Professional Documents

Culture Documents

35 08 Q Mark Fire Door Fitting Instructions

35 08 Q Mark Fire Door Fitting Instructions

Uploaded by

MaríaPaula CheheidCopyright:

Available Formats

You might also like

- Processing of Bopp FilmDocument49 pagesProcessing of Bopp FilmHassan Ali Khan78% (9)

- Mil-Prf-85285e T2 PDFDocument3 pagesMil-Prf-85285e T2 PDFLuis Barrios ArandaNo ratings yet

- SUPERWOOD INDUSTRIES SDN BHD - Catalogue (1) (Door)Document18 pagesSUPERWOOD INDUSTRIES SDN BHD - Catalogue (1) (Door)project.skabai02No ratings yet

- Posi Struts DetailsDocument15 pagesPosi Struts DetailsSuciul E ViuNo ratings yet

- Cavity Instructions 2016Document2 pagesCavity Instructions 2016James GraveyNo ratings yet

- Sliding Door Installation InstructionsDocument2 pagesSliding Door Installation InstructionsJaseSG1No ratings yet

- Care & Installation Instructions: Bifold Door Pre - Installation Instructions Bifold Door Installation InstructionsDocument1 pageCare & Installation Instructions: Bifold Door Pre - Installation Instructions Bifold Door Installation Instructionskevin_au18No ratings yet

- BCA GN 16 Guarding To Openable Windows With Low Cills Rev 1 Sept 2016Document5 pagesBCA GN 16 Guarding To Openable Windows With Low Cills Rev 1 Sept 2016HarveyNo ratings yet

- Instruções Bate Maca 1800Document2 pagesInstruções Bate Maca 1800Rafael FlorentinoNo ratings yet

- Ig Gabions May 2015Document2 pagesIg Gabions May 2015LynxNo ratings yet

- DX Suspended Ceiling System Usg BoralDocument48 pagesDX Suspended Ceiling System Usg BoralmctmcNo ratings yet

- Crystal Door Installation Guide 2019 - MasterDocument13 pagesCrystal Door Installation Guide 2019 - MasterDarshan DolasNo ratings yet

- Upvc Window InstallDocument9 pagesUpvc Window InstallAdrian JugariuNo ratings yet

- Dry Wall Partition Meathod StatementDocument4 pagesDry Wall Partition Meathod StatementAmit Khazanchi0% (1)

- MacGregor Mathers - GoeciaDocument1 pageMacGregor Mathers - GoeciaCamilo Alejandro PalaciosNo ratings yet

- Breakglass 2000 Installation Guide BRDocument3 pagesBreakglass 2000 Installation Guide BREdilton Hilario BuqueNo ratings yet

- Breakglass Breakglass: Specifications (Quick Reference)Document2 pagesBreakglass Breakglass: Specifications (Quick Reference)HUGO FERNANDEZ DE LARANo ratings yet

- How To Build A Partition Wall: 0845 274 1000 Wickes - Co.ukDocument4 pagesHow To Build A Partition Wall: 0845 274 1000 Wickes - Co.ukRenganathan V SankaranNo ratings yet

- Shield Assembly GuideDocument20 pagesShield Assembly GuideBrett DarbyNo ratings yet

- Composite Fire Door Installation GuideDocument16 pagesComposite Fire Door Installation GuideRichard WardNo ratings yet

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuidePrinz MarkNo ratings yet

- Strongboy - Instructions For UseDocument2 pagesStrongboy - Instructions For UseandrewheNo ratings yet

- Installing Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsDocument4 pagesInstalling Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsAjay DattNo ratings yet

- WDD Installation Guide 2020Document13 pagesWDD Installation Guide 2020Ciaran MaguireNo ratings yet

- Mecalux Pallet Racking Assembly: Guide To Assembly & UsageDocument6 pagesMecalux Pallet Racking Assembly: Guide To Assembly & UsageUni ToolsNo ratings yet

- Good Neighbour: Secure & Stylish Fencing, We'Ll Bring TheDocument6 pagesGood Neighbour: Secure & Stylish Fencing, We'Ll Bring TheDario RisticNo ratings yet

- Standard Bracing of 'Room in The Roof' (Attic) Trussed Rafter RoofsDocument4 pagesStandard Bracing of 'Room in The Roof' (Attic) Trussed Rafter Roofsbigmac2No ratings yet

- Timber Crib Retaining Wall: Product Installation GuideDocument2 pagesTimber Crib Retaining Wall: Product Installation GuideKenneth KnoxNo ratings yet

- Wall200 Installs 1611 Rev 1Document1 pageWall200 Installs 1611 Rev 1Annavale MateoNo ratings yet

- 2-SUNLITE 10mm Au Installation Instructions Oct2014-With-Wind-LoadsDocument2 pages2-SUNLITE 10mm Au Installation Instructions Oct2014-With-Wind-LoadsElizabeth MPazNo ratings yet

- Brosur CoatingDocument4 pagesBrosur CoatingMuhammad AlfianNo ratings yet

- Brosur Fire StopDocument13 pagesBrosur Fire StopSaidAnwarNo ratings yet

- COLUMNASDocument10 pagesCOLUMNASRoger Geronimo Jiménez100% (1)

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuiderfadeNo ratings yet

- Gabions: Product Installation GuideDocument2 pagesGabions: Product Installation Guidesgm6911No ratings yet

- Ancon Two-Part Wall Tie: Installation GuideDocument2 pagesAncon Two-Part Wall Tie: Installation GuideHASEEBNo ratings yet

- Horizontal Wall CladdingDocument3 pagesHorizontal Wall Claddingrobld56No ratings yet

- FS2009 3031Document25 pagesFS2009 3031SanjayNo ratings yet

- Mounting Flush Door-Bracket TypeDocument2 pagesMounting Flush Door-Bracket TypeAndrew jakeNo ratings yet

- Method Statement For Drywall Work: Installation GuideDocument2 pagesMethod Statement For Drywall Work: Installation GuideMacaNo ratings yet

- IG de Reno Mattresses InstallationDocument2 pagesIG de Reno Mattresses InstallationSílvio GonçalvesNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Measurement Guide: For Andersen® Luminaire Retractable Insect Screen DoorDocument1 pageMeasurement Guide: For Andersen® Luminaire Retractable Insect Screen DoorHannah SeokNo ratings yet

- Gab ElectricoDocument6 pagesGab ElectricoelchulocoriaNo ratings yet

- Door Stop InstallationDocument20 pagesDoor Stop InstallationAdrian JugariuNo ratings yet

- Mild Steel, Single Door Enclosure - Wall Mounted EnclosuresDocument1 pageMild Steel, Single Door Enclosure - Wall Mounted EnclosuresqsNo ratings yet

- Installation Guide: 1) Foundation PreparationDocument7 pagesInstallation Guide: 1) Foundation PreparationdarkchechoNo ratings yet

- Electromagnetic Lock Installation Instruction (Indoor Series)Document2 pagesElectromagnetic Lock Installation Instruction (Indoor Series)Marcin B.No ratings yet

- Security Door Controls: Installation Instructions SERIES 1510, 1570, 1580 EMLOCKDocument4 pagesSecurity Door Controls: Installation Instructions SERIES 1510, 1570, 1580 EMLOCKSunday ChanNo ratings yet

- Corrugated Profile Fitting GuideDocument3 pagesCorrugated Profile Fitting GuideYol AtienzaNo ratings yet

- 800 - 800w - 855 - g2-800 - Handrails - INSTALL V2Document6 pages800 - 800w - 855 - g2-800 - Handrails - INSTALL V2engelboghdady86No ratings yet

- Guide To Installation of Steel Windows: Sealing The JointDocument6 pagesGuide To Installation of Steel Windows: Sealing The JointKristoffer Jose AlcantaraNo ratings yet

- Friend Zoned Love Trap 1St Edition Tory Baker Online Ebook Texxtbook Full Chapter PDFDocument24 pagesFriend Zoned Love Trap 1St Edition Tory Baker Online Ebook Texxtbook Full Chapter PDFeverett.warren672100% (11)

- Perform With Precision: Box Culvert TravelerDocument14 pagesPerform With Precision: Box Culvert Traveler魏雨辰No ratings yet

- Miniskaff Assembly Instructions PDFDocument2 pagesMiniskaff Assembly Instructions PDFthailanNo ratings yet

- Flat RoofDocument2 pagesFlat RoofHarry ThienNo ratings yet

- Clearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You SafeDocument2 pagesClearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You Safeapuhapuh_153349No ratings yet

- TerrameshInstallationGuideNZ 0Document2 pagesTerrameshInstallationGuideNZ 0Jorge RosalNo ratings yet

- Brief Installation Guide For Fibrolit UltraDocument2 pagesBrief Installation Guide For Fibrolit UltraK PreitoNo ratings yet

- Balcony, Terrace WindowsDocument4 pagesBalcony, Terrace WindowsJAYAKUMAR GOPALAKRISHNANNo ratings yet

- Fire Door Installation GuideDocument37 pagesFire Door Installation GuideMaríaPaula CheheidNo ratings yet

- 81FW0000Document4 pages81FW0000MaríaPaula CheheidNo ratings yet

- Fire Door Inspections & Checklist - Steel Door InstituteDocument10 pagesFire Door Inspections & Checklist - Steel Door InstituteMaríaPaula CheheidNo ratings yet

- BBC 1 9 Uses of TimeDocument3 pagesBBC 1 9 Uses of TimeMaríaPaula CheheidNo ratings yet

- FDS User GuideDocument410 pagesFDS User GuideMaríaPaula CheheidNo ratings yet

- Guia General Linear Heat Detection Application GuideDocument74 pagesGuia General Linear Heat Detection Application GuideMaríaPaula CheheidNo ratings yet

- Fds Evac GuideDocument113 pagesFds Evac GuideMaríaPaula CheheidNo ratings yet

- Report On Considerations For Dedicating The Smoke Ventilation Strategy To The Protection of The StairwellDocument4 pagesReport On Considerations For Dedicating The Smoke Ventilation Strategy To The Protection of The StairwellMaríaPaula CheheidNo ratings yet

- Ultra Electric Sprayers: Graco's Complete Line of High-Performance Professional Electric SprayersDocument12 pagesUltra Electric Sprayers: Graco's Complete Line of High-Performance Professional Electric SprayersMaríaPaula CheheidNo ratings yet

- 3ME MatInteractive PDFDocument192 pages3ME MatInteractive PDFMaríaPaula CheheidNo ratings yet

- Emat TB-10 CoCDocument1 pageEmat TB-10 CoCMaríaPaula CheheidNo ratings yet

- Solenoid ValveDocument3 pagesSolenoid ValveSaravanapriya Karthik0% (1)

- Rectangular Beam AnalysisDocument5 pagesRectangular Beam AnalysisheshamNo ratings yet

- 99 269 Testing of Plastics and Rubber e enDocument56 pages99 269 Testing of Plastics and Rubber e enFerryNo ratings yet

- Determining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsDocument4 pagesDetermining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsFernando Da RosNo ratings yet

- CHE406 - Past Exam QuestionsDocument16 pagesCHE406 - Past Exam QuestionsCamila Shaine BelmonteNo ratings yet

- Data Sheets PDFDocument58 pagesData Sheets PDFRamy MahmoudNo ratings yet

- CCS 《GUIDELINES FOR FATIGUE STRENGTH ASSESSMENT OF OFFSHORE ENGINEERING STRUCTURES》2013Document110 pagesCCS 《GUIDELINES FOR FATIGUE STRENGTH ASSESSMENT OF OFFSHORE ENGINEERING STRUCTURES》2013frank.wangNo ratings yet

- Rekap Kehadiran KBLDP 19052021 Rev1Document231 pagesRekap Kehadiran KBLDP 19052021 Rev1noviNo ratings yet

- Catalogue 2019-HD: Belt Maintenance Equipment - Belt Lacing 750kN/mDocument48 pagesCatalogue 2019-HD: Belt Maintenance Equipment - Belt Lacing 750kN/mSaúl Mauricio FernandezNo ratings yet

- 5054 TW D 35 PDFDocument43 pages5054 TW D 35 PDFbalaramNo ratings yet

- Chapter 12 - ThermodynamicsDocument69 pagesChapter 12 - Thermodynamicszahid_polyNo ratings yet

- 004aisi4140 - 105KDocument4 pages004aisi4140 - 105Ksundaramoorthy kamanNo ratings yet

- Reinforced Strip FoundationDocument22 pagesReinforced Strip FoundationGautam PaulNo ratings yet

- Diederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During TunnelingDocument28 pagesDiederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During Tunnelingfatihkaya_16No ratings yet

- 500 Design and Installation GuideDocument34 pages500 Design and Installation GuideghfgjNo ratings yet

- Low-Pressure Injection Molding of Ceramic Springs: Israel Krindges and Raquel AndreolaDocument6 pagesLow-Pressure Injection Molding of Ceramic Springs: Israel Krindges and Raquel AndreolaSanjay PatelNo ratings yet

- Is 10204 PDFDocument4 pagesIs 10204 PDFDimple EntertainmentNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Final Research ProposalDocument7 pagesFinal Research ProposalbasnielNo ratings yet

- BD 1668419731 Steelium Brochure MinDocument20 pagesBD 1668419731 Steelium Brochure MinVenkatesh VenkatNo ratings yet

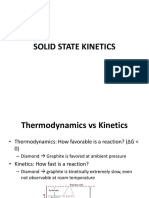

- Solid State KineticsDocument13 pagesSolid State KineticsHudi NurwendiNo ratings yet

- 87 1786Document13 pages87 1786fiorela oreNo ratings yet

- MultiCore - ClassD - ThickWall IS19642Document1 pageMultiCore - ClassD - ThickWall IS19642Tumbin DilseNo ratings yet

- Brochure Adv NDT - PT. Prominent Energy ServicesDocument2 pagesBrochure Adv NDT - PT. Prominent Energy ServicesRizki YudaNo ratings yet

- Lot - 44, 1140 Richmond Road, Marsden Park: NorthDocument1 pageLot - 44, 1140 Richmond Road, Marsden Park: NorthVinay RaoNo ratings yet

- Murtfeldt Material S Group Material-S-1000-Green Technical Data enDocument1 pageMurtfeldt Material S Group Material-S-1000-Green Technical Data enPedro Henriques RamosNo ratings yet

- Articol-Thermal Inertia Effect in Old BuildingsDocument6 pagesArticol-Thermal Inertia Effect in Old BuildingsMicuta LaviniaNo ratings yet

- 1175 PDFDocument24 pages1175 PDFMuhammad HamzaNo ratings yet

35 08 Q Mark Fire Door Fitting Instructions

35 08 Q Mark Fire Door Fitting Instructions

Uploaded by

MaríaPaula CheheidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

35 08 Q Mark Fire Door Fitting Instructions

35 08 Q Mark Fire Door Fitting Instructions

Uploaded by

MaríaPaula CheheidCopyright:

Available Formats

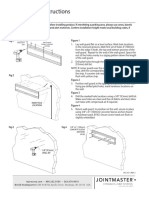

Place the door and frame in structural opening The positioning of installation fixings in height

and then open the door 90 degrees. Position a must be planned to avoid conflicts with the lock

suitable packer beneath the opening edge of keeps, draught and intumescent fire seals.

Q-Mark Fire Door installation the door leaf, ensure the hinge side of the

Maximum of 600mm centres between fixings.

guidance instructions frame is plumb to both internal and external

faces using a spirit level. Figure 3

Read through the Instructions thoroughly

Additional fixing for frame widths over 1100mm

before commencing any work If the floor is not level, fit packers under the

= =

jambs.

Check the structural opening size against the

door set, it is recommended that there is a Pack the hinge side of the frame ensuring the

5mm clearance gap all the way around the frame is plum and square, check that the leg is 100

outer edge of the frame. not bowed.

600 Max.

Work in accordance with the sites manual Figure 2

handling policy, it is advised that two persons

lift, move and position the door set.

Additional hinge

for tall or wide doors

600 Max.

Figure 1 90° 90°

600 Max.

600 Max.

100

Fire Door fixing locations

90° 90°

1255 Page 1 of 6 Form 35-08 (11.12.2020)

Note: See Sealing Structural Openings Drill through the frame on the lock side at the

top of the frame as below in Figure 6 (see

Drill through the frame into the wall as shown Figure 3 for dimensions), secure with a frame

Ensure that frame is plumb, before fixing the in Figure 5 below, then loosely secure each fixing and horse shoe packer.

hinge side of the door frame fixing into the wall, then tap the horse

shoe packers into position, before fully securing Check that the frame is square and plum as

Drill through the frame on the hinge side so each frame fixing check that the frame has not shown in Figure 1 and Figure 2

that the fixings are in the intumescent groove, moved out of square and is still plumb.

the fixings need to pass through the horse shoe

packers. Figure 6

Appropriate Steel Fixings for the frame Figure 5

thickness and that suits the wall substrate must

penetrate a minimum of 40mm as Figures 4a/b

Hardwood & plasterboard packers can be used

on FD60 fire rated doors, plastic horseshoe

packers can be used on FD30 fire rated doors

Figure 4a FD30 frame

Min = 40mm

Figure 4b FD60 frame

Min = 40mm

1255 Page 2 of 6 Form 35-08 (11.12.2020)

Figure 8 Figure 9

See below for permitted door gaps with top &

With the door almost closed, align the edge of side gaps having a tolerance of +/- 1mm

the door with the edge of the frame, so that

the gap is the same from the top to bottom of

the door.

3

Figure 7

3 3

When all fixings are secured, the nominal gaps

Equal gap should be as shown in Figure 9

*

If fitting a lock (Certifire CE marked) ensure the

relevant intumescent is fitted as per

manufactures instructions. Apply an intumescent mastic sealant between

the frame and the structural opening all around

Check the operation of the lock the frame.

Repeat this procedure after each frame fixing Adjust the lock keep to ensure that the lock

point, this will allow for any possible bow or latches correctly *3mm max if smoke rated and no drop seal

twist of the door leaf. fitted

1255 Page 3 of 6 Form 35-08 (11.12.2020)

Doorset configurations allowed dependant on

the hinge type and the product Field of

Application

Single Leaf single acting Double Leaf single acting

At the meeting stiles of double doors, the brush

seal must touch the opposite door to create a

smoke seal

3

Single Leaf double acting Double Leaf single acting

3 3

1255 Page 4 of 6 Form 35-08 (11.12.2020)

Acrylic intumescent mastic

Acrylic intumescent, must be tested to EN 1366

part 4, BS 476 Part 22, BS 476 part 20 or BS

1&2

EN 1634-1. Integrity to be as fire doorset or

Sealing Structural Openings higher as stated in BS 8214:2016 clause 9.4.2

The door frame to structural opening must be Mineral fibre/ceramic fibre to meet Euroclass

protected by using one of the following A1 or A2 to EN13501-1 and heat resistant to at

methods and as shown in BS 8214:2016 clause least 1000° C.

9.4.1 tables

Note: Expanding foam is only suitable for

1. Joints up to 10mm must be sealed on both FD30 fire doors, specification of fire foam

sides as shown, with a 10mm depth of acrylic Frame fixing Mineral fibre infill for must be as per BS 8214:2016 clause 9.4.2

joints exceeding 10mm

intumescent mastic. 15mm thick architraves

Q-Mark Fire Rating Identification Plugs are

overlapping at least 15mm each side Fire stopping product

fitted on the edge of the door, below the top

2. Gaps between 10mm and 20mm must be hinge

tightly packed with mineral fibre/ceramic fibre

3 Fit the intumescent strips which are supplied

capped on both sides with a 10mm depth of

loose into the frame grooves, ensure that the

acrylic intumescent mastic

intumescent is cut and profiled neatly around

3. Joints up to 20mm must be tightly packed the keeps and hinges, the intumescent strips

with mineral fibre/ceramic fibre capped on both must be fitted to obtain the products fire rating

sides with a 10mm depth of acrylic intumescent

If a Drop Seal is fitted adjust as required by

mastic, with 15mm thick architraves

adjusting the end button on the drop seal

overlapping at least 15mm each side

Fit a face fix overhead door closer as per

4. Timber based or non-combustible sub-frame Frame fixing Architrave 15mm thick manufactures instructions, and integral door

up to 50mm thick, with gaps up to 10mm 10mm of acrylic intumescent mastic

or full depth PU foam closers if required are to be supplied and pre-

between components filled on both sides with

Sub-frame fixing machined by Pendle Doors.

10mm depth of acrylic intumescent and 15mm

Integral door closers must be fitted with the

thick architraves overlapping at least 15mm 4 intumescent kit if supplied with the closer

each side

All Door Closers, Hinges and Locks must be CE

Architraves are to be manufactured from the

marked

same timber as the doorset frame or of a

density and approved species that meets the Locks, Keeps, Shoot Bolts and Butt Hinges must

required fire rating be fitted with intumescent kits

Frame fixing Architrave 15mm thick

1255 Page 5 of 6 Form 35-08 (11.12.2020)

Note: See Sealing Structural Openings Example shows a FD30 door with a yellow plug

with a silver insert stating the door is hung in a

Q-Mark plugs denote the period of fire

frame with ironmongery fitted, also a yellow

resistance, the approval of elements including

Note: Modifications or additions are not plug with an orange insert stating the door has

intumescent and glazing

permitted to door assemblies and doorsets, a glazed vision panel

unless allowed within the product Field of Q-Mark plugs are positioned below the top

Application hinge if fitted or prepared for.

FD30 - Door lipping can be trimmed by 2mm if If a door blank is supplied with no hinges or

door edge has no ironmongery or product preparation the plug or plugs are fitted

preparation centrally in the top edge of the door

FD60 - Door lipping can be trimmed by 2mm if

door edge has no ironmongery or product

preparation

BS EN 1935

Grade 13

FD90 - No Modifications or additions are

allowed

FD120 - No Modifications or additions are

allowed

Note: A Gold inner can only be supplied and

fitted by a Certified Q-Mark installer

Note: Pendle Doors does not take any

responsibility, or endorse the use of any

product(s) in the fitting of doorsets.

Pendle Doors strongly recommends that

installation of fire doors should be carried

out by qualified installers

1255 Page 6 of 6 Form 35-08 (11.12.2020)

You might also like

- Processing of Bopp FilmDocument49 pagesProcessing of Bopp FilmHassan Ali Khan78% (9)

- Mil-Prf-85285e T2 PDFDocument3 pagesMil-Prf-85285e T2 PDFLuis Barrios ArandaNo ratings yet

- SUPERWOOD INDUSTRIES SDN BHD - Catalogue (1) (Door)Document18 pagesSUPERWOOD INDUSTRIES SDN BHD - Catalogue (1) (Door)project.skabai02No ratings yet

- Posi Struts DetailsDocument15 pagesPosi Struts DetailsSuciul E ViuNo ratings yet

- Cavity Instructions 2016Document2 pagesCavity Instructions 2016James GraveyNo ratings yet

- Sliding Door Installation InstructionsDocument2 pagesSliding Door Installation InstructionsJaseSG1No ratings yet

- Care & Installation Instructions: Bifold Door Pre - Installation Instructions Bifold Door Installation InstructionsDocument1 pageCare & Installation Instructions: Bifold Door Pre - Installation Instructions Bifold Door Installation Instructionskevin_au18No ratings yet

- BCA GN 16 Guarding To Openable Windows With Low Cills Rev 1 Sept 2016Document5 pagesBCA GN 16 Guarding To Openable Windows With Low Cills Rev 1 Sept 2016HarveyNo ratings yet

- Instruções Bate Maca 1800Document2 pagesInstruções Bate Maca 1800Rafael FlorentinoNo ratings yet

- Ig Gabions May 2015Document2 pagesIg Gabions May 2015LynxNo ratings yet

- DX Suspended Ceiling System Usg BoralDocument48 pagesDX Suspended Ceiling System Usg BoralmctmcNo ratings yet

- Crystal Door Installation Guide 2019 - MasterDocument13 pagesCrystal Door Installation Guide 2019 - MasterDarshan DolasNo ratings yet

- Upvc Window InstallDocument9 pagesUpvc Window InstallAdrian JugariuNo ratings yet

- Dry Wall Partition Meathod StatementDocument4 pagesDry Wall Partition Meathod StatementAmit Khazanchi0% (1)

- MacGregor Mathers - GoeciaDocument1 pageMacGregor Mathers - GoeciaCamilo Alejandro PalaciosNo ratings yet

- Breakglass 2000 Installation Guide BRDocument3 pagesBreakglass 2000 Installation Guide BREdilton Hilario BuqueNo ratings yet

- Breakglass Breakglass: Specifications (Quick Reference)Document2 pagesBreakglass Breakglass: Specifications (Quick Reference)HUGO FERNANDEZ DE LARANo ratings yet

- How To Build A Partition Wall: 0845 274 1000 Wickes - Co.ukDocument4 pagesHow To Build A Partition Wall: 0845 274 1000 Wickes - Co.ukRenganathan V SankaranNo ratings yet

- Shield Assembly GuideDocument20 pagesShield Assembly GuideBrett DarbyNo ratings yet

- Composite Fire Door Installation GuideDocument16 pagesComposite Fire Door Installation GuideRichard WardNo ratings yet

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuidePrinz MarkNo ratings yet

- Strongboy - Instructions For UseDocument2 pagesStrongboy - Instructions For UseandrewheNo ratings yet

- Installing Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsDocument4 pagesInstalling Gyprock Plasterboard: How To Install Gyprock Plasterboard Walls and CeilingsAjay DattNo ratings yet

- WDD Installation Guide 2020Document13 pagesWDD Installation Guide 2020Ciaran MaguireNo ratings yet

- Mecalux Pallet Racking Assembly: Guide To Assembly & UsageDocument6 pagesMecalux Pallet Racking Assembly: Guide To Assembly & UsageUni ToolsNo ratings yet

- Good Neighbour: Secure & Stylish Fencing, We'Ll Bring TheDocument6 pagesGood Neighbour: Secure & Stylish Fencing, We'Ll Bring TheDario RisticNo ratings yet

- Standard Bracing of 'Room in The Roof' (Attic) Trussed Rafter RoofsDocument4 pagesStandard Bracing of 'Room in The Roof' (Attic) Trussed Rafter Roofsbigmac2No ratings yet

- Timber Crib Retaining Wall: Product Installation GuideDocument2 pagesTimber Crib Retaining Wall: Product Installation GuideKenneth KnoxNo ratings yet

- Wall200 Installs 1611 Rev 1Document1 pageWall200 Installs 1611 Rev 1Annavale MateoNo ratings yet

- 2-SUNLITE 10mm Au Installation Instructions Oct2014-With-Wind-LoadsDocument2 pages2-SUNLITE 10mm Au Installation Instructions Oct2014-With-Wind-LoadsElizabeth MPazNo ratings yet

- Brosur CoatingDocument4 pagesBrosur CoatingMuhammad AlfianNo ratings yet

- Brosur Fire StopDocument13 pagesBrosur Fire StopSaidAnwarNo ratings yet

- COLUMNASDocument10 pagesCOLUMNASRoger Geronimo Jiménez100% (1)

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuiderfadeNo ratings yet

- Gabions: Product Installation GuideDocument2 pagesGabions: Product Installation Guidesgm6911No ratings yet

- Ancon Two-Part Wall Tie: Installation GuideDocument2 pagesAncon Two-Part Wall Tie: Installation GuideHASEEBNo ratings yet

- Horizontal Wall CladdingDocument3 pagesHorizontal Wall Claddingrobld56No ratings yet

- FS2009 3031Document25 pagesFS2009 3031SanjayNo ratings yet

- Mounting Flush Door-Bracket TypeDocument2 pagesMounting Flush Door-Bracket TypeAndrew jakeNo ratings yet

- Method Statement For Drywall Work: Installation GuideDocument2 pagesMethod Statement For Drywall Work: Installation GuideMacaNo ratings yet

- IG de Reno Mattresses InstallationDocument2 pagesIG de Reno Mattresses InstallationSílvio GonçalvesNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Measurement Guide: For Andersen® Luminaire Retractable Insect Screen DoorDocument1 pageMeasurement Guide: For Andersen® Luminaire Retractable Insect Screen DoorHannah SeokNo ratings yet

- Gab ElectricoDocument6 pagesGab ElectricoelchulocoriaNo ratings yet

- Door Stop InstallationDocument20 pagesDoor Stop InstallationAdrian JugariuNo ratings yet

- Mild Steel, Single Door Enclosure - Wall Mounted EnclosuresDocument1 pageMild Steel, Single Door Enclosure - Wall Mounted EnclosuresqsNo ratings yet

- Installation Guide: 1) Foundation PreparationDocument7 pagesInstallation Guide: 1) Foundation PreparationdarkchechoNo ratings yet

- Electromagnetic Lock Installation Instruction (Indoor Series)Document2 pagesElectromagnetic Lock Installation Instruction (Indoor Series)Marcin B.No ratings yet

- Security Door Controls: Installation Instructions SERIES 1510, 1570, 1580 EMLOCKDocument4 pagesSecurity Door Controls: Installation Instructions SERIES 1510, 1570, 1580 EMLOCKSunday ChanNo ratings yet

- Corrugated Profile Fitting GuideDocument3 pagesCorrugated Profile Fitting GuideYol AtienzaNo ratings yet

- 800 - 800w - 855 - g2-800 - Handrails - INSTALL V2Document6 pages800 - 800w - 855 - g2-800 - Handrails - INSTALL V2engelboghdady86No ratings yet

- Guide To Installation of Steel Windows: Sealing The JointDocument6 pagesGuide To Installation of Steel Windows: Sealing The JointKristoffer Jose AlcantaraNo ratings yet

- Friend Zoned Love Trap 1St Edition Tory Baker Online Ebook Texxtbook Full Chapter PDFDocument24 pagesFriend Zoned Love Trap 1St Edition Tory Baker Online Ebook Texxtbook Full Chapter PDFeverett.warren672100% (11)

- Perform With Precision: Box Culvert TravelerDocument14 pagesPerform With Precision: Box Culvert Traveler魏雨辰No ratings yet

- Miniskaff Assembly Instructions PDFDocument2 pagesMiniskaff Assembly Instructions PDFthailanNo ratings yet

- Flat RoofDocument2 pagesFlat RoofHarry ThienNo ratings yet

- Clearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You SafeDocument2 pagesClearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You Safeapuhapuh_153349No ratings yet

- TerrameshInstallationGuideNZ 0Document2 pagesTerrameshInstallationGuideNZ 0Jorge RosalNo ratings yet

- Brief Installation Guide For Fibrolit UltraDocument2 pagesBrief Installation Guide For Fibrolit UltraK PreitoNo ratings yet

- Balcony, Terrace WindowsDocument4 pagesBalcony, Terrace WindowsJAYAKUMAR GOPALAKRISHNANNo ratings yet

- Fire Door Installation GuideDocument37 pagesFire Door Installation GuideMaríaPaula CheheidNo ratings yet

- 81FW0000Document4 pages81FW0000MaríaPaula CheheidNo ratings yet

- Fire Door Inspections & Checklist - Steel Door InstituteDocument10 pagesFire Door Inspections & Checklist - Steel Door InstituteMaríaPaula CheheidNo ratings yet

- BBC 1 9 Uses of TimeDocument3 pagesBBC 1 9 Uses of TimeMaríaPaula CheheidNo ratings yet

- FDS User GuideDocument410 pagesFDS User GuideMaríaPaula CheheidNo ratings yet

- Guia General Linear Heat Detection Application GuideDocument74 pagesGuia General Linear Heat Detection Application GuideMaríaPaula CheheidNo ratings yet

- Fds Evac GuideDocument113 pagesFds Evac GuideMaríaPaula CheheidNo ratings yet

- Report On Considerations For Dedicating The Smoke Ventilation Strategy To The Protection of The StairwellDocument4 pagesReport On Considerations For Dedicating The Smoke Ventilation Strategy To The Protection of The StairwellMaríaPaula CheheidNo ratings yet

- Ultra Electric Sprayers: Graco's Complete Line of High-Performance Professional Electric SprayersDocument12 pagesUltra Electric Sprayers: Graco's Complete Line of High-Performance Professional Electric SprayersMaríaPaula CheheidNo ratings yet

- 3ME MatInteractive PDFDocument192 pages3ME MatInteractive PDFMaríaPaula CheheidNo ratings yet

- Emat TB-10 CoCDocument1 pageEmat TB-10 CoCMaríaPaula CheheidNo ratings yet

- Solenoid ValveDocument3 pagesSolenoid ValveSaravanapriya Karthik0% (1)

- Rectangular Beam AnalysisDocument5 pagesRectangular Beam AnalysisheshamNo ratings yet

- 99 269 Testing of Plastics and Rubber e enDocument56 pages99 269 Testing of Plastics and Rubber e enFerryNo ratings yet

- Determining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsDocument4 pagesDetermining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsFernando Da RosNo ratings yet

- CHE406 - Past Exam QuestionsDocument16 pagesCHE406 - Past Exam QuestionsCamila Shaine BelmonteNo ratings yet

- Data Sheets PDFDocument58 pagesData Sheets PDFRamy MahmoudNo ratings yet

- CCS 《GUIDELINES FOR FATIGUE STRENGTH ASSESSMENT OF OFFSHORE ENGINEERING STRUCTURES》2013Document110 pagesCCS 《GUIDELINES FOR FATIGUE STRENGTH ASSESSMENT OF OFFSHORE ENGINEERING STRUCTURES》2013frank.wangNo ratings yet

- Rekap Kehadiran KBLDP 19052021 Rev1Document231 pagesRekap Kehadiran KBLDP 19052021 Rev1noviNo ratings yet

- Catalogue 2019-HD: Belt Maintenance Equipment - Belt Lacing 750kN/mDocument48 pagesCatalogue 2019-HD: Belt Maintenance Equipment - Belt Lacing 750kN/mSaúl Mauricio FernandezNo ratings yet

- 5054 TW D 35 PDFDocument43 pages5054 TW D 35 PDFbalaramNo ratings yet

- Chapter 12 - ThermodynamicsDocument69 pagesChapter 12 - Thermodynamicszahid_polyNo ratings yet

- 004aisi4140 - 105KDocument4 pages004aisi4140 - 105Ksundaramoorthy kamanNo ratings yet

- Reinforced Strip FoundationDocument22 pagesReinforced Strip FoundationGautam PaulNo ratings yet

- Diederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During TunnelingDocument28 pagesDiederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During Tunnelingfatihkaya_16No ratings yet

- 500 Design and Installation GuideDocument34 pages500 Design and Installation GuideghfgjNo ratings yet

- Low-Pressure Injection Molding of Ceramic Springs: Israel Krindges and Raquel AndreolaDocument6 pagesLow-Pressure Injection Molding of Ceramic Springs: Israel Krindges and Raquel AndreolaSanjay PatelNo ratings yet

- Is 10204 PDFDocument4 pagesIs 10204 PDFDimple EntertainmentNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Final Research ProposalDocument7 pagesFinal Research ProposalbasnielNo ratings yet

- BD 1668419731 Steelium Brochure MinDocument20 pagesBD 1668419731 Steelium Brochure MinVenkatesh VenkatNo ratings yet

- Solid State KineticsDocument13 pagesSolid State KineticsHudi NurwendiNo ratings yet

- 87 1786Document13 pages87 1786fiorela oreNo ratings yet

- MultiCore - ClassD - ThickWall IS19642Document1 pageMultiCore - ClassD - ThickWall IS19642Tumbin DilseNo ratings yet

- Brochure Adv NDT - PT. Prominent Energy ServicesDocument2 pagesBrochure Adv NDT - PT. Prominent Energy ServicesRizki YudaNo ratings yet

- Lot - 44, 1140 Richmond Road, Marsden Park: NorthDocument1 pageLot - 44, 1140 Richmond Road, Marsden Park: NorthVinay RaoNo ratings yet

- Murtfeldt Material S Group Material-S-1000-Green Technical Data enDocument1 pageMurtfeldt Material S Group Material-S-1000-Green Technical Data enPedro Henriques RamosNo ratings yet

- Articol-Thermal Inertia Effect in Old BuildingsDocument6 pagesArticol-Thermal Inertia Effect in Old BuildingsMicuta LaviniaNo ratings yet

- 1175 PDFDocument24 pages1175 PDFMuhammad HamzaNo ratings yet