Professional Documents

Culture Documents

Tablas de Conversión de Torque Hyctor

Tablas de Conversión de Torque Hyctor

Uploaded by

Bladimyr CardenasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tablas de Conversión de Torque Hyctor

Tablas de Conversión de Torque Hyctor

Uploaded by

Bladimyr CardenasCopyright:

Available Formats

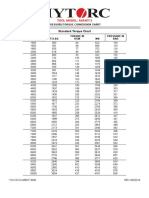

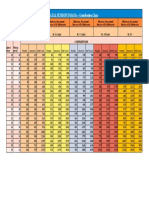

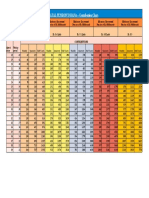

HYTORC

TOOL MODEL: HY-.5XLT

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN TORQUE IN PRESSURE IN

PSI FT. LBS. KGM NM BAR

1500 55 8 75 104

1600 59 8 80 110

1800 67 9 91 124

2000 75 10 102 138

2200 83 12 113 152

2400 92 13 124 165

2600 100 14 136 179

2800 109 15 147 193

3000 117 16 159 207

3200 125 17 169 220

3400 133 18 180 234

3600 140 19 190 248

3800 148 20 201 262

4000 156 22 211 276

4200 164 23 223 290

4400 172 24 234 303

4600 181 25 245 317

4800 189 26 256 331

5000 197 27 267 345

5200 206 28 279 358

5400 215 30 291 372

5600 223 31 303 386

5800 232 32 315 400

6000 241 33 327 414

6200 249 34 338 427

6400 257 36 349 441

6600 266 37 360 455

6800 274 38 371 468

7000 282 39 382 482

7200 289 40 392 496

7400 296 41 402 510

7600 304 42 412 524

7800 311 43 421 538

8000 318 44 431 552

8200 326 45 442 565

8400 334 46 453 579

8600 342 47 464 593

8800 350 48 474 607

9000 358 50 485 620

9200 366 51 496 634

9400 374 52 506 648

9600 381 53 517 662

9800 389 54 528 676

10000 397 55 538 690

* ISO DOCUMENT 9000 REV. 2/18/1997

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions should be

observed to avoid accidents or personal injury. The following tips will assist you.

• READ ALL INSTUCTIONS.

• KEEP WORK AREA CLEAN AND WELL LIT.

• CONSIDER WORK AREA ENVIRONMENT. Electrical Pumps should never be used in an atmosphere which can be

considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact can cause sparks, precautions

should be taken.

• AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

• STAY CLEAR DURING OPERATION. In most cases, the tool will allow “hands free” operation. If the tool must be held or steadied

during operation, use alternative means of securing the tool to the application

• GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being used.

• STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

• USE RIGHT TOOL. Don’t force small tools or attachments to do the job of a larger tool. Don’t use a tool for purposes not intended.

• PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety shoes and other

applicable clothing.

• USE SAFETY GLASSES.

• MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of moving the equipment.

• MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual damage frequently and

always prior to use. Always follow instruction for proper tool and pump maintenance. Refer to the Operations Maintenance Section for

further clarification

• STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the influence of any mood altering

substances.

• PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

• PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to “ride up” or to “creep”, stop and re-adjust the reaction arm to a more solid and

secure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and reaction surfaces.

• ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are the correct size and

fully engage the nut. Hidden flaws, however, remain a possibility which could cause breakage, so stay clear of sockets during operation

• DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)

NOTE: Hytorc Pumps are designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

You might also like

- XLCT-8-Torque-Conversion-Chart (1)Document2 pagesXLCT-8-Torque-Conversion-Chart (1)victor villaNo ratings yet

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- Tabla STEALTH 14Document2 pagesTabla STEALTH 14luz_cuellar_15No ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- 0,5 XLTDocument2 pages0,5 XLTFranciscoJSilvaNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- MXTP 01 Torque Conversion ChartDocument2 pagesMXTP 01 Torque Conversion ChartjavhirNo ratings yet

- Standard Torque Chart: Tool Model: MXT 1Document2 pagesStandard Torque Chart: Tool Model: MXT 1Wahyu WidiyantoNo ratings yet

- 1XLT TR2Document2 pages1XLT TR2FranciscoJSilvaNo ratings yet

- STEALTH 2 Torque Conversion ChartDocument2 pagesSTEALTH 2 Torque Conversion Chartluisantoniojimenezperez31No ratings yet

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- RTX04 Torque ChartDocument1 pageRTX04 Torque ChartYang Kyo OhNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- Sitio WebDocument15 pagesSitio WebRoberto RodriguezNo ratings yet

- HighTensileFastners PDFDocument24 pagesHighTensileFastners PDFMallika SahniNo ratings yet

- Polycab Price List 16th October 2021Document2 pagesPolycab Price List 16th October 2021Kushal DixitNo ratings yet

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- Partial Horizontal Tank Volumes: ParametersDocument4 pagesPartial Horizontal Tank Volumes: ParametersSagar DhuriNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- Kode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)Document7 pagesKode HS Deskripsi HS January Nil/Val (US $) January BRT/WGT (KG)eniNo ratings yet

- Indice IntraindustrialDocument17 pagesIndice IntraindustrialJuan Camilo ArboledaNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- catchment area to runoff yield 2 ١Document1 pagecatchment area to runoff yield 2 ١Ahmed NabilNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- Test 11Document3 pagesTest 11shinjuvijayNo ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Laboratory Exercise No. 5 Rheological PropertiesDocument16 pagesLaboratory Exercise No. 5 Rheological PropertiesANIME CHANNo ratings yet

- Measurements For Anchor-Chain and AccessoriesDocument4 pagesMeasurements For Anchor-Chain and AccessoriesOzata TersanesiNo ratings yet

- Phone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Document2 pagesPhone:-Director Office FAX WWW - Kerala.gov - in 0471-2305230 0471-2305193 0471-2301740Akhila kumarNo ratings yet

- MEIZON GUTU DDocument7 pagesMEIZON GUTU DlevisontawandaNo ratings yet

- Apy ChartDocument1 pageApy ChartTechnology GamerNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFPravrutti DahiwaleNo ratings yet

- Apy ChartDocument1 pageApy ChartMohit PathaniaNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFSHUBHAJIT NANDINo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFAswin AbiNo ratings yet

- Apy ChartDocument1 pageApy Chartkrishna garaiNo ratings yet

- Apy ChartDocument1 pageApy Chartvmcon kkl 2020No ratings yet

- apy chartDocument1 pageapy chartBiltu BasakNo ratings yet

- Apy ChartDocument1 pageApy ChartJai mishraNo ratings yet

- Apy ChartDocument1 pageApy ChartUday GopalNo ratings yet

- APY Chart PDFDocument1 pageAPY Chart PDFRahul TadeNo ratings yet

- Apy ChartDocument1 pageApy ChartPRANAV MUKTIBODHNo ratings yet

- Apy Chart PDFDocument1 pageApy Chart PDFavinash1987100% (1)

- Apy ChartDocument1 pageApy ChartClassicaverNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Electric Door ChimsDocument13 pagesElectric Door ChimsSabhaya ChiragNo ratings yet

- Problem Statement DraftDocument4 pagesProblem Statement Draftapi-491319450No ratings yet

- University of Cagayan Valley School of Criminology 32Document6 pagesUniversity of Cagayan Valley School of Criminology 32janna danNo ratings yet

- 8100 Series Fire Pumps: Replacement Parts ForDocument10 pages8100 Series Fire Pumps: Replacement Parts ForAlvialvarezNo ratings yet

- Urine Case 2010-2Document9 pagesUrine Case 2010-2hendra_darmawan_4No ratings yet

- Test Methods: Specifications Premium Diesel Current ASTM D 975 Issues Test MethodsDocument12 pagesTest Methods: Specifications Premium Diesel Current ASTM D 975 Issues Test MethodsNattapong PongbootNo ratings yet

- A Presentation On: Presented byDocument67 pagesA Presentation On: Presented byOlufemi KolawoleNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2006/0252856 A1Document4 pagesPatent Application Publication (10) Pub. No.: US 2006/0252856 A1هیمن مNo ratings yet

- Check Your Listening Comprehension - Matching SpeakersDocument50 pagesCheck Your Listening Comprehension - Matching Speakerslindazykov43719No ratings yet

- Lincoln Invertec 270t ManualDocument14 pagesLincoln Invertec 270t ManualecocadecNo ratings yet

- Risk Management For SchoolsDocument3 pagesRisk Management For SchoolsERNEST APPIAHNo ratings yet

- Climate and Consumption Pattern - Demand and Supply of Water District ConcessionairesDocument3 pagesClimate and Consumption Pattern - Demand and Supply of Water District ConcessionairesIJAERS JOURNALNo ratings yet

- Health Problems Illnesses Sickness Ailments Injuries Pictionary Poster Vocabulary WorksheetDocument2 pagesHealth Problems Illnesses Sickness Ailments Injuries Pictionary Poster Vocabulary WorksheetTania Lopez100% (1)

- Abb TmaxDocument382 pagesAbb TmaxMohammed AbdelsalamNo ratings yet

- Managing Remuneration MCQDocument5 pagesManaging Remuneration MCQlol100% (1)

- Concept Questions From Marine BiologyDocument2 pagesConcept Questions From Marine BiologyJameeNo ratings yet

- Analysis of The Effects of Broken Family On Ourl Lady of Fatima UniversityDocument10 pagesAnalysis of The Effects of Broken Family On Ourl Lady of Fatima UniversityMark Angelo MacedaNo ratings yet

- Emergency Preparedness Audit - GuideDocument20 pagesEmergency Preparedness Audit - GuideMaricris Napigkit SerranoNo ratings yet

- Masters of The House (Fitch 8 June 2005) A Review of UK RMBS Master Trusts PDFDocument32 pagesMasters of The House (Fitch 8 June 2005) A Review of UK RMBS Master Trusts PDFfodriscollNo ratings yet

- Al-Fasi Et Al.2015 PDFDocument8 pagesAl-Fasi Et Al.2015 PDFUmroh NuryantoNo ratings yet

- Gender and Development: Name: Date Submitted: Course & Year: TeacherDocument4 pagesGender and Development: Name: Date Submitted: Course & Year: TeacherJonah TongcoNo ratings yet

- ThesisDocument17 pagesThesisDena EstoNo ratings yet

- HEALTH 9 QUARTER2 MODULE3 WeeK5-6Document9 pagesHEALTH 9 QUARTER2 MODULE3 WeeK5-6Heidee Basas100% (3)

- MGMT 591-Final Project Duewk7Document13 pagesMGMT 591-Final Project Duewk7jmquint00100% (1)

- Hofstead Cultural DimensionDocument29 pagesHofstead Cultural DimensionAbhishek PathodeNo ratings yet

- 2.TT Ref620Document21 pages2.TT Ref620Nermina MalićevićNo ratings yet

- Star Health and Allied Insurance Company LimitedDocument16 pagesStar Health and Allied Insurance Company LimitedManikandan VijayanarayananNo ratings yet

- 3 Thiazine, Oxazine, and Phenazine Leuco Dyes: Tran Van ThienDocument2 pages3 Thiazine, Oxazine, and Phenazine Leuco Dyes: Tran Van ThienFakhar AhmadNo ratings yet

- Solid Waste Management: By: Dr. Mohd Ariffin Abu HassanDocument47 pagesSolid Waste Management: By: Dr. Mohd Ariffin Abu HassanFaiqa Abd Aziz100% (1)

- The Therapist Within You: A Handbook of Kinesiology Self-Therapy With The Pendulum - Jonathan LivingstoneDocument5 pagesThe Therapist Within You: A Handbook of Kinesiology Self-Therapy With The Pendulum - Jonathan LivingstonegihasaryNo ratings yet