Laser Rebar ScannerDocument91 pagesLaser Rebar ScannerŽarko LazićNo ratings yet

- FB IMG 1684668999877 jKOZzhvdAlIZwZQDocument21 pagesFB IMG 1684668999877 jKOZzhvdAlIZwZQŽarko LazićNo ratings yet

- Effect of External Post-Tensioning in Retrofitting of RC BeamsDocument8 pagesEffect of External Post-Tensioning in Retrofitting of RC BeamsŽarko LazićNo ratings yet

- 2020 Catalog of Pile Integrity TesterDocument3 pages2020 Catalog of Pile Integrity TesterŽarko LazićNo ratings yet

- Dragoslav Andric Sah Igra MilionaDocument109 pagesDragoslav Andric Sah Igra MilionaŽarko LazićNo ratings yet

- FB IMG 1682199359798 YP1uATAzViXe4DTDocument16 pagesFB IMG 1682199359798 YP1uATAzViXe4DTŽarko LazićNo ratings yet

- Introduction of Possible Inspection Methods For Evaluating Thermal Aging Status of Existing Pre-Insulated District Heating SystemsDocument29 pagesIntroduction of Possible Inspection Methods For Evaluating Thermal Aging Status of Existing Pre-Insulated District Heating SystemsŽarko LazićNo ratings yet

- Sp208-04ex 6Document22 pagesSp208-04ex 6Žarko LazićNo ratings yet

- P61-Pile Integrity TesterDocument23 pagesP61-Pile Integrity TesterŽarko LazićNo ratings yet

- External Pressure & Loading Analysis To Tunnel, Pipe Culvert & Arch Culvert Wall.Document8 pagesExternal Pressure & Loading Analysis To Tunnel, Pipe Culvert & Arch Culvert Wall.Žarko LazićNo ratings yet

- Sp208-04ex 5Document17 pagesSp208-04ex 5Žarko LazićNo ratings yet

- Dynamic Performance of A Stayed Highway Bridge Under Traffic Loads: Design Predictions vs. Dynamic Test ResultsDocument10 pagesDynamic Performance of A Stayed Highway Bridge Under Traffic Loads: Design Predictions vs. Dynamic Test ResultsŽarko LazićNo ratings yet

- Opt. 1: GDocument4 pagesOpt. 1: GŽarko LazićNo ratings yet

- Prediction of Undrained Shear Strength and CorrelaDocument9 pagesPrediction of Undrained Shear Strength and CorrelaŽarko LazićNo ratings yet

- SP 273 15Document18 pagesSP 273 15Žarko LazićNo ratings yet

- GredaDocument1 pageGredaŽarko LazićNo ratings yet

- In-Situ Evaluation of Structures Using Load TestingDocument11 pagesIn-Situ Evaluation of Structures Using Load TestingŽarko LazićNo ratings yet

- Shake Table Tests of Tall-Pier Bridges To Evaluate Seismic PerformanceDocument13 pagesShake Table Tests of Tall-Pier Bridges To Evaluate Seismic PerformanceŽarko LazićNo ratings yet

- Vibration Versus de Ection Control For Bridges With High-Performance Steel GirdersDocument11 pagesVibration Versus de Ection Control For Bridges With High-Performance Steel GirdersŽarko LazićNo ratings yet

- Greda 2. HOP 50x50x3 3. HOP 80x80x3 4. HOP 60x60x3 Ram: V - 4Document1 pageGreda 2. HOP 50x50x3 3. HOP 80x80x3 4. HOP 60x60x3 Ram: V - 4Žarko LazićNo ratings yet

- Value Chart For YES Prosperity Edge Credit CardDocument1 pageValue Chart For YES Prosperity Edge Credit CardRajeev KumarNo ratings yet

- Agreement of 34 Buffer Shed ProjectDocument6 pagesAgreement of 34 Buffer Shed ProjectenigmaNo ratings yet

- Aggregate Supply AnswersDocument10 pagesAggregate Supply AnswersMomoNo ratings yet

- TreesDocument15 pagesTreesMuhammad HaseebNo ratings yet

- L7 - Environmental Economics IDocument19 pagesL7 - Environmental Economics I楊子慶No ratings yet

- Super Abrasive CatalogueDocument8 pagesSuper Abrasive CatalogueBorisNo ratings yet

- Cheque Requisition Form SampleDocument1 pageCheque Requisition Form SamplehenaediNo ratings yet

- Capex - Loma Larga - INV MetalsDocument2 pagesCapex - Loma Larga - INV MetalsEzequiel Guillermo Trejo NavasNo ratings yet

- Lesson 4 - PMP - Prep - Integration Management - V2-1 PDFDocument31 pagesLesson 4 - PMP - Prep - Integration Management - V2-1 PDFJohn ChibweNo ratings yet

- DS (Pan Africanism)Document59 pagesDS (Pan Africanism)Eden Alvaro EmilyNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- Penetron LetterDocument3 pagesPenetron LetterPartha GangopadhyayNo ratings yet

- Introduction To Financial ProgrammingDocument60 pagesIntroduction To Financial ProgrammingKARANGWA MATHIASNo ratings yet

- 3D2N Semporna MabulDocument3 pages3D2N Semporna MabulFARHAH FATIHAH BINTI AZLAN -No ratings yet

- Connection Data Sheet NSMAX GR 55ksi (Rev.0 2020.06.24)Document21 pagesConnection Data Sheet NSMAX GR 55ksi (Rev.0 2020.06.24)LiLiNo ratings yet

- Cma Final SCM - Vol 1Document405 pagesCma Final SCM - Vol 1Pritam patelNo ratings yet

- ABC Costing Classic Pen CaseDocument3 pagesABC Costing Classic Pen CaseNISHANT KATKARNo ratings yet

- ADAMA SCIENCE TripDocument4 pagesADAMA SCIENCE TripeyobNo ratings yet

- Inductive Grammar Chart (Unit 5, Page 38)Document1 pageInductive Grammar Chart (Unit 5, Page 38)Englishmeif Ohb XalapaNo ratings yet

- Akshaya Nidhi Case SummaryDocument3 pagesAkshaya Nidhi Case SummaryAnanda BudiNo ratings yet

- Solicitation Letter FinesDocument2 pagesSolicitation Letter FinesdylanNo ratings yet

- FDNACCT Business Case - 3T1819 PDFDocument2 pagesFDNACCT Business Case - 3T1819 PDFRoy BonitezNo ratings yet

- How To Use Linear Equations in Everyday LifeDocument3 pagesHow To Use Linear Equations in Everyday LifeSundaraneedi Naveen Kumar100% (1)

- Math Suggestion and SolutionDocument22 pagesMath Suggestion and SolutionCasanovicNo ratings yet

- Eco211-Revision ExercisesDocument4 pagesEco211-Revision ExercisesfarahNo ratings yet

- Fa048 1407enDocument58 pagesFa048 1407envirk_70No ratings yet